Professional Documents

Culture Documents

Equipment List

Equipment List

Uploaded by

Justin GordonCopyright:

Available Formats

You might also like

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Flatpack 2 DC-DC Converter SystemDocument2 pagesFlatpack 2 DC-DC Converter SystemPhuongLeNo ratings yet

- Free Download Here: John P Uyemura Introduction To Vlsi PDFDocument2 pagesFree Download Here: John P Uyemura Introduction To Vlsi PDFThree PlusNo ratings yet

- Viking E-3 031797Document10 pagesViking E-3 031797Chirasak PaksasornNo ratings yet

- Starter Kit - AXC 1050 PN STARTERKIT - 2400361: Key Commercial DataDocument4 pagesStarter Kit - AXC 1050 PN STARTERKIT - 2400361: Key Commercial DataItachi UchihaNo ratings yet

- Monitoring Level and Pressure in A Rotary FillerDocument2 pagesMonitoring Level and Pressure in A Rotary FillerpfalencarNo ratings yet

- Netcol5000-A025 In-Row Air Cooled Smart Cooling Product Quick Guide (300 MM Width)Document34 pagesNetcol5000-A025 In-Row Air Cooled Smart Cooling Product Quick Guide (300 MM Width)Myo Min HeinNo ratings yet

- Electrical Design Analysis For Commercial Building SampleDocument14 pagesElectrical Design Analysis For Commercial Building SampleMichael AngeloNo ratings yet

- Moxa TRC 190 Series Datasheet v1.1Document4 pagesMoxa TRC 190 Series Datasheet v1.1Akmal FahmiNo ratings yet

- Moxa TRC 190 Series Datasheet v1.0Document4 pagesMoxa TRC 190 Series Datasheet v1.0Bsd FareedNo ratings yet

- CablesDocument152 pagesCablesSandra EcheverriNo ratings yet

- Tidalflux 2300 F Tidalflux 2300 F Tidalflux 2300 F Tidalflux 2300 FDocument24 pagesTidalflux 2300 F Tidalflux 2300 F Tidalflux 2300 F Tidalflux 2300 FmelbisferNo ratings yet

- Datasheet VIO L208 Rev1 - 0Document3 pagesDatasheet VIO L208 Rev1 - 0Juan Carlos MayNo ratings yet

- Valvula de Diluvio Horiozntal 6inDocument4 pagesValvula de Diluvio Horiozntal 6inJosé Martín Meza CabillasNo ratings yet

- BOQ-PROPOSAL - Convention Center - RPMDocument6 pagesBOQ-PROPOSAL - Convention Center - RPMWendell CapacioNo ratings yet

- PCN - 191031001CUS - CS Connector Push-Pull Tab Material PBT Replace PA (191212) PDFDocument2 pagesPCN - 191031001CUS - CS Connector Push-Pull Tab Material PBT Replace PA (191212) PDFJake MoralesNo ratings yet

- File 2020 03 22 21 39 49Document24 pagesFile 2020 03 22 21 39 49Prabhakar BhandarkarNo ratings yet

- Balun Pasivo 16 CHPFM809-4MPDocument4 pagesBalun Pasivo 16 CHPFM809-4MPMauricio Conus SanchezNo ratings yet

- Caudal o MetroDocument20 pagesCaudal o MetropeskamasNo ratings yet

- Rovemavvi200 UnileverDocument16 pagesRovemavvi200 UnileverAhmad عfiaNo ratings yet

- Vikings-Preaction FoamWater System Supplied by A Bladder TankDocument12 pagesVikings-Preaction FoamWater System Supplied by A Bladder TankHenry WuNo ratings yet

- Moxa TRC 2190 Series Datasheet v1.0Document4 pagesMoxa TRC 2190 Series Datasheet v1.0kapileswar pradhanNo ratings yet

- Jintai SD12Document3 pagesJintai SD12Victory JiangNo ratings yet

- WFDTH Waterflow Detector: Sprinkler Systems MonitoringDocument2 pagesWFDTH Waterflow Detector: Sprinkler Systems MonitoringArgile-assholeNo ratings yet

- Flex-Room-Design-Guide-V1.9 sh4Document1 pageFlex-Room-Design-Guide-V1.9 sh4Anonymous XYAPaxjbYNo ratings yet

- TDS-Dualpotsandfilter 10K HT-HFDocument3 pagesTDS-Dualpotsandfilter 10K HT-HFBambang Yan ArdiantoNo ratings yet

- KIT-H7022 Product DataDocument2 pagesKIT-H7022 Product DataMohamed AmineNo ratings yet

- Coiled Tubing Tension Frame Standard Type PDFDocument2 pagesCoiled Tubing Tension Frame Standard Type PDFArgonauta_navegadorNo ratings yet

- Idea 41 Ce (En)Document2 pagesIdea 41 Ce (En)Milos StevanovicNo ratings yet

- Kinetix 5000 Shared-Bus Connector Kits: Installation InstructionsDocument4 pagesKinetix 5000 Shared-Bus Connector Kits: Installation InstructionsSamuel OliveiraNo ratings yet

- d2 Panel Bom NishanthDocument4 pagesd2 Panel Bom Nishanthgeorgetony123No ratings yet

- LCA: Calculation Rules: Description Value UnitDocument1 pageLCA: Calculation Rules: Description Value Unitqc_531040655No ratings yet

- Bus Coupler - IL PB BK DP/V1-PAC - 2862246: Key Commercial DataDocument8 pagesBus Coupler - IL PB BK DP/V1-PAC - 2862246: Key Commercial Dataanne jolivetNo ratings yet

- 011092Document12 pages011092syed mustafa aliNo ratings yet

- STE Mobile Sensor Sorting ENDocument2 pagesSTE Mobile Sensor Sorting ENEdwardes A Dias JrNo ratings yet

- CTRLX I/O: Ethernet Switch Port Xb-Et-31 1 × InterfaceDocument5 pagesCTRLX I/O: Ethernet Switch Port Xb-Et-31 1 × Interface705695No ratings yet

- Stationary Pump Technical Data BSA2109H DDocument2 pagesStationary Pump Technical Data BSA2109H Dserai168.cbcsbNo ratings yet

- Wet Bell Control Panel Cabin Campana Humeda Con LARSDocument11 pagesWet Bell Control Panel Cabin Campana Humeda Con LARSrogermorenofNo ratings yet

- Voith Servo Punch UnitDocument5 pagesVoith Servo Punch Unittammam shamiNo ratings yet

- SITRANS F FlowmetersDocument5 pagesSITRANS F FlowmetersAnonymous c78RiR0Iw4No ratings yet

- Patch Cord Cat 6a y 6a Blindado 28awg 1.5mts LSZH Leviton AzulDocument2 pagesPatch Cord Cat 6a y 6a Blindado 28awg 1.5mts LSZH Leviton AzulDavid MolinaNo ratings yet

- Idea 40Document2 pagesIdea 40Milos StevanovicNo ratings yet

- Onset Hobo Trade T Cdi 5200 5400 User ManualDocument3 pagesOnset Hobo Trade T Cdi 5200 5400 User Manualpaull20020% (1)

- Typ10 EnusDocument70 pagesTyp10 EnusAmir AlibegovićNo ratings yet

- Base 2/08Document167 pagesBase 2/08Jardel SilvaNo ratings yet

- 08-Chemical Dosing EquipmentDocument48 pages08-Chemical Dosing Equipmentagung ramdhaniNo ratings yet

- K-1 Cement RetainerDocument1 pageK-1 Cement RetainerRogelio RayaNo ratings yet

- Antena 3.8M-4096-535Document36 pagesAntena 3.8M-4096-535Naim MalzzNo ratings yet

- Screenshot 2022-06-30 at 2.15.50 PMDocument5 pagesScreenshot 2022-06-30 at 2.15.50 PMricky.douglasNo ratings yet

- 410 Fibre Optic Cable Blowing-In DevicesDocument17 pages410 Fibre Optic Cable Blowing-In DevicesKlanac BrčkoNo ratings yet

- Product Information BAT54-RailDocument2 pagesProduct Information BAT54-RailFederico FranchinoNo ratings yet

- W24 Indoor/Outdoor Distribution Box: DescriptionDocument4 pagesW24 Indoor/Outdoor Distribution Box: DescriptionAntony SánchezNo ratings yet

- QTY CalcDocument2 pagesQTY CalcAtulNo ratings yet

- Component Code ZZ: Printed in Japan (02) 21Document140 pagesComponent Code ZZ: Printed in Japan (02) 21Олексій РумянцевNo ratings yet

- Bul HY14-1483-M4 23-5090 - 2Document8 pagesBul HY14-1483-M4 23-5090 - 2Surafel AbebeNo ratings yet

- LGU Javier SB Hall AV Equipment 10 FinalDocument8 pagesLGU Javier SB Hall AV Equipment 10 FinalTONIX TVNo ratings yet

- Pac8000 Controllers Ds Gfa1831Document2 pagesPac8000 Controllers Ds Gfa1831mealysrNo ratings yet

- Technical Data: Vertical and Horizontal Bladder Tanks Model VFT ASME Sec - VIII Div.1 - U-1ADocument11 pagesTechnical Data: Vertical and Horizontal Bladder Tanks Model VFT ASME Sec - VIII Div.1 - U-1Arusli bahtiarNo ratings yet

- Prodelin Ku Band 4096-582Document29 pagesProdelin Ku Band 4096-582r0dxNo ratings yet

- Afl/Fujikura Fusion Splicers: FSM-60R12 Fusion SplicerDocument2 pagesAfl/Fujikura Fusion Splicers: FSM-60R12 Fusion SplicerRaymond Tee Chai YongNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Track Format of Magnetic Stripe Cards 2Document72 pagesTrack Format of Magnetic Stripe Cards 2Justin GordonNo ratings yet

- Card-O-Rama: Magnetic Stripe Technology and BeyondDocument129 pagesCard-O-Rama: Magnetic Stripe Technology and BeyondJustin GordonNo ratings yet

- Zytel FG101L NC010 SdsDocument7 pagesZytel FG101L NC010 SdsJustin GordonNo ratings yet

- VncserverstatusDocument2 pagesVncserverstatusJustin GordonNo ratings yet

- Flexicon Part Quote - 14440Document5 pagesFlexicon Part Quote - 14440Justin GordonNo ratings yet

- Hempco Canada Super FoodsDocument1 pageHempco Canada Super FoodsJustin GordonNo ratings yet

- Spring Financial - The FoundationDocument8 pagesSpring Financial - The FoundationJustin GordonNo ratings yet

- Installation and Service InstructionsDocument8 pagesInstallation and Service Instructionsrommel duranNo ratings yet

- Unit I Semiconductor DevicesDocument15 pagesUnit I Semiconductor DeviceskannanchammyNo ratings yet

- TM1 RM1Document16 pagesTM1 RM1Nikulas HawlaNo ratings yet

- Frequency DNA and The Human BodypdfDocument6 pagesFrequency DNA and The Human BodypdfRegaldna Felix100% (1)

- GifaDocument331 pagesGifaMatiasNo ratings yet

- Configured 2668 Series DatasheetDocument2 pagesConfigured 2668 Series Datasheetmaverick23113636No ratings yet

- Micom P127Document25 pagesMicom P127Vijayaganthaan VisvanatthanNo ratings yet

- Abb Controls Mini Circuit Breaker Catalog 08-25-16 230729 153102Document80 pagesAbb Controls Mini Circuit Breaker Catalog 08-25-16 230729 153102endalkachew sintayehuNo ratings yet

- Dokumen - Tips Free Download Here Neamen Electronicpdf Free Download Here Ee334 Mcgraw HillDocument2 pagesDokumen - Tips Free Download Here Neamen Electronicpdf Free Download Here Ee334 Mcgraw HillroshikaNo ratings yet

- Induction Motor BasicDocument72 pagesInduction Motor BasickoushikNo ratings yet

- Electric Current and CircuitsDocument33 pagesElectric Current and CircuitssatikantNo ratings yet

- 1.2.4.AK SequentialLogicDesign - Counters - DLBDocument7 pages1.2.4.AK SequentialLogicDesign - Counters - DLBSean MonahanNo ratings yet

- Basic ElectronicsDocument1 pageBasic ElectronicsBibin K VijayanNo ratings yet

- Implementation of Solar Cap and Its Judicious UseDocument26 pagesImplementation of Solar Cap and Its Judicious UseShivam Jindal100% (1)

- 5 Minute Guide Electricity StorageDocument17 pages5 Minute Guide Electricity StorageCarlos HolguinNo ratings yet

- MSB Schematic - BSE1 (62) XX-01 - (T1)Document1 pageMSB Schematic - BSE1 (62) XX-01 - (T1)Miguel Louie Sarigumba IIINo ratings yet

- Information Sheet BulbDocument9 pagesInformation Sheet BulbRex Chambers LadaoNo ratings yet

- Proposed Laboratory Tool Kit For CPE107LDocument3 pagesProposed Laboratory Tool Kit For CPE107LArete JinseiNo ratings yet

- OMS 1600 Boosters-Amps Rev-A 09jan07Document23 pagesOMS 1600 Boosters-Amps Rev-A 09jan07Marcelo MonteiroNo ratings yet

- Rollarc r400 r400d Contactor EN PDFDocument28 pagesRollarc r400 r400d Contactor EN PDFthanh_cdt01No ratings yet

- Leister's Hot Air Blowers: Intelligent and FlexibleDocument3 pagesLeister's Hot Air Blowers: Intelligent and FlexibleAnya RumeserNo ratings yet

- Class11 Chemistry 1 Unit02 NCERT TextBook English EditionDocument44 pagesClass11 Chemistry 1 Unit02 NCERT TextBook English EditionAkash SharmaNo ratings yet

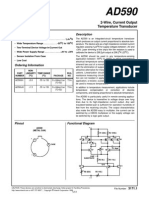

- AD590Document11 pagesAD590Timmy Neil SixxNo ratings yet

- Introduction Home Automation Circuit Diagram Components Required Components Description Circuit Description Applications ConclusionDocument26 pagesIntroduction Home Automation Circuit Diagram Components Required Components Description Circuit Description Applications ConclusionPratiksha SharmaNo ratings yet

- BB Battery Ups BP17-12 PDFDocument1 pageBB Battery Ups BP17-12 PDFElvis DiazNo ratings yet

- Gele ATSCDocument10 pagesGele ATSCAde ApriNo ratings yet

- CTS Lift and Escalator Mechanic - CTS - NSQF-5 PDFDocument68 pagesCTS Lift and Escalator Mechanic - CTS - NSQF-5 PDFVISHALNo ratings yet

- Cotech EMT707CTL Energy Meter - Priza ProgramabilaDocument5 pagesCotech EMT707CTL Energy Meter - Priza ProgramabilaConstantinNo ratings yet

- WST 2100 Pbach R Me 0042Document206 pagesWST 2100 Pbach R Me 0042teamlc100% (1)

Equipment List

Equipment List

Uploaded by

Justin GordonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equipment List

Equipment List

Uploaded by

Justin GordonCopyright:

Available Formats

2400 Emrick Boulevard

Bethlehem, PA 18020-8006

USA

Equipment List

Tel: 1-888-FLEXICON

Tel: 1-610-814-2400

CUSTOMER: HEMPCO CANADA SUPER FOODS

FLEXICON CORPORATION Fax: 1-610-814-0600

www.flexicon.com ORDER No. 92841 DWG REV: B DATE: 1/6/2020

INFORMATION SET FORTH IN THIS DRAWING IS PROPRIETARY DWG No.: TFC-00219704 PAGE: 1 of 6

WITH FLEXICON CORPORATION.

ITEM QTY MODEL No. DESCRIPTION

System 1 Hemp Heart Transfer

1.1 2 HPN-H040-P18-X -Type "N" floor hopper

-1 cubic foot measured capacity

-Measures 18" square x 28" high

-Extended legs

-Includes flanged outlet to mate with non-metered inlet adapter

-Designed to be used with parallel automatic cable tensioner

1.1.1 2 VPP-H -Mounting pad for pneumatic turbine vibrator

1.1.2 2 IAN-H040 -Non-metered inlet adapter

-Includes polycarbonate viewing window

-Includes (2) compression couplings for connection to conveying line

Requires metered feed

1.2 1 ATP-H040W-X -Parallel automatic cable tensioner

-Maintains and monitors cable tension within conveyor circuit

-Precision polymer tensioning wheel includes wheel groove wiper

-Single point adjustment for setting initial cable tension

-Includes cleanout port with bolted cap

-Includes 24 VDC NEMA 4 limit switch to indicate wire rope tension is out of

range

-Includes (2) compression couplings for connection to conveying line

-Includes analog output (4-20 mA)

1.3 1 UBCS-H040-120-X -Flexi-disc® tubular cable conveyor

-Includes (4) 4" diameter x 20' long stainless steel conveyor sections

-Includes (4) 90 degree 48" radius stainless steel elbows and (15)

conveying line compression couplings

-Includes (2) 4" diameter x 32" long clear viewing tube sections with

grounding kit

-Coated cable assembly with two-piece ultra-high molecular weight

polyethylene conveying discs

-Precision polymer drive wheel includes wheel groove wiper

-Cable connector includes urethane wiper disc

-Includes customized toolkit to facilitate conveyor installation

-Conveying line support brackets and hangers not includedh

1.4 1 IDVN-H040W -Tubular discharge valve

-Allows material to discharge or bypass a material discharge point

-Pneumatically actuated

-Includes 24 VDC NEMA 4 solenoid valve, filter, and regulator with gauge

-Includes 24 VDC NEMA 4 limit switches

-Includes air jets to assist in material discharge

-Requires 80 psi air supply

-Includes (2) compression couplings for connection to conveying line

1.4.1 1 DCV-H040-2 -Tubular discharge valve material discharge adapter

-To facilitate connection to flexible spouting, valves, or other round

process connections

1.4.2 8 FS-H06 -6" diameter flexible down spouting

-Clear PVC construction with completely enclosed wire reinforcement

2400 Emrick Boulevard

Bethlehem, PA 18020-8006

USA

Equipment List

Tel: 1-888-FLEXICON

Tel: 1-610-814-2400

CUSTOMER: HEMPCO CANADA SUPER FOODS

FLEXICON CORPORATION Fax: 1-610-814-0600

www.flexicon.com ORDER No. 92841 DWG REV: B DATE: 1/6/2020

INFORMATION SET FORTH IN THIS DRAWING IS PROPRIETARY DWG No.: TFC-00219704 PAGE: 2 of 6

WITH FLEXICON CORPORATION.

ITEM QTY MODEL No. DESCRIPTION

1.5 1 IDIN-H040N -Full-flow inline discharge

-Material discharge for tubular cable conveyor

-Includes (2) compression couplings for connection to conveying line

1.5.1 1 DCI-H040-2 -Full-flow inline discharge material discharge adapter

-To facilitate connection to flexible spouting, valves, or other round

process connections

1.5.2 8 FS-H06 -6" diameter flexible down spouting

-Clear PVC construction with completely enclosed wire reinforcement

1.6 1 BRR-01018T-125-X -Gear drive assembly

-1 hp, 1725 rpm, 3 phase, 60 Hz TEFC motor with right angle gear reduction

unit

-Motor rated for 575 Volts

1.6.1 1 DCW-H040-2 -Drive wheel housing material discharge adapter

-To facilitate connection to flexible spouting, valves, or other round

process connections

Discharge into waste bin

1.6.2 8 FS-H06 -6" diameter flexible down spouting

-Clear PVC construction with completely enclosed wire reinforcement

1.6.3 1 AK-HW -Air knife assembly

-Directs a curtain of air over the cable and disc assembly to dislodge

material particles

-Includes 24 VDC NEMA 4 solenoid valve, filter and regulator with gauge

-Requires 60-80 psi air supply

1.7 1 BFB-CFHW -Basic bulk bag filling station

-Includes static bulk bag strap hooks with hinged strap retainers

-Constructed of structural mild steel, primed and painted

-Adjustable in height through the use of a fork truck to accommodate bulk

bags ranging from 36" to 72" high with a maximum width of 36" at the bag

seam and 48" at the widest point when full

-Designed for 4000 lb capacity bulk bag maximum

-Accomodates maximum pallet size of 44" x 48"

-Includes inflatable inlet seal designed to interface with 14" to 22" diameter

x 18" long minimum bulk bag inlet spout

-With air displacement vent and filter sock

-Operator toggle switch with inflate/deflate positions, with regulator to

prevent over-inflating

-Requires 60-80 psi air supply

-Note: please complete and return drawing #SD-BF-09

2400 Emrick Boulevard

Bethlehem, PA 18020-8006

USA

Equipment List

Tel: 1-888-FLEXICON

Tel: 1-610-814-2400

CUSTOMER: HEMPCO CANADA SUPER FOODS

FLEXICON CORPORATION Fax: 1-610-814-0600

www.flexicon.com ORDER No. 92841 DWG REV: B DATE: 1/6/2020

INFORMATION SET FORTH IN THIS DRAWING IS PROPRIETARY DWG No.: TFC-00219704 PAGE: 3 of 6

WITH FLEXICON CORPORATION.

ITEM QTY MODEL No. DESCRIPTION

1.8 1 SR7-W010-57-X -Control panel in NEMA 4X stainless steel enclosure

-Includes programmable logic controller (PLC) to govern system

functionality

-Includes non-reversing motor starter for conveyor drive

-Includes 4” touchscreen HMI for operator interface

-Includes 24 VDC control voltage

-Includes lockable fused disconnect switch

-Includes Emergency Stop push button with category 1 safety circuit

-(2) position selector on HMI for material source

-(2) position selector on HMI for material destination

-Provisions to open/close (1) material flow control

-CSA approved

-Control panel requires field mounting and external wiring

2400 Emrick Boulevard

Bethlehem, PA 18020-8006

USA

Equipment List

Tel: 1-888-FLEXICON

Tel: 1-610-814-2400

CUSTOMER: HEMPCO CANADA SUPER FOODS

FLEXICON CORPORATION Fax: 1-610-814-0600

www.flexicon.com ORDER No. 92841 DWG REV: B DATE: 1/6/2020

INFORMATION SET FORTH IN THIS DRAWING IS PROPRIETARY DWG No.: TFC-00219829 PAGE: 4 of 6

WITH FLEXICON CORPORATION.

ITEM QTY MODEL No. DESCRIPTION

System 2 Hemp Fines Transfer

2.1 2 HPN-H040-P18-X -Type "N" floor hopper

-1 cubic foot measured capacity

-Measures 18" square x 28" high

-Extended legs

-Includes flanged outlet to mate with non-metered inlet adapter

-Designed to be used with parallel automatic cable tensioner

2.1.1 2 VPP-H -Mounting pad for pneumatic turbine vibrator

2.1.2 2 IAN-H040 -Non-metered inlet adapter

-Includes polycarbonate viewing window

-Includes (2) compression couplings for connection to conveying line

Requires metered feed

2.2 1 ATP-H040W-X -Parallel automatic cable tensioner

-Maintains and monitors cable tension within conveyor circuit

-Precision polymer tensioning wheel includes wheel groove wiper

-Single point adjustment for setting initial cable tension

-Includes cleanout port with bolted cap

-Includes 24 VDC NEMA 4 limit switch to indicate wire rope tension is out of

range

-Includes (2) compression couplings for connection to conveying line

-Includes analog output (4-20 mA)

2.3 1 UBCS-H040-140-X -Flexi-disc® tubular cable conveyor

-Includes (4) 4” diameter x 20’ long and (1) 10’ long stainless steel conveyor

sections

-Includes (4) 90 degree 48" radius stainless steel elbows and (16)

conveying line compression couplings

-Includes (2) 4" diameter x 32" long clear viewing tube sections with

grounding kit

-Coated cable assembly with two-piece ultra-high molecular weight

polyethylene conveying discs

-Precision polymer drive wheel includes wheel groove wiper

-Cable connector includes urethane wiper disc

-Includes customized toolkit to facilitate conveyor installation

-Conveying line support brackets and hangers not included

2.4 1 IDVN-H040W -Tubular discharge valve

-Allows material to discharge or bypass a material discharge point

-Pneumatically actuated

-Includes 24 VDC NEMA 4 solenoid valve, filter, and regulator with gauge

-Includes 24 VDC NEMA 4 limit switches

-Includes air jets to assist in material discharge

-Requires 80 psi air supply

-Includes (2) compression couplings for connection to conveying line

2.4.1 1 DCV-H040-2 -Tubular discharge valve material discharge adapter

-To facilitate connection to flexible spouting, valves, or other round

process connections

2400 Emrick Boulevard

Bethlehem, PA 18020-8006

USA

Equipment List

Tel: 1-888-FLEXICON

Tel: 1-610-814-2400

CUSTOMER: HEMPCO CANADA SUPER FOODS

FLEXICON CORPORATION Fax: 1-610-814-0600

www.flexicon.com ORDER No. 92841 DWG REV: B DATE: 1/6/2020

INFORMATION SET FORTH IN THIS DRAWING IS PROPRIETARY DWG No.: TFC-00219829 PAGE: 5 of 6

WITH FLEXICON CORPORATION.

ITEM QTY MODEL No. DESCRIPTION

2.4.2 8 FS-H06 -6" diameter flexible down spouting

-Clear PVC construction with completely enclosed wire reinforcement

2.5 1 IDIN-H040N -Full-flow inline discharge

-Material discharge for tubular cable conveyor

-Includes (2) compression couplings for connection to conveying line

2.5.1 1 DCI-H040-2 -Full-flow inline discharge material discharge adapter

-To facilitate connection to flexible spouting, valves, or other round

process connections

2.5.2 8 FS-H06 -6" diameter flexible down spouting

-Clear PVC construction with completely enclosed wire reinforcement

2.6 1 BRR-01018T-125-X -Gear drive assembly

-1 hp, 1725 rpm, 3 phase, 60 Hz TEFC motor with right angle gear reduction

unit

-Motor rated for 575 Volts

2.6.1 1 DCW-H040-2 -Drive wheel housing material discharge adapter

-To facilitate connection to flexible spouting, valves, or other round

process connections

To Waste Bin

2.6.2 8 FS-H06 -6" diameter flexible down spouting

-Clear PVC construction with completely enclosed wire reinforcement

2.6.3 1 AK-HW -Air knife assembly

-Directs a curtain of air over the cable and disc assembly to dislodge

material particles

-Includes 24 VDC NEMA 4 solenoid valve, filter and regulator with gauge

-Requires 60-80 psi air supply

2.7 2 BFB-CFHW -Basic bulk bag filling station

-Includes static bulk bag strap hooks with hinged strap retainers

-Constructed of structural mild steel, primed and painted

-Adjustable in height through the use of a fork truck to accommodate bulk

bags ranging from 36" to 72" high with a maximum width of 36" at the bag

seam and 48" at the widest point when full

-Designed for 4000 lb capacity bulk bag maximum

-Accomodates maximum pallet size of 44" x 48"

-Includes inflatable inlet seal designed to interface with 14" to 22" diameter

x 18" long minimum bulk bag inlet spout

-With air displacement vent and filter sock

-Operator toggle switch with inflate/deflate positions, with regulator to

prevent over-inflating

-Requires 60-80 psi air supply

-Note: please complete and return drawing #SD-BF-09

2400 Emrick Boulevard

Bethlehem, PA 18020-8006

USA

Equipment List

Tel: 1-888-FLEXICON

Tel: 1-610-814-2400

CUSTOMER: HEMPCO CANADA SUPER FOODS

FLEXICON CORPORATION Fax: 1-610-814-0600

www.flexicon.com ORDER No. 92841 DWG REV: B DATE: 1/6/2020

INFORMATION SET FORTH IN THIS DRAWING IS PROPRIETARY DWG No.: TFC-00219829 PAGE: 6 of 6

WITH FLEXICON CORPORATION.

ITEM QTY MODEL No. DESCRIPTION

2.8 1 SR7-W010-57-X -Control panel in NEMA 4X stainless steel enclosure

-Includes programmable logic controller (PLC) to govern system

functionality

-Includes non-reversing motor starter for conveyor drive

-Includes 4” touchscreen HMI for operator interface

-Includes 24 VDC control voltage

-Includes lockable fused disconnect switch

-Includes Emergency Stop push button with category 1 safety circuit

-(2) position selector on HMI for material destination

-(2) position selector on HMI for material source

-Provisions to open/close (1) material flow control

-CSA approved

-Control panel requires field mounting and external wiring

You might also like

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Flatpack 2 DC-DC Converter SystemDocument2 pagesFlatpack 2 DC-DC Converter SystemPhuongLeNo ratings yet

- Free Download Here: John P Uyemura Introduction To Vlsi PDFDocument2 pagesFree Download Here: John P Uyemura Introduction To Vlsi PDFThree PlusNo ratings yet

- Viking E-3 031797Document10 pagesViking E-3 031797Chirasak PaksasornNo ratings yet

- Starter Kit - AXC 1050 PN STARTERKIT - 2400361: Key Commercial DataDocument4 pagesStarter Kit - AXC 1050 PN STARTERKIT - 2400361: Key Commercial DataItachi UchihaNo ratings yet

- Monitoring Level and Pressure in A Rotary FillerDocument2 pagesMonitoring Level and Pressure in A Rotary FillerpfalencarNo ratings yet

- Netcol5000-A025 In-Row Air Cooled Smart Cooling Product Quick Guide (300 MM Width)Document34 pagesNetcol5000-A025 In-Row Air Cooled Smart Cooling Product Quick Guide (300 MM Width)Myo Min HeinNo ratings yet

- Electrical Design Analysis For Commercial Building SampleDocument14 pagesElectrical Design Analysis For Commercial Building SampleMichael AngeloNo ratings yet

- Moxa TRC 190 Series Datasheet v1.1Document4 pagesMoxa TRC 190 Series Datasheet v1.1Akmal FahmiNo ratings yet

- Moxa TRC 190 Series Datasheet v1.0Document4 pagesMoxa TRC 190 Series Datasheet v1.0Bsd FareedNo ratings yet

- CablesDocument152 pagesCablesSandra EcheverriNo ratings yet

- Tidalflux 2300 F Tidalflux 2300 F Tidalflux 2300 F Tidalflux 2300 FDocument24 pagesTidalflux 2300 F Tidalflux 2300 F Tidalflux 2300 F Tidalflux 2300 FmelbisferNo ratings yet

- Datasheet VIO L208 Rev1 - 0Document3 pagesDatasheet VIO L208 Rev1 - 0Juan Carlos MayNo ratings yet

- Valvula de Diluvio Horiozntal 6inDocument4 pagesValvula de Diluvio Horiozntal 6inJosé Martín Meza CabillasNo ratings yet

- BOQ-PROPOSAL - Convention Center - RPMDocument6 pagesBOQ-PROPOSAL - Convention Center - RPMWendell CapacioNo ratings yet

- PCN - 191031001CUS - CS Connector Push-Pull Tab Material PBT Replace PA (191212) PDFDocument2 pagesPCN - 191031001CUS - CS Connector Push-Pull Tab Material PBT Replace PA (191212) PDFJake MoralesNo ratings yet

- File 2020 03 22 21 39 49Document24 pagesFile 2020 03 22 21 39 49Prabhakar BhandarkarNo ratings yet

- Balun Pasivo 16 CHPFM809-4MPDocument4 pagesBalun Pasivo 16 CHPFM809-4MPMauricio Conus SanchezNo ratings yet

- Caudal o MetroDocument20 pagesCaudal o MetropeskamasNo ratings yet

- Rovemavvi200 UnileverDocument16 pagesRovemavvi200 UnileverAhmad عfiaNo ratings yet

- Vikings-Preaction FoamWater System Supplied by A Bladder TankDocument12 pagesVikings-Preaction FoamWater System Supplied by A Bladder TankHenry WuNo ratings yet

- Moxa TRC 2190 Series Datasheet v1.0Document4 pagesMoxa TRC 2190 Series Datasheet v1.0kapileswar pradhanNo ratings yet

- Jintai SD12Document3 pagesJintai SD12Victory JiangNo ratings yet

- WFDTH Waterflow Detector: Sprinkler Systems MonitoringDocument2 pagesWFDTH Waterflow Detector: Sprinkler Systems MonitoringArgile-assholeNo ratings yet

- Flex-Room-Design-Guide-V1.9 sh4Document1 pageFlex-Room-Design-Guide-V1.9 sh4Anonymous XYAPaxjbYNo ratings yet

- TDS-Dualpotsandfilter 10K HT-HFDocument3 pagesTDS-Dualpotsandfilter 10K HT-HFBambang Yan ArdiantoNo ratings yet

- KIT-H7022 Product DataDocument2 pagesKIT-H7022 Product DataMohamed AmineNo ratings yet

- Coiled Tubing Tension Frame Standard Type PDFDocument2 pagesCoiled Tubing Tension Frame Standard Type PDFArgonauta_navegadorNo ratings yet

- Idea 41 Ce (En)Document2 pagesIdea 41 Ce (En)Milos StevanovicNo ratings yet

- Kinetix 5000 Shared-Bus Connector Kits: Installation InstructionsDocument4 pagesKinetix 5000 Shared-Bus Connector Kits: Installation InstructionsSamuel OliveiraNo ratings yet

- d2 Panel Bom NishanthDocument4 pagesd2 Panel Bom Nishanthgeorgetony123No ratings yet

- LCA: Calculation Rules: Description Value UnitDocument1 pageLCA: Calculation Rules: Description Value Unitqc_531040655No ratings yet

- Bus Coupler - IL PB BK DP/V1-PAC - 2862246: Key Commercial DataDocument8 pagesBus Coupler - IL PB BK DP/V1-PAC - 2862246: Key Commercial Dataanne jolivetNo ratings yet

- 011092Document12 pages011092syed mustafa aliNo ratings yet

- STE Mobile Sensor Sorting ENDocument2 pagesSTE Mobile Sensor Sorting ENEdwardes A Dias JrNo ratings yet

- CTRLX I/O: Ethernet Switch Port Xb-Et-31 1 × InterfaceDocument5 pagesCTRLX I/O: Ethernet Switch Port Xb-Et-31 1 × Interface705695No ratings yet

- Stationary Pump Technical Data BSA2109H DDocument2 pagesStationary Pump Technical Data BSA2109H Dserai168.cbcsbNo ratings yet

- Wet Bell Control Panel Cabin Campana Humeda Con LARSDocument11 pagesWet Bell Control Panel Cabin Campana Humeda Con LARSrogermorenofNo ratings yet

- Voith Servo Punch UnitDocument5 pagesVoith Servo Punch Unittammam shamiNo ratings yet

- SITRANS F FlowmetersDocument5 pagesSITRANS F FlowmetersAnonymous c78RiR0Iw4No ratings yet

- Patch Cord Cat 6a y 6a Blindado 28awg 1.5mts LSZH Leviton AzulDocument2 pagesPatch Cord Cat 6a y 6a Blindado 28awg 1.5mts LSZH Leviton AzulDavid MolinaNo ratings yet

- Idea 40Document2 pagesIdea 40Milos StevanovicNo ratings yet

- Onset Hobo Trade T Cdi 5200 5400 User ManualDocument3 pagesOnset Hobo Trade T Cdi 5200 5400 User Manualpaull20020% (1)

- Typ10 EnusDocument70 pagesTyp10 EnusAmir AlibegovićNo ratings yet

- Base 2/08Document167 pagesBase 2/08Jardel SilvaNo ratings yet

- 08-Chemical Dosing EquipmentDocument48 pages08-Chemical Dosing Equipmentagung ramdhaniNo ratings yet

- K-1 Cement RetainerDocument1 pageK-1 Cement RetainerRogelio RayaNo ratings yet

- Antena 3.8M-4096-535Document36 pagesAntena 3.8M-4096-535Naim MalzzNo ratings yet

- Screenshot 2022-06-30 at 2.15.50 PMDocument5 pagesScreenshot 2022-06-30 at 2.15.50 PMricky.douglasNo ratings yet

- 410 Fibre Optic Cable Blowing-In DevicesDocument17 pages410 Fibre Optic Cable Blowing-In DevicesKlanac BrčkoNo ratings yet

- Product Information BAT54-RailDocument2 pagesProduct Information BAT54-RailFederico FranchinoNo ratings yet

- W24 Indoor/Outdoor Distribution Box: DescriptionDocument4 pagesW24 Indoor/Outdoor Distribution Box: DescriptionAntony SánchezNo ratings yet

- QTY CalcDocument2 pagesQTY CalcAtulNo ratings yet

- Component Code ZZ: Printed in Japan (02) 21Document140 pagesComponent Code ZZ: Printed in Japan (02) 21Олексій РумянцевNo ratings yet

- Bul HY14-1483-M4 23-5090 - 2Document8 pagesBul HY14-1483-M4 23-5090 - 2Surafel AbebeNo ratings yet

- LGU Javier SB Hall AV Equipment 10 FinalDocument8 pagesLGU Javier SB Hall AV Equipment 10 FinalTONIX TVNo ratings yet

- Pac8000 Controllers Ds Gfa1831Document2 pagesPac8000 Controllers Ds Gfa1831mealysrNo ratings yet

- Technical Data: Vertical and Horizontal Bladder Tanks Model VFT ASME Sec - VIII Div.1 - U-1ADocument11 pagesTechnical Data: Vertical and Horizontal Bladder Tanks Model VFT ASME Sec - VIII Div.1 - U-1Arusli bahtiarNo ratings yet

- Prodelin Ku Band 4096-582Document29 pagesProdelin Ku Band 4096-582r0dxNo ratings yet

- Afl/Fujikura Fusion Splicers: FSM-60R12 Fusion SplicerDocument2 pagesAfl/Fujikura Fusion Splicers: FSM-60R12 Fusion SplicerRaymond Tee Chai YongNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Track Format of Magnetic Stripe Cards 2Document72 pagesTrack Format of Magnetic Stripe Cards 2Justin GordonNo ratings yet

- Card-O-Rama: Magnetic Stripe Technology and BeyondDocument129 pagesCard-O-Rama: Magnetic Stripe Technology and BeyondJustin GordonNo ratings yet

- Zytel FG101L NC010 SdsDocument7 pagesZytel FG101L NC010 SdsJustin GordonNo ratings yet

- VncserverstatusDocument2 pagesVncserverstatusJustin GordonNo ratings yet

- Flexicon Part Quote - 14440Document5 pagesFlexicon Part Quote - 14440Justin GordonNo ratings yet

- Hempco Canada Super FoodsDocument1 pageHempco Canada Super FoodsJustin GordonNo ratings yet

- Spring Financial - The FoundationDocument8 pagesSpring Financial - The FoundationJustin GordonNo ratings yet

- Installation and Service InstructionsDocument8 pagesInstallation and Service Instructionsrommel duranNo ratings yet

- Unit I Semiconductor DevicesDocument15 pagesUnit I Semiconductor DeviceskannanchammyNo ratings yet

- TM1 RM1Document16 pagesTM1 RM1Nikulas HawlaNo ratings yet

- Frequency DNA and The Human BodypdfDocument6 pagesFrequency DNA and The Human BodypdfRegaldna Felix100% (1)

- GifaDocument331 pagesGifaMatiasNo ratings yet

- Configured 2668 Series DatasheetDocument2 pagesConfigured 2668 Series Datasheetmaverick23113636No ratings yet

- Micom P127Document25 pagesMicom P127Vijayaganthaan VisvanatthanNo ratings yet

- Abb Controls Mini Circuit Breaker Catalog 08-25-16 230729 153102Document80 pagesAbb Controls Mini Circuit Breaker Catalog 08-25-16 230729 153102endalkachew sintayehuNo ratings yet

- Dokumen - Tips Free Download Here Neamen Electronicpdf Free Download Here Ee334 Mcgraw HillDocument2 pagesDokumen - Tips Free Download Here Neamen Electronicpdf Free Download Here Ee334 Mcgraw HillroshikaNo ratings yet

- Induction Motor BasicDocument72 pagesInduction Motor BasickoushikNo ratings yet

- Electric Current and CircuitsDocument33 pagesElectric Current and CircuitssatikantNo ratings yet

- 1.2.4.AK SequentialLogicDesign - Counters - DLBDocument7 pages1.2.4.AK SequentialLogicDesign - Counters - DLBSean MonahanNo ratings yet

- Basic ElectronicsDocument1 pageBasic ElectronicsBibin K VijayanNo ratings yet

- Implementation of Solar Cap and Its Judicious UseDocument26 pagesImplementation of Solar Cap and Its Judicious UseShivam Jindal100% (1)

- 5 Minute Guide Electricity StorageDocument17 pages5 Minute Guide Electricity StorageCarlos HolguinNo ratings yet

- MSB Schematic - BSE1 (62) XX-01 - (T1)Document1 pageMSB Schematic - BSE1 (62) XX-01 - (T1)Miguel Louie Sarigumba IIINo ratings yet

- Information Sheet BulbDocument9 pagesInformation Sheet BulbRex Chambers LadaoNo ratings yet

- Proposed Laboratory Tool Kit For CPE107LDocument3 pagesProposed Laboratory Tool Kit For CPE107LArete JinseiNo ratings yet

- OMS 1600 Boosters-Amps Rev-A 09jan07Document23 pagesOMS 1600 Boosters-Amps Rev-A 09jan07Marcelo MonteiroNo ratings yet

- Rollarc r400 r400d Contactor EN PDFDocument28 pagesRollarc r400 r400d Contactor EN PDFthanh_cdt01No ratings yet

- Leister's Hot Air Blowers: Intelligent and FlexibleDocument3 pagesLeister's Hot Air Blowers: Intelligent and FlexibleAnya RumeserNo ratings yet

- Class11 Chemistry 1 Unit02 NCERT TextBook English EditionDocument44 pagesClass11 Chemistry 1 Unit02 NCERT TextBook English EditionAkash SharmaNo ratings yet

- AD590Document11 pagesAD590Timmy Neil SixxNo ratings yet

- Introduction Home Automation Circuit Diagram Components Required Components Description Circuit Description Applications ConclusionDocument26 pagesIntroduction Home Automation Circuit Diagram Components Required Components Description Circuit Description Applications ConclusionPratiksha SharmaNo ratings yet

- BB Battery Ups BP17-12 PDFDocument1 pageBB Battery Ups BP17-12 PDFElvis DiazNo ratings yet

- Gele ATSCDocument10 pagesGele ATSCAde ApriNo ratings yet

- CTS Lift and Escalator Mechanic - CTS - NSQF-5 PDFDocument68 pagesCTS Lift and Escalator Mechanic - CTS - NSQF-5 PDFVISHALNo ratings yet

- Cotech EMT707CTL Energy Meter - Priza ProgramabilaDocument5 pagesCotech EMT707CTL Energy Meter - Priza ProgramabilaConstantinNo ratings yet

- WST 2100 Pbach R Me 0042Document206 pagesWST 2100 Pbach R Me 0042teamlc100% (1)