Professional Documents

Culture Documents

Real Time Inventory Relocation.

Real Time Inventory Relocation.

Uploaded by

Abhijeet Pawar0 ratings0% found this document useful (0 votes)

10 views4 pages1. The document describes a real-time inventory locating and tracking system using RFID in a warehouse environment. Infrastructure includes a forklift equipped with an RFID reader and tablet, WiFi access points, and a server.

2. Inventories are stored either on permanent racks or temporary locations if racks are full, and may be relocated when space frees up.

3. The system allows workers to receive inventory relocation assignments on their tablet, locate the inventory using RFID, confirm, pick it up, and place it in the new assigned location, updating the inventory system.

Original Description:

Original Title

Real time inventory relocation.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document describes a real-time inventory locating and tracking system using RFID in a warehouse environment. Infrastructure includes a forklift equipped with an RFID reader and tablet, WiFi access points, and a server.

2. Inventories are stored either on permanent racks or temporary locations if racks are full, and may be relocated when space frees up.

3. The system allows workers to receive inventory relocation assignments on their tablet, locate the inventory using RFID, confirm, pick it up, and place it in the new assigned location, updating the inventory system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views4 pagesReal Time Inventory Relocation.

Real Time Inventory Relocation.

Uploaded by

Abhijeet Pawar1. The document describes a real-time inventory locating and tracking system using RFID in a warehouse environment. Infrastructure includes a forklift equipped with an RFID reader and tablet, WiFi access points, and a server.

2. Inventories are stored either on permanent racks or temporary locations if racks are full, and may be relocated when space frees up.

3. The system allows workers to receive inventory relocation assignments on their tablet, locate the inventory using RFID, confirm, pick it up, and place it in the new assigned location, updating the inventory system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

Real Time Inventory Locating and Tracking In Warehouse

Using RFID Forklift Reader UF – 001/004

2 common scenarios - to locate and to track inventories real time in warehouse environment.

1. Inventories are store on to permanent

racking system.

OR

2. Inventories are placed on a temporary location in the

case when racking system is over loaded. Inventories

may be relocate when permanent racks are available.

Infrastructure & Components

The following Wireless LAN-based infrastructure was set up for this deployment:

Wi-Fi Access Point

Provides Wireless LAN coverage to warehouse to

Forklift (with RFID Reader) connect mobile computer with the laptop

RFID Pallet Tag

RFID reader transmits data to

mobile computer via Bluetooth

Mobile Computer

Windows CE / Android tablet

computer placed inside forklift to

communicate with RFID reader via

Bluetooth

RFID Rack Tag

Server

Receives IDs of tags scanned by Forklift RFID

reader in real-time, transferred over Wi-Fi.

Infrastructure & Components

A fully equipped forklift with RFID reader, antenna and tablet PC.

Choice of tablet PC or laptop with Bluetooth and WIFI

connectivities.

UF – 001 + Antenna

This is the latest version of Forklift Reader UF – 001 with

flexibility of changging antenna types for various applications.

Also, it comes with a rugged metal casing.

For more detail see UF – 001/004 catalog.

Actual Implementation Of Inventory Relocation In Progress

Inventory relocation assignment received on Tablet PC.

Worker locates inventory on racking system. Worker confirms inventory,

inventory matches location and picks up

inventory.

Worker finds new location and places inventory to newly assigned location on

The new location of the inventory is updated to the rack.

inventory system.

You might also like

- Next-Generation Partnering: SAP Partner Demo Environment, Shared OptionDocument25 pagesNext-Generation Partnering: SAP Partner Demo Environment, Shared OptionAbhijeet PawarNo ratings yet

- RTLS Installation Manual: Date Modified: June 4, 2014Document52 pagesRTLS Installation Manual: Date Modified: June 4, 2014Asif Belal100% (1)

- Asset Tracking For Physical Goods For Agromall Strategy DocumentDocument11 pagesAsset Tracking For Physical Goods For Agromall Strategy DocumentAderayo OnipedeNo ratings yet

- Indra RWRDocument6 pagesIndra RWRNasir Khan BhittaniNo ratings yet

- 7id ASFINAG Ironside MaintenanceDocument2 pages7id ASFINAG Ironside MaintenanceCWDNo ratings yet

- Smart Factory Quick Action GuideDocument6 pagesSmart Factory Quick Action GuideMagesh JayakumarNo ratings yet

- FRANK Operating Instructions General Version v.1.6.0 October 2023 v1.9Document24 pagesFRANK Operating Instructions General Version v.1.6.0 October 2023 v1.9Ariel Horta LoeraNo ratings yet

- AAS BR214A Kaye LabWatchLT 051314 WebDocument12 pagesAAS BR214A Kaye LabWatchLT 051314 WebRicardo DurànNo ratings yet

- FRANK Operating Instructions General Version v.1.5.1.0 August 2023 v1.8Document24 pagesFRANK Operating Instructions General Version v.1.5.1.0 August 2023 v1.8chamberlain2406No ratings yet

- 1885 DatasheetDocument2 pages1885 DatasheetOdino AlmeidaNo ratings yet

- RFD8500 Specification SheetDocument4 pagesRFD8500 Specification SheetCrescendo Solusi TamaNo ratings yet

- Radio-Frequency Identification (RFID) Is An Emerging Technology, WhichDocument15 pagesRadio-Frequency Identification (RFID) Is An Emerging Technology, WhichSelva KumarNo ratings yet

- A4 BrochureDocument26 pagesA4 BrochuresentyNo ratings yet

- Hawk Maker Datasheet Digital Matter V5Document6 pagesHawk Maker Datasheet Digital Matter V5igreenNo ratings yet

- Iv7 Rfid Vehicle Reader Data Sheet enDocument2 pagesIv7 Rfid Vehicle Reader Data Sheet enMArceloNo ratings yet

- Stellar Cyber's Sensors - See The Whole Picture With 360º VisibilityDocument3 pagesStellar Cyber's Sensors - See The Whole Picture With 360º VisibilityramramNo ratings yet

- Smart Supply Chain Management Using Internet of Things (Iot) and Low Power Wireless Communication SystemsDocument4 pagesSmart Supply Chain Management Using Internet of Things (Iot) and Low Power Wireless Communication SystemsMuhammad Rizki RNo ratings yet

- Assets Tracking Presentation: 25-August-2022Document14 pagesAssets Tracking Presentation: 25-August-2022Ibrahim Al TamimiNo ratings yet

- Dhi nvr608 32 4ks2 - Datasheet - 20170615Document3 pagesDhi nvr608 32 4ks2 - Datasheet - 20170615Jorge CasaliNo ratings yet

- TCI 727 Spectrum Monitoring System PDFDocument8 pagesTCI 727 Spectrum Monitoring System PDFustamNo ratings yet

- Forti WLCDocument6 pagesForti WLCll_lvl4st3r_llNo ratings yet

- PratikDocument31 pagesPratikmks88750No ratings yet

- Aruba's Location and Asset Tracking SolutionDocument2 pagesAruba's Location and Asset Tracking SolutionLeandro BitencourtNo ratings yet

- Connecting A RFID Reader To A Steppiii, Bolero-Lt, FOX3 & FOX/-LT/-IN/-EN DeviceDocument11 pagesConnecting A RFID Reader To A Steppiii, Bolero-Lt, FOX3 & FOX/-LT/-IN/-EN DeviceTk RachidNo ratings yet

- Oracle WMS (Warehouse Management System) - An OverviewDocument11 pagesOracle WMS (Warehouse Management System) - An Overviewsj7hyd100% (1)

- Arubaos Rfprotect Module: Data SheetDocument3 pagesArubaos Rfprotect Module: Data SheetWK OngNo ratings yet

- Avirtech-Biota Solutions For Connected Plantations-003aDocument43 pagesAvirtech-Biota Solutions For Connected Plantations-003aTaufan Afid Ahmad YunusNo ratings yet

- DHI-NVR608R-64/128-4KS2: 64/128 Channel Ultra 4K H.265 Network Video RecorderDocument3 pagesDHI-NVR608R-64/128-4KS2: 64/128 Channel Ultra 4K H.265 Network Video RecorderMmd KaissNo ratings yet

- Invensys Foxboro PDFDocument20 pagesInvensys Foxboro PDFPustinjak SaharicNo ratings yet

- FANUC Robot General I (E) v20 S PDFDocument6 pagesFANUC Robot General I (E) v20 S PDFRaghavendra DeshpandeNo ratings yet

- Hid Pacs Aero Controllers Ds en PDFDocument8 pagesHid Pacs Aero Controllers Ds en PDFfransNo ratings yet

- (Neelamatha) Abstract-: Keywords: Mobile RFID, Mobile RFID Security, RFID SecurityDocument11 pages(Neelamatha) Abstract-: Keywords: Mobile RFID, Mobile RFID Security, RFID SecurityM Rajasekhar ReddyNo ratings yet

- Multibeam Antenne en WebDocument4 pagesMultibeam Antenne en WebRavi KiranNo ratings yet

- LTR Survey p1Document9 pagesLTR Survey p1arunNo ratings yet

- 221 WipDocument2 pages221 WipKhang LêNo ratings yet

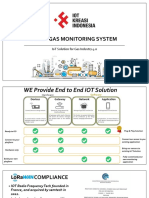

- Smart Gas Monitoring System - IKI 2022 - 220315 - 095227Document21 pagesSmart Gas Monitoring System - IKI 2022 - 220315 - 095227Citra NusantaraNo ratings yet

- Business PlanDocument2 pagesBusiness PlanDiane CruzNo ratings yet

- Chapter 5 Design Guidelines Section 5.5 Electrical Subsection 5.5.2 TelecommunicationsDocument4 pagesChapter 5 Design Guidelines Section 5.5 Electrical Subsection 5.5.2 TelecommunicationskapsarcNo ratings yet

- Time-of-Flight 8x8 Multizone Ranging Sensor With Wide Field of ViewDocument38 pagesTime-of-Flight 8x8 Multizone Ranging Sensor With Wide Field of ViewVinicius BarozziNo ratings yet

- Ap460c Data SheetDocument13 pagesAp460c Data SheetErick Alfredo RosasNo ratings yet

- Ultra High Frequency 840Document22 pagesUltra High Frequency 840Melkamu YigzawNo ratings yet

- RFD8500 Specification SheetDocument2 pagesRFD8500 Specification SheetservicerNo ratings yet

- RFIDAsset TrackDocument8 pagesRFIDAsset Trackamna shahbazNo ratings yet

- Advanced Feeder ProtectionDocument8 pagesAdvanced Feeder Protectionmani shankarNo ratings yet

- Avirtech-Biota Solutions For Connected Plantations-003dDocument51 pagesAvirtech-Biota Solutions For Connected Plantations-003dTaufan Afid Ahmad YunusNo ratings yet

- Abstract-: Keywords: Mobile RFID, Mobile RFID Security, RFID SecurityDocument11 pagesAbstract-: Keywords: Mobile RFID, Mobile RFID Security, RFID SecurityxjrufusjeraldNo ratings yet

- Fortinac: Ruckus Zone Director Wireless Controller IntegrationDocument13 pagesFortinac: Ruckus Zone Director Wireless Controller IntegrationarryNo ratings yet

- Chapter-1 Introduction About ProjectDocument65 pagesChapter-1 Introduction About ProjectNikhilNo ratings yet

- Robot Localization Via Passive UHF-RFID Technology State-of-the-Art and ChallengesDocument8 pagesRobot Localization Via Passive UHF-RFID Technology State-of-the-Art and ChallengesNiran S NarayananNo ratings yet

- Radio FrequencyDocument2 pagesRadio FrequencyalikramNo ratings yet

- CATC Merlin II: Bluetooth V1.2 Protocol AnalyzerDocument2 pagesCATC Merlin II: Bluetooth V1.2 Protocol AnalyzerGeneration GenerationNo ratings yet

- Yang 2015Document14 pagesYang 2015anagha.langheNo ratings yet

- Multi-Pod Vs Multi-Site InfographicDocument1 pageMulti-Pod Vs Multi-Site InfographicFathul NurulNo ratings yet

- Foreign Object Debris Detection - Xsight SystemsDocument4 pagesForeign Object Debris Detection - Xsight SystemsIsrael ExporterNo ratings yet

- Sensors: The Design of RFID Conveyor Belt Gate Systems Using An Antenna Control UnitDocument12 pagesSensors: The Design of RFID Conveyor Belt Gate Systems Using An Antenna Control UnitHarshal PatilNo ratings yet

- Imx1 Eu Datasheetpdf GL All Imx1Document8 pagesImx1 Eu Datasheetpdf GL All Imx1Francisco BezerraNo ratings yet

- Dapserver Brochure 31995a en LTR 201803Document8 pagesDapserver Brochure 31995a en LTR 201803Carlos Víctor Cunalema MorochoNo ratings yet

- 5 Anand Poojary VviDocument5 pages5 Anand Poojary VviashwinjamadagniNo ratings yet

- Ipd Va40: Multi-Camera Vision ApplianceDocument2 pagesIpd Va40: Multi-Camera Vision Appliancealejo linaresNo ratings yet

- HRT-HOOD™: A Structured Design Method for Hard Real-Time Ada SystemsFrom EverandHRT-HOOD™: A Structured Design Method for Hard Real-Time Ada SystemsNo ratings yet

- SAP Partner Demo Environment: Landscape ArchitectureDocument2 pagesSAP Partner Demo Environment: Landscape ArchitectureAbhijeet PawarNo ratings yet

- Benefits of Excellence in Finance TransformationDocument1 pageBenefits of Excellence in Finance TransformationAbhijeet PawarNo ratings yet

- S4 HANA SAP Implementation Project For Precast Construction Businesses in SingaporeDocument13 pagesS4 HANA SAP Implementation Project For Precast Construction Businesses in SingaporeAbhijeet PawarNo ratings yet

- Presentation Flow: Public © 2023 SAP SE or An SAP Affiliate Company. All Rights Reserved. ǀDocument31 pagesPresentation Flow: Public © 2023 SAP SE or An SAP Affiliate Company. All Rights Reserved. ǀAbhijeet PawarNo ratings yet

- Sap Erp Essential Training: A Professional'S Guide To Delivering Business Value Using Sap ErpDocument128 pagesSap Erp Essential Training: A Professional'S Guide To Delivering Business Value Using Sap ErpAbhijeet PawarNo ratings yet

- UST Supply Chain Overview: CustomersDocument2 pagesUST Supply Chain Overview: CustomersAbhijeet PawarNo ratings yet

- DDA Assessment Results - UST LTD 230822Document20 pagesDDA Assessment Results - UST LTD 230822Abhijeet PawarNo ratings yet

- DPM Online QC Batch Card Rev1Document13 pagesDPM Online QC Batch Card Rev1Abhijeet PawarNo ratings yet

- S4HC Disc Assessment Results - UST - 21 July 22 R0Document17 pagesS4HC Disc Assessment Results - UST - 21 July 22 R0Abhijeet PawarNo ratings yet

- Blueprint Order Fulfilment Overall ProcessDocument1 pageBlueprint Order Fulfilment Overall ProcessAbhijeet PawarNo ratings yet

- CSS - 05-Module 5.2 - Network Devices1Document6 pagesCSS - 05-Module 5.2 - Network Devices1Elixa HernandezNo ratings yet

- Chapter 2 - Networking & TelecommunicationDocument32 pagesChapter 2 - Networking & TelecommunicationFafa ZeronineNo ratings yet

- 3 PD CliveDocument13 pages3 PD CliveADODARIYA KASHYAP POPATBHAINo ratings yet

- Jamming SolutionsDocument12 pagesJamming SolutionsEsam MohamadNo ratings yet

- Mototrbo DGP E and DGP E Series: You'Re Completely ConnectedDocument4 pagesMototrbo DGP E and DGP E Series: You'Re Completely ConnectedSebastián GómezNo ratings yet

- Tilgin HG2330 QuickGuideDocument18 pagesTilgin HG2330 QuickGuideEric LaubscherNo ratings yet

- Z790 Gaming Plus WifiDocument1 pageZ790 Gaming Plus Wifisecondfoundation2024No ratings yet

- 03 PO - SS1103 - E01 - 1 ZXA10 C300V2 GPON System Structure - 20151231-55pDocument54 pages03 PO - SS1103 - E01 - 1 ZXA10 C300V2 GPON System Structure - 20151231-55pservicios machalaNo ratings yet

- Catalogue 1021Document10 pagesCatalogue 1021chrisNo ratings yet

- Zte Mf60: Quick GuideDocument16 pagesZte Mf60: Quick GuideRicky EastborneoboyNo ratings yet

- AIS Over WiFi With The DT-06 ModuleDocument2 pagesAIS Over WiFi With The DT-06 ModuleAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Department of Education: Silanga National High SchoolDocument4 pagesDepartment of Education: Silanga National High SchoolNimfa SeparaNo ratings yet

- Samsung CLP-510 Series - User & Setup GuideDocument266 pagesSamsung CLP-510 Series - User & Setup GuideVlad Florescu100% (1)

- Esp32-C3 Datasheet enDocument47 pagesEsp32-C3 Datasheet enStepan BorisovichNo ratings yet

- CBRSDocument86 pagesCBRSsellabi100% (2)

- BB PlansDocument2 pagesBB PlansSilki GargNo ratings yet

- Iconverge Price ListDocument3 pagesIconverge Price ListPatrick Ramos0% (3)

- Wifi Based Led Text Scrolling Display-1Document11 pagesWifi Based Led Text Scrolling Display-1Rakesh Reddy BaddipadigeNo ratings yet

- Cosy - 131 Ref ManualDocument40 pagesCosy - 131 Ref ManualWim BoermansNo ratings yet

- Holston Modem ManualDocument323 pagesHolston Modem ManualMacT MilNo ratings yet

- CnPilot Participant GuideDocument54 pagesCnPilot Participant GuideRyan Jobel GabudaoNo ratings yet

- Icstation Com Esp8266 Wifi Channel Relay Module Rewitch Wireless Transmitter Smart Home P 134212 HTMLDocument1 pageIcstation Com Esp8266 Wifi Channel Relay Module Rewitch Wireless Transmitter Smart Home P 134212 HTMLMarck SolterNo ratings yet

- M3 SEDataSheet6 4 2012Document2 pagesM3 SEDataSheet6 4 2012Pravesh Kumar ThakurNo ratings yet

- Ip Camera Quick Installation ManualDocument10 pagesIp Camera Quick Installation ManualjankovalNo ratings yet

- Backtrack 4 and Wifi Setup For BeginnersDocument4 pagesBacktrack 4 and Wifi Setup For Beginnersbhuvi2312No ratings yet

- CSE 3711 Lecture-No. 2 (Summer 2023) - Computer Networks and The InternetDocument101 pagesCSE 3711 Lecture-No. 2 (Summer 2023) - Computer Networks and The InternetsaifulNo ratings yet

- Upload HaloP-outputDocument15 pagesUpload HaloP-outputHưng LươngNo ratings yet

- Ivrfb 06sc SH Outdoor VRF UnitDocument24 pagesIvrfb 06sc SH Outdoor VRF UnitRegan GurungNo ratings yet

- LG G2 D802 User ManualDocument124 pagesLG G2 D802 User Manualshoshon021No ratings yet

- HD Mini Cam Manual v1Document20 pagesHD Mini Cam Manual v1hlim_13No ratings yet