Professional Documents

Culture Documents

Nissan Almera n16 2001 Electronic Repair Manual 137

Nissan Almera n16 2001 Electronic Repair Manual 137

Uploaded by

netifig352Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nissan Almera n16 2001 Electronic Repair Manual 137

Nissan Almera n16 2001 Electronic Repair Manual 137

Uploaded by

netifig352Copyright:

Available Formats

CYLINDER BLOCK QG

Inspection (Cont’d)

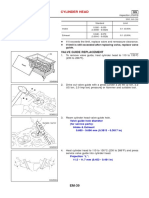

4. Measure outer diameter “Dp” of each crankshaft pin journal.

5. Calculate connecting rod bearing clearance.

Connecting rod bearing clearance = C − Dp

Standard: 0.014 - 0.039 mm (0.0006 - 0.0015 in)

Limit: 0.1 mm (0.004 in)

If it exceeds the limit, replace bearing.

If clearance cannot be adjusted using any standard bearing

grade, grind crankshaft journal and use undersized bearing.

Refer to step 5, EM-57.

AEM028

+ If a new bearing, crankshaft or connecting rod is replaced,

select connecting rod bearing according to the following table.

Connecting rod bearing grade number:

These numbers are punched in either Arabic or Roman numerals.

Crankshaft pin journal grade number Connecting rod bearing grade color

0 —

1 Brown

2 Green

SEM437CA

Method B (Using Plastigage)

CAUTION:

+ Do not turn crankshaft or connecting rod while Plastigage

is being inserted.

+ If incorrect bearing clearance exists, use a thicker or

undersized main bearing to ensure specified clearance.

EM142

CONNECTING ROD BUSHING CLEARANCE (SMALL

END) NJEM0026S09

1. Measure inner diameter “C” of bushing.

AEM029

2. Measure outer diameter “Dp” of piston pin.

3. Calculate connecting rod bushing clearance.

Connecting rod bushing clearance = C − Dp

Standard:

0.005 - 0.017 mm (0.0002 - 0.0007 in)

Limit:

0.023 mm (0.0009 in)

If it exceeds the limit, replace connecting rod assembly or

connecting rod bushing and/or piston pin.

AEM030

EM-59

You might also like

- YD25DDTi and ZD30DDT Engines in NISSAN Repair ManualsDocument19 pagesYD25DDTi and ZD30DDT Engines in NISSAN Repair ManualsMoaed Kanbar91% (105)

- Nissan Almera n16 2001 Electronic Repair Manual 111Document1 pageNissan Almera n16 2001 Electronic Repair Manual 111netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 194Document1 pageNissan Almera n16 2001 Electronic Repair Manual 194netifig352No ratings yet

- ScaniaDocument6 pagesScaniaGustavo Paez100% (2)

- YD25 Engine MechDocument35 pagesYD25 Engine MechAlex Hernandez100% (3)

- 19d Impeller SpacingDocument9 pages19d Impeller Spacingbtgottlieb100% (1)

- MANUAL BOOK DifferentialDocument14 pagesMANUAL BOOK DifferentialHaris100% (2)

- Toyota 2azfe Valve Clearance PDFDocument9 pagesToyota 2azfe Valve Clearance PDFMarcos EmmanuelNo ratings yet

- 61SNC01 - 07 - Engine Mechanical - BlockDocument30 pages61SNC01 - 07 - Engine Mechanical - BlockangelvalladaresNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 116Document1 pageNissan Almera n16 2001 Electronic Repair Manual 116netifig352No ratings yet

- Clutch Hino 3.5Document4 pagesClutch Hino 3.5Yeam_90No ratings yet

- Mbnz-om906la-Om926la Manual Repair - PDF Versión 1Document2 pagesMbnz-om906la-Om926la Manual Repair - PDF Versión 1Aron Emanuel Mendoza LopezNo ratings yet

- Einbau Gleitlager en PDFDocument4 pagesEinbau Gleitlager en PDFMohammed SaberNo ratings yet

- 4JG2 Timing Spec PDFDocument3 pages4JG2 Timing Spec PDF650LNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 114Document1 pageNissan Almera n16 2001 Electronic Repair Manual 114netifig352No ratings yet

- 联轴器找中心Coupling AlignmentDocument27 pages联轴器找中心Coupling Alignmentfelix asadeNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument17 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceHenry SilvaNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 200Document1 pageNissan Almera n16 2001 Electronic Repair Manual 200netifig352No ratings yet

- DisassemblyDocument8 pagesDisassemblyEdson CRNo ratings yet

- QuickGuide Dial-Indicators PDFDocument4 pagesQuickGuide Dial-Indicators PDFAsyifatunSholihahNo ratings yet

- Flowserve Seal - ISC2 - Install - LTRDocument8 pagesFlowserve Seal - ISC2 - Install - LTRjame11inNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 115Document1 pageNissan Almera n16 2001 Electronic Repair Manual 115netifig352No ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument29 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceEdU RECTIFICANo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument16 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceAntonio TorresNo ratings yet

- 2005 Seadoo Rotax 1503 4 Tech Shop Manual - 101 EndDocument24 pages2005 Seadoo Rotax 1503 4 Tech Shop Manual - 101 EndOscar Eduardo GomezNo ratings yet

- MSD Pro-Billet Marine Distributor: Chevrolet, PN 8560, With Slip Collar, PN 8562, Ford, PN 85806Document8 pagesMSD Pro-Billet Marine Distributor: Chevrolet, PN 8560, With Slip Collar, PN 8562, Ford, PN 85806kkg4782No ratings yet

- 0901d19680056c36 PDF Preview MediumDocument36 pages0901d19680056c36 PDF Preview Mediummikko intalNo ratings yet

- 0901d19680056c36 PDF Preview MediumDocument36 pages0901d19680056c36 PDF Preview Mediummikko intalNo ratings yet

- 2 3 Wheeler Lab ManualDocument21 pages2 3 Wheeler Lab ManualAmitesh ShrivastavaNo ratings yet

- 08 Testing&Adjustment Tier3 Engine - 1602Document23 pages08 Testing&Adjustment Tier3 Engine - 1602gustavo333martinsNo ratings yet

- B3E011011211E01Document3 pagesB3E011011211E01Ngô Văn HưngNo ratings yet

- CBM820 Service ManualDocument41 pagesCBM820 Service Manualhaithembs2017No ratings yet

- Clutch: Click On The Applicable Bookmark To Selected The Required Model YearDocument9 pagesClutch: Click On The Applicable Bookmark To Selected The Required Model YearCao LanNo ratings yet

- Er 82Document2 pagesEr 82Dibyendu ChakrabortyNo ratings yet

- INA Ball ScrewsDocument16 pagesINA Ball ScrewsRuben PauwelsNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument22 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceIslam AttiaNo ratings yet

- Figure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingDocument4 pagesFigure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingСергей КолесниковNo ratings yet

- Transfer CaseDocument43 pagesTransfer CasePopescu Vasile IonNo ratings yet

- Manual de Reparación Sello FlowserveDocument8 pagesManual de Reparación Sello FlowservejorgeNo ratings yet

- 035 - 319 - Technical Manual - Mechanical Units Bar End Commands - Campagnolo - Rev00 - 05 - 15Document6 pages035 - 319 - Technical Manual - Mechanical Units Bar End Commands - Campagnolo - Rev00 - 05 - 15theteamofthedragonflyNo ratings yet

- GD705A-5 Adjusting ValveDocument3 pagesGD705A-5 Adjusting ValveSurya FaniNo ratings yet

- GW491QE Petrol Engine Service Manual ClutchDocument4 pagesGW491QE Petrol Engine Service Manual ClutchAlbert BriceñoNo ratings yet

- kx80 Página 111Document1 pagekx80 Página 111PabloNo ratings yet

- 4M41Document10 pages4M41Guadalupe GuerreroNo ratings yet

- Connecting Rod - Inspect: Shutdown SIS Previous ScreenDocument4 pagesConnecting Rod - Inspect: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Measuring of Swing Bearing ClearanceDocument3 pagesMeasuring of Swing Bearing ClearanceSunil Singh100% (1)

- Inspection: 1. Clean Cylinder BlockDocument7 pagesInspection: 1. Clean Cylinder Blockdolphi_742078No ratings yet

- Design and Function: Marine Transmissions Gearboxes, Drives, IPSDocument80 pagesDesign and Function: Marine Transmissions Gearboxes, Drives, IPSSON100% (1)

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

- 1B Engine Mechanical (4JJ1 Without DPD) PDFDocument762 pages1B Engine Mechanical (4JJ1 Without DPD) PDFPatricio ValenciaNo ratings yet

- Mitutoyo ID C Absolute Digital IndicatorDocument2 pagesMitutoyo ID C Absolute Digital IndicatorMarco BcNo ratings yet

- Mitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Document61 pagesMitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Miroslav TabakovskiNo ratings yet

- Installation Manual For Level Control Diaphragm: AddressDocument11 pagesInstallation Manual For Level Control Diaphragm: AddresspredilettoNo ratings yet

- 23gearboxDocument56 pages23gearboxcarzclassixNo ratings yet

- Engine MechanicalDocument17 pagesEngine MechanicalAdrian Marian GafincuNo ratings yet

- Clutch: Click On The Applicable Bookmark To Selected The Required Model YearDocument7 pagesClutch: Click On The Applicable Bookmark To Selected The Required Model YearhafizinnaimNo ratings yet

- Manual de Calibracion de Valvulas Del Daihatsu Toyota TeriosDocument10 pagesManual de Calibracion de Valvulas Del Daihatsu Toyota Teriosahmed zhranNo ratings yet

- Manual de Calibracion de Valvulas Del Daihatsu Toyota TeriosDocument10 pagesManual de Calibracion de Valvulas Del Daihatsu Toyota Teriosahmed zhranNo ratings yet

- Calibracion de Valvulas Toyota 1nz YarisDocument11 pagesCalibracion de Valvulas Toyota 1nz Yariscpaolinod100% (4)

- Cylinder Block (1Az-Fe) : OverhaulDocument17 pagesCylinder Block (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Operating Instruction Underbody ClampDocument2 pagesOperating Instruction Underbody ClampBe HappyNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 140Document1 pageNissan Almera n16 2001 Electronic Repair Manual 140netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 138Document1 pageNissan Almera n16 2001 Electronic Repair Manual 138netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 139Document1 pageNissan Almera n16 2001 Electronic Repair Manual 139netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 141Document1 pageNissan Almera n16 2001 Electronic Repair Manual 141netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 110Document1 pageNissan Almera n16 2001 Electronic Repair Manual 110netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 108Document1 pageNissan Almera n16 2001 Electronic Repair Manual 108netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 114Document1 pageNissan Almera n16 2001 Electronic Repair Manual 114netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 118Document1 pageNissan Almera n16 2001 Electronic Repair Manual 118netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 107Document1 pageNissan Almera n16 2001 Electronic Repair Manual 107netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 109Document1 pageNissan Almera n16 2001 Electronic Repair Manual 109netifig352No ratings yet

- Timing Chain: JEM147GDocument1 pageTiming Chain: JEM147Gnetifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 177Document1 pageNissan Almera n16 2001 Electronic Repair Manual 177netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 115Document1 pageNissan Almera n16 2001 Electronic Repair Manual 115netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 197Document1 pageNissan Almera n16 2001 Electronic Repair Manual 197netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 116Document1 pageNissan Almera n16 2001 Electronic Repair Manual 116netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 170Document1 pageNissan Almera n16 2001 Electronic Repair Manual 170netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 117Document1 pageNissan Almera n16 2001 Electronic Repair Manual 117netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 195Document1 pageNissan Almera n16 2001 Electronic Repair Manual 195netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 166Document1 pageNissan Almera n16 2001 Electronic Repair Manual 166netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 182Document1 pageNissan Almera n16 2001 Electronic Repair Manual 182netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 178Document1 pageNissan Almera n16 2001 Electronic Repair Manual 178netifig352No ratings yet

- Removal and Installation: Intake ManifoldDocument1 pageRemoval and Installation: Intake Manifoldnetifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 176Document1 pageNissan Almera n16 2001 Electronic Repair Manual 176netifig352No ratings yet

- Changing Air Cleaner FilterDocument1 pageChanging Air Cleaner Filternetifig352No ratings yet

- Oil PanDocument1 pageOil Pannetifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 163Document1 pageNissan Almera n16 2001 Electronic Repair Manual 163netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 167Document1 pageNissan Almera n16 2001 Electronic Repair Manual 167netifig352No ratings yet

- Installation: Drive BeltsDocument1 pageInstallation: Drive Beltsnetifig352No ratings yet