Professional Documents

Culture Documents

Asterix 750

Asterix 750

Uploaded by

Thomas RisingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asterix 750

Asterix 750

Uploaded by

Thomas RisingCopyright:

Available Formats

TECHNICAL INFORMATION

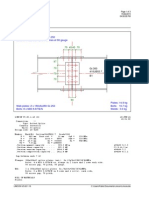

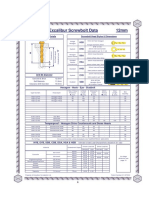

ASTERIX Aluminium Scaffold Beam

Image Description Weight

ASTERIX Aluminium beam 0.75x1m 6.94

ASTERIX Aluminium beam 0.75x2m 12.72

ASTERIX Aluminium beam 0.75x3m 18.49

ASTERIX Aluminium beam 0.75x4m 24.27

ASTERIX Aluminium beam 0.75x5m 30.04

ASTERIX Aluminium beam 0.75x6m 35.82

D78 Spigot 6HS 0.72

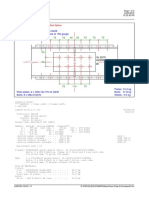

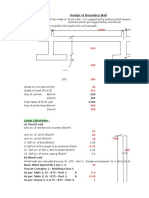

Cross section: Puncheon locations: Connections:

Cx: 2.415 cm BS0005

Cz: 37.52 cm

Ax: 12.3 cm2 BS000

Ixx: 15195.9 cm4

Izz: 29.9 cm4

BS000

Permissible bending moment (kNm):

Joint, 1 bolt each side, all lacing intervals(not reommended) :- 17.20

Joint, 2 bolts each side, all lacing intervals :- 34.20

Joint, 3 bolts each side, all lacing intervals :- 51.30

Beam, compression chord lacing at 1.0m c/c(See Note 9) :- 41.34 * requires 6 bolts total at each joint

Beam, compression chord lacing at 1.2m c/c(See Note 9) :- 35.60 * requires 6 bolts total at each joint

Permissible shear force (kN):

All restraint intervals :- 37.57

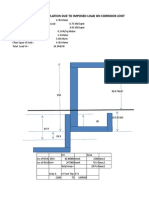

Compression chord lacing at 1.0-1.3m c/c(See note 8) :- Span (m)

4.0 6.0 8.0 10.0 12.0

Uniform Load (kN/m) 25.05 13.20 6.72 4.05 2.26

Deflection (mm) 7.85 20.95 33.69 49.58 57.42

Single point load at mid span (kN) 55.12 33.01 23.52 18.23 13.57

Deflection (mm) 6.91 13.97 23.58 35.70 45.94

Two point loads at third spans (kN) 37.57 24.76 17.64 13.67 10.18

Deflection (mm) 8.02 17.85 30.13 45.61 58.70

Three point load at quarter spans (kN) 25.05 16.51 11.76 9.11 6.79

Deflection (mm) 7.46 16.58 28.00 42.39 54.55

Maximum single point load limited to 29.5kN across all load conditions.

Notes:

1. Safe load data given for guidance only and assumes simple supports each end.

2. This TI sheet is to be read in conjunction with the ASTERIX User Guide.

3. Data provided is calculated in accordance with EN 1999 and factored to EN 12811.

4. Data provided assumes spigoted connections using steel spigot BS0005.

5. All spigoted connections secured using quick release pin AF0001 or G8.8 M12x60 Bolt with nut AF0007

6. All loads must be applied within 150mm from a node point.

7. All supports must have a minimum width of 35mm.

8. Lacing tubes must be connected using a minimum 3kN connection.

9. For 4 bolt connections joint moment is decisive. Higher values may only be used where joint positions can be planned.

TI 003-K12-01

You might also like

- Purlin & Sagrod Design (NSCP 2015)Document4 pagesPurlin & Sagrod Design (NSCP 2015)Jake Cortez67% (3)

- Examen FinalDocument16 pagesExamen FinalMario MerinoNo ratings yet

- Instructions For Using SimpleDyno 6.5Document40 pagesInstructions For Using SimpleDyno 6.5maxdan11167% (3)

- Topqm Infoservice New Cqi 9 4.edition 2020 v001 enDocument6 pagesTopqm Infoservice New Cqi 9 4.edition 2020 v001 enDFLQMS50% (2)

- Purlin & Sagrod Design (NSCP 2015)Document7 pagesPurlin & Sagrod Design (NSCP 2015)Glaizel Morcilla0% (1)

- Asterix HD - 1328Document1 pageAsterix HD - 1328Thomas RisingNo ratings yet

- RC 1616 Beam Tabulated ReportDocument6 pagesRC 1616 Beam Tabulated Reportperunding thdNo ratings yet

- PDF For 450mm Aluminium BeamsDocument1 pagePDF For 450mm Aluminium BeamsantoninoNo ratings yet

- Connections UB457 191x98xconnDocument3 pagesConnections UB457 191x98xconnihpeterNo ratings yet

- 10MT Gantry DesignDocument7 pages10MT Gantry Designvinit soodNo ratings yet

- TugasDocument12 pagesTugasArifNo ratings yet

- PadfootDocument3 pagesPadfootfazila fauzi100% (1)

- Design Data: 1.hydrodynamic CoefficientDocument8 pagesDesign Data: 1.hydrodynamic CoefficientIrfan Muhammad YusufNo ratings yet

- Graduation Project Ps 1Document55 pagesGraduation Project Ps 1Himanshu SauravNo ratings yet

- 500 m3 Cylindrical Tank - SampleDocument18 pages500 m3 Cylindrical Tank - SamplechrisNo ratings yet

- Unnamed2 HEA280Document3 pagesUnnamed2 HEA280SerkanAydoğduNo ratings yet

- Geometric Properties: Ed C, RDDocument1 pageGeometric Properties: Ed C, RDAnonymous qEPNPwANo ratings yet

- Killarney Brick & Block 170 Singles Rev 01Document2 pagesKillarney Brick & Block 170 Singles Rev 01Forbes KambaNo ratings yet

- Design Tables R00Document4 pagesDesign Tables R00maheshbandham100% (1)

- Deck SlabDocument10 pagesDeck SlabArun EthirajNo ratings yet

- Box Girder DesignDocument13 pagesBox Girder DesignAbdulaziz Al-ghamdiNo ratings yet

- Column DesignDocument22 pagesColumn DesignMuhammad Atif IqbalNo ratings yet

- Hamt K: 1 Basic ParameterDocument7 pagesHamt K: 1 Basic ParameterVenkatesha HebbarNo ratings yet

- Coverspan 750 Beams DataDocument1 pageCoverspan 750 Beams DataAlbion RoverNo ratings yet

- Axis: 1 Storey: 2: Bending (Top Edge) ..Document33 pagesAxis: 1 Storey: 2: Bending (Top Edge) ..okechukwu1benjaminNo ratings yet

- Working Stress Design Topic 1.1Document16 pagesWorking Stress Design Topic 1.1ONIFA NAHYOMI ELLOISA M.No ratings yet

- FOUNDATION DESIGN Cantilever RoofDocument9 pagesFOUNDATION DESIGN Cantilever RoofswapnilNo ratings yet

- Unnamed Gornja GredaDocument7 pagesUnnamed Gornja GredasehmediaNo ratings yet

- Rafi - PDF Base PlateDocument3 pagesRafi - PDF Base PlatemohamedNo ratings yet

- Crane Girder Design Sheet - ASD 2005Document36 pagesCrane Girder Design Sheet - ASD 2005Panha Menh100% (4)

- Design Calculation For 9 MM Fibrous Plaster CeilingDocument13 pagesDesign Calculation For 9 MM Fibrous Plaster CeilingNur Fadzlini RamliNo ratings yet

- Midasit: 1. General InformationDocument7 pagesMidasit: 1. General InformationKomiNo ratings yet

- 25m Single Lane Bridge Design Calculations LatestDocument23 pages25m Single Lane Bridge Design Calculations Latestdravinonares100% (1)

- Design of R.C.C Column Footing: Input DetailsDocument15 pagesDesign of R.C.C Column Footing: Input DetailsAbilaash VelumaniNo ratings yet

- Lang and Fulton Loading Tables Electrofused GratingsDocument3 pagesLang and Fulton Loading Tables Electrofused GratingsAlessandro NavachNo ratings yet

- Deflection Calculation Due To Imposed Load On Corridor JoistDocument14 pagesDeflection Calculation Due To Imposed Load On Corridor JoistranjitNo ratings yet

- 25m Single Lane Bridge Design Calculations LatestDocument30 pages25m Single Lane Bridge Design Calculations LatestklynchelleNo ratings yet

- Slab Design Calculation PDFDocument2 pagesSlab Design Calculation PDFRandy ViolaNo ratings yet

- FinalDocument42 pagesFinalVishnu Kumar0% (1)

- Limcon SpliceDocument3 pagesLimcon SpliceconorkellysligoNo ratings yet

- Beam ReportDocument64 pagesBeam ReportOkechukwu BenjaminNo ratings yet

- Bolt Group Analysis and Anchor Bolt ResisitanceDocument3 pagesBolt Group Analysis and Anchor Bolt ResisitancebereketNo ratings yet

- Cellular Beam L 9MDocument15 pagesCellular Beam L 9MAnh KyNo ratings yet

- Cable Ladder Support System Me Catalog Css 19 - 91Document1 pageCable Ladder Support System Me Catalog Css 19 - 91novo orderNo ratings yet

- Juja RCBeamDes22Document36 pagesJuja RCBeamDes22derichanzuNo ratings yet

- Experiment 04: Behaviour of Reinforced Concrete Beams Under TorsionDocument10 pagesExperiment 04: Behaviour of Reinforced Concrete Beams Under TorsionKhimavathBharathNaikNo ratings yet

- Bare Aluminium Conductors AAC According To UNE 21018Document7 pagesBare Aluminium Conductors AAC According To UNE 21018Mary MaNo ratings yet

- Column DesignDocument20 pagesColumn DesignSaman AdelNo ratings yet

- (123doc) BTL Ket Cau ThepDocument50 pages(123doc) BTL Ket Cau ThepTrương Ngọc TraiNo ratings yet

- Design of Steel Batten Column: Grid ID K4 1.0 Sectional PropertiesDocument7 pagesDesign of Steel Batten Column: Grid ID K4 1.0 Sectional PropertiesBijay ThapaNo ratings yet

- F3 (Fact.) F3 (Unfact.) Joint Label Unique Name Load Case/ComboDocument29 pagesF3 (Fact.) F3 (Unfact.) Joint Label Unique Name Load Case/ComboKhim KhadkaNo ratings yet

- PCV CableDocument12 pagesPCV CableMahamud MusaNo ratings yet

- PVC and XLPE Cable Current RatingDocument25 pagesPVC and XLPE Cable Current RatingMahamud MusaNo ratings yet

- Connection DesignDocument17 pagesConnection Designrekcah ehtNo ratings yet

- Boundray Wall Design Data Ganj BasodaDocument6 pagesBoundray Wall Design Data Ganj BasodaShubham KhareNo ratings yet

- Roof Beam Design CalculationDocument11 pagesRoof Beam Design CalculationArnold VercelesNo ratings yet

- Second Floor Beam Design SummaryDocument14 pagesSecond Floor Beam Design SummaryREC ALFONSO CINCONo ratings yet

- 230 600 3.975 S2 Shorter Edge S5 Shorter Edge: Mulim 0.36 FCK B Xulim (d-0.42 Xulim)Document4 pages230 600 3.975 S2 Shorter Edge S5 Shorter Edge: Mulim 0.36 FCK B Xulim (d-0.42 Xulim)Mustafa RupawalaNo ratings yet

- Siwes PresentationDocument21 pagesSiwes PresentationmelskureNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- WPHL 18 021 02Document1 pageWPHL 18 021 02Thomas RisingNo ratings yet

- Invoice (1604 13478)Document6 pagesInvoice (1604 13478)Thomas RisingNo ratings yet

- Bridging and FanDocument1 pageBridging and FanThomas RisingNo ratings yet

- 3856 54873 Vr+access+28pp+a5Document28 pages3856 54873 Vr+access+28pp+a5Thomas RisingNo ratings yet

- Licence For Alterations 3rd FloorDocument25 pagesLicence For Alterations 3rd FloorThomas RisingNo ratings yet

- 09 00975 Lbcalt-Location Plan-335380Document1 page09 00975 Lbcalt-Location Plan-335380Thomas RisingNo ratings yet

- Brace LoadingsDocument1 pageBrace LoadingsThomas RisingNo ratings yet

- 16 10598 Full-1190 A 025 001 P0 Existing Basement Plan-4544108Document1 page16 10598 Full-1190 A 025 001 P0 Existing Basement Plan-4544108Thomas RisingNo ratings yet

- 300Z Specsheet2-43Document56 pages300Z Specsheet2-43Thomas Rising100% (1)

- Asterix HD - 1328Document1 pageAsterix HD - 1328Thomas RisingNo ratings yet

- 16 MMDocument1 page16 MMThomas RisingNo ratings yet

- 12 MMDocument1 page12 MMThomas RisingNo ratings yet

- Brisko Ringlok V0.2Document35 pagesBrisko Ringlok V0.2Thomas RisingNo ratings yet

- Manual - HAKI Universal S4 AL - INTDocument28 pagesManual - HAKI Universal S4 AL - INTThomas RisingNo ratings yet

- SCP U HeadsDocument1 pageSCP U HeadsThomas RisingNo ratings yet

- 1300xbeam TechsheetDocument3 pages1300xbeam TechsheetThomas RisingNo ratings yet

- Cranepads Catv1Document6 pagesCranepads Catv1Thomas RisingNo ratings yet

- AST BracketDocument1 pageAST BracketThomas RisingNo ratings yet

- Uc Boyutlu Baglanma Stilleri Olcegi ToadDocument21 pagesUc Boyutlu Baglanma Stilleri Olcegi Toad4sq8vnbsv2No ratings yet

- Dmitri Wright Artist Statement(s)Document3 pagesDmitri Wright Artist Statement(s)Marko DjuricaNo ratings yet

- Cohen 1967Document14 pagesCohen 1967Easa YahiyaNo ratings yet

- Original Paper of Dammann Opt Commun 1971Document4 pagesOriginal Paper of Dammann Opt Commun 1971Raghvendra PratapNo ratings yet

- T00 MasterFrame Getting Started Tutorial PDFDocument36 pagesT00 MasterFrame Getting Started Tutorial PDFJEMAYERNo ratings yet

- Review of Economics Rules: The Rights and Wrongs of The Dismal ScienceDocument4 pagesReview of Economics Rules: The Rights and Wrongs of The Dismal ScienceTalhaNo ratings yet

- Wa0000.Document2 pagesWa0000.Bonga percyNo ratings yet

- English For Scie Nce and Techno LogyDocument15 pagesEnglish For Scie Nce and Techno Logynur ainun lubisNo ratings yet

- Option d1 PagesDocument9 pagesOption d1 PagesMohammad SuliemanNo ratings yet

- Dalumpines Case 3Document9 pagesDalumpines Case 3Jessa Mae LabinghisaNo ratings yet

- E C O - P R I N T I N G - 2 0 2 3 - Compressed - Compressed PDFDocument32 pagesE C O - P R I N T I N G - 2 0 2 3 - Compressed - Compressed PDFguru jiNo ratings yet

- Sadomasochism Accor Sadomasochism According To Freud's Psychosexual Stages of Chosexual Stages of Development TheoryDocument10 pagesSadomasochism Accor Sadomasochism According To Freud's Psychosexual Stages of Chosexual Stages of Development TheoryDolce BbNo ratings yet

- 3189 PDFDocument5 pages3189 PDFVln SekharNo ratings yet

- Cabinet Thermal Solutions: Web: EmailDocument8 pagesCabinet Thermal Solutions: Web: EmailXiaofeng XuNo ratings yet

- ST2133 ASDT 2021 GuideDocument242 pagesST2133 ASDT 2021 GuideZainab RiazNo ratings yet

- Dynamic Flow Products Pvt. LTDDocument3 pagesDynamic Flow Products Pvt. LTDThee BouyyNo ratings yet

- RM 201 Exercise No. 1Document3 pagesRM 201 Exercise No. 1Audrey Kristina MaypaNo ratings yet

- Revision 7Document2 pagesRevision 7aZriey ajizzzNo ratings yet

- Environmental Management - Sagmon ReportDocument10 pagesEnvironmental Management - Sagmon Reportjellian sagmonNo ratings yet

- RCPA Strategic PlanDocument16 pagesRCPA Strategic PlanAleka SevilleNo ratings yet

- Rational Numbers: Pre-RequisitesDocument74 pagesRational Numbers: Pre-RequisitesBestowal Infotechs 2018No ratings yet

- CPCCCA3025 PresentationDocument34 pagesCPCCCA3025 PresentationPranay BansalNo ratings yet

- Sampling Distribution and Simulation in RDocument10 pagesSampling Distribution and Simulation in RPremier PublishersNo ratings yet

- Draft of Research PaperDocument13 pagesDraft of Research Paperapi-744867091No ratings yet

- 385W PERC Module: JAM72S01 365-385/PRDocument2 pages385W PERC Module: JAM72S01 365-385/PRAmreican PrideNo ratings yet

- Belden 9842 Data SheetDocument2 pagesBelden 9842 Data SheetFranklin GuillenNo ratings yet

- Analysis of AAC Precast Lintels Embedded in Walls Different ConstructionDocument10 pagesAnalysis of AAC Precast Lintels Embedded in Walls Different ConstructionselegaNo ratings yet