Professional Documents

Culture Documents

EBECRYL 640 20 TO - EN - Letter

EBECRYL 640 20 TO - EN - Letter

Uploaded by

Mauricio Botero0 ratings0% found this document useful (0 votes)

12 views1 pageOriginal Title

EBECRYL-640-20-TO_EN_Letter

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

12 views1 pageEBECRYL 640 20 TO - EN - Letter

EBECRYL 640 20 TO - EN - Letter

Uploaded by

Mauricio BoteroCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

EBECRYL® 640/20 TO

Technical Datasheet

EPOXY ACRYLATE OLIGOMER

INTRODUCTION PHYSICAL PROPERTIES

EBECRYL® 640/20 TO is a modified diacrylate ester of bisphenol A epoxy Density, g/cm3 1.15

resin. This product is characterized by its light colour, fast cure response Molecular weight, theoretical ca. 500

and improved pigment wetting. Films of EBECRYL® 640/20 TO cured by Functionality, theoretical 2

ultraviolet light (UV) or electron beam (EB) exhibit high surface hardness Polymer solids, % by weight 100

and gloss and the excellent solvent resistance typical of an epoxy resin.

x

EBECRYL® 640/20 TO finds broad use in UV/EB applications, such as inks,

coatings and overprint varnishes.

VISCOSITY REDUCTION

x EBECRYL® 640/20 TO can be diluted with reactive monomers such as 1,6-

PERFORMANCE HIGHLIGHTS hexanediol diacrylate (HDDA)(1), tripropyleneglycol diacrylate (TPGDA)(1),

trimethylolpropane triacrylate (TMPTA)(1) and oligotriacrylate (OTA 480)(1).

EBECRYL® 640/20 TO is characterised by: The specific reactive diluent(s) used will influence performance properties

· Light colour such as hardness and flexibility.

(1)

· Fast cure response product of allnex

· Low irritancy x

· Improved pigment wetting

STORAGE AND HANDLING

UV/EB cured products based on EBECRYL® 640/20 TO are characterised by

the following performance properties: Care should be taken not to expose radiation curable products to

· High surface hardness temperatures exceeding 40°C for prolonged periods or to direct sunlight.

· High gloss This might cause uncontrollable polymerization of the product with

· Excellent solvent resistance generation of heat.

· Good water resistance Storage and handling should be in stainless steel, amber glass, amber

The actual properties of UV/EB cured products also depend on the polyethylene or baked phenolic lined containers. Do not store this material

selection of the other formulation components, such as reactive diluent(s), under an oxygen free atmosphere. Use dry air to displace material removed

additives and photo initiators. from the container. This material should not be stored for more than 2

years.

x

SUGGESTED APPLICATIONS x

PRECAUTION

Formulated UV/EB curable products containing EBECRYL® 640/20 TO may

be applied by lithographic, screen, gravure, direct or reverse roll, and The following is a summary of the precautions to be taken when handling

curtain coating methods. EBECRYL® 640/20 TO is recommended for use in: this product. Please refer to the Safety Data Sheet for further details.

· Overprint varnishes The toxicological properties of this material have not been fully

· Lithographic and screen inks determined. Products of this type can be expected to be eye and skin

· Coatings for paper, paperboard, wood, chipboard and rigid irritant and have the potential to cause sensitization or other allergic

plastics responses. Appropriate precautions should be taken to avoid eye and skin

· Paper upgrading contact and to avoid inhalation of the aerosols or vapours. Consult the

· Fast cure response relevant Safety Data Sheet for appropriate handling procedures and

· Laminating adhesives protective equipment prior to using this or any other material referred to in

· Wood sealers and top coats this bulletin.

See Safety Data Sheet for emergency and first aid procedures.

x

x

TYPICAL VALUES

STATUTORY LABELING

Höppler viscosity at 25°C, mPa.s ca. 75000

Colour, Gardner max. 3 Please refer to Safety Data Sheet.

version 3.0 Worldwide Contact Info: www.allnex.com Page 1/1

Disclaimer: allnex Group companies ('allnex') exclude all liability with respect to the use made by anyone of the information contained herein. The information contained herein represents allnex's best knowledge but

does not constitute any express or implied guarantee or warranty as to the accuracy, the completeness or relevance of the data set out herein. Nothing contained herein shall be construed as conferring any license or

right under any patent or other intellectual property rights of allnex or of any third party. The information relating to the products is given for information purposes only. No guarantee or warranty is provided that the

product and/or information is suitable for any specific use, performance or result. Any unauthorized use of the product or information may infringe the intellectual property rights of allnex, including its patent rights.

The user should perform his/her own tests to determine the suitability for a particular purpose. The final choice of use of a product and/or information as well as the investigation of any possible violation of

intellectual property rights or misappropriation of trade secrets of allnex and/or third parties remain the sole responsibility of the user.

Notice: Trademarks indicated with ® , TM or * as well as the allnex name and logo are registered, unregistered or pending trademarks of Allnex Netherlands B.V. or its directly or indirectly affiliated allnex Group

companies. ©2020 allnex Group. All Rights Reserved.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CBOE C2 SPXPM Oct2011Document23 pagesCBOE C2 SPXPM Oct2011Mauricio BoteroNo ratings yet

- Clearing Cryptocurrency Customer Agreement-2.0.0Document34 pagesClearing Cryptocurrency Customer Agreement-2.0.0Mauricio BoteroNo ratings yet

- By SectorDocument16 pagesBy SectorMauricio BoteroNo ratings yet

- Index PERDocument21 pagesIndex PERMauricio BoteroNo ratings yet

- CG Axa Schengen Low Cost enDocument9 pagesCG Axa Schengen Low Cost enMauricio BoteroNo ratings yet

- Ebook Earnings Season PDFDocument13 pagesEbook Earnings Season PDFMauricio BoteroNo ratings yet

- High Frequency Plastics Welding Machines: Monga StrayfieldDocument8 pagesHigh Frequency Plastics Welding Machines: Monga StrayfieldMauricio BoteroNo ratings yet

- Introduction To WWTPs DesignDocument55 pagesIntroduction To WWTPs Designalvaro.roldan1No ratings yet

- Factors Affecting Superheat Control 1951Document14 pagesFactors Affecting Superheat Control 1951A-ar FebreNo ratings yet

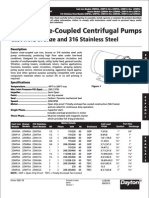

- Dayton Close Coupled Centrifugal Pumps OIPM PDFDocument48 pagesDayton Close Coupled Centrifugal Pumps OIPM PDFstepa79No ratings yet

- Balancing Equations: Practice ProblemsDocument10 pagesBalancing Equations: Practice Problemskhalil rehmanNo ratings yet

- Engineering Guide User InterfacesDocument12 pagesEngineering Guide User Interfacessav33No ratings yet

- MetalaxylM 240502 153746Document72 pagesMetalaxylM 240502 153746HidayatRustdyNo ratings yet

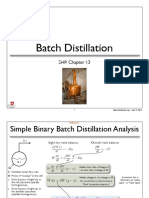

- Batch DistillationDocument9 pagesBatch DistillationJuan Camilo CárdenasNo ratings yet

- CR - Kinetic Isotope EffectsDocument107 pagesCR - Kinetic Isotope EffectsAnil KumarNo ratings yet

- Major 07Document28 pagesMajor 07irshadjamadar124No ratings yet

- Health Benefits and Possible Risks of Herbal Medicine: March 2016Document21 pagesHealth Benefits and Possible Risks of Herbal Medicine: March 2016Juan GomezNo ratings yet

- PH of Soil Solution in Water and KCLDocument16 pagesPH of Soil Solution in Water and KCLJia Hui100% (1)

- Key Concepts in Agriculture and Farming Hazem Shawky Fouda Full ChapterDocument67 pagesKey Concepts in Agriculture and Farming Hazem Shawky Fouda Full Chapterglenn.hamilton954100% (7)

- Fluconazole - Customer - Notification - Recall Communication - LetterDocument1 pageFluconazole - Customer - Notification - Recall Communication - Lettermohammed shaffi abdul rahmanNo ratings yet

- Astm D6317 - 2000Document7 pagesAstm D6317 - 2000teymurNo ratings yet

- Exp 2Document3 pagesExp 2Farhatul Abrar AnandaNo ratings yet

- Performance Characteristics: Giemsa StainDocument1 pagePerformance Characteristics: Giemsa StainTanveerNo ratings yet

- (MySchoolChildren) SKEMA Biologi Percubaan SPM 2012 SBP QDocument27 pages(MySchoolChildren) SKEMA Biologi Percubaan SPM 2012 SBP QIsmaliza IshakNo ratings yet

- Subsea EngineeringDocument2 pagesSubsea Engineeringgupta_hemanshu1986252100% (1)

- Graphene Batteries Users GuideDocument25 pagesGraphene Batteries Users Guidemekavinash0% (1)

- Document PDFDocument14 pagesDocument PDFismaieel manhalNo ratings yet

- Brochure - M Series en - Pompa OBLDocument6 pagesBrochure - M Series en - Pompa OBLAmrina RosyadaNo ratings yet

- 02 - Retaining Wall Confined WaterproofingDocument6 pages02 - Retaining Wall Confined Waterproofingannayya.chandrashekar Civil EngineerNo ratings yet

- Product Nasivion SprayDocument5 pagesProduct Nasivion SprayMueen mohsinNo ratings yet

- Convential Drilling Vs MPD StodleDocument83 pagesConvential Drilling Vs MPD StodleSyed Irtaza100% (2)

- 2.10 Fly and Bottom Ash SystemDocument31 pages2.10 Fly and Bottom Ash SystemDangolNo ratings yet

- Fabrication Standard of Duct-AcDocument5 pagesFabrication Standard of Duct-AcVicky KumarNo ratings yet

- Leidenfrost EffectDocument10 pagesLeidenfrost EffectSnowswimmerNo ratings yet

- EN 14110 - ThermoDocument4 pagesEN 14110 - ThermoLuciana TrisnaNo ratings yet

- DisolventesDocument2 pagesDisolventesolga mariaNo ratings yet

- Magnetic Response of Stainless Steels: What Are The Basic Magnetic Properties of Materials?Document3 pagesMagnetic Response of Stainless Steels: What Are The Basic Magnetic Properties of Materials?hendraox3996No ratings yet