Professional Documents

Culture Documents

Kelly Calculation1

Kelly Calculation1

Uploaded by

Berat Değirmenci0 ratings0% found this document useful (0 votes)

6 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

6 views1 pageKelly Calculation1

Kelly Calculation1

Uploaded by

Berat DeğirmenciCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

£

Kelly bars are designed for the purpose of transferring torques and pressures onto a driling tool.

The kelly used must therefore be treated with as much care as the driling rig and the tool and

bits themselves in order that consistent drilling performance be ensured,

1 INSTRUCTIONS

to the supplied work instructions for drilling rigs, tools and accessories

These supplementary instructions serve to help avoiding unnecessar

CAUTION wear. ¢ "y

A The following work instructions specific to kelly bars are a supplement

* Not all types of kellys are designed for the full torque of the rotary drive of the

drilling rig: Know the max. permissible torque for the kelly and do not exceed it with

the rotary drive.

* Kellys and drilling tools are allowed to be used only for drilling applications; earth-

moving, conveying or levelling jobs are not permissible.

«Kellys may not be used for bringing borehole casings or drilling tools into alignment.

+ Kellys may be operated with free-fall facility only as long as the total load on the

kelly rope does not exceed half of the max. pulling capacity of the corresponding

winch,

Exampl

Pulling capacity of main Weight of kelly: 7.6 tonnes (see chapter

winch is 20 tonnes (type 4/44) "Tech. Data")

+ +

Weight of auger bit! 1.6 tonnes (see imprint

1500 mm) on tool)

Calculation: 20 tonnes 0 tonnes > Total: 9.2 tonnes

Summation: _ Kelly may still be used with free-fall.

* With a kelly inserted in a borehole, it is no longer allowed to make any readjust-

ments with the base machine or at the mast of the drilling rig.

Exception:

If the mast is displaced from is initial working angle, due to the working forces, it

must be readjusted

A Kelly and mast be parallel at all times of operation

CAUTION

2 KBM/2004

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 3288 Workshop + Other PDFDocument111 pages3288 Workshop + Other PDFBerat DeğirmenciNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

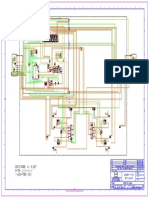

- KSS 80 ZV-2 - Elektri̇kDocument5 pagesKSS 80 ZV-2 - Elektri̇kBerat DeğirmenciNo ratings yet

- Grader ProductivityDocument3 pagesGrader ProductivityBerat Değirmenci100% (1)

- bg22 HalatDocument2 pagesbg22 HalatBerat DeğirmenciNo ratings yet

- EKO75 KW VST Air Cooled Electrical DiagramDocument13 pagesEKO75 KW VST Air Cooled Electrical DiagramBerat DeğirmenciNo ratings yet

- Master Notice BETM - ENDocument60 pagesMaster Notice BETM - ENBerat DeğirmenciNo ratings yet

- EKO75 KW VST Air Cooled Electrical DiagramDocument13 pagesEKO75 KW VST Air Cooled Electrical DiagramBerat DeğirmenciNo ratings yet

- U-064 Istanbul Metro MSV 50-1-1500 20171103 PDFDocument90 pagesU-064 Istanbul Metro MSV 50-1-1500 20171103 PDFBerat DeğirmenciNo ratings yet

- S-360 S-363 SchemeDocument27 pagesS-360 S-363 SchemeBerat DeğirmenciNo ratings yet

- Hydraforce PR10-36Document2 pagesHydraforce PR10-36Berat DeğirmenciNo ratings yet

- 02 - U-064 - ISTANBUL - METRO - PROJECT - Technical Data - EN PDFDocument5 pages02 - U-064 - ISTANBUL - METRO - PROJECT - Technical Data - EN PDFBerat DeğirmenciNo ratings yet

- Hydraulic Trainings For Axial Piston UnitsDocument29 pagesHydraulic Trainings For Axial Piston UnitsNBRellos100% (28)

- 07 U-064 ISTANBUL METRO PROJECT Drawings ENDocument4 pages07 U-064 ISTANBUL METRO PROJECT Drawings ENBerat DeğirmenciNo ratings yet

- FD 1800 G 00915 Man Eng DigDocument42 pagesFD 1800 G 00915 Man Eng DigBerat DeğirmenciNo ratings yet

- U-064 - MSV50 - Hydraulic Components - FDocument2 pagesU-064 - MSV50 - Hydraulic Components - FBerat DeğirmenciNo ratings yet

- U-064 - MSV50 - Hydraulic Diagram - FDocument1 pageU-064 - MSV50 - Hydraulic Diagram - FBerat DeğirmenciNo ratings yet

- Zte6550 Operation and Maintenance ManualDocument392 pagesZte6550 Operation and Maintenance ManualBerat DeğirmenciNo ratings yet