Professional Documents

Culture Documents

Replace V-Belts With Cogged or Synchronous Belt Drives: Suggested Actions

Replace V-Belts With Cogged or Synchronous Belt Drives: Suggested Actions

Uploaded by

srinivas raghavanCopyright:

Available Formats

You might also like

- CDK Digital Marketing CaseDocument3 pagesCDK Digital Marketing CaseMaya YammineNo ratings yet

- Internal and External Spline Teeth - Gears - Internal and External Spline Teeth, Spline Connections With Involute Flanks, Spline Connections With Straight FlanksDocument13 pagesInternal and External Spline Teeth - Gears - Internal and External Spline Teeth, Spline Connections With Involute Flanks, Spline Connections With Straight Flankssrinivas raghavanNo ratings yet

- Hypoid Vs Worm Gear EfficienciesDocument6 pagesHypoid Vs Worm Gear EfficienciesZoran Danilov100% (1)

- On The Energy Optimized Control of Standard and High-Efficiency Induction Motors in CT and HVAC ApplicationsDocument10 pagesOn The Energy Optimized Control of Standard and High-Efficiency Induction Motors in CT and HVAC ApplicationsKise RyotaNo ratings yet

- Trabajo 1Document8 pagesTrabajo 1Mauren Fernanda Mateus OrdoñezNo ratings yet

- V Belt Selection Its A Veritable CinchDocument5 pagesV Belt Selection Its A Veritable CinchSergio Rolla GuimaraesNo ratings yet

- Steer by Wire Systems Integrated Torque Feedback TaenDocument5 pagesSteer by Wire Systems Integrated Torque Feedback TaenPhúc KhangNo ratings yet

- Energy Tips - Steam: Consider Steam Turbine Drives For Rotating EquipmentDocument2 pagesEnergy Tips - Steam: Consider Steam Turbine Drives For Rotating EquipmentMohammedBujairNo ratings yet

- Gearmotor Sizing Guide PDFDocument5 pagesGearmotor Sizing Guide PDFAnonymous Hy5Ir9QXNo ratings yet

- Offers Alternative To Three-Stage Helical Bevel Gearboxes and Worm GearingDocument4 pagesOffers Alternative To Three-Stage Helical Bevel Gearboxes and Worm GearingAyush ShrivastavaNo ratings yet

- Steam Tip Sheet #16Document2 pagesSteam Tip Sheet #16Muhammad NaeemNo ratings yet

- 9900-4044 00 Tco PDFDocument10 pages9900-4044 00 Tco PDFmhafizanNo ratings yet

- 7 DD 0031Document3 pages7 DD 0031fstaday6624No ratings yet

- Pitch Control Critical For Wind PowerDocument6 pagesPitch Control Critical For Wind Powermehdi amelNo ratings yet

- Gatesfacts™ Technical Information Library: "Belt Drive Efficiencies Pa NoteDocument2 pagesGatesfacts™ Technical Information Library: "Belt Drive Efficiencies Pa NoteAndyNo ratings yet

- MotorsDocument2 pagesMotorsRajendra KumarNo ratings yet

- Clutch Systems: For Passenger Cars Up To 800 NMDocument10 pagesClutch Systems: For Passenger Cars Up To 800 NMTavi PetrisorNo ratings yet

- Energy Efficient MotorsDocument8 pagesEnergy Efficient MotorsformechNo ratings yet

- Energies 15 06700 v3Document36 pagesEnergies 15 06700 v3Peng LiNo ratings yet

- Recent Development and Advancement of Regenerative Braking in Electric BikeDocument4 pagesRecent Development and Advancement of Regenerative Braking in Electric BikeIJMTST-Online JournalNo ratings yet

- Perhitungan Gearbox Part-1 PDFDocument32 pagesPerhitungan Gearbox Part-1 PDFHermawan SuwantoNo ratings yet

- Energy Efficient Motors Full Seminar Report, Abstract and Presentation DownloadDocument7 pagesEnergy Efficient Motors Full Seminar Report, Abstract and Presentation DownloadJIN KHATRI33% (3)

- Saepaper Lacerte 2014-12-12Document12 pagesSaepaper Lacerte 2014-12-12Thiên ThanhNo ratings yet

- Magna Drive QDocument2 pagesMagna Drive QHari Krishna.MNo ratings yet

- Application of Resistance Energy Model TDocument13 pagesApplication of Resistance Energy Model T18118135No ratings yet

- Matecconf Eureca2018 02011Document15 pagesMatecconf Eureca2018 02011Aseel QasaimehNo ratings yet

- Timing Belt Drives and Their Advantages Regarding Engine Efficiency and NVH CharacteristicsDocument3 pagesTiming Belt Drives and Their Advantages Regarding Engine Efficiency and NVH Characteristicsu.rghu.kNo ratings yet

- Benefits of Variable Speed Drives in Sugar Production: White PaperDocument12 pagesBenefits of Variable Speed Drives in Sugar Production: White PaperMashudi FikriNo ratings yet

- Steam Turbine Replacement by High Speed Electric System Driven CompressorsDocument9 pagesSteam Turbine Replacement by High Speed Electric System Driven CompressorsJoffre BourgeoisNo ratings yet

- NTB Flat Belt AdvantagesDocument4 pagesNTB Flat Belt AdvantagesPUSHKARKHANNANo ratings yet

- Increasing Availability Through Advanced Gearless Drive TechnologyDocument12 pagesIncreasing Availability Through Advanced Gearless Drive TechnologyJaime Magno Gutierrez RamirezNo ratings yet

- Mechatronic Analysis Improves EfficiencyDocument2 pagesMechatronic Analysis Improves EfficiencyMilan PavlovicNo ratings yet

- AEGIS Enews 11-2014Document3 pagesAEGIS Enews 11-201436turkNo ratings yet

- Department of Mechanical EngineeringDocument23 pagesDepartment of Mechanical EngineeringMail ManNo ratings yet

- Driving Towards A Better FutureDocument5 pagesDriving Towards A Better FuturePravit MartroNo ratings yet

- Consider Steam Turbine Drives For Rotating EquipmentDocument2 pagesConsider Steam Turbine Drives For Rotating EquipmentAnonymous dqbb02DUhNo ratings yet

- Electromechanical ActuatorsDocument4 pagesElectromechanical ActuatorsMohammed Asif NNo ratings yet

- Achieving Fuel Savings For Anchor Handling Tug Supply Vessels Through Electric Propulsion - ABBDocument4 pagesAchieving Fuel Savings For Anchor Handling Tug Supply Vessels Through Electric Propulsion - ABByw_oulalaNo ratings yet

- Tting The Most Out of Your Motor Drive StmicroelectronicsDocument16 pagesTting The Most Out of Your Motor Drive StmicroelectronicsaircarmediaNo ratings yet

- 1706597156091_SEMINAR PPTDocument18 pages1706597156091_SEMINAR PPTRahul VarmanNo ratings yet

- Xpert Energy Savings Assessment Flyer MotorDocument2 pagesXpert Energy Savings Assessment Flyer MotorJeisson HolguinNo ratings yet

- Energy Conversion and Management: Jaeyun Lee, Bumkyoo ChoiDocument7 pagesEnergy Conversion and Management: Jaeyun Lee, Bumkyoo ChoiTika YuliNo ratings yet

- Energy Loss and Belt EfficiencyDocument10 pagesEnergy Loss and Belt Efficiencyjoao2222No ratings yet

- Irjet V4i4595 PDFDocument3 pagesIrjet V4i4595 PDFUjash VasaniNo ratings yet

- Cement Brochure2019-WebDocument28 pagesCement Brochure2019-WebpchizumilaNo ratings yet

- Energy Saving With Variable Speed Drives in Industry ApplicationsDocument7 pagesEnergy Saving With Variable Speed Drives in Industry ApplicationsHitesh PanigrahiNo ratings yet

- Energy Answers For MotorsDocument4 pagesEnergy Answers For Motorsdetroit44No ratings yet

- Wind Turbine Term PaperDocument4 pagesWind Turbine Term Paperaflsrxfoe100% (1)

- Motors Best Practice ToolDocument8 pagesMotors Best Practice ToolAngshuman DuttaNo ratings yet

- Rinne Et Al.2009 CeldasDocument7 pagesRinne Et Al.2009 Celdasmamg4415No ratings yet

- Drive Train AssemblyDocument10 pagesDrive Train Assemblychandrakesh chauhanNo ratings yet

- Digital Technologies For Thermal Power Plants Improves Performance and RoiDocument5 pagesDigital Technologies For Thermal Power Plants Improves Performance and RoineerajNo ratings yet

- Induction Versus Synchronous: How To Select The Right Type of MotorDocument2 pagesInduction Versus Synchronous: How To Select The Right Type of MotorPedro BortotNo ratings yet

- GEA34130 AeroderivativeGT - Whitepaper - R6Document10 pagesGEA34130 AeroderivativeGT - Whitepaper - R6Cecilia CabreraNo ratings yet

- Motores EficienciaDocument35 pagesMotores EficienciapatricioNo ratings yet

- Motor Systems: BestpracticesDocument2 pagesMotor Systems: BestpracticesIdhamtanahbaruNo ratings yet

- Innovation Landscape brief: Utility-scale BatteriesFrom EverandInnovation Landscape brief: Utility-scale BatteriesNo ratings yet

- A Text Book on Power Distribution and Distributed GenerationFrom EverandA Text Book on Power Distribution and Distributed GenerationNo ratings yet

- Reducing Airlines’ Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemFrom EverandReducing Airlines’ Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Fueling Healthy Communities V1 Energy Storage Secure Supplies Whitepaper: POWER TO GAS ENERGY STORAGEFrom EverandFueling Healthy Communities V1 Energy Storage Secure Supplies Whitepaper: POWER TO GAS ENERGY STORAGENo ratings yet

- ಉಪದೇಶರತ್ತಿನಮಾಲೈDocument14 pagesಉಪದೇಶರತ್ತಿನಮಾಲೈsrinivas raghavanNo ratings yet

- Chapter 14 AgileDocument11 pagesChapter 14 Agilesrinivas raghavanNo ratings yet

- Chapter 3 Role of Project Manager 6th EditionDocument21 pagesChapter 3 Role of Project Manager 6th Editionsrinivas raghavanNo ratings yet

- PW, SP : Mounting Instructions Montageanleitung Notice de MontageDocument52 pagesPW, SP : Mounting Instructions Montageanleitung Notice de Montagesrinivas raghavanNo ratings yet

- Chapter 11 - Risk Management 6th. EditionDocument41 pagesChapter 11 - Risk Management 6th. Editionsrinivas raghavanNo ratings yet

- Chapter 5 Scope Management 6th. EditionDocument29 pagesChapter 5 Scope Management 6th. Editionsrinivas raghavanNo ratings yet

- rc3d Leg Datasheet enDocument3 pagesrc3d Leg Datasheet ensrinivas raghavanNo ratings yet

- Fisa Tehnica PW12CDocument4 pagesFisa Tehnica PW12Csrinivas raghavanNo ratings yet

- 115 SARDataProcessing BrochureDocument2 pages115 SARDataProcessing Brochuresrinivas raghavanNo ratings yet

- Namalwar DDDocument2 pagesNamalwar DDsrinivas raghavanNo ratings yet

- sb8 Datasheet enDocument3 pagessb8 Datasheet ensrinivas raghavanNo ratings yet

- Montageanleitung Notice de Montage: Mounting InstructionsDocument36 pagesMontageanleitung Notice de Montage: Mounting Instructionssrinivas raghavanNo ratings yet

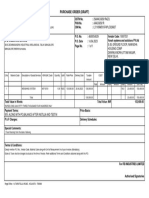

- Purchase Order (Draft) IFB Industries LimitedDocument1 pagePurchase Order (Draft) IFB Industries Limitedsrinivas raghavanNo ratings yet

- Introduction To Aerospace Materials by A Mouritz - PDF DriveDocument2 pagesIntroduction To Aerospace Materials by A Mouritz - PDF Drivesrinivas raghavanNo ratings yet

- Why Do We Outrage - #IAmBuddhaDocument4 pagesWhy Do We Outrage - #IAmBuddhasrinivas raghavanNo ratings yet

- Poorna Brahma & Poornatwa Siddhanta PDFDocument315 pagesPoorna Brahma & Poornatwa Siddhanta PDFsrinivas raghavan100% (1)

- Bearing MaterialDocument2 pagesBearing Materialsrinivas raghavanNo ratings yet

- How To Add Your Resume On LinkedIn (4 Options) - ZipJobDocument13 pagesHow To Add Your Resume On LinkedIn (4 Options) - ZipJobsrinivas raghavanNo ratings yet

- Industry 4.0 - Reimagining Manufacturing Operations After COVID-19 - McKinseyDocument15 pagesIndustry 4.0 - Reimagining Manufacturing Operations After COVID-19 - McKinseysrinivas raghavanNo ratings yet

- 10K PlanDocument1 page10K Plansrinivas raghavanNo ratings yet

- Chapter 1 Audit Under TaxDocument15 pagesChapter 1 Audit Under TaxSaurabh GogawaleNo ratings yet

- Chapter 7 The Regular Output VATDocument28 pagesChapter 7 The Regular Output VATCathy Marie Angela ArellanoNo ratings yet

- 36 Loss Disallowance Slides and ExamplesDocument51 pages36 Loss Disallowance Slides and ExamplesCourt RobertsNo ratings yet

- Living IT Quiz 2Document6 pagesLiving IT Quiz 2田中麗奈No ratings yet

- Advance Performance ManagementDocument53 pagesAdvance Performance ManagementAyesha HamidNo ratings yet

- ECS2608 Assignment 3Document8 pagesECS2608 Assignment 3Jason Warren BlandNo ratings yet

- L1LSFCY US Feeder Fund PPMDocument60 pagesL1LSFCY US Feeder Fund PPMlaquetengoNo ratings yet

- Axie Infinity: Business Breakdowns Research: Company History & Key PeopleDocument12 pagesAxie Infinity: Business Breakdowns Research: Company History & Key Peoplekuri suchanNo ratings yet

- Revision Q&ADocument5 pagesRevision Q&ADylan Rabin PereiraNo ratings yet

- Additional Exercise On Cash Flows With Relative SolutionsDocument2 pagesAdditional Exercise On Cash Flows With Relative Solutionspratama aditara100% (1)

- Time Value of Money Problem and Solution 5Document4 pagesTime Value of Money Problem and Solution 5Vonreev OntoyNo ratings yet

- Foreign Exchange System of City Bank LimitedDocument10 pagesForeign Exchange System of City Bank Limitedsibgat ullahNo ratings yet

- Manufacturing Methods: An IntroductionDocument18 pagesManufacturing Methods: An IntroductionRafiqueNo ratings yet

- RFBT Quiz #1 - ObligationDocument11 pagesRFBT Quiz #1 - Obligationrandyblanza201486% (7)

- Ch02 P20 Build A Model SolutionDocument6 pagesCh02 P20 Build A Model Solutionsonam agrawalNo ratings yet

- Mateo Manuscript Om Buma 20093Document13 pagesMateo Manuscript Om Buma 20093Mhico MateoNo ratings yet

- 2point2 Capital - Investor Update Q4 FY20Document6 pages2point2 Capital - Investor Update Q4 FY20Rakesh PandeyNo ratings yet

- CHAPTER 1 Business ProposalDocument5 pagesCHAPTER 1 Business Proposallagatic1821No ratings yet

- Today Economics Ca Foundation QPDocument4 pagesToday Economics Ca Foundation QPAparnaNo ratings yet

- Ra 265Document34 pagesRa 265Raezel Louise VelayoNo ratings yet

- Experience IIFTDocument4 pagesExperience IIFTJayesh JaiswalNo ratings yet

- Existing Problems and Solutions in Managing The Development of Social EntrepreneurshipDocument6 pagesExisting Problems and Solutions in Managing The Development of Social EntrepreneurshipAcademic JournalNo ratings yet

- Maruti Suzuki Pricing StrategiesDocument14 pagesMaruti Suzuki Pricing StrategiesDev MitraNo ratings yet

- Project On Tata Motors 1Document86 pagesProject On Tata Motors 1Kotresh KpNo ratings yet

- United State Senate Banking Committee Letter To James Dimon CEO JP Morgan ChaseDocument5 pagesUnited State Senate Banking Committee Letter To James Dimon CEO JP Morgan ChaseJaniceWolkGrenadierNo ratings yet

- How To Complete Your W-8Ben FormDocument2 pagesHow To Complete Your W-8Ben FormSun WestNo ratings yet

- Closing and Worksheet: 20.1 Closing Entries For Revenue AccountsDocument8 pagesClosing and Worksheet: 20.1 Closing Entries For Revenue AccountsZaheer Swati100% (1)

- UMB - MTS - Chapter 2 Integration Project ManagementDocument44 pagesUMB - MTS - Chapter 2 Integration Project ManagementKartika Sri RahayuNo ratings yet

- Allama Iqbal Open University: Report of Business LawDocument17 pagesAllama Iqbal Open University: Report of Business Lawmanomasho100% (2)

Replace V-Belts With Cogged or Synchronous Belt Drives: Suggested Actions

Replace V-Belts With Cogged or Synchronous Belt Drives: Suggested Actions

Uploaded by

srinivas raghavanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Replace V-Belts With Cogged or Synchronous Belt Drives: Suggested Actions

Replace V-Belts With Cogged or Synchronous Belt Drives: Suggested Actions

Uploaded by

srinivas raghavanCopyright:

Available Formats

Steam Motors Compressed Air

Replace V-Belts with Cogged or

Synchronous Belt Drives

Suggested Actions

Conduct a survey of belt-driven About one-third of the electric motors in the industrial and commercial sectors use belt

equipment in your plant. Gather drives. Belt drives provide flexibility in the positioning of the motor relative to the load.

application and operating hour data. Pulleys (sheaves) of varying diameters allow the speed of the driven equipment to be

Then, determine the cost effectiveness increased or decreased. A properly designed belt transmission system provides high efficien-

of replacing existing V-belts with cy, low noise, does not require lubrication, and presents low maintenance requirements.

synchronous belts and sprockets. However, certain types of belts are more efficient than others, offering potential energy cost

Consider synchronous belts for all savings.

new installations as the price premi-

um is small due to the avoidance of The majority of belt drives use V-belts. V-belts use a trapezoidal cross section to create a

conventional pulley costs. Install wedging action on the pulleys to increase friction and the belt’s power transfer capability.

cogged belts where the retrofit of a Joined or multiple belts are specified for heavy loads. V-belt drives can have a peak efficiency

synchronous belt is not cost effective. of 95% to 98% at the time of installation. Efficiency is also dependent on pulley size, driven

torque, under or over-belting, and V-belt design and construction. Efficiency deteriorates by

as much as 5% (to a nominal efficiency of 93%) over time if slippage occurs because the belt

Centrifugal Fan and Pump is not periodically re-tensioned.

Considerations Cogged belts have slots that run perpendicular to the belt’s length. The slots reduce the belt’s

For centrifugal fans and pumps, which bending resistance. Cogged belts can be used with the same pulleys as equivalently rated V-

exhibit a strong relationship between belts. They run cooler, last longer, and have an efficiency that is about 2% higher than that of

operating speed and power, synchro- standard V-belts.

nous belt sprockets must be selected

that take into account the absence of Synchronous belts (also called

slippage. Operating costs could actually timing, positive-drive, or high-

increase if slippage is reduced and a Photo Courtesy of Gates Rubber Company

torque drive belts) are toothed

centrifugal load is driven at a slightly and require the installation of

higher speed. mating toothed-drive sprockets.

Synchronous belts offer an effi-

Application Considerations ciency of about 98% and maintain

that efficiency over a wide load

Synchronous belts are the most efficient range. In contrast, V-belts have a

choice. However, cogged belts may be sharp reduction in efficiency at

a better choice when vibration damping high torque due to increasing

is needed or shock loads cause abrupt slippage. Synchronous belts

torque changes that could shear a require less maintenance and

synchronous belt’s teeth. Synchronous retensioning, operate in wet and

belts also make a whirring noise that oily environments, and run slip-free. But, synchronous belts are noisy, unsuitable for shock

might be objectionable in some loads, and transfer vibrations.

applications.

Example

A continuously operating, 100-hp, supply-air fan motor (93% efficient) operates at an average load

of 75% while consuming 527,000 kWh annually. What are the annual energy and dollar savings if a

For additional information on 93% efficient (E1) V-belt is replaced with a 98% efficient (E2) synchronous belt? Electricity is priced

industrial energy efficiency at $0.05/kWh.

measures, contact the E

Energy Savings = Annual Energy Use x (1 - 1 )

OIT Clearinghouse at E2

(800) 862-2086. 93

= 527,000 kWh/year x (1 - ) = 26,888 kWh/year

98

Annual Dollar Savings = 26,888 kWh x $0.05/kWh = $1,345

OFFICE OF INDUSTRIAL TECHNOLOGIES

ENERGY EFFICIENCY AND RENEWABLE ENERGY • U.S. DEPARTMENT OF ENERGY

About DOE’s Office of Industrial Technologies

The Office of Industrial Technologies (OIT), through partnerships with industry, government, and non-governmental organizations,

develops and delivers advanced energy efficiency, renewable energy, and pollution prevention technologies for industrial applications.

OIT is part of the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy.

OIT encourages industry-wide efforts to boost resource productivity through a strategy called Industries of the Future (IOF). IOF focuses on

the following nine energy and resource intensive industries:

Agriculture Chemicals Glass Mining Steel

Aluminum Forest Products Metal Casting Petroleum

To help industries begin to save energy, reduce costs, and cut pollution right away, OIT offers a comprehensive portfolio of emerging

technology, practices, tools, information, and resources in a variety of application areas, such as motor systems, steam systems, compressed

air systems, and combined heat and power systems. Likewise, OIT’s Industrial Assessment Centers (IAC), located throughout the U.S., offer

energy, waste, and productivity assessments to small and medium-sized manufacturers. Users can take advantage of the abundant resources,

such as software, fact sheets, training materials, etc., available from OIT.

Motor Systems — helps industry increase productivity and reliability through energy-efficient electric motor-driven systems.

Documents - Software –

Buying an Energy-Efficient Electric Motor MotorMaster+ 3.0 and training CD

Optimizing Your Motor-Driven System ASDMaster

Frequently Asked Questions on: The Impacts of the Pumping System Assessment Tool

Energy Policy Act of 1992 on Industrial End Users of Training –

Electric Motor-Driven Systems MotorMaster+ 3.0 Software

Energy Management for Motor Driven Systems Adjustable Speed Drive Application

Improving Pumping System Performance: A Sourcebook Pumping System Optimization

for Industry Pumping System Assessment Tool

Access the Web site at www.motor.doe.gov.

Steam Systems — helps industry enhance productivity, increase profits, and reduce emissions through better steam system management.

Documents – Case Studies –

Energy Efficiency Handbook Georgia Pacific Achieves 6-Month Payback

Plant Services Article - The Steam Challenge Bethlehem Steel Showcase Demonstration

Energy Manager Article - Steaming Ahead Software –

Oak Ridge National Laboratory’s Insulation Guidelines 3EPlus Software for Determining Optimal Insulation Thickness

1998 IETC Steam Session Papers

Access the Web site at www.oit.doe.gov/steam.

Compressed Air Systems — dedicated to improving the efficiency and performance of industrial compressed air systems.

Documents – Training –

Improving Compressed Air System Performance: Fundamentals of Compressed Air Systems

A Sourcebook for Industry (For schedule and location, call (800) 862-2086)

Access the Web site at www.knowpressure.org.

Industrial Assessment Centers — enable small and medium-sized manufacturers to have comprehensive industrial assessments

performed at no cost to the manufacturer.

Documents – Access the Web site at www.oit.doe.gov/iac.

IAC Database

For more information, simply check the box next to the product, fill out the form below and fax back to (360) 586-8303:

Name: __________________________________________________________ Title: ________________________________________________________

Organization: __________________________________________________________________________________________________________________

Address: ______________________________________________________________________________________________________________________

City: ______________________________________________________________ State: ____________________________ Zip: ____________________

Phone: ______________________________ Fax: ______________________________ E-mail: ______________________________________________

Comments: ____________________________________________________________________________________________________________________

For more information on Motor, Steam, Compressed Air Systems, and IACs, call the OIT Clearinghouse at (800) 862-2086,

or access the Web site at www.oit.doe.gov.

Motor Tip Sheet #3 • January 2000 • DOE/GO-102000-0972

You might also like

- CDK Digital Marketing CaseDocument3 pagesCDK Digital Marketing CaseMaya YammineNo ratings yet

- Internal and External Spline Teeth - Gears - Internal and External Spline Teeth, Spline Connections With Involute Flanks, Spline Connections With Straight FlanksDocument13 pagesInternal and External Spline Teeth - Gears - Internal and External Spline Teeth, Spline Connections With Involute Flanks, Spline Connections With Straight Flankssrinivas raghavanNo ratings yet

- Hypoid Vs Worm Gear EfficienciesDocument6 pagesHypoid Vs Worm Gear EfficienciesZoran Danilov100% (1)

- On The Energy Optimized Control of Standard and High-Efficiency Induction Motors in CT and HVAC ApplicationsDocument10 pagesOn The Energy Optimized Control of Standard and High-Efficiency Induction Motors in CT and HVAC ApplicationsKise RyotaNo ratings yet

- Trabajo 1Document8 pagesTrabajo 1Mauren Fernanda Mateus OrdoñezNo ratings yet

- V Belt Selection Its A Veritable CinchDocument5 pagesV Belt Selection Its A Veritable CinchSergio Rolla GuimaraesNo ratings yet

- Steer by Wire Systems Integrated Torque Feedback TaenDocument5 pagesSteer by Wire Systems Integrated Torque Feedback TaenPhúc KhangNo ratings yet

- Energy Tips - Steam: Consider Steam Turbine Drives For Rotating EquipmentDocument2 pagesEnergy Tips - Steam: Consider Steam Turbine Drives For Rotating EquipmentMohammedBujairNo ratings yet

- Gearmotor Sizing Guide PDFDocument5 pagesGearmotor Sizing Guide PDFAnonymous Hy5Ir9QXNo ratings yet

- Offers Alternative To Three-Stage Helical Bevel Gearboxes and Worm GearingDocument4 pagesOffers Alternative To Three-Stage Helical Bevel Gearboxes and Worm GearingAyush ShrivastavaNo ratings yet

- Steam Tip Sheet #16Document2 pagesSteam Tip Sheet #16Muhammad NaeemNo ratings yet

- 9900-4044 00 Tco PDFDocument10 pages9900-4044 00 Tco PDFmhafizanNo ratings yet

- 7 DD 0031Document3 pages7 DD 0031fstaday6624No ratings yet

- Pitch Control Critical For Wind PowerDocument6 pagesPitch Control Critical For Wind Powermehdi amelNo ratings yet

- Gatesfacts™ Technical Information Library: "Belt Drive Efficiencies Pa NoteDocument2 pagesGatesfacts™ Technical Information Library: "Belt Drive Efficiencies Pa NoteAndyNo ratings yet

- MotorsDocument2 pagesMotorsRajendra KumarNo ratings yet

- Clutch Systems: For Passenger Cars Up To 800 NMDocument10 pagesClutch Systems: For Passenger Cars Up To 800 NMTavi PetrisorNo ratings yet

- Energy Efficient MotorsDocument8 pagesEnergy Efficient MotorsformechNo ratings yet

- Energies 15 06700 v3Document36 pagesEnergies 15 06700 v3Peng LiNo ratings yet

- Recent Development and Advancement of Regenerative Braking in Electric BikeDocument4 pagesRecent Development and Advancement of Regenerative Braking in Electric BikeIJMTST-Online JournalNo ratings yet

- Perhitungan Gearbox Part-1 PDFDocument32 pagesPerhitungan Gearbox Part-1 PDFHermawan SuwantoNo ratings yet

- Energy Efficient Motors Full Seminar Report, Abstract and Presentation DownloadDocument7 pagesEnergy Efficient Motors Full Seminar Report, Abstract and Presentation DownloadJIN KHATRI33% (3)

- Saepaper Lacerte 2014-12-12Document12 pagesSaepaper Lacerte 2014-12-12Thiên ThanhNo ratings yet

- Magna Drive QDocument2 pagesMagna Drive QHari Krishna.MNo ratings yet

- Application of Resistance Energy Model TDocument13 pagesApplication of Resistance Energy Model T18118135No ratings yet

- Matecconf Eureca2018 02011Document15 pagesMatecconf Eureca2018 02011Aseel QasaimehNo ratings yet

- Timing Belt Drives and Their Advantages Regarding Engine Efficiency and NVH CharacteristicsDocument3 pagesTiming Belt Drives and Their Advantages Regarding Engine Efficiency and NVH Characteristicsu.rghu.kNo ratings yet

- Benefits of Variable Speed Drives in Sugar Production: White PaperDocument12 pagesBenefits of Variable Speed Drives in Sugar Production: White PaperMashudi FikriNo ratings yet

- Steam Turbine Replacement by High Speed Electric System Driven CompressorsDocument9 pagesSteam Turbine Replacement by High Speed Electric System Driven CompressorsJoffre BourgeoisNo ratings yet

- NTB Flat Belt AdvantagesDocument4 pagesNTB Flat Belt AdvantagesPUSHKARKHANNANo ratings yet

- Increasing Availability Through Advanced Gearless Drive TechnologyDocument12 pagesIncreasing Availability Through Advanced Gearless Drive TechnologyJaime Magno Gutierrez RamirezNo ratings yet

- Mechatronic Analysis Improves EfficiencyDocument2 pagesMechatronic Analysis Improves EfficiencyMilan PavlovicNo ratings yet

- AEGIS Enews 11-2014Document3 pagesAEGIS Enews 11-201436turkNo ratings yet

- Department of Mechanical EngineeringDocument23 pagesDepartment of Mechanical EngineeringMail ManNo ratings yet

- Driving Towards A Better FutureDocument5 pagesDriving Towards A Better FuturePravit MartroNo ratings yet

- Consider Steam Turbine Drives For Rotating EquipmentDocument2 pagesConsider Steam Turbine Drives For Rotating EquipmentAnonymous dqbb02DUhNo ratings yet

- Electromechanical ActuatorsDocument4 pagesElectromechanical ActuatorsMohammed Asif NNo ratings yet

- Achieving Fuel Savings For Anchor Handling Tug Supply Vessels Through Electric Propulsion - ABBDocument4 pagesAchieving Fuel Savings For Anchor Handling Tug Supply Vessels Through Electric Propulsion - ABByw_oulalaNo ratings yet

- Tting The Most Out of Your Motor Drive StmicroelectronicsDocument16 pagesTting The Most Out of Your Motor Drive StmicroelectronicsaircarmediaNo ratings yet

- 1706597156091_SEMINAR PPTDocument18 pages1706597156091_SEMINAR PPTRahul VarmanNo ratings yet

- Xpert Energy Savings Assessment Flyer MotorDocument2 pagesXpert Energy Savings Assessment Flyer MotorJeisson HolguinNo ratings yet

- Energy Conversion and Management: Jaeyun Lee, Bumkyoo ChoiDocument7 pagesEnergy Conversion and Management: Jaeyun Lee, Bumkyoo ChoiTika YuliNo ratings yet

- Energy Loss and Belt EfficiencyDocument10 pagesEnergy Loss and Belt Efficiencyjoao2222No ratings yet

- Irjet V4i4595 PDFDocument3 pagesIrjet V4i4595 PDFUjash VasaniNo ratings yet

- Cement Brochure2019-WebDocument28 pagesCement Brochure2019-WebpchizumilaNo ratings yet

- Energy Saving With Variable Speed Drives in Industry ApplicationsDocument7 pagesEnergy Saving With Variable Speed Drives in Industry ApplicationsHitesh PanigrahiNo ratings yet

- Energy Answers For MotorsDocument4 pagesEnergy Answers For Motorsdetroit44No ratings yet

- Wind Turbine Term PaperDocument4 pagesWind Turbine Term Paperaflsrxfoe100% (1)

- Motors Best Practice ToolDocument8 pagesMotors Best Practice ToolAngshuman DuttaNo ratings yet

- Rinne Et Al.2009 CeldasDocument7 pagesRinne Et Al.2009 Celdasmamg4415No ratings yet

- Drive Train AssemblyDocument10 pagesDrive Train Assemblychandrakesh chauhanNo ratings yet

- Digital Technologies For Thermal Power Plants Improves Performance and RoiDocument5 pagesDigital Technologies For Thermal Power Plants Improves Performance and RoineerajNo ratings yet

- Induction Versus Synchronous: How To Select The Right Type of MotorDocument2 pagesInduction Versus Synchronous: How To Select The Right Type of MotorPedro BortotNo ratings yet

- GEA34130 AeroderivativeGT - Whitepaper - R6Document10 pagesGEA34130 AeroderivativeGT - Whitepaper - R6Cecilia CabreraNo ratings yet

- Motores EficienciaDocument35 pagesMotores EficienciapatricioNo ratings yet

- Motor Systems: BestpracticesDocument2 pagesMotor Systems: BestpracticesIdhamtanahbaruNo ratings yet

- Innovation Landscape brief: Utility-scale BatteriesFrom EverandInnovation Landscape brief: Utility-scale BatteriesNo ratings yet

- A Text Book on Power Distribution and Distributed GenerationFrom EverandA Text Book on Power Distribution and Distributed GenerationNo ratings yet

- Reducing Airlines’ Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemFrom EverandReducing Airlines’ Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Fueling Healthy Communities V1 Energy Storage Secure Supplies Whitepaper: POWER TO GAS ENERGY STORAGEFrom EverandFueling Healthy Communities V1 Energy Storage Secure Supplies Whitepaper: POWER TO GAS ENERGY STORAGENo ratings yet

- ಉಪದೇಶರತ್ತಿನಮಾಲೈDocument14 pagesಉಪದೇಶರತ್ತಿನಮಾಲೈsrinivas raghavanNo ratings yet

- Chapter 14 AgileDocument11 pagesChapter 14 Agilesrinivas raghavanNo ratings yet

- Chapter 3 Role of Project Manager 6th EditionDocument21 pagesChapter 3 Role of Project Manager 6th Editionsrinivas raghavanNo ratings yet

- PW, SP : Mounting Instructions Montageanleitung Notice de MontageDocument52 pagesPW, SP : Mounting Instructions Montageanleitung Notice de Montagesrinivas raghavanNo ratings yet

- Chapter 11 - Risk Management 6th. EditionDocument41 pagesChapter 11 - Risk Management 6th. Editionsrinivas raghavanNo ratings yet

- Chapter 5 Scope Management 6th. EditionDocument29 pagesChapter 5 Scope Management 6th. Editionsrinivas raghavanNo ratings yet

- rc3d Leg Datasheet enDocument3 pagesrc3d Leg Datasheet ensrinivas raghavanNo ratings yet

- Fisa Tehnica PW12CDocument4 pagesFisa Tehnica PW12Csrinivas raghavanNo ratings yet

- 115 SARDataProcessing BrochureDocument2 pages115 SARDataProcessing Brochuresrinivas raghavanNo ratings yet

- Namalwar DDDocument2 pagesNamalwar DDsrinivas raghavanNo ratings yet

- sb8 Datasheet enDocument3 pagessb8 Datasheet ensrinivas raghavanNo ratings yet

- Montageanleitung Notice de Montage: Mounting InstructionsDocument36 pagesMontageanleitung Notice de Montage: Mounting Instructionssrinivas raghavanNo ratings yet

- Purchase Order (Draft) IFB Industries LimitedDocument1 pagePurchase Order (Draft) IFB Industries Limitedsrinivas raghavanNo ratings yet

- Introduction To Aerospace Materials by A Mouritz - PDF DriveDocument2 pagesIntroduction To Aerospace Materials by A Mouritz - PDF Drivesrinivas raghavanNo ratings yet

- Why Do We Outrage - #IAmBuddhaDocument4 pagesWhy Do We Outrage - #IAmBuddhasrinivas raghavanNo ratings yet

- Poorna Brahma & Poornatwa Siddhanta PDFDocument315 pagesPoorna Brahma & Poornatwa Siddhanta PDFsrinivas raghavan100% (1)

- Bearing MaterialDocument2 pagesBearing Materialsrinivas raghavanNo ratings yet

- How To Add Your Resume On LinkedIn (4 Options) - ZipJobDocument13 pagesHow To Add Your Resume On LinkedIn (4 Options) - ZipJobsrinivas raghavanNo ratings yet

- Industry 4.0 - Reimagining Manufacturing Operations After COVID-19 - McKinseyDocument15 pagesIndustry 4.0 - Reimagining Manufacturing Operations After COVID-19 - McKinseysrinivas raghavanNo ratings yet

- 10K PlanDocument1 page10K Plansrinivas raghavanNo ratings yet

- Chapter 1 Audit Under TaxDocument15 pagesChapter 1 Audit Under TaxSaurabh GogawaleNo ratings yet

- Chapter 7 The Regular Output VATDocument28 pagesChapter 7 The Regular Output VATCathy Marie Angela ArellanoNo ratings yet

- 36 Loss Disallowance Slides and ExamplesDocument51 pages36 Loss Disallowance Slides and ExamplesCourt RobertsNo ratings yet

- Living IT Quiz 2Document6 pagesLiving IT Quiz 2田中麗奈No ratings yet

- Advance Performance ManagementDocument53 pagesAdvance Performance ManagementAyesha HamidNo ratings yet

- ECS2608 Assignment 3Document8 pagesECS2608 Assignment 3Jason Warren BlandNo ratings yet

- L1LSFCY US Feeder Fund PPMDocument60 pagesL1LSFCY US Feeder Fund PPMlaquetengoNo ratings yet

- Axie Infinity: Business Breakdowns Research: Company History & Key PeopleDocument12 pagesAxie Infinity: Business Breakdowns Research: Company History & Key Peoplekuri suchanNo ratings yet

- Revision Q&ADocument5 pagesRevision Q&ADylan Rabin PereiraNo ratings yet

- Additional Exercise On Cash Flows With Relative SolutionsDocument2 pagesAdditional Exercise On Cash Flows With Relative Solutionspratama aditara100% (1)

- Time Value of Money Problem and Solution 5Document4 pagesTime Value of Money Problem and Solution 5Vonreev OntoyNo ratings yet

- Foreign Exchange System of City Bank LimitedDocument10 pagesForeign Exchange System of City Bank Limitedsibgat ullahNo ratings yet

- Manufacturing Methods: An IntroductionDocument18 pagesManufacturing Methods: An IntroductionRafiqueNo ratings yet

- RFBT Quiz #1 - ObligationDocument11 pagesRFBT Quiz #1 - Obligationrandyblanza201486% (7)

- Ch02 P20 Build A Model SolutionDocument6 pagesCh02 P20 Build A Model Solutionsonam agrawalNo ratings yet

- Mateo Manuscript Om Buma 20093Document13 pagesMateo Manuscript Om Buma 20093Mhico MateoNo ratings yet

- 2point2 Capital - Investor Update Q4 FY20Document6 pages2point2 Capital - Investor Update Q4 FY20Rakesh PandeyNo ratings yet

- CHAPTER 1 Business ProposalDocument5 pagesCHAPTER 1 Business Proposallagatic1821No ratings yet

- Today Economics Ca Foundation QPDocument4 pagesToday Economics Ca Foundation QPAparnaNo ratings yet

- Ra 265Document34 pagesRa 265Raezel Louise VelayoNo ratings yet

- Experience IIFTDocument4 pagesExperience IIFTJayesh JaiswalNo ratings yet

- Existing Problems and Solutions in Managing The Development of Social EntrepreneurshipDocument6 pagesExisting Problems and Solutions in Managing The Development of Social EntrepreneurshipAcademic JournalNo ratings yet

- Maruti Suzuki Pricing StrategiesDocument14 pagesMaruti Suzuki Pricing StrategiesDev MitraNo ratings yet

- Project On Tata Motors 1Document86 pagesProject On Tata Motors 1Kotresh KpNo ratings yet

- United State Senate Banking Committee Letter To James Dimon CEO JP Morgan ChaseDocument5 pagesUnited State Senate Banking Committee Letter To James Dimon CEO JP Morgan ChaseJaniceWolkGrenadierNo ratings yet

- How To Complete Your W-8Ben FormDocument2 pagesHow To Complete Your W-8Ben FormSun WestNo ratings yet

- Closing and Worksheet: 20.1 Closing Entries For Revenue AccountsDocument8 pagesClosing and Worksheet: 20.1 Closing Entries For Revenue AccountsZaheer Swati100% (1)

- UMB - MTS - Chapter 2 Integration Project ManagementDocument44 pagesUMB - MTS - Chapter 2 Integration Project ManagementKartika Sri RahayuNo ratings yet

- Allama Iqbal Open University: Report of Business LawDocument17 pagesAllama Iqbal Open University: Report of Business Lawmanomasho100% (2)