Professional Documents

Culture Documents

Collier de Serrage MIKAFOR

Collier de Serrage MIKAFOR

Uploaded by

Aimé MEDOUSOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Collier de Serrage MIKAFOR

Collier de Serrage MIKAFOR

Uploaded by

Aimé MEDOUSCopyright:

Available Formats

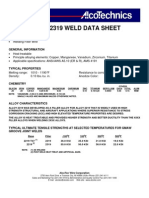

Supra Heavy-Duty Hose

W2 Clamp Stainless Steel

High Pressure series

Supra Heavy-duty hose clamp W2

Ø Application Reference r e a b Max. Values* Max. Values* Box Packing

Information d mm W2 Torque (Nm) Pressure (Bars) Quantity

The Supra range is the natural 17-19 03019012 M6 8 18 +0,2 19,8 10 45 50 400

evolution of the Super W1 19-21 03019020 M6 8 18 +0,2 19,8 10 45 50 400

Clamp. Due to its revolutionary 21-23 03019039 M6 8 18 +0,2 19,8 10 45 50 400

swiveling bridge, Supra W2 can 23-25 03019047 M6 8 18 +0,2 19,8 10 45 50 400

be mounted in the most 25-27 03019055 M6 8 18 +0,2 19,8 10 45 50 400

awkward applications without 27-29 03019063 M6 8 18 +0,2 19,8 10 45 50 200

having to remove the hose. It 29-31 03019071 M7 10 20 +0,3 22 13 40 50 50

can be opened up and fastened 31-34 03019080 M7 10 20 +0,3 22 13 40 50 50

again when in place without

34-37 03019098 M7 10 20 +0,3 22 13 40 50 50

dislodging any other parts of the

37-40 03019100 M7 10 20 +0,3 22 13 40 50 50

clamp, making assembly much

easier. 40-43 03019119 M7 10 20 +0,3 22 13 40 50 50

Thanks to the beveled edges, 43-47 03019127 M7 10 20 +0,3 22 16 36 50 50

the hose is protected from 47-51 03019135 M7 10 20 +0,3 22 16 36 50 50

damage. The Supra W2 clamp 51-55 03019143 M7 10 20 +0,3 22 16 36 25 25

complies fully with the RoHs 55-59 03019151 M7 10 20 +0,3 22 16 36 25 25

directive EU 20032/95/EC dated 59-63 03019160 M7 10 20 +0,3 22 16 36 25 25

1st July 2006. 63-68 03019178 M7 10 20 +0,3 22 16 36 25 25

The high-strength bolt, designed 68-73 03019186 M8 13 25 +0,4 27,5 30 28 25 25

and manufactured by Mikalor 73-79 03019194 M8 13 25 +0,4 27,5 30 28 25 25

specifically for this clamp, 79-85 03019207 M8 13 25 +0,4 27,5 30 28 25 25

together with the captive nut and 85-91 03019215 M8 13 25 +0,4 27,5 30 20 25 25

spacer system allow you to 91-97 03019223 M8 13 25 +0,4 27,5 30 20 25 25

clamp the most demanding of 97-104 03019231 M8 13 25 +0,4 27,5 30 20 25 25

hose assemblies. 104-112 03019240 M8 13 25 +0,4 27,5 30 12 25 25

This is the clamp of choice for 112-121 03019258 M8 13 25 +0,4 27,5 30 12 25 25

professionals in the industrial

121-130 03019266 M8 13 25 +0,4 27,5 30 12 25 25

hose, automotive and agricultural

130-140 03019274 M10 15 28 +0,4 31 45 9 10 10

machinery sectors as well as in

all industrial applications where 140-150 03019282 M10 15 28 +0,4 31 45 9 10 10

an outstanding and above all 150-162 03019290 M10 15 28 +0,4 31 45 9 10 10

reliable heavy-duty clamp is 162-174 03019303 M10 15 28 +0,4 31 45 6 10 10

required. 174-187 03019311 M10 15 28 +0,4 31 45 6 10 10

187-200 03019320 M10 15 28 +0,4 31 45 6 10 10

*The maximum application pressure 200-213 03019338 M10 15 28 +0,4 31 45 3 10 10

can vary depending on the type of hose 213-226 03019346 M10 15 28 +0,4 31 45 3 10 10

used and the geometry of the coupling. 226-239 03019354 M10 15 28 +0,4 31 45 3 10 10

Patented Worldwide 239-252 03019362 M10 15 28 +0,4 31 45 3 10 10

b

e

W2 Materials

r 8.8

Band and Bridge:

X6Cr17 Stainless steel

(DIN 1.4016) (AISI-430)

Ød

SECTION A-A

Bolt:

Qst 36-3 Mild steel 43-47

Pat. A

(DIN 1.0213)

Silver-white Cr3 Zinc-Plated

A a

45

You might also like

- Terberg 2Document385 pagesTerberg 2hoi83% (6)

- Parts Manual Serial No 23124Document200 pagesParts Manual Serial No 23124Cesar Augusto Aquino100% (1)

- Mikalor Clamp TableDocument2 pagesMikalor Clamp TableRini Agnesty SkbNo ratings yet

- Truma Spare PartsDocument56 pagesTruma Spare PartsZoran Prokic100% (1)

- Supra ClampDocument6 pagesSupra ClampManh Tien NgoNo ratings yet

- Collier MIKALOR W4Document1 pageCollier MIKALOR W4Aimé MEDOUSNo ratings yet

- Mikalor Supra W4 Bolt ClampDocument2 pagesMikalor Supra W4 Bolt ClampJai BhandariNo ratings yet

- 511147-200 SPM20CE sn00000 E.P REV2Document46 pages511147-200 SPM20CE sn00000 E.P REV2XXXNinjabeastNo ratings yet

- Yanmar Special Tool Yanmar 6n330Document9 pagesYanmar Special Tool Yanmar 6n330boris345678No ratings yet

- Valvula Elevacion CofreDocument2 pagesValvula Elevacion CofreJaime JimenezNo ratings yet

- Linde Service GuideDocument3 pagesLinde Service GuideMário AndradeNo ratings yet

- HoseClip Mikalor SupraDocument2 pagesHoseClip Mikalor Supraali.baydar1907No ratings yet

- Ersatzteilliste SD20 Bis SD185 enDocument5 pagesErsatzteilliste SD20 Bis SD185 enAswin AntonyNo ratings yet

- Linde Service GuideDocument3 pagesLinde Service GuideMário AndradeNo ratings yet

- SDG100S 3a1 3a5Document66 pagesSDG100S 3a1 3a5КонстантинNo ratings yet

- Sectional SVP Platen E BarDocument1 pageSectional SVP Platen E Barbruno franco di domenico di domenicoNo ratings yet

- IPM III MultiDocument57 pagesIPM III MultigalateaciclesNo ratings yet

- P4 Stretcher Tail SpareDocument10 pagesP4 Stretcher Tail Spareguptatanmay102No ratings yet

- HFO PurifierDocument12 pagesHFO PurifiervishakNo ratings yet

- Testes Do InjetorDocument8 pagesTestes Do Injetormarco medeirosNo ratings yet

- Project Name - : RatlamDocument3 pagesProject Name - : RatlamArjun BharambeNo ratings yet

- Catalog Piese Schimb CarraroTigretrac - 4400 - HSTDocument240 pagesCatalog Piese Schimb CarraroTigretrac - 4400 - HSTDragos Voda67% (3)

- DH LM50 enDocument16 pagesDH LM50 enFINIZOLA64No ratings yet

- Din 69002Document3 pagesDin 69002Dule JovanovicNo ratings yet

- Exs 306Document21 pagesExs 306Millena FerreiraNo ratings yet

- Curtis E50 Pump Parts ListDocument8 pagesCurtis E50 Pump Parts ListrobertNo ratings yet

- каталог palfinger mbb 1000Document13 pagesкаталог palfinger mbb 1000MixaKranovoiNo ratings yet

- Mikasa MCD-218CEH Concrete CutterDocument17 pagesMikasa MCD-218CEH Concrete CutterSameh FayedNo ratings yet

- Basic Weight Reduction FD3sDocument4 pagesBasic Weight Reduction FD3sJorge Florian OrtizNo ratings yet

- 0906-0154 (Issue 6)Document2 pages0906-0154 (Issue 6)M Arshad Iqbal HarralNo ratings yet

- A 2319 TdsDocument2 pagesA 2319 TdsSyam NathNo ratings yet

- Spareparts Kesla 20rh II GB 2015 10Document121 pagesSpareparts Kesla 20rh II GB 2015 10Дмитрий ЧернеевNo ratings yet

- 124 Safety Bar Behind CabinDocument1 page124 Safety Bar Behind CabinCharaf DineNo ratings yet

- 100112-124 - Safety Bar Behind CabinDocument1 page100112-124 - Safety Bar Behind CabinCharaf DineNo ratings yet

- Деталировка CO2 - 30E3 oldDocument21 pagesДеталировка CO2 - 30E3 oldAnonymous wpUyixsjNo ratings yet

- Rawlbolt: Shield Anchor Loose BoltDocument2 pagesRawlbolt: Shield Anchor Loose BoltBappy IslamNo ratings yet

- ValveDocument7 pagesValvecarlos030476No ratings yet

- PG 450-150 Parts ManualDocument48 pagesPG 450-150 Parts ManualRobert BungalawanNo ratings yet

- Chain Saw g5200 PDFDocument18 pagesChain Saw g5200 PDFaumaNo ratings yet

- Part List Yanmar 4tnv84t-Gge Hartech, ReturnDocument6 pagesPart List Yanmar 4tnv84t-Gge Hartech, ReturnJohny WijanarkoNo ratings yet

- Parts Catalog Engine Generator SDG100S 6A6Document30 pagesParts Catalog Engine Generator SDG100S 6A6Teddy NsNo ratings yet

- Part PowerBox 20ft&40ftDocument26 pagesPart PowerBox 20ft&40ftthainarimeNo ratings yet

- MASTIL 20WHE 163966-68 G25TV-4C 10000 REF - EPMT0231 (Ord. P16M016073)Document5 pagesMASTIL 20WHE 163966-68 G25TV-4C 10000 REF - EPMT0231 (Ord. P16M016073)Neoz CuandonNo ratings yet

- Series: Single Stage Reciprocating CompressorDocument8 pagesSeries: Single Stage Reciprocating CompressorrobertNo ratings yet

- Din 6316Document2 pagesDin 6316Dule JovanovicNo ratings yet

- Sdg100as 3a6Document36 pagesSdg100as 3a6КонстантинNo ratings yet

- Unit Iza DoraDocument118 pagesUnit Iza DoraMarcos DanielNo ratings yet

- YRG074 Root Grapple Part ManualDocument2 pagesYRG074 Root Grapple Part ManualOmar MalervaNo ratings yet

- ENmkb 237191 000 ENDocument20 pagesENmkb 237191 000 ENmohammadNo ratings yet

- CS440-01 SPC R223.1337-01Document26 pagesCS440-01 SPC R223.1337-01jorge geovanni ordenes avalosNo ratings yet

- 201PO OthersDocument9 pages201PO Otherschella sankarNo ratings yet

- 900201-357 - Hydraulic SystemDocument1 page900201-357 - Hydraulic SystemCharaf EddineNo ratings yet

- VishalDocument3 pagesVishalPrince MittalNo ratings yet

- DL 450CRDocument17 pagesDL 450CRkhanhphanNo ratings yet

- Ac Series - 10 Seer - X3 3Ph Split Air Conditioner Fourth Generation (Style A)Document2 pagesAc Series - 10 Seer - X3 3Ph Split Air Conditioner Fourth Generation (Style A)Armando Corral BlancoNo ratings yet

- PDS655S 404 405Document59 pagesPDS655S 404 405Naing Min HtunNo ratings yet

- Hydrualic Pump and RockShaftDocument4 pagesHydrualic Pump and RockShaftrajkiran_rajNo ratings yet

- WIDOS 001/2013: 05.40.50/00 HYDR. HOSES SIDE Conveyor 4Document1 pageWIDOS 001/2013: 05.40.50/00 HYDR. HOSES SIDE Conveyor 4minhkhoinguyen0923No ratings yet

- Linde E15 324-1989Document3 pagesLinde E15 324-1989Ionut GrozaNo ratings yet

- MSR Oven 3 MiesterhorstDocument3 pagesMSR Oven 3 MiesterhorstMohammed KhanNo ratings yet

- MikauDocument4 pagesMikauSanju BangshiNo ratings yet

- General Catalogue Push Fittings RC 0135ENDocument12 pagesGeneral Catalogue Push Fittings RC 0135ENwodrNo ratings yet

- Design of Three Cell RCC Box Type Viaduct/ Minor Bridge MNB-02 at Chainage 19+324Document78 pagesDesign of Three Cell RCC Box Type Viaduct/ Minor Bridge MNB-02 at Chainage 19+324Mrinal Koyal100% (1)

- Form Pendaftaran Dan Penilaian ChsemsDocument11 pagesForm Pendaftaran Dan Penilaian ChsemsFansyuri IlhamNo ratings yet

- 1200 - 6 - Refractory Work PDFDocument8 pages1200 - 6 - Refractory Work PDFmangeshshinde124No ratings yet

- Pitzl - Design Manual Connectors - HVP Connectors, SPP ConnectorsDocument32 pagesPitzl - Design Manual Connectors - HVP Connectors, SPP ConnectorsStefan IonitaNo ratings yet

- Side Wall VerificationDocument19 pagesSide Wall Verificationkheang amgNo ratings yet

- Design Cal For Rigid PavementDocument6 pagesDesign Cal For Rigid PavementrachanaNo ratings yet

- Turbomax Vuw 242Document60 pagesTurbomax Vuw 242yo8rmhNo ratings yet

- Ground Floor PlanDocument1 pageGround Floor PlanAnkit SandhuNo ratings yet

- Kei Industries Limited (Mumbai)Document13 pagesKei Industries Limited (Mumbai)anirban 007No ratings yet

- Piping Plans Pocket Guide HorizontalDocument49 pagesPiping Plans Pocket Guide Horizontalmuho1No ratings yet

- Pattern MaterialsDocument16 pagesPattern MaterialsMani Kandan100% (1)

- Étude Expérimentale Des Systèmes de Planchers Composites Acier-Bois Formés À FroidDocument6 pagesÉtude Expérimentale Des Systèmes de Planchers Composites Acier-Bois Formés À Froiddiablo kouamNo ratings yet

- Impacts of Delays in Project Completion in Terms of Time and CostDocument6 pagesImpacts of Delays in Project Completion in Terms of Time and CostIJRASETPublicationsNo ratings yet

- C&W HAND BOOK-27.03.2015 - With HeadingDocument464 pagesC&W HAND BOOK-27.03.2015 - With Headingjoby100% (2)

- Unit 3 - 1 - Design of Spur and Helical GearsDocument41 pagesUnit 3 - 1 - Design of Spur and Helical GearsY20me135 V.LokeshNo ratings yet

- BMC 4 - Expansion JointsDocument12 pagesBMC 4 - Expansion JointsKreya PatelNo ratings yet

- DSR Electrical 2012Document60 pagesDSR Electrical 2012vijay_raina31140% (1)

- CSL FinalDocument24 pagesCSL FinalArun Meda0% (1)

- Fastener ListDocument9 pagesFastener ListMani Rathinam RajamaniNo ratings yet

- Flour Milling Part IDocument24 pagesFlour Milling Part ILeo_1982100% (1)

- Purlin Cleat 220908Document24 pagesPurlin Cleat 220908kalpanaadhi100% (2)

- Durability of Concrete ArticleDocument2 pagesDurability of Concrete ArticleShahab SadeghpourNo ratings yet

- Inside Reading Unit 5 Test: ©oxford University Press. Permission Granted To Reproduce For Classroom UseDocument3 pagesInside Reading Unit 5 Test: ©oxford University Press. Permission Granted To Reproduce For Classroom UsepeinisNo ratings yet

- Rectangular BasePlate DesignDocument13 pagesRectangular BasePlate DesignMuhammad HasanNo ratings yet

- Piping Coordination SystemsDocument28 pagesPiping Coordination Systemsfarmanali07No ratings yet

- CE2201 - Mechanics of Solids Two Mark With AnswersDocument18 pagesCE2201 - Mechanics of Solids Two Mark With AnswersBoopathi ShanmugamNo ratings yet

- Research Paper and ReportsDocument77 pagesResearch Paper and ReportsSHUBHAM NANCHENo ratings yet