Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

15 viewsSkill Matrix

Skill Matrix

Uploaded by

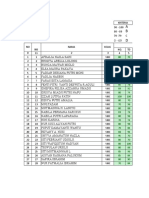

Bijay SinghThe document outlines a mechanical maintenance skill matrix for various employees, rating their competency levels from 1-100 across 44 key responsibilities related to maintaining furnaces, drilling machines, blowers, and other industrial equipment. Jitenda Singh and Atul Rao generally have the highest competency ratings, while Raju Shirke and SS Mishra are closer to the group average. Overall competency levels vary across responsibilities, with some employees stronger in areas like inspections while weaker in hydraulics troubleshooting.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You might also like

- Case International 235 235H 245 255 265 275 Shop ManualDocument128 pagesCase International 235 235H 245 255 265 275 Shop ManualCopyMaster267% (12)

- Case International 235 235h 245 255 265 275 Shop ManualDocument10 pagesCase International 235 235h 245 255 265 275 Shop Manualmarcus100% (46)

- Honda Accord 2002Document87 pagesHonda Accord 2002Mac PirxNo ratings yet

- Installation Manual YC YDDocument54 pagesInstallation Manual YC YDIsrael ArceoNo ratings yet

- User Manual: Couple Tank ExperimentDocument22 pagesUser Manual: Couple Tank ExperimentRUBEN DARIO TAMAYO BALLIVIANNo ratings yet

- Total School Affiliated From CBSE For HARYANADocument69 pagesTotal School Affiliated From CBSE For HARYANABijay SinghNo ratings yet

- Hyderabad DataDocument70 pagesHyderabad DataBijay Singh50% (2)

- Nilai Inggris XII BDocument8 pagesNilai Inggris XII BWidiNo ratings yet

- Akutansi Jasa BaruDocument793 pagesAkutansi Jasa BaruilhamdzakipratamaNo ratings yet

- Leger - K2013 - X IIS 1Document6 pagesLeger - K2013 - X IIS 1sman1 lemboNo ratings yet

- Format Nilai Keterampilan eRaporSMK Fisika X TPM 1Document2 pagesFormat Nilai Keterampilan eRaporSMK Fisika X TPM 1Rafli ChrisnantoNo ratings yet

- Format Nilai Keterampilan eRaporSMK Fisika X TITL 2Document2 pagesFormat Nilai Keterampilan eRaporSMK Fisika X TITL 2Rafli ChrisnantoNo ratings yet

- Format Nilai Keterampilan ERaporSMK Fisika X TPM 2Document2 pagesFormat Nilai Keterampilan ERaporSMK Fisika X TPM 2Rafli ChrisnantoNo ratings yet

- Nilai Keterampilan VI BDocument8 pagesNilai Keterampilan VI BWidiNo ratings yet

- No. Nama Pertemuan 1 2 3 4 5 6 2.86% 2.86% 2.86% 2.86% 2.86% 2.86%Document3 pagesNo. Nama Pertemuan 1 2 3 4 5 6 2.86% 2.86% 2.86% 2.86% 2.86% 2.86%ardaNo ratings yet

- Format Nilai Keterampilan eRaporSMK Fisika X TITL 1Document2 pagesFormat Nilai Keterampilan eRaporSMK Fisika X TITL 1Rafli ChrisnantoNo ratings yet

- Update Nilai Online Batch 7 Day 1Document2 pagesUpdate Nilai Online Batch 7 Day 1silviantiintaNo ratings yet

- a7acda76-c2cd-4727-b1a0-e43df835d492 (1)Document3 pagesa7acda76-c2cd-4727-b1a0-e43df835d492 (1)JESUS ALBERTO IBARRA ARMENDARIZNo ratings yet

- Format Nilai Keterampilan eRaporSMK Fisika X TEI 2Document2 pagesFormat Nilai Keterampilan eRaporSMK Fisika X TEI 2Rafli ChrisnantoNo ratings yet

- Pengolahan Nilai B. Arab Kls 3 A LELLYDocument6 pagesPengolahan Nilai B. Arab Kls 3 A LELLYLutfatul KhoiriahNo ratings yet

- Quran Hadiakidah Akhla Fikih Ski 1 1 1 1Document3 pagesQuran Hadiakidah Akhla Fikih Ski 1 1 1 1ithauNo ratings yet

- Leger - K2013 - X IPS 3Document6 pagesLeger - K2013 - X IPS 3Laras PoliyamaNo ratings yet

- NO Nama NIS Nisn: Mohammad Sahli Gilang RamadhaniDocument9 pagesNO Nama NIS Nisn: Mohammad Sahli Gilang RamadhanironyNo ratings yet

- SYAZANA IZZATI - 6BME1 - Assignment Control Chart 2021Document4 pagesSYAZANA IZZATI - 6BME1 - Assignment Control Chart 2021Syazana IzzatiNo ratings yet

- Manual de Partes XJF-XJFDocument28 pagesManual de Partes XJF-XJFJose HernandezzNo ratings yet

- Format Nilai Keterampilan eRaporSMK Fisika X TEI 1Document2 pagesFormat Nilai Keterampilan eRaporSMK Fisika X TEI 1Rafli ChrisnantoNo ratings yet

- Pages From BOBCAT S175 SKID STEERDocument2 pagesPages From BOBCAT S175 SKID STEERgerman gualavisiNo ratings yet

- Nilai STTB Kop KeahlianDocument7 pagesNilai STTB Kop Keahlianwifq41d1.dataNo ratings yet

- Log SheefDocument1 pageLog SheefShuar diynNo ratings yet

- Xi KepegawaianDocument12 pagesXi Kepegawaiantekla laianNo ratings yet

- Leger Nilai Rapor Kelas XI TPM 1Document4 pagesLeger Nilai Rapor Kelas XI TPM 1Ardia VeveNo ratings yet

- Sem 1 Kelas 9 ADocument4 pagesSem 1 Kelas 9 Ananang003No ratings yet

- Leger - K2013 - X IPS 1Document6 pagesLeger - K2013 - X IPS 1Deni SandraNo ratings yet

- Leger - K2013 - Kelas 7EDocument1 pageLeger - K2013 - Kelas 7EYulis WicaksonoNo ratings yet

- Rekap 5bDocument17 pagesRekap 5bWong GalauNo ratings yet

- Rekap 5aDocument4 pagesRekap 5aWong GalauNo ratings yet

- QC-QGV 40-400hp-8p-APDocument2 pagesQC-QGV 40-400hp-8p-APwilliambach2018No ratings yet

- Plug C - KO 2019Document8 pagesPlug C - KO 2019almiraNo ratings yet

- UH 1 UH 2 UH 3 UH 4 RRT NU H T 1 T 2 T 3 T 4 RE TGS NP UH UT S UA S Optim UM Akhir Predi KATDocument10 pagesUH 1 UH 2 UH 3 UH 4 RRT NU H T 1 T 2 T 3 T 4 RE TGS NP UH UT S UA S Optim UM Akhir Predi KATPutri NazillaNo ratings yet

- SMP Plus It Husnul Khotimah Leger Nilai Siswa Kelas 8B Tahun Pelajaran: 2020 / 2021, Semester: 2Document4 pagesSMP Plus It Husnul Khotimah Leger Nilai Siswa Kelas 8B Tahun Pelajaran: 2020 / 2021, Semester: 2smpithusnul khotimahNo ratings yet

- Book 3Document7 pagesBook 3Khaja Musab ManzoorNo ratings yet

- KIỂM ĐẾM THIẾT BỊ KHÔNG SỬ DỤNGDocument7 pagesKIỂM ĐẾM THIẾT BỊ KHÔNG SỬ DỤNGKEO TUNNo ratings yet

- Rekap Nilai SKP 2023Document3 pagesRekap Nilai SKP 2023Baiq Alwinda Asri JuliantiNo ratings yet

- Daftar Nilai IKM Ganjil 2022Document5 pagesDaftar Nilai IKM Ganjil 2022nurindahamalia52No ratings yet

- Leger Nilai Rapor Kelas X PSPTVDocument5 pagesLeger Nilai Rapor Kelas X PSPTVHendro SetyonoNo ratings yet

- RTWALLDocument18 pagesRTWALLJomar CerdaNo ratings yet

- PasDocument2 pagesPasUran Web ArtNo ratings yet

- 1.1 MATERIALS Grading Information 11-2018Document20 pages1.1 MATERIALS Grading Information 11-2018Tran Quoc VietNo ratings yet

- SMP Plus It Husnul Khotimah Leger Nilai Siswa Kelas 8A Tahun Pelajaran: 2020 / 2021, Semester: 2Document4 pagesSMP Plus It Husnul Khotimah Leger Nilai Siswa Kelas 8A Tahun Pelajaran: 2020 / 2021, Semester: 2smpithusnul khotimahNo ratings yet

- Leger - K2013 - Kelas 8 F TerbukaDocument4 pagesLeger - K2013 - Kelas 8 F TerbukaMerlyn LengoNo ratings yet

- Leger K2013 Kelas 8 BDocument3 pagesLeger K2013 Kelas 8 Bbhayu_pijarNo ratings yet

- PPKN XI RPLDocument22 pagesPPKN XI RPLSiti RahmahNo ratings yet

- SMP Negeri 1 Tasifeto Barat Leger Nilai Siswa Kelas Kelas 8 E Tahun Pelajaran: 2019 / 2020, Semester: 1Document4 pagesSMP Negeri 1 Tasifeto Barat Leger Nilai Siswa Kelas Kelas 8 E Tahun Pelajaran: 2019 / 2020, Semester: 1Merlyn LengoNo ratings yet

- 0 - 69 NilaiDocument4 pages0 - 69 NilaiMohamad BotutiheNo ratings yet

- XJS-XJF CompressorsDocument32 pagesXJS-XJF CompressorsJuan Carlos Arreola GuitierrezNo ratings yet

- Daftar Nilai Guru Xi TBSM 3Document1 pageDaftar Nilai Guru Xi TBSM 3Mau LanaNo ratings yet

- Kelas: VI (Enam) Mata Pelajaran: Matematika Nama: Daftar Nilai Semester 1 SD Negeri 14 Suak TapehDocument3 pagesKelas: VI (Enam) Mata Pelajaran: Matematika Nama: Daftar Nilai Semester 1 SD Negeri 14 Suak TapehAni KhanifatunNo ratings yet

- Daftar Nilai Guru X TBSM 2Document1 pageDaftar Nilai Guru X TBSM 2Mau LanaNo ratings yet

- STANDARD Engine Vs My Engine Volumetric EfficentyDocument198 pagesSTANDARD Engine Vs My Engine Volumetric EfficentySmoking WheelsNo ratings yet

- Isma Yuniar - Tugas Latihan 1Document8 pagesIsma Yuniar - Tugas Latihan 1isma yuniarNo ratings yet

- Tugas Latihan 1Document8 pagesTugas Latihan 1isma yuniarNo ratings yet

- Turbine 6 Final ReportDocument20 pagesTurbine 6 Final ReportDangolNo ratings yet

- Daftar Nilai Siswa Ipa Sma Negeri 101 Dagelan: NO Nama Matematika B Indonesia B Inggris Kimia Fisika Biologi Rata RataDocument4 pagesDaftar Nilai Siswa Ipa Sma Negeri 101 Dagelan: NO Nama Matematika B Indonesia B Inggris Kimia Fisika Biologi Rata RatadindaNo ratings yet

- Analisis Nilai KeterampilanDocument6 pagesAnalisis Nilai KeterampilanAdit TaufiqNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- SCH GGNDocument14 pagesSCH GGNBijay SinghNo ratings yet

- UntitledDocument3 pagesUntitledBijay SinghNo ratings yet

- S.No. Name Data Leads Admission School SeminarDocument2 pagesS.No. Name Data Leads Admission School SeminarBijay SinghNo ratings yet

- Apna Swag Dance Studio: The Ultimate 2019Document6 pagesApna Swag Dance Studio: The Ultimate 2019Bijay SinghNo ratings yet

- How To Get Over Depression?Document6 pagesHow To Get Over Depression?Bijay SinghNo ratings yet

- Company List of Faridabad RoughDocument4 pagesCompany List of Faridabad RoughBijay SinghNo ratings yet

- SCH GGNDocument21 pagesSCH GGNBijay SinghNo ratings yet

- Phase III B 10.11.09Document159 pagesPhase III B 10.11.09Bijay SinghNo ratings yet

- Graduate Mechanical Engineer: EligibilityDocument1 pageGraduate Mechanical Engineer: EligibilityBijay SinghNo ratings yet

- Diploma in Nautical Science:: FeesDocument1 pageDiploma in Nautical Science:: FeesBijay SinghNo ratings yet

- Esc101: Fundamentals of Computing: 2011-12-Monsoon SemesterDocument6 pagesEsc101: Fundamentals of Computing: 2011-12-Monsoon SemesterMukesh Kumar DewraNo ratings yet

- Bearmach Parts Ed12Document67 pagesBearmach Parts Ed12Dakarman100% (2)

- Quarterly Building Inspection ReportDocument12 pagesQuarterly Building Inspection Reportvishwas salunkheNo ratings yet

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- 8085 Microprocessor InterruptsDocument33 pages8085 Microprocessor InterruptsAASTHA KIETNo ratings yet

- Mag 2 Fire Alarm ManualDocument2 pagesMag 2 Fire Alarm ManualTomas MoynihanNo ratings yet

- Property of American Airlines: MaintenanceDocument44 pagesProperty of American Airlines: MaintenanceVFinNo ratings yet

- 2015 Nissan 370Z 3.7L Eng VIN A BaseDocument69 pages2015 Nissan 370Z 3.7L Eng VIN A BaseData TécnicaNo ratings yet

- 10 Best Ergonomic Chairs For Watching TVDocument12 pages10 Best Ergonomic Chairs For Watching TVbernNo ratings yet

- SchneiderDocument46 pagesSchneiderTareq JildehNo ratings yet

- Amplificador de Audio para SordosDocument3 pagesAmplificador de Audio para SordosAlberto Jimenez100% (1)

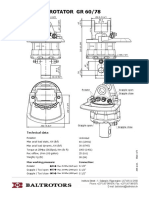

- Rotator Baltrotors GR60-78Document3 pagesRotator Baltrotors GR60-78Anonymous 80HAPYsoNo ratings yet

- Um3ab1 Cylinder HeadDocument2 pagesUm3ab1 Cylinder HeadBurik8100% (1)

- NDT Request - RT DTD 06.05.19Document81 pagesNDT Request - RT DTD 06.05.19Kushal PraviraNo ratings yet

- ExMa DatasheetDocument2 pagesExMa Datasheetmanoj_sitecNo ratings yet

- 14twelve Bandsaw ManualDocument68 pages14twelve Bandsaw Manualpdxcraftsman5888No ratings yet

- Appliance DiagnosisDocument76 pagesAppliance Diagnosisjergreen6100% (1)

- D425ie D5100 enDocument45 pagesD425ie D5100 enSelamet RezkiNo ratings yet

- Axle Boot MarutiDocument2 pagesAxle Boot MarutinrjmanitNo ratings yet

- OccuSwitch - LRM1070-80 SENSOR DE MOVIMIENTODocument7 pagesOccuSwitch - LRM1070-80 SENSOR DE MOVIMIENTOPEDRO NAVAJASNo ratings yet

- Chapter6 Speed Control DCDocument36 pagesChapter6 Speed Control DCAzmi Shah Alias KhooNo ratings yet

- Canrig Part Number Description: Component Literature: Top DriveDocument2 pagesCanrig Part Number Description: Component Literature: Top DriveAlex RamirezNo ratings yet

- The Effects of System Grounding & Probability of Arc Flash Reduction - I-Gard - Ajit Bapat - October 27 2014Document81 pagesThe Effects of System Grounding & Probability of Arc Flash Reduction - I-Gard - Ajit Bapat - October 27 2014add8742No ratings yet

- Type 1098-EGR & 1098H-EGR Pilot-Operated Regulators: Instruction ManualDocument30 pagesType 1098-EGR & 1098H-EGR Pilot-Operated Regulators: Instruction ManualDjebali MouradNo ratings yet

- About 888 Metrohm TitrandoDocument57 pagesAbout 888 Metrohm TitrandoElena Erlauer100% (1)

- Ball Screw DocumentationDocument12 pagesBall Screw DocumentationMoldovan Gheorghe100% (1)

- Cupra Born 11 21 enDocument343 pagesCupra Born 11 21 enkrackeurhrwNo ratings yet

Skill Matrix

Skill Matrix

Uploaded by

Bijay Singh0 ratings0% found this document useful (0 votes)

15 views1 pageThe document outlines a mechanical maintenance skill matrix for various employees, rating their competency levels from 1-100 across 44 key responsibilities related to maintaining furnaces, drilling machines, blowers, and other industrial equipment. Jitenda Singh and Atul Rao generally have the highest competency ratings, while Raju Shirke and SS Mishra are closer to the group average. Overall competency levels vary across responsibilities, with some employees stronger in areas like inspections while weaker in hydraulics troubleshooting.

Original Description:

sfsdgdfgf

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines a mechanical maintenance skill matrix for various employees, rating their competency levels from 1-100 across 44 key responsibilities related to maintaining furnaces, drilling machines, blowers, and other industrial equipment. Jitenda Singh and Atul Rao generally have the highest competency ratings, while Raju Shirke and SS Mishra are closer to the group average. Overall competency levels vary across responsibilities, with some employees stronger in areas like inspections while weaker in hydraulics troubleshooting.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

15 views1 pageSkill Matrix

Skill Matrix

Uploaded by

Bijay SinghThe document outlines a mechanical maintenance skill matrix for various employees, rating their competency levels from 1-100 across 44 key responsibilities related to maintaining furnaces, drilling machines, blowers, and other industrial equipment. Jitenda Singh and Atul Rao generally have the highest competency ratings, while Raju Shirke and SS Mishra are closer to the group average. Overall competency levels vary across responsibilities, with some employees stronger in areas like inspections while weaker in hydraulics troubleshooting.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 1

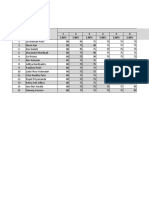

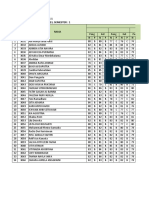

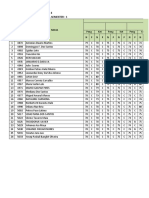

BF Mechanical Maintenance Skill Matrix

Optimum Skill Jitenda Atul SVT KN Raju SS AK DS

Sl. No. Key responsibility Competency Index Thanekar singh Rao Rechanna Dalvi Shirke Thapa Mishra Billav Average Surve Singh Pinto Mishra Patil Anil Average

1 Carry out normal PM jobs. 100 65 82 80 75 68 75 80 80 80 76 80 80 82 77 73 72 77

2 Carry out Shut Down PM jobs. 100 62 82 80 75 70 77 90 80 77 77 80 78 80 75 73 72 76

3 Carry out Daily check list. 100 65 82 80 75 68 68 75 80 77 74 80 78 80 75 75 73 76

Routine inspection & Trouble shooting of

Taphole Drill M/C Forward & Reverse

4 percussion hammering devices. 100 65 85 80 85 75 75 85 80 77 79 85 77 80 73 73 72 75

Checking of Drill M/C centering w. r. t. Taphole

5 & correction of the same. 100 65 85 80 85 80 77 80 80 77 79 85 77 80 72 73 72 75

Inspection of Mudgun Ram Indicator device &

6 adjustment of the same. 100 65 85 80 80 75 75 80 80 78 78 85 78 80 73 70 72 75

Routine inspection & Trouble shooting of

7 Taphole Drill M/C, Mudgun Hydralic System. 100 68 83 75 80 75 72 80 80 78 77 88 80 80 73 70 70 75

Cleaning of Water line strainer in Mudgun

8 Hydraulic power pack oil cooler. 100 70 83 77 85 75 72 80 80 75 77 85 80 78 73 70 70 74

Replacement of front protection plates & shank

9 adopter of Drill M/c. 100 70 83 77 80 80 75 75 75 75 77 83 80 78 73 70 70 74

10 Replacement of Mudgun nozzle. 100 68 82 75 80 80 75 75 75 75 76 83 78 78 73 72 70 74

Segregation & Salvaging of Drill rods of different

11 sizes. 100 72 85 80 85 80 77 75 75 72 78 75 73 85 78 75 72 77

12 Replacement of Blowpipes & Downlegs. 100 68 85 80 80 75 75 75 77 75 77 73 71 73 73 72 68 71

13 Alignment & Centering of Blowpipe. 100 67 85 80 80 75 75 80 80 73 77 73 73 75 72 70 68 72

Routine inspection & monitoring of blast

14 leakages at Tuyere Platform. 100 72 80 75 80 85 75 75 80 75 77 80 75 75 72 70 68 72

Replacement of peephole assembly & glass

15 with valve. 100 70 77 75 80 85 75 75 77 73 76 73 73 78 73 73 72 74

Routine inspection & monitoring of Furnace

16 Water cooling system 100 70 80 75 80 80 73 75 82 73 76 80 75 75 72 70 68 72

17 Replacement of Furnace water cooling hoses. 100 70 80 75 80 80 73 75 78 73 76 80 73 75 72 70 68 72

18 Monitoring of Furnace proper. 100 68 82 72 80 80 73 75 78 75 76 80 75 75 72 70 68 72

19 Routine inspection of BLT charging system. 100 68 82 75 80 80 75 80 78 75 77 80 75 75 72 70 68 72

Arresting of bf gas leakages at BLT & Dust

20 catcher. 100 68 80 75 80 80 75 80 75 75 76 78 74 75 72 71 68 72

Inspection of BLT Hydraulic system & regular

21 venting of oil cooler. 100 68 80 75 80 80 73 80 78 75 77 78 72 73 73 72 68 72

22 Stock rods inspection & brake setting. 100 70 82 75 80 80 75 75 75 70 76 73 70 70 70 70 68 70

Routine inspection & Trouble shooting of BLT

23 Centralised grease lubrication system. 100 65 82 75 80 80 75 80 75 70 76 75 73 73 70 70 68 71

24 Housekeeping of plant/ machineries. 100 77 85 82 90 90 80 70 78 73 81 72 72 70 72 73 72 72

Replaement of Gas cooler bundle & Suction

25 filter elements of Screw Compressor. 100 67 80 80 90 90 80 80 75 73 79 78 72 80 75 73 72 74

Start up and grid connection of the gas

26 expansion turbine 100 67 80 77 80 80 75 80 75 85 78 83 75 75 72 70 68 72

27 Shutting down of the Gas expansion turbine 100 70 80 77 80 80 75 75 77 85 78 83 77 75 72 72 70 73

Starting and shutting down the screw

28 compressors 100 70 82 77 80 80 75 75 75 85 78 83 77 75 72 72 70 73

29 Opening and closing of backdrafts 100 70 85 80 80 80 75 70 77 85 78 83 77 73 70 70 68 71

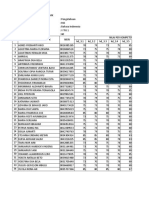

30 Adjustment of crane brakes 100 65 82 75 80 80 75 75 75 80 76 78 75 75 72 70 68 72

31 Trouble shooting of Hydraulics 100 65 75 73 72 80 75 70 70 70 72 63 65 70 62 65 62 65

32 Reading of hydraulic circuits 100 65 67 65 65 80 65 70 70 70 69 65 65 70 63 65 62 65

Furnace water cooling changeover from Group

33 # 2 to Group # 5 & back. 100 70 83 77 80 80 75 70 75 70 76 73 72 73 68 70 68 70

34 Emergency handling during power failure. 100 70 80 77 80 80 75 70 77 72 76 70 70 68 65 67 66 67

Replacement & cleaning of water line stainer &

35 oil filter of Gas expansion turbine. 100 70 77 75 80 80 75 75 75 70 75 73 72 73 70 70 68 70

36 Gearbox assembly & repair. 100 70 72 73 72 72 72 70 73 68 71 68 70 68 67 65 67 67

37 Alignment of rotary equipments. 100 65 72 67 67 68 68 70 75 70 69 72 72 72 67 67 62 68

38 Mechanical seal installation & maintenance. 100 67 75 70 70 70 70 75 73 68 71 70 70 70 63 63 62 66

39 Proper Manpower utilisation. 100 67 85 77 75 75 75 70 75 70 74 75 72 70 67 67 65 68

40 Safety of mapower, machine & equipments. 100 70 80 77 75 75 75 65 75 73 74 75 73 75 72 72 70 72

41 Checking equipment health. 100 70 85 80 80 80 80 67 77 73 77 77 72 73 68 68 68 70

42 Recording of Notifications. 100 65 80 80 75 75 75 70 73 73 74 78 74 75 70 68 68 71

43 Attending Equipments break downs. 100 72 82 75 75 75 75 67 77 73 74 75 72 73 77 75 72 74

44 TPM, Six Sigma Activities in Shift. 100 68 70 70 70 70 70 70 70 73 70 73 70 72 67 67 65 68

45 Self Motivation. 100 70 85 77 77 77 77 67 72 73 75 73 73 73 68 65 65 69

46 Reaction Time. 100 70 82 77 77 77 77 67 75 73 75 75 72 72 67 65 65 68

Temperament ( i.e., keeping cool under

47 pressure ) 100 75 83 82 82 82 82 70 75 73 78 77 73 73 68 67 67 70

48 Communication. 100 75 85 82 82 82 82 67 72 73 78 77 72 72 67 65 65 68

49 Willingness to take responsibility 100 75 83 82 82 82 82 67 75 75 78 75 72 70 67 65 65 68

50 Proper handover takeover of the shift. 100 75 85 82 82 82 82 67 75 78 79 75 73 70 67 65 65 68

Average 69 81 77 79 78 75 74 76 75 76 77 74 74 71 70 68

You might also like

- Case International 235 235H 245 255 265 275 Shop ManualDocument128 pagesCase International 235 235H 245 255 265 275 Shop ManualCopyMaster267% (12)

- Case International 235 235h 245 255 265 275 Shop ManualDocument10 pagesCase International 235 235h 245 255 265 275 Shop Manualmarcus100% (46)

- Honda Accord 2002Document87 pagesHonda Accord 2002Mac PirxNo ratings yet

- Installation Manual YC YDDocument54 pagesInstallation Manual YC YDIsrael ArceoNo ratings yet

- User Manual: Couple Tank ExperimentDocument22 pagesUser Manual: Couple Tank ExperimentRUBEN DARIO TAMAYO BALLIVIANNo ratings yet

- Total School Affiliated From CBSE For HARYANADocument69 pagesTotal School Affiliated From CBSE For HARYANABijay SinghNo ratings yet

- Hyderabad DataDocument70 pagesHyderabad DataBijay Singh50% (2)

- Nilai Inggris XII BDocument8 pagesNilai Inggris XII BWidiNo ratings yet

- Akutansi Jasa BaruDocument793 pagesAkutansi Jasa BaruilhamdzakipratamaNo ratings yet

- Leger - K2013 - X IIS 1Document6 pagesLeger - K2013 - X IIS 1sman1 lemboNo ratings yet

- Format Nilai Keterampilan eRaporSMK Fisika X TPM 1Document2 pagesFormat Nilai Keterampilan eRaporSMK Fisika X TPM 1Rafli ChrisnantoNo ratings yet

- Format Nilai Keterampilan eRaporSMK Fisika X TITL 2Document2 pagesFormat Nilai Keterampilan eRaporSMK Fisika X TITL 2Rafli ChrisnantoNo ratings yet

- Format Nilai Keterampilan ERaporSMK Fisika X TPM 2Document2 pagesFormat Nilai Keterampilan ERaporSMK Fisika X TPM 2Rafli ChrisnantoNo ratings yet

- Nilai Keterampilan VI BDocument8 pagesNilai Keterampilan VI BWidiNo ratings yet

- No. Nama Pertemuan 1 2 3 4 5 6 2.86% 2.86% 2.86% 2.86% 2.86% 2.86%Document3 pagesNo. Nama Pertemuan 1 2 3 4 5 6 2.86% 2.86% 2.86% 2.86% 2.86% 2.86%ardaNo ratings yet

- Format Nilai Keterampilan eRaporSMK Fisika X TITL 1Document2 pagesFormat Nilai Keterampilan eRaporSMK Fisika X TITL 1Rafli ChrisnantoNo ratings yet

- Update Nilai Online Batch 7 Day 1Document2 pagesUpdate Nilai Online Batch 7 Day 1silviantiintaNo ratings yet

- a7acda76-c2cd-4727-b1a0-e43df835d492 (1)Document3 pagesa7acda76-c2cd-4727-b1a0-e43df835d492 (1)JESUS ALBERTO IBARRA ARMENDARIZNo ratings yet

- Format Nilai Keterampilan eRaporSMK Fisika X TEI 2Document2 pagesFormat Nilai Keterampilan eRaporSMK Fisika X TEI 2Rafli ChrisnantoNo ratings yet

- Pengolahan Nilai B. Arab Kls 3 A LELLYDocument6 pagesPengolahan Nilai B. Arab Kls 3 A LELLYLutfatul KhoiriahNo ratings yet

- Quran Hadiakidah Akhla Fikih Ski 1 1 1 1Document3 pagesQuran Hadiakidah Akhla Fikih Ski 1 1 1 1ithauNo ratings yet

- Leger - K2013 - X IPS 3Document6 pagesLeger - K2013 - X IPS 3Laras PoliyamaNo ratings yet

- NO Nama NIS Nisn: Mohammad Sahli Gilang RamadhaniDocument9 pagesNO Nama NIS Nisn: Mohammad Sahli Gilang RamadhanironyNo ratings yet

- SYAZANA IZZATI - 6BME1 - Assignment Control Chart 2021Document4 pagesSYAZANA IZZATI - 6BME1 - Assignment Control Chart 2021Syazana IzzatiNo ratings yet

- Manual de Partes XJF-XJFDocument28 pagesManual de Partes XJF-XJFJose HernandezzNo ratings yet

- Format Nilai Keterampilan eRaporSMK Fisika X TEI 1Document2 pagesFormat Nilai Keterampilan eRaporSMK Fisika X TEI 1Rafli ChrisnantoNo ratings yet

- Pages From BOBCAT S175 SKID STEERDocument2 pagesPages From BOBCAT S175 SKID STEERgerman gualavisiNo ratings yet

- Nilai STTB Kop KeahlianDocument7 pagesNilai STTB Kop Keahlianwifq41d1.dataNo ratings yet

- Log SheefDocument1 pageLog SheefShuar diynNo ratings yet

- Xi KepegawaianDocument12 pagesXi Kepegawaiantekla laianNo ratings yet

- Leger Nilai Rapor Kelas XI TPM 1Document4 pagesLeger Nilai Rapor Kelas XI TPM 1Ardia VeveNo ratings yet

- Sem 1 Kelas 9 ADocument4 pagesSem 1 Kelas 9 Ananang003No ratings yet

- Leger - K2013 - X IPS 1Document6 pagesLeger - K2013 - X IPS 1Deni SandraNo ratings yet

- Leger - K2013 - Kelas 7EDocument1 pageLeger - K2013 - Kelas 7EYulis WicaksonoNo ratings yet

- Rekap 5bDocument17 pagesRekap 5bWong GalauNo ratings yet

- Rekap 5aDocument4 pagesRekap 5aWong GalauNo ratings yet

- QC-QGV 40-400hp-8p-APDocument2 pagesQC-QGV 40-400hp-8p-APwilliambach2018No ratings yet

- Plug C - KO 2019Document8 pagesPlug C - KO 2019almiraNo ratings yet

- UH 1 UH 2 UH 3 UH 4 RRT NU H T 1 T 2 T 3 T 4 RE TGS NP UH UT S UA S Optim UM Akhir Predi KATDocument10 pagesUH 1 UH 2 UH 3 UH 4 RRT NU H T 1 T 2 T 3 T 4 RE TGS NP UH UT S UA S Optim UM Akhir Predi KATPutri NazillaNo ratings yet

- SMP Plus It Husnul Khotimah Leger Nilai Siswa Kelas 8B Tahun Pelajaran: 2020 / 2021, Semester: 2Document4 pagesSMP Plus It Husnul Khotimah Leger Nilai Siswa Kelas 8B Tahun Pelajaran: 2020 / 2021, Semester: 2smpithusnul khotimahNo ratings yet

- Book 3Document7 pagesBook 3Khaja Musab ManzoorNo ratings yet

- KIỂM ĐẾM THIẾT BỊ KHÔNG SỬ DỤNGDocument7 pagesKIỂM ĐẾM THIẾT BỊ KHÔNG SỬ DỤNGKEO TUNNo ratings yet

- Rekap Nilai SKP 2023Document3 pagesRekap Nilai SKP 2023Baiq Alwinda Asri JuliantiNo ratings yet

- Daftar Nilai IKM Ganjil 2022Document5 pagesDaftar Nilai IKM Ganjil 2022nurindahamalia52No ratings yet

- Leger Nilai Rapor Kelas X PSPTVDocument5 pagesLeger Nilai Rapor Kelas X PSPTVHendro SetyonoNo ratings yet

- RTWALLDocument18 pagesRTWALLJomar CerdaNo ratings yet

- PasDocument2 pagesPasUran Web ArtNo ratings yet

- 1.1 MATERIALS Grading Information 11-2018Document20 pages1.1 MATERIALS Grading Information 11-2018Tran Quoc VietNo ratings yet

- SMP Plus It Husnul Khotimah Leger Nilai Siswa Kelas 8A Tahun Pelajaran: 2020 / 2021, Semester: 2Document4 pagesSMP Plus It Husnul Khotimah Leger Nilai Siswa Kelas 8A Tahun Pelajaran: 2020 / 2021, Semester: 2smpithusnul khotimahNo ratings yet

- Leger - K2013 - Kelas 8 F TerbukaDocument4 pagesLeger - K2013 - Kelas 8 F TerbukaMerlyn LengoNo ratings yet

- Leger K2013 Kelas 8 BDocument3 pagesLeger K2013 Kelas 8 Bbhayu_pijarNo ratings yet

- PPKN XI RPLDocument22 pagesPPKN XI RPLSiti RahmahNo ratings yet

- SMP Negeri 1 Tasifeto Barat Leger Nilai Siswa Kelas Kelas 8 E Tahun Pelajaran: 2019 / 2020, Semester: 1Document4 pagesSMP Negeri 1 Tasifeto Barat Leger Nilai Siswa Kelas Kelas 8 E Tahun Pelajaran: 2019 / 2020, Semester: 1Merlyn LengoNo ratings yet

- 0 - 69 NilaiDocument4 pages0 - 69 NilaiMohamad BotutiheNo ratings yet

- XJS-XJF CompressorsDocument32 pagesXJS-XJF CompressorsJuan Carlos Arreola GuitierrezNo ratings yet

- Daftar Nilai Guru Xi TBSM 3Document1 pageDaftar Nilai Guru Xi TBSM 3Mau LanaNo ratings yet

- Kelas: VI (Enam) Mata Pelajaran: Matematika Nama: Daftar Nilai Semester 1 SD Negeri 14 Suak TapehDocument3 pagesKelas: VI (Enam) Mata Pelajaran: Matematika Nama: Daftar Nilai Semester 1 SD Negeri 14 Suak TapehAni KhanifatunNo ratings yet

- Daftar Nilai Guru X TBSM 2Document1 pageDaftar Nilai Guru X TBSM 2Mau LanaNo ratings yet

- STANDARD Engine Vs My Engine Volumetric EfficentyDocument198 pagesSTANDARD Engine Vs My Engine Volumetric EfficentySmoking WheelsNo ratings yet

- Isma Yuniar - Tugas Latihan 1Document8 pagesIsma Yuniar - Tugas Latihan 1isma yuniarNo ratings yet

- Tugas Latihan 1Document8 pagesTugas Latihan 1isma yuniarNo ratings yet

- Turbine 6 Final ReportDocument20 pagesTurbine 6 Final ReportDangolNo ratings yet

- Daftar Nilai Siswa Ipa Sma Negeri 101 Dagelan: NO Nama Matematika B Indonesia B Inggris Kimia Fisika Biologi Rata RataDocument4 pagesDaftar Nilai Siswa Ipa Sma Negeri 101 Dagelan: NO Nama Matematika B Indonesia B Inggris Kimia Fisika Biologi Rata RatadindaNo ratings yet

- Analisis Nilai KeterampilanDocument6 pagesAnalisis Nilai KeterampilanAdit TaufiqNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- SCH GGNDocument14 pagesSCH GGNBijay SinghNo ratings yet

- UntitledDocument3 pagesUntitledBijay SinghNo ratings yet

- S.No. Name Data Leads Admission School SeminarDocument2 pagesS.No. Name Data Leads Admission School SeminarBijay SinghNo ratings yet

- Apna Swag Dance Studio: The Ultimate 2019Document6 pagesApna Swag Dance Studio: The Ultimate 2019Bijay SinghNo ratings yet

- How To Get Over Depression?Document6 pagesHow To Get Over Depression?Bijay SinghNo ratings yet

- Company List of Faridabad RoughDocument4 pagesCompany List of Faridabad RoughBijay SinghNo ratings yet

- SCH GGNDocument21 pagesSCH GGNBijay SinghNo ratings yet

- Phase III B 10.11.09Document159 pagesPhase III B 10.11.09Bijay SinghNo ratings yet

- Graduate Mechanical Engineer: EligibilityDocument1 pageGraduate Mechanical Engineer: EligibilityBijay SinghNo ratings yet

- Diploma in Nautical Science:: FeesDocument1 pageDiploma in Nautical Science:: FeesBijay SinghNo ratings yet

- Esc101: Fundamentals of Computing: 2011-12-Monsoon SemesterDocument6 pagesEsc101: Fundamentals of Computing: 2011-12-Monsoon SemesterMukesh Kumar DewraNo ratings yet

- Bearmach Parts Ed12Document67 pagesBearmach Parts Ed12Dakarman100% (2)

- Quarterly Building Inspection ReportDocument12 pagesQuarterly Building Inspection Reportvishwas salunkheNo ratings yet

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- 8085 Microprocessor InterruptsDocument33 pages8085 Microprocessor InterruptsAASTHA KIETNo ratings yet

- Mag 2 Fire Alarm ManualDocument2 pagesMag 2 Fire Alarm ManualTomas MoynihanNo ratings yet

- Property of American Airlines: MaintenanceDocument44 pagesProperty of American Airlines: MaintenanceVFinNo ratings yet

- 2015 Nissan 370Z 3.7L Eng VIN A BaseDocument69 pages2015 Nissan 370Z 3.7L Eng VIN A BaseData TécnicaNo ratings yet

- 10 Best Ergonomic Chairs For Watching TVDocument12 pages10 Best Ergonomic Chairs For Watching TVbernNo ratings yet

- SchneiderDocument46 pagesSchneiderTareq JildehNo ratings yet

- Amplificador de Audio para SordosDocument3 pagesAmplificador de Audio para SordosAlberto Jimenez100% (1)

- Rotator Baltrotors GR60-78Document3 pagesRotator Baltrotors GR60-78Anonymous 80HAPYsoNo ratings yet

- Um3ab1 Cylinder HeadDocument2 pagesUm3ab1 Cylinder HeadBurik8100% (1)

- NDT Request - RT DTD 06.05.19Document81 pagesNDT Request - RT DTD 06.05.19Kushal PraviraNo ratings yet

- ExMa DatasheetDocument2 pagesExMa Datasheetmanoj_sitecNo ratings yet

- 14twelve Bandsaw ManualDocument68 pages14twelve Bandsaw Manualpdxcraftsman5888No ratings yet

- Appliance DiagnosisDocument76 pagesAppliance Diagnosisjergreen6100% (1)

- D425ie D5100 enDocument45 pagesD425ie D5100 enSelamet RezkiNo ratings yet

- Axle Boot MarutiDocument2 pagesAxle Boot MarutinrjmanitNo ratings yet

- OccuSwitch - LRM1070-80 SENSOR DE MOVIMIENTODocument7 pagesOccuSwitch - LRM1070-80 SENSOR DE MOVIMIENTOPEDRO NAVAJASNo ratings yet

- Chapter6 Speed Control DCDocument36 pagesChapter6 Speed Control DCAzmi Shah Alias KhooNo ratings yet

- Canrig Part Number Description: Component Literature: Top DriveDocument2 pagesCanrig Part Number Description: Component Literature: Top DriveAlex RamirezNo ratings yet

- The Effects of System Grounding & Probability of Arc Flash Reduction - I-Gard - Ajit Bapat - October 27 2014Document81 pagesThe Effects of System Grounding & Probability of Arc Flash Reduction - I-Gard - Ajit Bapat - October 27 2014add8742No ratings yet

- Type 1098-EGR & 1098H-EGR Pilot-Operated Regulators: Instruction ManualDocument30 pagesType 1098-EGR & 1098H-EGR Pilot-Operated Regulators: Instruction ManualDjebali MouradNo ratings yet

- About 888 Metrohm TitrandoDocument57 pagesAbout 888 Metrohm TitrandoElena Erlauer100% (1)

- Ball Screw DocumentationDocument12 pagesBall Screw DocumentationMoldovan Gheorghe100% (1)

- Cupra Born 11 21 enDocument343 pagesCupra Born 11 21 enkrackeurhrwNo ratings yet