Professional Documents

Culture Documents

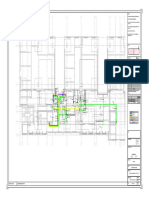

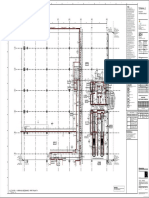

8 Mms Ga DRG at 500 MM Clearance Ground

8 Mms Ga DRG at 500 MM Clearance Ground

Uploaded by

Yashwant VermaCopyright:

Available Formats

You might also like

- Method Statement For Rotating Equipment InstallationDocument10 pagesMethod Statement For Rotating Equipment Installationคุณพ่อน้อง บิ๊กบอส100% (4)

- P&ID For Air CoolersDocument9 pagesP&ID For Air CoolersAvinash ShuklaNo ratings yet

- Ferco Doors-Fire Shutter Installation Insulated Manual Rev 01Document13 pagesFerco Doors-Fire Shutter Installation Insulated Manual Rev 01Ziaul HaqNo ratings yet

- E&I On Cable Routing LayoutDocument2 pagesE&I On Cable Routing LayoutAhmed GattoufiNo ratings yet

- P02-Abd-U06-Nu3-Ltg-Acc-5100 Abd2Document1 pageP02-Abd-U06-Nu3-Ltg-Acc-5100 Abd2mohammadNo ratings yet

- DWARAKA TIRUMALA Q-LINES Base Plate & Truss MarkingDocument1 pageDWARAKA TIRUMALA Q-LINES Base Plate & Truss MarkingVenkata Bhaskar DameraNo ratings yet

- Tab Riy Me SD DR SFL 104aDocument1 pageTab Riy Me SD DR SFL 104aamostafacandpegNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- General Notes:: 00ENB20BB001 Raw Co Storage TankDocument1 pageGeneral Notes:: 00ENB20BB001 Raw Co Storage Tankmustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- KIA B03 L&T A - BW L1 SPD 1174 1 - Comments PDFDocument1 pageKIA B03 L&T A - BW L1 SPD 1174 1 - Comments PDFVarunn VelNo ratings yet

- KIA B03 L&T A - BW L1 SPD 1174 1 - Comments PDFDocument1 pageKIA B03 L&T A - BW L1 SPD 1174 1 - Comments PDFVarunn VelNo ratings yet

- Wsd-Mkul-01-2022-Rc-001 To 004-1Document1 pageWsd-Mkul-01-2022-Rc-001 To 004-1Project ManagerStructuresNo ratings yet

- HD BoltDocument1 pageHD BoltrajamasaNo ratings yet

- Detail of Locking Rrangement of The Main Gate From Both SidesDocument1 pageDetail of Locking Rrangement of The Main Gate From Both Sidesmohammed amir aliNo ratings yet

- 8948 Rev1 Milton Wsg001 Eng Sh5 1Document1 page8948 Rev1 Milton Wsg001 Eng Sh5 1tshepo hlakudiNo ratings yet

- Kia B03 L&T A - BW L1 SPD 1171 2 PDFDocument1 pageKia B03 L&T A - BW L1 SPD 1171 2 PDFVarunn VelNo ratings yet

- MATCHLINE E 4039.000 SEE DWG. 5220-65K-001: NotesDocument1 pageMATCHLINE E 4039.000 SEE DWG. 5220-65K-001: NotesJonathanSaucedoNo ratings yet

- IQ360-000-M6-SG-00003 Rev03Document1 pageIQ360-000-M6-SG-00003 Rev03mustafa1989ocNo ratings yet

- Matchline N 8278.770 See DWG 3420-65H-007Document1 pageMatchline N 8278.770 See DWG 3420-65H-007JonathanSaucedoNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Longitudinal Section A-A View 'B': NotesDocument1 pageLongitudinal Section A-A View 'B': NotesMAULIK RAVALNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- No.20 - TBN Oil Piping 2of2Document1 pageNo.20 - TBN Oil Piping 2of2Adetunji Babatunde TaiwoNo ratings yet

- Road "B" Road "B": Thai Oil Public Company LimitedDocument1 pageRoad "B" Road "B": Thai Oil Public Company LimitedRachane NuanyaiNo ratings yet

- WSA20-MPX-04000-ME-DRG-21600002 (00) - Riser Details - Sheet 2 - SWDocument1 pageWSA20-MPX-04000-ME-DRG-21600002 (00) - Riser Details - Sheet 2 - SWAnh Khoa LeNo ratings yet

- Attachment - 2 - GA For Shop Fabricated Tanks PDFDocument3 pagesAttachment - 2 - GA For Shop Fabricated Tanks PDFShah Newaz KabirNo ratings yet

- 00-A-01i-00007 - Overall Interior Details Sheet 1 - Doors - Rev No - 1Document1 page00-A-01i-00007 - Overall Interior Details Sheet 1 - Doors - Rev No - 1Forhad HossainNo ratings yet

- WH03-JC-102 - JACK COLUMN - Rev 0Document1 pageWH03-JC-102 - JACK COLUMN - Rev 0TAMILarasuNo ratings yet

- WH03-JC-101 - JACK COLUMN - Rev 0Document1 pageWH03-JC-101 - JACK COLUMN - Rev 0TAMILarasuNo ratings yet

- General Notes:: 00ENB20BB003 Treated Co Storage TankDocument1 pageGeneral Notes:: 00ENB20BB003 Treated Co Storage Tankmustafa1989ocNo ratings yet

- Staircase Drawing - North - Sh-01 of 02Document1 pageStaircase Drawing - North - Sh-01 of 02SanjayNo ratings yet

- For Construction: PG214 PG207 PG208Document8 pagesFor Construction: PG214 PG207 PG208Dito Narendra RakasiwiNo ratings yet

- Notes: No. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadDocument1 pageNotes: No. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadANIL PLAMOOTTILNo ratings yet

- No. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadDocument1 pageNo. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadANIL PLAMOOTTILNo ratings yet

- Terminal 2: E48 E50 E53 E55 E49 E52 E51 E54Document1 pageTerminal 2: E48 E50 E53 E55 E49 E52 E51 E54waz ahmedNo ratings yet

- 25635-220-M6-0210-00001-R2 Chancadora 1Document1 page25635-220-M6-0210-00001-R2 Chancadora 1Victor Guzman PretellNo ratings yet

- VVVVDocument1 pageVVVVSanjoy SanyalNo ratings yet

- DT No. BS-30014-0 - Layout For Limestone Injection System (R1)Document2 pagesDT No. BS-30014-0 - Layout For Limestone Injection System (R1)Sukhdeb BiswakarmaNo ratings yet

- Asset Development Plan 1 (ADP-1) : 1 1 1 1 1 1 1 2 2 2 2 1 2 2 1 TotalDocument1 pageAsset Development Plan 1 (ADP-1) : 1 1 1 1 1 1 1 2 2 2 2 1 2 2 1 TotalTamil Arasu SNo ratings yet

- Structural DRGDocument1 pageStructural DRGkaushikc786No ratings yet

- Notes:: Surf. TreatmentDocument1 pageNotes:: Surf. Treatmentberliani navitasNo ratings yet

- Demin Water SystemDocument1 pageDemin Water Systemmohamed abourayaNo ratings yet

- Boundary Wall Hatisalah 20 BighaDocument1 pageBoundary Wall Hatisalah 20 Bighashouvik senNo ratings yet

- Road "A": PC PCDocument1 pageRoad "A": PC PCRachane NuanyaiNo ratings yet

- Dn107-P01a-Qbs-Pw-7004 7005 Rev00 - (BVC)Document2 pagesDn107-P01a-Qbs-Pw-7004 7005 Rev00 - (BVC)moon arainNo ratings yet

- Foundation DrawingsDocument3 pagesFoundation Drawingsحسام رسميNo ratings yet

- 01 PlinthDocument1 page01 PlinthHitesh DabhiNo ratings yet

- 2S6T 14a464 Ub PDFDocument3 pages2S6T 14a464 Ub PDFKemmerly ErazoNo ratings yet

- Approved For Construction: NotesDocument1 pageApproved For Construction: NotesamirNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Slk07-04-Fe-Igoms-Pgf-Sln-004 400 Vac Single Line Diagram 28-06-2024Document1 pageSlk07-04-Fe-Igoms-Pgf-Sln-004 400 Vac Single Line Diagram 28-06-2024Agung MaulanaNo ratings yet

- SM-J105H Esquematico Completo Anibal Garcia IrepairDocument6 pagesSM-J105H Esquematico Completo Anibal Garcia Irepairjhosseph contrerasNo ratings yet

- N OR TH: Key PlanDocument1 pageN OR TH: Key PlanArnold Ochochoque ArcosNo ratings yet

- Terminal 2: Level 4 - Retail Mezzanine - Part Plan - 54Document1 pageTerminal 2: Level 4 - Retail Mezzanine - Part Plan - 54waz ahmedNo ratings yet

- Sb62-Ig232 - Location of Spans & Tensions. Plan View. v1Document1 pageSb62-Ig232 - Location of Spans & Tensions. Plan View. v1hung.nguyenmanhNo ratings yet

- Stone Grinding Shed Detail Option-2-ModelDocument1 pageStone Grinding Shed Detail Option-2-ModelHabibur RahmanNo ratings yet

- Notes: Document Review Status (By Employer / PMC)Document1 pageNotes: Document Review Status (By Employer / PMC)Niwrati HolkarNo ratings yet

- 2411 QP SW XX DR BS53 00Document1 page2411 QP SW XX DR BS53 00Wilson UmaliNo ratings yet

- Typical Drawing of Compound WallDocument1 pageTypical Drawing of Compound WallAkshay KumarNo ratings yet

- Telecom Tower Construction ZTLDocument2 pagesTelecom Tower Construction ZTLNathaniel Williams100% (1)

- Elevation of LB-04 With RailingDocument1 pageElevation of LB-04 With RailingMahbub AlamNo ratings yet

- Joinery & MillworksDocument29 pagesJoinery & MillworksRamcy AddulamNo ratings yet

- Marine Railway Site InstallationDocument14 pagesMarine Railway Site Installationtapumonisha.navalNo ratings yet

- Falsework ManualDocument589 pagesFalsework Manualgeosherif72No ratings yet

- Wedged Piles Under Light StructuresDocument5 pagesWedged Piles Under Light StructuresKonstantin ArhipenkoNo ratings yet

- Addendum 1Document193 pagesAddendum 1Mahesh Sherkhane0% (1)

- Best Vision of Future LLC PortfolioDocument15 pagesBest Vision of Future LLC PortfolioMks MohinNo ratings yet

- Part S16 Cast in Place Concrete Piles (2008)Document3 pagesPart S16 Cast in Place Concrete Piles (2008)CK TangNo ratings yet

- Bangabandhu Sheikh Mujib Railway Bridge MansiaDocument2 pagesBangabandhu Sheikh Mujib Railway Bridge MansiaMujtanibah RojaNo ratings yet

- Procarga Catalogo CaldwellDocument28 pagesProcarga Catalogo CaldwellCenteno EduardoNo ratings yet

- 2011-Rapid Demountable Platform (RDP)Document11 pages2011-Rapid Demountable Platform (RDP)Mohd ShafiqNo ratings yet

- CD 360 Revision 2 Use of Compressive Membrane Action in Bridge Decks-WebDocument15 pagesCD 360 Revision 2 Use of Compressive Membrane Action in Bridge Decks-WebTrong TranNo ratings yet

- Sec 0 - Part 2 PDFDocument51 pagesSec 0 - Part 2 PDFDevaNo ratings yet

- Architecture TermsDocument3 pagesArchitecture TermsJoy RedolosaNo ratings yet

- Facility Design GuidelinesDocument440 pagesFacility Design GuidelinesWalid Abou HassanNo ratings yet

- Hard Hats With Higher Electrical Resistance ProtectionDocument3 pagesHard Hats With Higher Electrical Resistance ProtectionartmalemitNo ratings yet

- Retana Residence Approved DrawingsDocument31 pagesRetana Residence Approved DrawingsNova Mae RositeNo ratings yet

- Shenzhou Geosynthetics Product Lines - Great Vision Company 2019-2021Document6 pagesShenzhou Geosynthetics Product Lines - Great Vision Company 2019-2021Kyaw ThihaNo ratings yet

- Combined Pile Raft Foundation DesignDocument10 pagesCombined Pile Raft Foundation DesignMoe Oo Htun100% (2)

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Curtain Wall ItpDocument5 pagesCurtain Wall ItpYassin Derbeli100% (1)

- Prestressed Concrete: IndexDocument82 pagesPrestressed Concrete: IndexBA19ARC009 Deepali BhatiaNo ratings yet

- Second Floor Plan: T&B Master 'S Bed RoomDocument1 pageSecond Floor Plan: T&B Master 'S Bed RoomharabassNo ratings yet

- Rob S, Citadel of The Severed HandDocument1 pageRob S, Citadel of The Severed HandChristopher KindNo ratings yet

- Concise Selina Solutions Class 9 Maths Chapter 15 Construction of PolygonsDocument31 pagesConcise Selina Solutions Class 9 Maths Chapter 15 Construction of Polygonsbhaskar51178No ratings yet

- Construction ManagementDocument58 pagesConstruction Managementkrishna pillaiNo ratings yet

- Modpack Linki Oryginalne Puma145Document7 pagesModpack Linki Oryginalne Puma145jakubwid1No ratings yet

8 Mms Ga DRG at 500 MM Clearance Ground

8 Mms Ga DRG at 500 MM Clearance Ground

Uploaded by

Yashwant VermaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8 Mms Ga DRG at 500 MM Clearance Ground

8 Mms Ga DRG at 500 MM Clearance Ground

Uploaded by

Yashwant VermaCopyright:

Available Formats

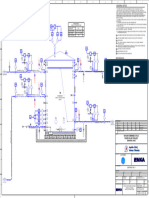

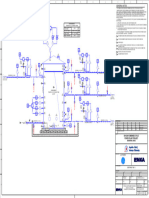

8 7 6 5 4 3 2 1

This drawing is property of SunEdison Infrastructure Limited and must not be copied without DRAWING CONVENTIONS ARE AS PER IS: 696 UNLESS AND OTHERWISE STATED 986 GENERAL NOTE:-

our consent nor made known to a third party. ALL DIMENSIONS ARE IN MILLIMETERS. 945 1. ALL DIMENSIONS ARE IN MILLIMETER (MM), UNLESS NOTED OTHERWISE.

2. GENERAL TOLERANCE IN ACCORDANCE WITH ISO 2768.

3. DIMENSIONS OF STRUCTURAL STEEL AS PER IS 811.

4030 40

9

4. ONE SET OF HARDWARE INCLUDES 1 BOLT, 1 NUT, 2 WASHERS AND 1 SPRING WASHER.

352 1700 1700 252 40

50 2Thk 5. GRADE OF CONCRETE SHALL BE M25.

14

C/C COLUMN C/C COLUMN

2Thk 6. GRADE OF BOLT FOR ALL CONNECTION SHALL BE SS-304 CLASS A2-70 & GI 5.6.

90

199

302

60

15

50

13 13 7. ALL BOLTS SHALL BE SNUG TIGHTENED AND FULL TIGHTNESS TO BE ENSURED BY 'TORQUE

1964

1360

10

6Thk WRENCH METHOD'.

D ISA 60x60x6THK

@ COLUMN

C-LIP 90X40X15X2THK

@ RAFTER

C-LIP 60X40X10X2THK

@ PURLIN

8. ROLLING AND CUTTING TOLERANCE FOR HR SHEET AS PER IS-1852:1985.

9. FABRICATION AND ERECTION SHALL BE CARRIED OUT IN ACCORDANCE WITH IS 800 AND IS 801.

D

175 10. INNER BEND RADIUS OF ALL SECTION IS '1.5XTHK'.

1964

1360

2Thk 2Thk 11. DIMENSIONS OF PLATES, FLAT BARS SHALL CONFORM TO LATEST IS 1730.

3

175 12. STRUCTURAL STEEL FOR PURLIN MEMBERS SHALL BE AS PER IS 15961 WITH MINIMUM YIELD

55

50

STRENGTH OF 550 MPA.

30 60 DETAIL - A @ PV MODULE

10 13. MARK THE CONCRETE PITS POSITION ON THE GROUND AS PER DRAWING.

70

ANGLE L 50X30X2THK

@ BRACING

ANGLE L 60X55X2THK

@ CLEAT PLATE PV WATTAGE : 330Wp 14. REMOVE THE VEGETATION/ GARBAGE /DUSTS OR ANY EXTRA COVERING AT RESPECTIVE

20

BRAND : ICON SOLAR PITS AREA.

624

125

100

PLT 175X70X3THK

@ PLATE

15. LEVEL THE GROUND SURFACE IF THE SLOPE OF THE GROUND EXCEEDS 3°.

80

16. ENSURE THE PITS MARKING ARE IN CORRECT LOCATION BEFORE STARTING DRILLING.

6 Thk.

BAR BENDING SCHEDULE

17. PIT SIZE SHALL BE UNFORM THROUGHOUT THE DEPTH.

35

18. ENSURE THE DEPTH OF PIT AS PER THE DRAWING AFTER DRILLING.

22.5

300

X2

10

12

BAR BAR DIA UNIT WT QTY TOTAL WT 19. PLEASE ENSURE THAT THERE SHOULD BE NO EXTRA MATERIAL/ SUBSTANCE/ PARTICLE IN

175

130

(mm) BENDING SHAPE (kg/m)

-Ø

12.5 6 Thk. MARK (Nos) (kg)

THE PIT BEFORE CONCRETING.

1964

1360

t

slo

1600

1 10 0.6170 24 23.675 20. REBRS SHALL BE ASSEMBLED IN A SEPARATE PLACE AND SHALL BE PLACED VERTICALLY IN

60

60

2 8 150 0.3950 42 11.601 TO THE PIT WITHOUT ANY INCLINATIONS.

25

100

50

125 35

TOTAL WEIGHT (kg) 35.28 21. USE PROPER SHUTTERING AND PLACE FOUNDATION BOLTS AS PER DESIGN.

PLT 35X60X6THK 22. SHUTTERING SHALL NOT ALLOW ANY LEAKAGES OF CONCRETE.

BAR BENDING SCHEDULE @ LA

@ STIFFENER PLATE 95 23. POUR CONCRETE MIXTURE M25 GRADE IN THE SHUTTERING BOX AFTER CHECKING THE

302

199

6 Thk.

1165 1700 1165 PLT 175X125X6THK

BAR BAR DIA UNIT WT QTY TOTAL WT ALIGNMENT OF FOUNDATION BOLTS.

@ BASE PLATE J-BOLTS - 300X95X50 (mm)

BENDING SHAPE

(kg/m) (Nos) (kg)

986 20 MARK

24. BASE PLATES SHALL BE PLACED IN SUCH A WAY THAT CENTRE LINE OF PILE AND PLATE ARE

Ø10 MM

302 1700 1700 302 SECTION PARTS 3 10 1050

0.6170 4 2.5914 IN LINE.

C/C RAFTER C/C RAFTER 25. BASE PLATES SHALL BE ALIGNED BEFORE PLACING THE STRUCTURE.

C 4 8 0.3950 5 1.5800

C

150

100

TOP VIEW 5 8 150 0.3950 2 0.1185 26. ENSURE TO MAINTAIN PROPER CONCRETE WATER CURING METHODS.

TOTAL WEIGHT (kg) 4.2899 27. ASSEMBLE THE MMS AFTER CONCRETE INITIAL SETTING TIME.

BOLTS TORQUE CHART (N.m)

Bolts size (mm)

Bolt Grade

50

PV MODULE

DETAIL - A

Ø50 M6 M8 M10 M12 M14 M16 M18 M20 M22 M24

4 9.5 19 35 50 80 110 160 215 275

200

ISA 50X50X6Th.

COLUMN-2

4.6

ISA 50X50X6Th. 5.6 4.6 11 22 39 62 95 130 184 290 315

COLUMN-2 4

196

AJB 193

5

193

5

136

0 8.8 10 25 50 85 140 215 305 435 590 750

564

1385

15 35 75 130 205 315 435 620 850 1070

200

L50X30X2Th.

BACK BRACING

L50X30X2Th.

BACK BRACING 20

CS60X40X10X2Th.

PURLIN

10.9

3000

PLATE PLATE PLATE 624 ISA 50X50X6Th. 12.9 18 45 85 150 240 370 510 725 985 1255

COLUMN-2

175X70X3THK 175X70X3THK 175X70X3THK

DIA 10mm ROD

SAG ROD L50X30X2Th. SS304 8.7 21.2 42 73 118 180 258 370 485 603

400

400

400

BACK BRACING

2168

4 LIGHTING ARRESTER

1385

PLT 60X35X6Th.

196 11

79

75

75

550

PLT 175X125X6Th. STIFFENER PLATE 0

BASE PLATE 136 3

MATERIAL SPECIFICATIONS

25

Ø65

25

Ø10 THREADED ROD, 100LG PLATE

400

CS90X40X15X2Th.

WELDED TO MAIN BAR L 60X55X2Th. RAFTER 175X70X3THK

ANGLE CLEAT L50X30X2Th.

ISA 50X50X6Th. SIDE BRACING

100

G.L G.L G.L G.L PART NO. DESCRIPTION MATERIAL FINISH

382

COLUMN-1

300

PLT 175X125X6Th.

615 PLT 60X35X6Th. BOLT M10X20mm LG BASE PLATE

STIFFENER PLATE

*DEPENDS ON SITE CONDITION

EARTHING

1425

1425

25°

Ø8 @ 200mm C\C

2 A A A A 1 COLUMN IS808 E350MPa HDG

75

4 NOS OF Ø10 STIRRUP BAR 4 NOS OF Ø10

100

1 1

500

MAIN BAR MAIN BAR Ø10 THREADED ROD, 100LG C C

25

400

WELDED TO MAIN BAR

1000*

Ø8 ROD INSERTED

G.L

4 NOS OF Ø10

MAIN BAR 1

G.L 1

4 NOS OF Ø10

G.L G.L 3

4 NOS OF Ø10

ACROSS THE DIA 5

G.L

2 COLUMN BASE PLATE IS2062 E350MPa HDG

B B

MAIN BAR MAIN BAR

M25 CONCRETE PILE

200mm X 150mm

1000

2150 B B 3 RAFTER IS2062 E350MPa HDG

0 0

*DEPENDS ON SITE CONDITION

B B B B

700

M25 CONCRETE PILE

50

50

50

200mm X 150mm

Ø8 @ 200mm C\C

2

STIRRUP BAR

4 BRACING CONNECTION PLATE IS2062 E250MPa HDG

1000*

Ø8 @ 200mm C\C

4 STIRRUP BAR

150 150 150 Ø8 @ 200mm C\C Ø8 @ 200mm C\C

50

STIRRUP BAR 2 2 STIRRUP BAR

1700 1700

C/C COLUMN C/C COLUMN

200 5 BRACING IS2062 E350MPa HDG

BACK VIEW

50

50

M25 CONCRETE PILE

200mm X 150mm

6 PURLIN IS2062 E350MPa HDG

7 CLEAT PLATE IS 2062 E250MPa HDG

SIDE VIEW

8 SAG ROD IS 1732 E250MPa HDG

9 J-BOLTS IS-730 - E250 MPA HDG

80

# 100mm GAP SHALL BE MAINTAINED BETWEEN TWO TABLE OF 2X4MMS

150

37.5 37.5

35

62.5

35 80 35 MATERIAL: AS PER DRAWING :- Ishaan Solar Power Pvt Ltd

Developer

5 FINISH: AS PER DRAWING EPC:- SunEdison Infrastructure Ltd

Ø6

4 Nos of Ø10 4 DRAWN: YRV 09-04-2021

200

130

200

200

1

130

175

3 CHECKED: RC 09-04-2021

2 APPROVED: DVSB 09-04-2021

A Ø8 @ 200 C\C A

62.5

35

125 150 1 SHEET No: 1 OF 1 SIGNED DATE

2

150 DATE AMENDMENTS SIGN REV. DRAWING NO:

VIEW C-C REV

VIEW B-B VIEW A-A SCALE TILTE SIL/TREDA/2X4MMS/GA-01 0

NTS

8 MMS GA DRG @ 500 MM CLEARANCE GROUND CUSTOMER: TREDA, TRIPURA

GENERAL FABRICATION TOLERANCE ARE CONFIRMING TO IS 7215 PROJECT: 5 KW / 10 KW SOLAR POWER PLANT

8 7 6 5 4 3 2 1

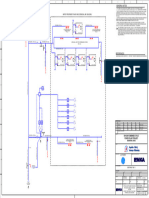

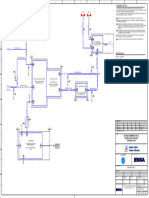

8 7 6 5 4 3 2 1

This drawing is property of SunEdison Infrastructure Limited and must not be DRAWING CONVENTIONS ARE AS PER IS: 696 UNLESS AND OTHERWISE STATED

copied without our consent nor made known to a third party. ALL DIMENSIONS ARE IN MILLIMETERS.

986

D 945 D

14

1964

1360

C C

DETAIL - A @ PV MODULE

PV WATTAGE : 330Wp

BRAND : ICON SOLAR

B B

SIDE VIEW

MATERIAL: Al. 6063 T6 Alloy

FINISH: Al. finish

SunEdison Infrastructure Ltd

4 DRAWN: YRV 09-04-2021

3 CHECKED: RC 09-04-2021

2 APPROVED: DVSB 09-04-2021

A 1 SHEET No: 1 OF 1 SIGNED DATE A

DATE AMENDMENTS SIGN REV. DRAWING NO: REV

SCALE TILTE SIL/TREDA/SHED/GA-001 1

NTS

CUSTOMER: TREDA, TRIPURA

GENERAL FABRICATION TOLERANCE ARE CONFIRMING TO IS 7215

GA ARRANGEMENT FOR AL. RAIL WITH L CLAMP OVER J-BOLT PROJECT: 5 KW / 10 KW SOLAR POWER PLANT

8 7 6 5 4 3 2 1

You might also like

- Method Statement For Rotating Equipment InstallationDocument10 pagesMethod Statement For Rotating Equipment Installationคุณพ่อน้อง บิ๊กบอส100% (4)

- P&ID For Air CoolersDocument9 pagesP&ID For Air CoolersAvinash ShuklaNo ratings yet

- Ferco Doors-Fire Shutter Installation Insulated Manual Rev 01Document13 pagesFerco Doors-Fire Shutter Installation Insulated Manual Rev 01Ziaul HaqNo ratings yet

- E&I On Cable Routing LayoutDocument2 pagesE&I On Cable Routing LayoutAhmed GattoufiNo ratings yet

- P02-Abd-U06-Nu3-Ltg-Acc-5100 Abd2Document1 pageP02-Abd-U06-Nu3-Ltg-Acc-5100 Abd2mohammadNo ratings yet

- DWARAKA TIRUMALA Q-LINES Base Plate & Truss MarkingDocument1 pageDWARAKA TIRUMALA Q-LINES Base Plate & Truss MarkingVenkata Bhaskar DameraNo ratings yet

- Tab Riy Me SD DR SFL 104aDocument1 pageTab Riy Me SD DR SFL 104aamostafacandpegNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- General Notes:: 00ENB20BB001 Raw Co Storage TankDocument1 pageGeneral Notes:: 00ENB20BB001 Raw Co Storage Tankmustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- KIA B03 L&T A - BW L1 SPD 1174 1 - Comments PDFDocument1 pageKIA B03 L&T A - BW L1 SPD 1174 1 - Comments PDFVarunn VelNo ratings yet

- KIA B03 L&T A - BW L1 SPD 1174 1 - Comments PDFDocument1 pageKIA B03 L&T A - BW L1 SPD 1174 1 - Comments PDFVarunn VelNo ratings yet

- Wsd-Mkul-01-2022-Rc-001 To 004-1Document1 pageWsd-Mkul-01-2022-Rc-001 To 004-1Project ManagerStructuresNo ratings yet

- HD BoltDocument1 pageHD BoltrajamasaNo ratings yet

- Detail of Locking Rrangement of The Main Gate From Both SidesDocument1 pageDetail of Locking Rrangement of The Main Gate From Both Sidesmohammed amir aliNo ratings yet

- 8948 Rev1 Milton Wsg001 Eng Sh5 1Document1 page8948 Rev1 Milton Wsg001 Eng Sh5 1tshepo hlakudiNo ratings yet

- Kia B03 L&T A - BW L1 SPD 1171 2 PDFDocument1 pageKia B03 L&T A - BW L1 SPD 1171 2 PDFVarunn VelNo ratings yet

- MATCHLINE E 4039.000 SEE DWG. 5220-65K-001: NotesDocument1 pageMATCHLINE E 4039.000 SEE DWG. 5220-65K-001: NotesJonathanSaucedoNo ratings yet

- IQ360-000-M6-SG-00003 Rev03Document1 pageIQ360-000-M6-SG-00003 Rev03mustafa1989ocNo ratings yet

- Matchline N 8278.770 See DWG 3420-65H-007Document1 pageMatchline N 8278.770 See DWG 3420-65H-007JonathanSaucedoNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Longitudinal Section A-A View 'B': NotesDocument1 pageLongitudinal Section A-A View 'B': NotesMAULIK RAVALNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- No.20 - TBN Oil Piping 2of2Document1 pageNo.20 - TBN Oil Piping 2of2Adetunji Babatunde TaiwoNo ratings yet

- Road "B" Road "B": Thai Oil Public Company LimitedDocument1 pageRoad "B" Road "B": Thai Oil Public Company LimitedRachane NuanyaiNo ratings yet

- WSA20-MPX-04000-ME-DRG-21600002 (00) - Riser Details - Sheet 2 - SWDocument1 pageWSA20-MPX-04000-ME-DRG-21600002 (00) - Riser Details - Sheet 2 - SWAnh Khoa LeNo ratings yet

- Attachment - 2 - GA For Shop Fabricated Tanks PDFDocument3 pagesAttachment - 2 - GA For Shop Fabricated Tanks PDFShah Newaz KabirNo ratings yet

- 00-A-01i-00007 - Overall Interior Details Sheet 1 - Doors - Rev No - 1Document1 page00-A-01i-00007 - Overall Interior Details Sheet 1 - Doors - Rev No - 1Forhad HossainNo ratings yet

- WH03-JC-102 - JACK COLUMN - Rev 0Document1 pageWH03-JC-102 - JACK COLUMN - Rev 0TAMILarasuNo ratings yet

- WH03-JC-101 - JACK COLUMN - Rev 0Document1 pageWH03-JC-101 - JACK COLUMN - Rev 0TAMILarasuNo ratings yet

- General Notes:: 00ENB20BB003 Treated Co Storage TankDocument1 pageGeneral Notes:: 00ENB20BB003 Treated Co Storage Tankmustafa1989ocNo ratings yet

- Staircase Drawing - North - Sh-01 of 02Document1 pageStaircase Drawing - North - Sh-01 of 02SanjayNo ratings yet

- For Construction: PG214 PG207 PG208Document8 pagesFor Construction: PG214 PG207 PG208Dito Narendra RakasiwiNo ratings yet

- Notes: No. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadDocument1 pageNotes: No. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadANIL PLAMOOTTILNo ratings yet

- No. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadDocument1 pageNo. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadANIL PLAMOOTTILNo ratings yet

- Terminal 2: E48 E50 E53 E55 E49 E52 E51 E54Document1 pageTerminal 2: E48 E50 E53 E55 E49 E52 E51 E54waz ahmedNo ratings yet

- 25635-220-M6-0210-00001-R2 Chancadora 1Document1 page25635-220-M6-0210-00001-R2 Chancadora 1Victor Guzman PretellNo ratings yet

- VVVVDocument1 pageVVVVSanjoy SanyalNo ratings yet

- DT No. BS-30014-0 - Layout For Limestone Injection System (R1)Document2 pagesDT No. BS-30014-0 - Layout For Limestone Injection System (R1)Sukhdeb BiswakarmaNo ratings yet

- Asset Development Plan 1 (ADP-1) : 1 1 1 1 1 1 1 2 2 2 2 1 2 2 1 TotalDocument1 pageAsset Development Plan 1 (ADP-1) : 1 1 1 1 1 1 1 2 2 2 2 1 2 2 1 TotalTamil Arasu SNo ratings yet

- Structural DRGDocument1 pageStructural DRGkaushikc786No ratings yet

- Notes:: Surf. TreatmentDocument1 pageNotes:: Surf. Treatmentberliani navitasNo ratings yet

- Demin Water SystemDocument1 pageDemin Water Systemmohamed abourayaNo ratings yet

- Boundary Wall Hatisalah 20 BighaDocument1 pageBoundary Wall Hatisalah 20 Bighashouvik senNo ratings yet

- Road "A": PC PCDocument1 pageRoad "A": PC PCRachane NuanyaiNo ratings yet

- Dn107-P01a-Qbs-Pw-7004 7005 Rev00 - (BVC)Document2 pagesDn107-P01a-Qbs-Pw-7004 7005 Rev00 - (BVC)moon arainNo ratings yet

- Foundation DrawingsDocument3 pagesFoundation Drawingsحسام رسميNo ratings yet

- 01 PlinthDocument1 page01 PlinthHitesh DabhiNo ratings yet

- 2S6T 14a464 Ub PDFDocument3 pages2S6T 14a464 Ub PDFKemmerly ErazoNo ratings yet

- Approved For Construction: NotesDocument1 pageApproved For Construction: NotesamirNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Slk07-04-Fe-Igoms-Pgf-Sln-004 400 Vac Single Line Diagram 28-06-2024Document1 pageSlk07-04-Fe-Igoms-Pgf-Sln-004 400 Vac Single Line Diagram 28-06-2024Agung MaulanaNo ratings yet

- SM-J105H Esquematico Completo Anibal Garcia IrepairDocument6 pagesSM-J105H Esquematico Completo Anibal Garcia Irepairjhosseph contrerasNo ratings yet

- N OR TH: Key PlanDocument1 pageN OR TH: Key PlanArnold Ochochoque ArcosNo ratings yet

- Terminal 2: Level 4 - Retail Mezzanine - Part Plan - 54Document1 pageTerminal 2: Level 4 - Retail Mezzanine - Part Plan - 54waz ahmedNo ratings yet

- Sb62-Ig232 - Location of Spans & Tensions. Plan View. v1Document1 pageSb62-Ig232 - Location of Spans & Tensions. Plan View. v1hung.nguyenmanhNo ratings yet

- Stone Grinding Shed Detail Option-2-ModelDocument1 pageStone Grinding Shed Detail Option-2-ModelHabibur RahmanNo ratings yet

- Notes: Document Review Status (By Employer / PMC)Document1 pageNotes: Document Review Status (By Employer / PMC)Niwrati HolkarNo ratings yet

- 2411 QP SW XX DR BS53 00Document1 page2411 QP SW XX DR BS53 00Wilson UmaliNo ratings yet

- Typical Drawing of Compound WallDocument1 pageTypical Drawing of Compound WallAkshay KumarNo ratings yet

- Telecom Tower Construction ZTLDocument2 pagesTelecom Tower Construction ZTLNathaniel Williams100% (1)

- Elevation of LB-04 With RailingDocument1 pageElevation of LB-04 With RailingMahbub AlamNo ratings yet

- Joinery & MillworksDocument29 pagesJoinery & MillworksRamcy AddulamNo ratings yet

- Marine Railway Site InstallationDocument14 pagesMarine Railway Site Installationtapumonisha.navalNo ratings yet

- Falsework ManualDocument589 pagesFalsework Manualgeosherif72No ratings yet

- Wedged Piles Under Light StructuresDocument5 pagesWedged Piles Under Light StructuresKonstantin ArhipenkoNo ratings yet

- Addendum 1Document193 pagesAddendum 1Mahesh Sherkhane0% (1)

- Best Vision of Future LLC PortfolioDocument15 pagesBest Vision of Future LLC PortfolioMks MohinNo ratings yet

- Part S16 Cast in Place Concrete Piles (2008)Document3 pagesPart S16 Cast in Place Concrete Piles (2008)CK TangNo ratings yet

- Bangabandhu Sheikh Mujib Railway Bridge MansiaDocument2 pagesBangabandhu Sheikh Mujib Railway Bridge MansiaMujtanibah RojaNo ratings yet

- Procarga Catalogo CaldwellDocument28 pagesProcarga Catalogo CaldwellCenteno EduardoNo ratings yet

- 2011-Rapid Demountable Platform (RDP)Document11 pages2011-Rapid Demountable Platform (RDP)Mohd ShafiqNo ratings yet

- CD 360 Revision 2 Use of Compressive Membrane Action in Bridge Decks-WebDocument15 pagesCD 360 Revision 2 Use of Compressive Membrane Action in Bridge Decks-WebTrong TranNo ratings yet

- Sec 0 - Part 2 PDFDocument51 pagesSec 0 - Part 2 PDFDevaNo ratings yet

- Architecture TermsDocument3 pagesArchitecture TermsJoy RedolosaNo ratings yet

- Facility Design GuidelinesDocument440 pagesFacility Design GuidelinesWalid Abou HassanNo ratings yet

- Hard Hats With Higher Electrical Resistance ProtectionDocument3 pagesHard Hats With Higher Electrical Resistance ProtectionartmalemitNo ratings yet

- Retana Residence Approved DrawingsDocument31 pagesRetana Residence Approved DrawingsNova Mae RositeNo ratings yet

- Shenzhou Geosynthetics Product Lines - Great Vision Company 2019-2021Document6 pagesShenzhou Geosynthetics Product Lines - Great Vision Company 2019-2021Kyaw ThihaNo ratings yet

- Combined Pile Raft Foundation DesignDocument10 pagesCombined Pile Raft Foundation DesignMoe Oo Htun100% (2)

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Curtain Wall ItpDocument5 pagesCurtain Wall ItpYassin Derbeli100% (1)

- Prestressed Concrete: IndexDocument82 pagesPrestressed Concrete: IndexBA19ARC009 Deepali BhatiaNo ratings yet

- Second Floor Plan: T&B Master 'S Bed RoomDocument1 pageSecond Floor Plan: T&B Master 'S Bed RoomharabassNo ratings yet

- Rob S, Citadel of The Severed HandDocument1 pageRob S, Citadel of The Severed HandChristopher KindNo ratings yet

- Concise Selina Solutions Class 9 Maths Chapter 15 Construction of PolygonsDocument31 pagesConcise Selina Solutions Class 9 Maths Chapter 15 Construction of Polygonsbhaskar51178No ratings yet

- Construction ManagementDocument58 pagesConstruction Managementkrishna pillaiNo ratings yet

- Modpack Linki Oryginalne Puma145Document7 pagesModpack Linki Oryginalne Puma145jakubwid1No ratings yet