Professional Documents

Culture Documents

Ultrasonic Pulse Velocity Test

Ultrasonic Pulse Velocity Test

Uploaded by

Srinivasulu Reddy KoduruCopyright:

Available Formats

You might also like

- Friction Coefficient of Steel On Concrete or Grout PDFDocument7 pagesFriction Coefficient of Steel On Concrete or Grout PDFLuis Ernesto Ramirez OsorioNo ratings yet

- The Diagonal Tension Behavior of Fiber Reinforced Concrete BeamsDocument7 pagesThe Diagonal Tension Behavior of Fiber Reinforced Concrete BeamsChris LumyNo ratings yet

- Performance of Bamboo Reinforced Concrete BeamDocument5 pagesPerformance of Bamboo Reinforced Concrete BeamKarthick .mNo ratings yet

- Abaqus AnalysisDocument12 pagesAbaqus AnalysisMohan BhalmeNo ratings yet

- An Analysis of The Behavior of Hybrid Steel Beam - RC Column ConnectionDocument13 pagesAn Analysis of The Behavior of Hybrid Steel Beam - RC Column ConnectionEhsan WasimNo ratings yet

- HW1 Solutions S14 MAE 3344Document4 pagesHW1 Solutions S14 MAE 3344trapstar15No ratings yet

- The Mechanical Property of Steel Reinforced Concrete Under Compressive Impact Loading Investigated With The SHPB ExperimentsDocument6 pagesThe Mechanical Property of Steel Reinforced Concrete Under Compressive Impact Loading Investigated With The SHPB ExperimentsInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Performance Investigation of Square Concrete-Fi Lled Steel Tube ColumnsDocument7 pagesPerformance Investigation of Square Concrete-Fi Lled Steel Tube Columnsjoamirhenrique_10316No ratings yet

- Artigo Sobre EstribosDocument5 pagesArtigo Sobre EstribosPaulo CotteNo ratings yet

- Fang, Lundgren, Chen, Zhu-Corrosion Influence On Bond in Reinforced ConcreteDocument9 pagesFang, Lundgren, Chen, Zhu-Corrosion Influence On Bond in Reinforced ConcretepinarinciNo ratings yet

- Abu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlateDocument11 pagesAbu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlatefaridNo ratings yet

- Sesmic Test On CFST ColumnDocument49 pagesSesmic Test On CFST ColumnPOOJA VNo ratings yet

- RC Notes by Engr. GREGDocument49 pagesRC Notes by Engr. GREGMichael SuanNo ratings yet

- Effect of Reinforcement On The Failure Load of RC Beams: Osama Salem, Arafa El-HellotyDocument16 pagesEffect of Reinforcement On The Failure Load of RC Beams: Osama Salem, Arafa El-HellotyHesham EdressNo ratings yet

- Assessment of Corrosion Rate in Prestressed Concrete With Acoustic EmissionDocument13 pagesAssessment of Corrosion Rate in Prestressed Concrete With Acoustic Emissionjesé m.No ratings yet

- Shear Strengthening Effect of RC Beams Retrofitted by Wire Mesh and SCCDocument6 pagesShear Strengthening Effect of RC Beams Retrofitted by Wire Mesh and SCCIkhlas KittaNo ratings yet

- Mechanism of Shear TransferDocument8 pagesMechanism of Shear TransferSana'a AamirNo ratings yet

- Non-Destructive Testing of Joints in Precast Element StructuresDocument10 pagesNon-Destructive Testing of Joints in Precast Element StructuresshakeebNo ratings yet

- Study On Deep BeamsDocument16 pagesStudy On Deep Beamsshailesh patilNo ratings yet

- Bond Characteristics High-Strength Steel ReinforcementDocument6 pagesBond Characteristics High-Strength Steel ReinforcementUmair BaigNo ratings yet

- Seminar On Durability and Lifecycle Evaluation of Concrete Structures-2006Document9 pagesSeminar On Durability and Lifecycle Evaluation of Concrete Structures-2006AsanNo ratings yet

- Definition of Brackish Water: ReferenceDocument2 pagesDefinition of Brackish Water: ReferenceHuaman Chavez Jesus AngelNo ratings yet

- Experimental Investigation of Surface Crack Initiation, Propagation and Tension Stiffening in Self-Compacting Steel-Fibre-Reinforced ConcreteDocument17 pagesExperimental Investigation of Surface Crack Initiation, Propagation and Tension Stiffening in Self-Compacting Steel-Fibre-Reinforced ConcreteIsmail MohammedNo ratings yet

- Material Science ExperimentDocument7 pagesMaterial Science ExperimentGan Kwang YongNo ratings yet

- Effect of Lathe Waste in Concrete As ReinforcementDocument6 pagesEffect of Lathe Waste in Concrete As ReinforcementAnkit GuptaNo ratings yet

- Deep BeamsDocument16 pagesDeep BeamsKimNo ratings yet

- Shear Strength Analysis and Prediction of Reinforced Concrete Transfer Beams in High-Rise BuildingsDocument21 pagesShear Strength Analysis and Prediction of Reinforced Concrete Transfer Beams in High-Rise Buildingsmohammed_fathelbabNo ratings yet

- Prestressed ConcreteDocument8 pagesPrestressed ConcreteYeswanth RaghavendraNo ratings yet

- Pre Stressed ConcreteDocument8 pagesPre Stressed Concretevamsi_rsNo ratings yet

- High Strength Reinforcement in Ordinary Reinforced and Fibre Reinforced Cement Composite Light Weight Concrete BramsDocument283 pagesHigh Strength Reinforcement in Ordinary Reinforced and Fibre Reinforced Cement Composite Light Weight Concrete Bramsab8ccw5288No ratings yet

- Copy ManuscriptDocument20 pagesCopy ManuscriptSREEKUMARA GANAPATHY V S stellamaryscoe.edu.inNo ratings yet

- Influence of Axial Load On Behavior of Belled Pile Reinforced With High-Strength Steel BarsDocument10 pagesInfluence of Axial Load On Behavior of Belled Pile Reinforced With High-Strength Steel BarscdestudosNo ratings yet

- Coeficientes de Friccion de Concreto Sobre Metal PDFDocument7 pagesCoeficientes de Friccion de Concreto Sobre Metal PDFLuis Ernesto Ramirez OsorioNo ratings yet

- Friction Coefficient of Steel On Concrete or GroutDocument7 pagesFriction Coefficient of Steel On Concrete or GroutLuis Ernesto Ramirez OsorioNo ratings yet

- Probetas Con CocoDocument7 pagesProbetas Con CocoPascual Pascual BetiñoNo ratings yet

- Ridged PavementDocument4 pagesRidged Pavementgetanna07No ratings yet

- Impact of Crack Width On Bond Confined and Unconfined RebarDocument10 pagesImpact of Crack Width On Bond Confined and Unconfined RebarbrahmabulNo ratings yet

- 2 PDFDocument107 pages2 PDFRajeev BujjiNo ratings yet

- Civil EngineeringDocument8 pagesCivil EngineeringA-16 Sai GunjalNo ratings yet

- Bearing Capacity of Partially Loaded Concrete ElemDocument9 pagesBearing Capacity of Partially Loaded Concrete ElemJuraj031No ratings yet

- Deep BeamDocument9 pagesDeep BeamDeana WhiteNo ratings yet

- ArcDocument17 pagesArcFatima AhmedNo ratings yet

- 1 s2.0 S0263823112000602 MainDocument9 pages1 s2.0 S0263823112000602 MainrudynyambiNo ratings yet

- SSRN Id4446360Document9 pagesSSRN Id4446360Almas XamiNo ratings yet

- Response of Ferrocement Confinement On Behavior of Square RC Short ColumnDocument10 pagesResponse of Ferrocement Confinement On Behavior of Square RC Short ColumnPANKAJ TAMBAKHENo ratings yet

- Failure Modes of RC Beams With High Strength ReinforcementDocument8 pagesFailure Modes of RC Beams With High Strength ReinforcementmfhfhfNo ratings yet

- SectionsDocument7 pagesSectionsImmanuel R WilliamNo ratings yet

- 1.1 Purpose Behind Project:: "Prestressing Technique"Document6 pages1.1 Purpose Behind Project:: "Prestressing Technique"MayankMehrotraNo ratings yet

- SSRN Id4447479Document7 pagesSSRN Id4447479Almas XamiNo ratings yet

- Art 12Document11 pagesArt 12rammirisNo ratings yet

- Ahn2002 Elbow FractureDocument13 pagesAhn2002 Elbow FractureKurra SrikanthNo ratings yet

- The Effect of Medium Strain Rates On The Mechanical Properties of High Performance SteelsDocument7 pagesThe Effect of Medium Strain Rates On The Mechanical Properties of High Performance SteelsPierre GarciaNo ratings yet

- Research On Property Property of Steel-Encased Concrete On Property of Steel - Encased Concrete Composite Beam With Superior PerformanceDocument4 pagesResearch On Property Property of Steel-Encased Concrete On Property of Steel - Encased Concrete Composite Beam With Superior PerformanceseventhsensegroupNo ratings yet

- Tests of Reinforced Concrete Continuous Deep Beams: Aci Structural Journal Technical PaperDocument9 pagesTests of Reinforced Concrete Continuous Deep Beams: Aci Structural Journal Technical PaperpicottNo ratings yet

- Ann 2006Document6 pagesAnn 2006sumanthNo ratings yet

- Enhancement of Shear Connectors For Steel-Concrete Composite StructuresDocument8 pagesEnhancement of Shear Connectors For Steel-Concrete Composite StructuresUsha EngineeringNo ratings yet

- Seismic Retrofit Techniques For Reinforced Concrete Bridge Columns ...Document10 pagesSeismic Retrofit Techniques For Reinforced Concrete Bridge Columns ...오상진No ratings yet

- Construction and Building Materials: L. Abosrra, A.F. Ashour, M. YouseffiDocument11 pagesConstruction and Building Materials: L. Abosrra, A.F. Ashour, M. YouseffiIsrael WakumaNo ratings yet

- 1 s2.0 S0263822309004528 MainDocument6 pages1 s2.0 S0263822309004528 Mainshashank chandraNo ratings yet

- Distoration of Pavement SlabDocument1 pageDistoration of Pavement SlabSrinivasulu Reddy KoduruNo ratings yet

- Jointed Plain Concrete PavementDocument1 pageJointed Plain Concrete PavementSrinivasulu Reddy KoduruNo ratings yet

- Factors Affecting FailuresDocument1 pageFactors Affecting FailuresSrinivasulu Reddy KoduruNo ratings yet

- Rigid Pavement Typical Cross SectionDocument1 pageRigid Pavement Typical Cross SectionSrinivasulu Reddy KoduruNo ratings yet

- Piles Based On FunctionDocument1 pagePiles Based On FunctionSrinivasulu Reddy KoduruNo ratings yet

- Distress TypesDocument1 pageDistress TypesSrinivasulu Reddy KoduruNo ratings yet

- End Bearing PileDocument1 pageEnd Bearing PileSrinivasulu Reddy KoduruNo ratings yet

- Classification of PilesDocument1 pageClassification of PilesSrinivasulu Reddy KoduruNo ratings yet

- Compaction PileDocument1 pageCompaction PileSrinivasulu Reddy KoduruNo ratings yet

- Fiction PileDocument1 pageFiction PileSrinivasulu Reddy KoduruNo ratings yet

- Flexure TestDocument1 pageFlexure TestSrinivasulu Reddy KoduruNo ratings yet

- Cause of Common Distresses PDFDocument1 pageCause of Common Distresses PDFSrinivasulu Reddy KoduruNo ratings yet

- Measurements of WorkabilityDocument1 pageMeasurements of WorkabilitySrinivasulu Reddy KoduruNo ratings yet

- MarkingDocument1 pageMarkingSrinivasulu Reddy KoduruNo ratings yet

- ApparatusDocument1 pageApparatusSrinivasulu Reddy KoduruNo ratings yet

- JACKING Box CulvertsDocument1 pageJACKING Box CulvertsSrinivasulu Reddy KoduruNo ratings yet

- CreepDocument1 pageCreepSrinivasulu Reddy KoduruNo ratings yet

- Bitumen Emulson (Cationic Type)Document1 pageBitumen Emulson (Cationic Type)Srinivasulu Reddy KoduruNo ratings yet

- Cationic TypeDocument1 pageCationic TypeSrinivasulu Reddy KoduruNo ratings yet

- Manhole ComponetsDocument1 pageManhole ComponetsSrinivasulu Reddy KoduruNo ratings yet

- Mid Girder SectionDocument1 pageMid Girder SectionSrinivasulu Reddy KoduruNo ratings yet

- Rectangualr Portal CulvertsDocument1 pageRectangualr Portal CulvertsSrinivasulu Reddy KoduruNo ratings yet

- 6-Ways Concrete BaseDocument1 page6-Ways Concrete BaseSrinivasulu Reddy KoduruNo ratings yet

- Ribbed Skew Haunch CulvertsDocument1 pageRibbed Skew Haunch CulvertsSrinivasulu Reddy KoduruNo ratings yet

- Precast LidsDocument1 pagePrecast LidsSrinivasulu Reddy KoduruNo ratings yet

- Maximun Fill HeightsDocument1 pageMaximun Fill HeightsSrinivasulu Reddy KoduruNo ratings yet

- Manhole ConfigurationsDocument1 pageManhole ConfigurationsSrinivasulu Reddy KoduruNo ratings yet

- Culverts BasesDocument1 pageCulverts BasesSrinivasulu Reddy KoduruNo ratings yet

- I. Utility Relocation Plan: Chapter 2. There Are 33 Lampposts Present Along The Project Alignment, Which Have BeenDocument1 pageI. Utility Relocation Plan: Chapter 2. There Are 33 Lampposts Present Along The Project Alignment, Which Have BeenSrinivasulu Reddy KoduruNo ratings yet

- Tied Deck SlabDocument1 pageTied Deck SlabSrinivasulu Reddy KoduruNo ratings yet

Ultrasonic Pulse Velocity Test

Ultrasonic Pulse Velocity Test

Uploaded by

Srinivasulu Reddy KoduruOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Pulse Velocity Test

Ultrasonic Pulse Velocity Test

Uploaded by

Srinivasulu Reddy KoduruCopyright:

Available Formats

Page 17

mass and rebounds. The amount of rebound is recorded on a scale and this gives an

indication of the concrete strength. The larger the rebound number is, the higher is the

concrete strength.

(b) Ultrasonic pulse velocity test

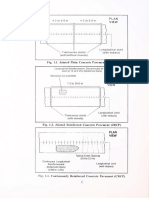

In the ultrasonic pulse velocity test the velocity of ultrasonic pulses that pass through

a concrete section from a transmitter to a receiver is measured. The pulse velocity is

correlated against strength. The higher the velocity is, the stronger is the concrete.

(c) Other non-destructive tests

Equipment has been developed to measure

1. crack widths and depths

2. water permeability and the surface dampness of concrete

3. depth of cover and the location of reinforcing bars

4. the electrochemical potential of reinforcing bars and hence the presence of

corrosion

2.5.3 Chemical tests

A complete range of chemical tests is available to measure

1. depth of carbonation

2. the cement content of the original mix

3. the content of salts such as chlorides and sulphates that may react and cause the

concrete to disintegrate or cause corrosion of the reinforcement

The reader should consult specialist literature.

2.6 REINFORCEMENT

Reinforcing bars are produced in two grades: hot rolled mild steel bars have a yield

strength fy of 250 N/mm2; hot rolled or cold worked high yield steel bars have a yield

strength fy of 460 N/mm2. Steel fabric is made from cold drawn steel wires welded to

form a mesh; it has a yield strength fy of 460 N/mm2.

The stress-strain curves for reinforcing bars are shown in Fig. 2.2. The hot rolled

bars have a definite yield point. A defined proof stress is recorded for the cold worked

bars. The value of Young’s modulus E is 200 kN/mm2. The idealized design stress-

strain curve for all reinforcing bars is shown in BS8110: Part 1 (see Fig. 3.1(b)). The

behaviour in tension and compression is taken to be the same.

Mild steel bars are produced as smooth round bars. High yield bars are produced as

deformed bars in two types defined in the code to increase bond stress:

You might also like

- Friction Coefficient of Steel On Concrete or Grout PDFDocument7 pagesFriction Coefficient of Steel On Concrete or Grout PDFLuis Ernesto Ramirez OsorioNo ratings yet

- The Diagonal Tension Behavior of Fiber Reinforced Concrete BeamsDocument7 pagesThe Diagonal Tension Behavior of Fiber Reinforced Concrete BeamsChris LumyNo ratings yet

- Performance of Bamboo Reinforced Concrete BeamDocument5 pagesPerformance of Bamboo Reinforced Concrete BeamKarthick .mNo ratings yet

- Abaqus AnalysisDocument12 pagesAbaqus AnalysisMohan BhalmeNo ratings yet

- An Analysis of The Behavior of Hybrid Steel Beam - RC Column ConnectionDocument13 pagesAn Analysis of The Behavior of Hybrid Steel Beam - RC Column ConnectionEhsan WasimNo ratings yet

- HW1 Solutions S14 MAE 3344Document4 pagesHW1 Solutions S14 MAE 3344trapstar15No ratings yet

- The Mechanical Property of Steel Reinforced Concrete Under Compressive Impact Loading Investigated With The SHPB ExperimentsDocument6 pagesThe Mechanical Property of Steel Reinforced Concrete Under Compressive Impact Loading Investigated With The SHPB ExperimentsInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Performance Investigation of Square Concrete-Fi Lled Steel Tube ColumnsDocument7 pagesPerformance Investigation of Square Concrete-Fi Lled Steel Tube Columnsjoamirhenrique_10316No ratings yet

- Artigo Sobre EstribosDocument5 pagesArtigo Sobre EstribosPaulo CotteNo ratings yet

- Fang, Lundgren, Chen, Zhu-Corrosion Influence On Bond in Reinforced ConcreteDocument9 pagesFang, Lundgren, Chen, Zhu-Corrosion Influence On Bond in Reinforced ConcretepinarinciNo ratings yet

- Abu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlateDocument11 pagesAbu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlatefaridNo ratings yet

- Sesmic Test On CFST ColumnDocument49 pagesSesmic Test On CFST ColumnPOOJA VNo ratings yet

- RC Notes by Engr. GREGDocument49 pagesRC Notes by Engr. GREGMichael SuanNo ratings yet

- Effect of Reinforcement On The Failure Load of RC Beams: Osama Salem, Arafa El-HellotyDocument16 pagesEffect of Reinforcement On The Failure Load of RC Beams: Osama Salem, Arafa El-HellotyHesham EdressNo ratings yet

- Assessment of Corrosion Rate in Prestressed Concrete With Acoustic EmissionDocument13 pagesAssessment of Corrosion Rate in Prestressed Concrete With Acoustic Emissionjesé m.No ratings yet

- Shear Strengthening Effect of RC Beams Retrofitted by Wire Mesh and SCCDocument6 pagesShear Strengthening Effect of RC Beams Retrofitted by Wire Mesh and SCCIkhlas KittaNo ratings yet

- Mechanism of Shear TransferDocument8 pagesMechanism of Shear TransferSana'a AamirNo ratings yet

- Non-Destructive Testing of Joints in Precast Element StructuresDocument10 pagesNon-Destructive Testing of Joints in Precast Element StructuresshakeebNo ratings yet

- Study On Deep BeamsDocument16 pagesStudy On Deep Beamsshailesh patilNo ratings yet

- Bond Characteristics High-Strength Steel ReinforcementDocument6 pagesBond Characteristics High-Strength Steel ReinforcementUmair BaigNo ratings yet

- Seminar On Durability and Lifecycle Evaluation of Concrete Structures-2006Document9 pagesSeminar On Durability and Lifecycle Evaluation of Concrete Structures-2006AsanNo ratings yet

- Definition of Brackish Water: ReferenceDocument2 pagesDefinition of Brackish Water: ReferenceHuaman Chavez Jesus AngelNo ratings yet

- Experimental Investigation of Surface Crack Initiation, Propagation and Tension Stiffening in Self-Compacting Steel-Fibre-Reinforced ConcreteDocument17 pagesExperimental Investigation of Surface Crack Initiation, Propagation and Tension Stiffening in Self-Compacting Steel-Fibre-Reinforced ConcreteIsmail MohammedNo ratings yet

- Material Science ExperimentDocument7 pagesMaterial Science ExperimentGan Kwang YongNo ratings yet

- Effect of Lathe Waste in Concrete As ReinforcementDocument6 pagesEffect of Lathe Waste in Concrete As ReinforcementAnkit GuptaNo ratings yet

- Deep BeamsDocument16 pagesDeep BeamsKimNo ratings yet

- Shear Strength Analysis and Prediction of Reinforced Concrete Transfer Beams in High-Rise BuildingsDocument21 pagesShear Strength Analysis and Prediction of Reinforced Concrete Transfer Beams in High-Rise Buildingsmohammed_fathelbabNo ratings yet

- Prestressed ConcreteDocument8 pagesPrestressed ConcreteYeswanth RaghavendraNo ratings yet

- Pre Stressed ConcreteDocument8 pagesPre Stressed Concretevamsi_rsNo ratings yet

- High Strength Reinforcement in Ordinary Reinforced and Fibre Reinforced Cement Composite Light Weight Concrete BramsDocument283 pagesHigh Strength Reinforcement in Ordinary Reinforced and Fibre Reinforced Cement Composite Light Weight Concrete Bramsab8ccw5288No ratings yet

- Copy ManuscriptDocument20 pagesCopy ManuscriptSREEKUMARA GANAPATHY V S stellamaryscoe.edu.inNo ratings yet

- Influence of Axial Load On Behavior of Belled Pile Reinforced With High-Strength Steel BarsDocument10 pagesInfluence of Axial Load On Behavior of Belled Pile Reinforced With High-Strength Steel BarscdestudosNo ratings yet

- Coeficientes de Friccion de Concreto Sobre Metal PDFDocument7 pagesCoeficientes de Friccion de Concreto Sobre Metal PDFLuis Ernesto Ramirez OsorioNo ratings yet

- Friction Coefficient of Steel On Concrete or GroutDocument7 pagesFriction Coefficient of Steel On Concrete or GroutLuis Ernesto Ramirez OsorioNo ratings yet

- Probetas Con CocoDocument7 pagesProbetas Con CocoPascual Pascual BetiñoNo ratings yet

- Ridged PavementDocument4 pagesRidged Pavementgetanna07No ratings yet

- Impact of Crack Width On Bond Confined and Unconfined RebarDocument10 pagesImpact of Crack Width On Bond Confined and Unconfined RebarbrahmabulNo ratings yet

- 2 PDFDocument107 pages2 PDFRajeev BujjiNo ratings yet

- Civil EngineeringDocument8 pagesCivil EngineeringA-16 Sai GunjalNo ratings yet

- Bearing Capacity of Partially Loaded Concrete ElemDocument9 pagesBearing Capacity of Partially Loaded Concrete ElemJuraj031No ratings yet

- Deep BeamDocument9 pagesDeep BeamDeana WhiteNo ratings yet

- ArcDocument17 pagesArcFatima AhmedNo ratings yet

- 1 s2.0 S0263823112000602 MainDocument9 pages1 s2.0 S0263823112000602 MainrudynyambiNo ratings yet

- SSRN Id4446360Document9 pagesSSRN Id4446360Almas XamiNo ratings yet

- Response of Ferrocement Confinement On Behavior of Square RC Short ColumnDocument10 pagesResponse of Ferrocement Confinement On Behavior of Square RC Short ColumnPANKAJ TAMBAKHENo ratings yet

- Failure Modes of RC Beams With High Strength ReinforcementDocument8 pagesFailure Modes of RC Beams With High Strength ReinforcementmfhfhfNo ratings yet

- SectionsDocument7 pagesSectionsImmanuel R WilliamNo ratings yet

- 1.1 Purpose Behind Project:: "Prestressing Technique"Document6 pages1.1 Purpose Behind Project:: "Prestressing Technique"MayankMehrotraNo ratings yet

- SSRN Id4447479Document7 pagesSSRN Id4447479Almas XamiNo ratings yet

- Art 12Document11 pagesArt 12rammirisNo ratings yet

- Ahn2002 Elbow FractureDocument13 pagesAhn2002 Elbow FractureKurra SrikanthNo ratings yet

- The Effect of Medium Strain Rates On The Mechanical Properties of High Performance SteelsDocument7 pagesThe Effect of Medium Strain Rates On The Mechanical Properties of High Performance SteelsPierre GarciaNo ratings yet

- Research On Property Property of Steel-Encased Concrete On Property of Steel - Encased Concrete Composite Beam With Superior PerformanceDocument4 pagesResearch On Property Property of Steel-Encased Concrete On Property of Steel - Encased Concrete Composite Beam With Superior PerformanceseventhsensegroupNo ratings yet

- Tests of Reinforced Concrete Continuous Deep Beams: Aci Structural Journal Technical PaperDocument9 pagesTests of Reinforced Concrete Continuous Deep Beams: Aci Structural Journal Technical PaperpicottNo ratings yet

- Ann 2006Document6 pagesAnn 2006sumanthNo ratings yet

- Enhancement of Shear Connectors For Steel-Concrete Composite StructuresDocument8 pagesEnhancement of Shear Connectors For Steel-Concrete Composite StructuresUsha EngineeringNo ratings yet

- Seismic Retrofit Techniques For Reinforced Concrete Bridge Columns ...Document10 pagesSeismic Retrofit Techniques For Reinforced Concrete Bridge Columns ...오상진No ratings yet

- Construction and Building Materials: L. Abosrra, A.F. Ashour, M. YouseffiDocument11 pagesConstruction and Building Materials: L. Abosrra, A.F. Ashour, M. YouseffiIsrael WakumaNo ratings yet

- 1 s2.0 S0263822309004528 MainDocument6 pages1 s2.0 S0263822309004528 Mainshashank chandraNo ratings yet

- Distoration of Pavement SlabDocument1 pageDistoration of Pavement SlabSrinivasulu Reddy KoduruNo ratings yet

- Jointed Plain Concrete PavementDocument1 pageJointed Plain Concrete PavementSrinivasulu Reddy KoduruNo ratings yet

- Factors Affecting FailuresDocument1 pageFactors Affecting FailuresSrinivasulu Reddy KoduruNo ratings yet

- Rigid Pavement Typical Cross SectionDocument1 pageRigid Pavement Typical Cross SectionSrinivasulu Reddy KoduruNo ratings yet

- Piles Based On FunctionDocument1 pagePiles Based On FunctionSrinivasulu Reddy KoduruNo ratings yet

- Distress TypesDocument1 pageDistress TypesSrinivasulu Reddy KoduruNo ratings yet

- End Bearing PileDocument1 pageEnd Bearing PileSrinivasulu Reddy KoduruNo ratings yet

- Classification of PilesDocument1 pageClassification of PilesSrinivasulu Reddy KoduruNo ratings yet

- Compaction PileDocument1 pageCompaction PileSrinivasulu Reddy KoduruNo ratings yet

- Fiction PileDocument1 pageFiction PileSrinivasulu Reddy KoduruNo ratings yet

- Flexure TestDocument1 pageFlexure TestSrinivasulu Reddy KoduruNo ratings yet

- Cause of Common Distresses PDFDocument1 pageCause of Common Distresses PDFSrinivasulu Reddy KoduruNo ratings yet

- Measurements of WorkabilityDocument1 pageMeasurements of WorkabilitySrinivasulu Reddy KoduruNo ratings yet

- MarkingDocument1 pageMarkingSrinivasulu Reddy KoduruNo ratings yet

- ApparatusDocument1 pageApparatusSrinivasulu Reddy KoduruNo ratings yet

- JACKING Box CulvertsDocument1 pageJACKING Box CulvertsSrinivasulu Reddy KoduruNo ratings yet

- CreepDocument1 pageCreepSrinivasulu Reddy KoduruNo ratings yet

- Bitumen Emulson (Cationic Type)Document1 pageBitumen Emulson (Cationic Type)Srinivasulu Reddy KoduruNo ratings yet

- Cationic TypeDocument1 pageCationic TypeSrinivasulu Reddy KoduruNo ratings yet

- Manhole ComponetsDocument1 pageManhole ComponetsSrinivasulu Reddy KoduruNo ratings yet

- Mid Girder SectionDocument1 pageMid Girder SectionSrinivasulu Reddy KoduruNo ratings yet

- Rectangualr Portal CulvertsDocument1 pageRectangualr Portal CulvertsSrinivasulu Reddy KoduruNo ratings yet

- 6-Ways Concrete BaseDocument1 page6-Ways Concrete BaseSrinivasulu Reddy KoduruNo ratings yet

- Ribbed Skew Haunch CulvertsDocument1 pageRibbed Skew Haunch CulvertsSrinivasulu Reddy KoduruNo ratings yet

- Precast LidsDocument1 pagePrecast LidsSrinivasulu Reddy KoduruNo ratings yet

- Maximun Fill HeightsDocument1 pageMaximun Fill HeightsSrinivasulu Reddy KoduruNo ratings yet

- Manhole ConfigurationsDocument1 pageManhole ConfigurationsSrinivasulu Reddy KoduruNo ratings yet

- Culverts BasesDocument1 pageCulverts BasesSrinivasulu Reddy KoduruNo ratings yet

- I. Utility Relocation Plan: Chapter 2. There Are 33 Lampposts Present Along The Project Alignment, Which Have BeenDocument1 pageI. Utility Relocation Plan: Chapter 2. There Are 33 Lampposts Present Along The Project Alignment, Which Have BeenSrinivasulu Reddy KoduruNo ratings yet

- Tied Deck SlabDocument1 pageTied Deck SlabSrinivasulu Reddy KoduruNo ratings yet