Professional Documents

Culture Documents

SNG Symp2019 KBR 2 K SAAT

SNG Symp2019 KBR 2 K SAAT

Uploaded by

marraezCopyright:

Available Formats

You might also like

- Fundamentals of General Organic and Biological Chemistry 8th Edition Mcmurry Test BankDocument35 pagesFundamentals of General Organic and Biological Chemistry 8th Edition Mcmurry Test Bankadamburtonbsdqicoewy100% (31)

- Crude Oil BlendingDocument20 pagesCrude Oil Blendingnedian_2006No ratings yet

- Isoalky Process Technology,: A New Era For Alkylation With Ionic Liquid AlkylationDocument16 pagesIsoalky Process Technology,: A New Era For Alkylation With Ionic Liquid AlkylationDavid RodriguesNo ratings yet

- Refining - VALERODocument35 pagesRefining - VALERORoozbeh P100% (1)

- EXX-EME-STD-0008 - Wear Liners For Plate Work and ChutesDocument22 pagesEXX-EME-STD-0008 - Wear Liners For Plate Work and Chutesjonodo89100% (1)

- Joint Coating Application & Pipe Coating Procedure-009-RappDocument8 pagesJoint Coating Application & Pipe Coating Procedure-009-Rappgst ajahNo ratings yet

- K-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsDocument17 pagesK-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsmarraezNo ratings yet

- Refining K-Saat 2022marDocument4 pagesRefining K-Saat 2022marmarraezNo ratings yet

- KBR Olefins Technologies Jeff Caton 6826Document24 pagesKBR Olefins Technologies Jeff Caton 6826swaggeroni yololo100% (1)

- 03 Road Map Presentation ItalyDocument26 pages03 Road Map Presentation ItalyKURAF MUHENDISLIK AŞ.No ratings yet

- 10 - Adding Value With SuperflexDocument15 pages10 - Adding Value With SuperflexAbhimanyu SharmaNo ratings yet

- STLE2017 Synthetics HydraulicsDocument58 pagesSTLE2017 Synthetics HydraulicsJako MishyNo ratings yet

- CBEN409 06 CokingDocument39 pagesCBEN409 06 CokingMohammad FarooqNo ratings yet

- Class01-Refinery Overview - 2020Document23 pagesClass01-Refinery Overview - 2020Shivam Kumar RaiNo ratings yet

- TIB 2017 Broschuere Kat U P EN RZ4 LowresDocument24 pagesTIB 2017 Broschuere Kat U P EN RZ4 LowresAngel Quiroz EspinozaNo ratings yet

- The Supply Chain Impacts of Cobalt ReportingDocument17 pagesThe Supply Chain Impacts of Cobalt ReportingetsimoNo ratings yet

- Intertanko Vetting Seminar Athens - May 15, 2007: Tim Plummer President Tesoro Maritime CompanyDocument26 pagesIntertanko Vetting Seminar Athens - May 15, 2007: Tim Plummer President Tesoro Maritime CompanyProlin NanduNo ratings yet

- Technical Data Sheet: SDA-EAGLE (SX35-18/50) 60%Document1 pageTechnical Data Sheet: SDA-EAGLE (SX35-18/50) 60%Fadi Magdy0% (1)

- Abdulkader - Djellout AlgeriaDocument59 pagesAbdulkader - Djellout AlgeriasashaNo ratings yet

- Unit-7 Petroleum RefiningDocument40 pagesUnit-7 Petroleum RefiningNeeraj YadavNo ratings yet

- Calcium Sulfonate Greases For Extreme EnvironmentDocument11 pagesCalcium Sulfonate Greases For Extreme EnvironmentnagbabuiNo ratings yet

- The Growing Demand For High Vis PAO Within AsiaDocument32 pagesThe Growing Demand For High Vis PAO Within AsiaDhroov SharmaNo ratings yet

- HIMBALT Presentation 2020 ENDocument9 pagesHIMBALT Presentation 2020 ENJorge ZegarraNo ratings yet

- Fuelco Logitank BrochureDocument8 pagesFuelco Logitank Brochuremuh_akbar2451No ratings yet

- BPZ Energy PresentationDocument25 pagesBPZ Energy PresentationjimenezvegaNo ratings yet

- Libya Chemical Plants ICIS ListDocument1 pageLibya Chemical Plants ICIS ListwillbeachamNo ratings yet

- Petroleum IndustryDocument39 pagesPetroleum IndustryQuenie Rose RontalNo ratings yet

- Technical Data Sheet: SNDA-EAGLE (COCX35-97/60) 60%Document1 pageTechnical Data Sheet: SNDA-EAGLE (COCX35-97/60) 60%Fadi MagdyNo ratings yet

- FUCHS RENOLIN Industrial Gear OilsDocument18 pagesFUCHS RENOLIN Industrial Gear OilsfajarfrankyNo ratings yet

- 2015 Oil Gas RefiningDocument33 pages2015 Oil Gas RefininggustavoemirNo ratings yet

- Age 10501Document21 pagesAge 10501karimirelayNo ratings yet

- Maximising Naphtha Through Hydrocracking Refinery of The FutureDocument25 pagesMaximising Naphtha Through Hydrocracking Refinery of The FutureMustafa AhsanNo ratings yet

- FAG-Arcanol Greases PDFDocument22 pagesFAG-Arcanol Greases PDFMark DiNo ratings yet

- Drilling Fluid Systems: © 2004 Baker Hughes Incorporated All Rights ReservedDocument33 pagesDrilling Fluid Systems: © 2004 Baker Hughes Incorporated All Rights ReservedKaleem UllahNo ratings yet

- Petro Canada Lubricants Handbook 2012 English PDFDocument212 pagesPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshNo ratings yet

- World RefiningDocument7 pagesWorld RefiningmarraezNo ratings yet

- Maximizing Utilization of Light Tight Oils Economics and Technology SolutionsDocument26 pagesMaximizing Utilization of Light Tight Oils Economics and Technology SolutionsM Scott GreenNo ratings yet

- LubeBaseStock - Dec 2003Document17 pagesLubeBaseStock - Dec 2003Mely LeivaNo ratings yet

- BR02V072021 - Rymax - Productcatalogus - 2021 - NEW DESIGN ISSUUDocument52 pagesBR02V072021 - Rymax - Productcatalogus - 2021 - NEW DESIGN ISSUUSinh LeNo ratings yet

- B-1114print Essential Expertise Mining PDFDocument4 pagesB-1114print Essential Expertise Mining PDFlpbeauchamp09No ratings yet

- Finishing Agents & Specialty ChemicalsDocument4 pagesFinishing Agents & Specialty Chemicals950 911No ratings yet

- Alternatives Study For The Technical Improvement of The Campo Arce Crude Oil QualityDocument6 pagesAlternatives Study For The Technical Improvement of The Campo Arce Crude Oil QualityChechotopol12No ratings yet

- 2 - SyntheticsDocument57 pages2 - SyntheticsRay Cepeda Mena100% (1)

- Lubrication GuidelinesDocument1 pageLubrication GuidelinesBzidroglioNo ratings yet

- DCU1Document25 pagesDCU1ashutosh kumarNo ratings yet

- Howard BevanDocument11 pagesHoward Bevanxtrooz abiNo ratings yet

- Valero Energy, Benicia: - Onkar Kotpalliwar Shivam SinghDocument53 pagesValero Energy, Benicia: - Onkar Kotpalliwar Shivam SinghNikhil GargNo ratings yet

- 16 - Upgrading Olefins For Gasoline BlendingDocument21 pages16 - Upgrading Olefins For Gasoline BlendingAbhimanyu SharmaNo ratings yet

- Modeling Heavy Oils in Aspen Hysys Engineering Excellence Webinar Series 26 January 2010Document59 pagesModeling Heavy Oils in Aspen Hysys Engineering Excellence Webinar Series 26 January 2010Hafiz Muhammad AbubakarNo ratings yet

- Product - Overview - EN Antiveining CoatingDocument12 pagesProduct - Overview - EN Antiveining CoatingSachin KumbharNo ratings yet

- FUCHS ClassicRange PDFDocument12 pagesFUCHS ClassicRange PDFFahad KhalidNo ratings yet

- Refining IndustryDocument73 pagesRefining IndustryMukesh Kumar MeenaNo ratings yet

- CWI Product Information Bulletin - New Engine Oil Specification May 2016Document2 pagesCWI Product Information Bulletin - New Engine Oil Specification May 2016roger gonzales hoyosNo ratings yet

- GFS - Organic CatalogDocument148 pagesGFS - Organic Catalognamandejustine02No ratings yet

- Carbonite - A New Carbon Based Energy FuelDocument18 pagesCarbonite - A New Carbon Based Energy FuelJorge MadiasNo ratings yet

- Product SelectionDocument28 pagesProduct Selectionarisqi wahyuNo ratings yet

- Tank Linings: Protective Coatings Which Divide The Cargo From The SteelDocument5 pagesTank Linings: Protective Coatings Which Divide The Cargo From The SteelgandungNo ratings yet

- Ici Supply Chain Management Report by Ali RazaDocument36 pagesIci Supply Chain Management Report by Ali RazarafeyNo ratings yet

- Rolcer Brochure v2Document4 pagesRolcer Brochure v2Francis XavierNo ratings yet

- Technical Data Sheet: LA-EAGLE (SW61-9/55) 70%Document1 pageTechnical Data Sheet: LA-EAGLE (SW61-9/55) 70%Fadi MagdyNo ratings yet

- MechReaction Liu 2016Document26 pagesMechReaction Liu 2016marraezNo ratings yet

- Sulfuric Acid Alkylation Technology: Dr. Girish K. Chitnis Mr. Ron D. Mcgihon Mr. Aneesh Prasad Mr. Christopher M. DeanDocument18 pagesSulfuric Acid Alkylation Technology: Dr. Girish K. Chitnis Mr. Ron D. Mcgihon Mr. Aneesh Prasad Mr. Christopher M. DeanmarraezNo ratings yet

- US8105968Document24 pagesUS8105968marraezNo ratings yet

- MD AlkyClean v2Document4 pagesMD AlkyClean v2marraezNo ratings yet

- US20220144724A1Document24 pagesUS20220144724A1marraezNo ratings yet

- MSDS Zeolite 25 JAN 2019Document4 pagesMSDS Zeolite 25 JAN 2019marraezNo ratings yet

- Zeolite MsdsDocument6 pagesZeolite MsdsmarraezNo ratings yet

- K-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsDocument17 pagesK-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsmarraezNo ratings yet

- Refining K-Saat 2022marDocument4 pagesRefining K-Saat 2022marmarraezNo ratings yet

- DuplicateDocument134 pagesDuplicatemarraezNo ratings yet

- Refractory Nitrogen Compounds in Hydrocr PDFDocument6 pagesRefractory Nitrogen Compounds in Hydrocr PDFmarraezNo ratings yet

- World RefiningDocument7 pagesWorld RefiningmarraezNo ratings yet

- Hydro Cracking For Maximizing Middle Dis PDFDocument9 pagesHydro Cracking For Maximizing Middle Dis PDFmarraezNo ratings yet

- Refinery Sulphur: European Oil Refining Conference Report US Gulf Refinery Sulphur Liquid Sulphur DistributionDocument4 pagesRefinery Sulphur: European Oil Refining Conference Report US Gulf Refinery Sulphur Liquid Sulphur DistributionmarraezNo ratings yet

- Some Aspects of Petroleum Refinery Simulation: A: The Nature of Crude OilDocument22 pagesSome Aspects of Petroleum Refinery Simulation: A: The Nature of Crude OilmarraezNo ratings yet

- Sulphur Magazine - Mar-Apr 2013 - Preventing Corrosion in Sulphur Storage TanksDocument6 pagesSulphur Magazine - Mar-Apr 2013 - Preventing Corrosion in Sulphur Storage TanksmarraezNo ratings yet

- Amine Cleaning Technology Tests Successfully in Aramco PlantsDocument12 pagesAmine Cleaning Technology Tests Successfully in Aramco PlantsmarraezNo ratings yet

- Csi 04Document24 pagesCsi 04marraezNo ratings yet

- Hottips 7Document4 pagesHottips 7marraezNo ratings yet

- Strength Development of Binary Cement Concrete UsiDocument18 pagesStrength Development of Binary Cement Concrete UsiAvinash LalNo ratings yet

- W10 W04 TOCFixedDocument1 pageW10 W04 TOCFixedInterweaveNo ratings yet

- Raised Floor NichiasDocument11 pagesRaised Floor NichiasMuhammad Rizki SahputraNo ratings yet

- HIGHWAY II - Unbounded Pavement MaterialsDocument43 pagesHIGHWAY II - Unbounded Pavement MaterialsMul'ataa Vission AbdiisaaNo ratings yet

- Tinuvin 292 October 2019 R4 IC PPDocument3 pagesTinuvin 292 October 2019 R4 IC PPسلطان ابوالعلاNo ratings yet

- Bromine Index of Petroleum-Based Hydrocarbons: Environmentally Beneficial Determination Based On ASTM D2710 and IP 299Document2 pagesBromine Index of Petroleum-Based Hydrocarbons: Environmentally Beneficial Determination Based On ASTM D2710 and IP 299riloaddNo ratings yet

- Tabela de Óleos LubrificantesDocument2 pagesTabela de Óleos LubrificantesAlbert MesquitaNo ratings yet

- 8oxidation Reduction ReactionsDocument50 pages8oxidation Reduction ReactionsMohamed AlQallafNo ratings yet

- Thermaline 450 PDSDocument4 pagesThermaline 450 PDSRicardo MartinezNo ratings yet

- Abstract of Quantities For Truck LaybyDocument3 pagesAbstract of Quantities For Truck LaybyStephen Rajkumar JayakumarNo ratings yet

- Doors Windows Glazing GlossaryDocument64 pagesDoors Windows Glazing GlossaryacetopposNo ratings yet

- B. Decalcomania C. Decoupage: A. Samsung ApplicationDocument2 pagesB. Decalcomania C. Decoupage: A. Samsung ApplicationVirgitth QuevedoNo ratings yet

- 2019-12 Combo SW155 Winter WoodDocument2 pages2019-12 Combo SW155 Winter WoodVasiliy DyominNo ratings yet

- Principles of Basic Laboratory TechniquesDocument28 pagesPrinciples of Basic Laboratory Techniqueslily august100% (1)

- 1.0 Input and Output Structure and Block Process Flow DiagramDocument7 pages1.0 Input and Output Structure and Block Process Flow DiagramMuhammad Khairul Nizam SuidNo ratings yet

- Jotatemp 650 BrochureDocument4 pagesJotatemp 650 BrochureANIBALLOPEZVEGANo ratings yet

- Department of Education: Republic of The P HilippinesDocument4 pagesDepartment of Education: Republic of The P HilippinesmjcNo ratings yet

- Matrix For Piping Work - ITP - Final - PK3Document4 pagesMatrix For Piping Work - ITP - Final - PK3Trương Ngọc SơnNo ratings yet

- Production of Urea Formaldehyde UF85-947312 - 2Document66 pagesProduction of Urea Formaldehyde UF85-947312 - 2Sanzar Rahman 1621555030No ratings yet

- GHJDocument163 pagesGHJAbdul Gafoor ShaikhNo ratings yet

- One-Bath Dyeing of Blended FabricsDocument4 pagesOne-Bath Dyeing of Blended FabricsNguyễn Huy CườngNo ratings yet

- Pidicrrete CF 351.Document1 pagePidicrrete CF 351.nickdash09No ratings yet

- Padel Traditional Technical Data SheetDocument2 pagesPadel Traditional Technical Data SheetT SharnoubylNo ratings yet

- BOQ of Viaduct at Ch. 5+165 PDFDocument3 pagesBOQ of Viaduct at Ch. 5+165 PDFpreetcivilNo ratings yet

- Extraction From C4 HydrocarbonsDocument2 pagesExtraction From C4 HydrocarbonsAubrey TawandaNo ratings yet

- Mar 21 AvlDocument1 pageMar 21 AvlBala KrishnanNo ratings yet

- O-Ring Reference GuideDocument63 pagesO-Ring Reference GuideVenu Gopal100% (1)

SNG Symp2019 KBR 2 K SAAT

SNG Symp2019 KBR 2 K SAAT

Uploaded by

marraezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SNG Symp2019 KBR 2 K SAAT

SNG Symp2019 KBR 2 K SAAT

Uploaded by

marraezCopyright:

Available Formats

K-SAAT

Breakthrough Solid Acid Alkylation Technology

Proud history, bright future.

Proud history, bright future.

©2019 KBR Inc. All Rights Reserved. ©2019 KBR Inc. All Rights Reserved.

The worldwide gasoline market is changing.

2 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Gasoline Market Overview

Demand Sulfur Octane

• Gasoline demand is steady or • Global environmental regulations • High-octane gasoline demand is

increasing across the globe require lower sulfur gasoline rising

• More cars in emerging markets • Hydrotreating lowers sulfur and • North America and Western

octane Europe are considering replacing

• Stricter environmental standards legacy alkylate production units

• Gasoline blending pool

• Stringent blend requirements components to increase octane • Availability of cheaper feedstock is

– Alkylate driving new applications

• High premium on low RVP – Isomerizate

– Ethanol

– Reformate • Developing countries are

– Etc. demanding higher octane

3 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Alkylate is the preferred premium gasoline blendstock.

4 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Alkylate – Liquid Gold

• High octane

• Low RVP

• Low sulfur

• No aromatics

• No olefins

5 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

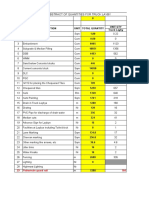

Gasoline Blend Components

Poly FCC Light FCC Heavy

C4 LSR Isomerate Gasoline Naphtha Naphtha Alkylate Reformate Ethers Ethanol

RON - -- -- + + - ++ ++ ++ ++

MON + -- -- - - -- ++ ++ ++ ++

RVP -- -- -- ++ -- ++ ++ ++ ++ --

E70 -- -- -- ++ -- ++ ++ ++ + --

Olefins + ++ ++ -- -- - ++ ++ ++ ++

Aromatics ++ ++ ++ ++ ++ + ++ -- ++ ++

Benzene ++ ? ++ ++ - ++ ++ ? ++ ++

Oxygen ++ ++ ++ ++ ++ ++ ++ ++ -- --

Alkylate is the preferred premium gasoline blendstock.

6 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Current alkylate technologies have significant challenges.

7 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Alkylate Production Challenges

• Liquid-Acid Catalyst Processes

• Handling

• Corrosion

• HSE

• Permitting

• Maintenance expense

• Conventional Solid-Acid Catalyst

Processes

• Poor stability

• Expensive processes

• Large inventories

• Limited feed stock flexibility

8 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

New technology overcomes these old challenges.

9 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

K-SAAT™

Solid Acid Alkylation Technology

Next generation solid acid alkylation technology.

High Alkylate Yield + High Octane Numbers

High Feed Flexibility

Safer, Simpler, More Reliable

ExSact™ Solid Catalyst

Low CAPEX/OPEX

10 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

High Alkylate Yield + High Octane Numbers

11 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Technology Comparison: Typical MTBE Raffinate Feed

K-SAAT Sulfuric Acid HF Acid

Alkylate RON 99+ 98 95 - 96

Alkylate Yield (vol/vol

1.88 1.77 1.78

Olefin)

Eliminates Acid Soluble

Yes No No

Oils?

Eliminates Liquid

Yes No No

Effluents?

CAPEX 1.0 1.6 -

OPEX 1.0 1.6 -

12 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

K-SAAT Product Quality

• Typically >1 point higher octane than liquid acids

• Typical values for potential olefinic feeds:

Propylene MTBE Butenes

Feed Ethylene* Amylenes

( 70% C3=) Raffinate (30% i-C4=)

RON 99 92 99 97 91

MON 94.5 90 95 93 89

*Liquid acid catalyst will not alkylate ethylene

13 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

High Feed Flexibility

14 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Feed Flexibility

• Simpler reactor design

• No refrigeration or acid handling

• Lower power consumption

• Inexpensive regeneration

• High tolerance for impurities

15 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Feed Flexibility

C2 - C5 Olefins + Iso-Butane Alkylate

C2, C2=

C3, C3=

iC4 C2

C4, iC4, C3

C4=, iC4=

FCC MTBE / ETBE K-SAAT LPG

C4, iC4, C4

C4=

C5, C5=

Alkylate

FCC Ethers

Gasoline

Gasoline

16 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

K-SAAT Flexibility

• K-SAAT can alkylate ethylene up to 100% purity

• Dimerization and alkylation steps in one reactor

Dimerization

Ethylene Ethylene Butenes

Alkylation

Butenes

Isobutane Trimethylpentanes

17 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

The key is ExSact™ Solid Acid Catalyst.

18 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

ExSact™ Catalyst

• Zeolite-based catalyst

• Selective to high-octane TMPs

• Eliminates acid-soluble oils

• Guaranteed 5-year life

• >24-hour cycle length

19 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Advantages of the ExSact™ Catalyst

Engineered Catalyst Optimized Reactions Superior Yield & Octane

• Optimized particle size and • Improved mass transfer to • Higher catalyst activity

shape prevent pore blockage • Longer cycle length (24 hr)

• Optimized Pore Structure • Promotes alkylation over • Longer catalyst life (5 yr)

on a micro and macro scale polymerization reactions • Higher alkylate octane

• Optimized Acid Site • Highly selective to 2,3,3- • Simplified process design

Strength & Distribution and 2,3,4-

trimethylpentane*

• Minimal isomerization of

trimethylpentanes to

dimethylhexanes

* 2,3,3- and 2,3,4-trimethylpentane research octane >100

20 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

K-SAAT Process – Safer, Simpler, More Reliable.

21 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

K-SAAT Process Scheme

Simple Process Isobutane Recycle

Low CAPEX

LPG Feed K-SAAT

Distillation

(Olefin + Feed Reactors

Isobutane) Treatment A+B

Alkylation

K-SAAT

Hydrogen

Reactor C

Regeneration Alkylate

Product

22 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

K-SAAT Reaction

• Typically 3 fixed-bed reactors

K-SAAT

• 24-hour cycle length Reactors

A+B

• Isobutane/olefin ratio ~10 Alkylation

• 20 barg & 50°C (290 psig & 120°F)

• Moderate temperature favors

alkylation K-SAAT

over polymerization reactions Reactor C

Regeneration

• No refrigeration required

• No liquid effluents or ASOs

• Reactor material: low alloy steel

23 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Process Scheme

24 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

K-SAAT Regeneration

• 12 hour regeneration cycle

K-SAAT

• Hot hydrogen regeneration: Reactors

A+B

• 20 barg & 275°C (290 psig & 525°F) Alkylation

• Hydrogen requirement: 0.87 kg/MT

alkylate (0.2 lb/BBL alkylate)

• Reformer grade hydrogen K-SAAT

(~80% purity) Reactor C

Regeneration

• Fired or MV Electric Heater

25 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Process Scheme – Regeneration

Reformer Grade Hydrogen (~80% purity)

26 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

Commercial References

27 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

References

2016

Haike Ruilin Chemical Co. Ltd.

2018 K-SAAT unit started 2018

Contract signed with CVR

K-SAAT Unit Start-up 2021

Shandong,

Wynnewood, OK, Henan,

China

USA China

2019

Contract signed with

confidential US client License signed with Luoyang

Aiyou Chemical Co.

2017

28 | K-SAAT Solid Acid Alkylation Technology Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

K-SAAT™

Solid Acid Alkylation Technology

Next generation solid acid alkylation technology.

High Alkylate Yield + High Octane Numbers

High Feed Flexibility

Safer, Simpler, More Reliable

ExSact™ Solid Catalyst

Low CAPEX/OPEX

29 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

31 | K-SAAT Solid Acid

Presentation Text Alkylation Technology

| Additional Text Proud history, bright future.

©2019 KBR Inc. All Rights Reserved.

You might also like

- Fundamentals of General Organic and Biological Chemistry 8th Edition Mcmurry Test BankDocument35 pagesFundamentals of General Organic and Biological Chemistry 8th Edition Mcmurry Test Bankadamburtonbsdqicoewy100% (31)

- Crude Oil BlendingDocument20 pagesCrude Oil Blendingnedian_2006No ratings yet

- Isoalky Process Technology,: A New Era For Alkylation With Ionic Liquid AlkylationDocument16 pagesIsoalky Process Technology,: A New Era For Alkylation With Ionic Liquid AlkylationDavid RodriguesNo ratings yet

- Refining - VALERODocument35 pagesRefining - VALERORoozbeh P100% (1)

- EXX-EME-STD-0008 - Wear Liners For Plate Work and ChutesDocument22 pagesEXX-EME-STD-0008 - Wear Liners For Plate Work and Chutesjonodo89100% (1)

- Joint Coating Application & Pipe Coating Procedure-009-RappDocument8 pagesJoint Coating Application & Pipe Coating Procedure-009-Rappgst ajahNo ratings yet

- K-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsDocument17 pagesK-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsmarraezNo ratings yet

- Refining K-Saat 2022marDocument4 pagesRefining K-Saat 2022marmarraezNo ratings yet

- KBR Olefins Technologies Jeff Caton 6826Document24 pagesKBR Olefins Technologies Jeff Caton 6826swaggeroni yololo100% (1)

- 03 Road Map Presentation ItalyDocument26 pages03 Road Map Presentation ItalyKURAF MUHENDISLIK AŞ.No ratings yet

- 10 - Adding Value With SuperflexDocument15 pages10 - Adding Value With SuperflexAbhimanyu SharmaNo ratings yet

- STLE2017 Synthetics HydraulicsDocument58 pagesSTLE2017 Synthetics HydraulicsJako MishyNo ratings yet

- CBEN409 06 CokingDocument39 pagesCBEN409 06 CokingMohammad FarooqNo ratings yet

- Class01-Refinery Overview - 2020Document23 pagesClass01-Refinery Overview - 2020Shivam Kumar RaiNo ratings yet

- TIB 2017 Broschuere Kat U P EN RZ4 LowresDocument24 pagesTIB 2017 Broschuere Kat U P EN RZ4 LowresAngel Quiroz EspinozaNo ratings yet

- The Supply Chain Impacts of Cobalt ReportingDocument17 pagesThe Supply Chain Impacts of Cobalt ReportingetsimoNo ratings yet

- Intertanko Vetting Seminar Athens - May 15, 2007: Tim Plummer President Tesoro Maritime CompanyDocument26 pagesIntertanko Vetting Seminar Athens - May 15, 2007: Tim Plummer President Tesoro Maritime CompanyProlin NanduNo ratings yet

- Technical Data Sheet: SDA-EAGLE (SX35-18/50) 60%Document1 pageTechnical Data Sheet: SDA-EAGLE (SX35-18/50) 60%Fadi Magdy0% (1)

- Abdulkader - Djellout AlgeriaDocument59 pagesAbdulkader - Djellout AlgeriasashaNo ratings yet

- Unit-7 Petroleum RefiningDocument40 pagesUnit-7 Petroleum RefiningNeeraj YadavNo ratings yet

- Calcium Sulfonate Greases For Extreme EnvironmentDocument11 pagesCalcium Sulfonate Greases For Extreme EnvironmentnagbabuiNo ratings yet

- The Growing Demand For High Vis PAO Within AsiaDocument32 pagesThe Growing Demand For High Vis PAO Within AsiaDhroov SharmaNo ratings yet

- HIMBALT Presentation 2020 ENDocument9 pagesHIMBALT Presentation 2020 ENJorge ZegarraNo ratings yet

- Fuelco Logitank BrochureDocument8 pagesFuelco Logitank Brochuremuh_akbar2451No ratings yet

- BPZ Energy PresentationDocument25 pagesBPZ Energy PresentationjimenezvegaNo ratings yet

- Libya Chemical Plants ICIS ListDocument1 pageLibya Chemical Plants ICIS ListwillbeachamNo ratings yet

- Petroleum IndustryDocument39 pagesPetroleum IndustryQuenie Rose RontalNo ratings yet

- Technical Data Sheet: SNDA-EAGLE (COCX35-97/60) 60%Document1 pageTechnical Data Sheet: SNDA-EAGLE (COCX35-97/60) 60%Fadi MagdyNo ratings yet

- FUCHS RENOLIN Industrial Gear OilsDocument18 pagesFUCHS RENOLIN Industrial Gear OilsfajarfrankyNo ratings yet

- 2015 Oil Gas RefiningDocument33 pages2015 Oil Gas RefininggustavoemirNo ratings yet

- Age 10501Document21 pagesAge 10501karimirelayNo ratings yet

- Maximising Naphtha Through Hydrocracking Refinery of The FutureDocument25 pagesMaximising Naphtha Through Hydrocracking Refinery of The FutureMustafa AhsanNo ratings yet

- FAG-Arcanol Greases PDFDocument22 pagesFAG-Arcanol Greases PDFMark DiNo ratings yet

- Drilling Fluid Systems: © 2004 Baker Hughes Incorporated All Rights ReservedDocument33 pagesDrilling Fluid Systems: © 2004 Baker Hughes Incorporated All Rights ReservedKaleem UllahNo ratings yet

- Petro Canada Lubricants Handbook 2012 English PDFDocument212 pagesPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshNo ratings yet

- World RefiningDocument7 pagesWorld RefiningmarraezNo ratings yet

- Maximizing Utilization of Light Tight Oils Economics and Technology SolutionsDocument26 pagesMaximizing Utilization of Light Tight Oils Economics and Technology SolutionsM Scott GreenNo ratings yet

- LubeBaseStock - Dec 2003Document17 pagesLubeBaseStock - Dec 2003Mely LeivaNo ratings yet

- BR02V072021 - Rymax - Productcatalogus - 2021 - NEW DESIGN ISSUUDocument52 pagesBR02V072021 - Rymax - Productcatalogus - 2021 - NEW DESIGN ISSUUSinh LeNo ratings yet

- B-1114print Essential Expertise Mining PDFDocument4 pagesB-1114print Essential Expertise Mining PDFlpbeauchamp09No ratings yet

- Finishing Agents & Specialty ChemicalsDocument4 pagesFinishing Agents & Specialty Chemicals950 911No ratings yet

- Alternatives Study For The Technical Improvement of The Campo Arce Crude Oil QualityDocument6 pagesAlternatives Study For The Technical Improvement of The Campo Arce Crude Oil QualityChechotopol12No ratings yet

- 2 - SyntheticsDocument57 pages2 - SyntheticsRay Cepeda Mena100% (1)

- Lubrication GuidelinesDocument1 pageLubrication GuidelinesBzidroglioNo ratings yet

- DCU1Document25 pagesDCU1ashutosh kumarNo ratings yet

- Howard BevanDocument11 pagesHoward Bevanxtrooz abiNo ratings yet

- Valero Energy, Benicia: - Onkar Kotpalliwar Shivam SinghDocument53 pagesValero Energy, Benicia: - Onkar Kotpalliwar Shivam SinghNikhil GargNo ratings yet

- 16 - Upgrading Olefins For Gasoline BlendingDocument21 pages16 - Upgrading Olefins For Gasoline BlendingAbhimanyu SharmaNo ratings yet

- Modeling Heavy Oils in Aspen Hysys Engineering Excellence Webinar Series 26 January 2010Document59 pagesModeling Heavy Oils in Aspen Hysys Engineering Excellence Webinar Series 26 January 2010Hafiz Muhammad AbubakarNo ratings yet

- Product - Overview - EN Antiveining CoatingDocument12 pagesProduct - Overview - EN Antiveining CoatingSachin KumbharNo ratings yet

- FUCHS ClassicRange PDFDocument12 pagesFUCHS ClassicRange PDFFahad KhalidNo ratings yet

- Refining IndustryDocument73 pagesRefining IndustryMukesh Kumar MeenaNo ratings yet

- CWI Product Information Bulletin - New Engine Oil Specification May 2016Document2 pagesCWI Product Information Bulletin - New Engine Oil Specification May 2016roger gonzales hoyosNo ratings yet

- GFS - Organic CatalogDocument148 pagesGFS - Organic Catalognamandejustine02No ratings yet

- Carbonite - A New Carbon Based Energy FuelDocument18 pagesCarbonite - A New Carbon Based Energy FuelJorge MadiasNo ratings yet

- Product SelectionDocument28 pagesProduct Selectionarisqi wahyuNo ratings yet

- Tank Linings: Protective Coatings Which Divide The Cargo From The SteelDocument5 pagesTank Linings: Protective Coatings Which Divide The Cargo From The SteelgandungNo ratings yet

- Ici Supply Chain Management Report by Ali RazaDocument36 pagesIci Supply Chain Management Report by Ali RazarafeyNo ratings yet

- Rolcer Brochure v2Document4 pagesRolcer Brochure v2Francis XavierNo ratings yet

- Technical Data Sheet: LA-EAGLE (SW61-9/55) 70%Document1 pageTechnical Data Sheet: LA-EAGLE (SW61-9/55) 70%Fadi MagdyNo ratings yet

- MechReaction Liu 2016Document26 pagesMechReaction Liu 2016marraezNo ratings yet

- Sulfuric Acid Alkylation Technology: Dr. Girish K. Chitnis Mr. Ron D. Mcgihon Mr. Aneesh Prasad Mr. Christopher M. DeanDocument18 pagesSulfuric Acid Alkylation Technology: Dr. Girish K. Chitnis Mr. Ron D. Mcgihon Mr. Aneesh Prasad Mr. Christopher M. DeanmarraezNo ratings yet

- US8105968Document24 pagesUS8105968marraezNo ratings yet

- MD AlkyClean v2Document4 pagesMD AlkyClean v2marraezNo ratings yet

- US20220144724A1Document24 pagesUS20220144724A1marraezNo ratings yet

- MSDS Zeolite 25 JAN 2019Document4 pagesMSDS Zeolite 25 JAN 2019marraezNo ratings yet

- Zeolite MsdsDocument6 pagesZeolite MsdsmarraezNo ratings yet

- K-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsDocument17 pagesK-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsmarraezNo ratings yet

- Refining K-Saat 2022marDocument4 pagesRefining K-Saat 2022marmarraezNo ratings yet

- DuplicateDocument134 pagesDuplicatemarraezNo ratings yet

- Refractory Nitrogen Compounds in Hydrocr PDFDocument6 pagesRefractory Nitrogen Compounds in Hydrocr PDFmarraezNo ratings yet

- World RefiningDocument7 pagesWorld RefiningmarraezNo ratings yet

- Hydro Cracking For Maximizing Middle Dis PDFDocument9 pagesHydro Cracking For Maximizing Middle Dis PDFmarraezNo ratings yet

- Refinery Sulphur: European Oil Refining Conference Report US Gulf Refinery Sulphur Liquid Sulphur DistributionDocument4 pagesRefinery Sulphur: European Oil Refining Conference Report US Gulf Refinery Sulphur Liquid Sulphur DistributionmarraezNo ratings yet

- Some Aspects of Petroleum Refinery Simulation: A: The Nature of Crude OilDocument22 pagesSome Aspects of Petroleum Refinery Simulation: A: The Nature of Crude OilmarraezNo ratings yet

- Sulphur Magazine - Mar-Apr 2013 - Preventing Corrosion in Sulphur Storage TanksDocument6 pagesSulphur Magazine - Mar-Apr 2013 - Preventing Corrosion in Sulphur Storage TanksmarraezNo ratings yet

- Amine Cleaning Technology Tests Successfully in Aramco PlantsDocument12 pagesAmine Cleaning Technology Tests Successfully in Aramco PlantsmarraezNo ratings yet

- Csi 04Document24 pagesCsi 04marraezNo ratings yet

- Hottips 7Document4 pagesHottips 7marraezNo ratings yet

- Strength Development of Binary Cement Concrete UsiDocument18 pagesStrength Development of Binary Cement Concrete UsiAvinash LalNo ratings yet

- W10 W04 TOCFixedDocument1 pageW10 W04 TOCFixedInterweaveNo ratings yet

- Raised Floor NichiasDocument11 pagesRaised Floor NichiasMuhammad Rizki SahputraNo ratings yet

- HIGHWAY II - Unbounded Pavement MaterialsDocument43 pagesHIGHWAY II - Unbounded Pavement MaterialsMul'ataa Vission AbdiisaaNo ratings yet

- Tinuvin 292 October 2019 R4 IC PPDocument3 pagesTinuvin 292 October 2019 R4 IC PPسلطان ابوالعلاNo ratings yet

- Bromine Index of Petroleum-Based Hydrocarbons: Environmentally Beneficial Determination Based On ASTM D2710 and IP 299Document2 pagesBromine Index of Petroleum-Based Hydrocarbons: Environmentally Beneficial Determination Based On ASTM D2710 and IP 299riloaddNo ratings yet

- Tabela de Óleos LubrificantesDocument2 pagesTabela de Óleos LubrificantesAlbert MesquitaNo ratings yet

- 8oxidation Reduction ReactionsDocument50 pages8oxidation Reduction ReactionsMohamed AlQallafNo ratings yet

- Thermaline 450 PDSDocument4 pagesThermaline 450 PDSRicardo MartinezNo ratings yet

- Abstract of Quantities For Truck LaybyDocument3 pagesAbstract of Quantities For Truck LaybyStephen Rajkumar JayakumarNo ratings yet

- Doors Windows Glazing GlossaryDocument64 pagesDoors Windows Glazing GlossaryacetopposNo ratings yet

- B. Decalcomania C. Decoupage: A. Samsung ApplicationDocument2 pagesB. Decalcomania C. Decoupage: A. Samsung ApplicationVirgitth QuevedoNo ratings yet

- 2019-12 Combo SW155 Winter WoodDocument2 pages2019-12 Combo SW155 Winter WoodVasiliy DyominNo ratings yet

- Principles of Basic Laboratory TechniquesDocument28 pagesPrinciples of Basic Laboratory Techniqueslily august100% (1)

- 1.0 Input and Output Structure and Block Process Flow DiagramDocument7 pages1.0 Input and Output Structure and Block Process Flow DiagramMuhammad Khairul Nizam SuidNo ratings yet

- Jotatemp 650 BrochureDocument4 pagesJotatemp 650 BrochureANIBALLOPEZVEGANo ratings yet

- Department of Education: Republic of The P HilippinesDocument4 pagesDepartment of Education: Republic of The P HilippinesmjcNo ratings yet

- Matrix For Piping Work - ITP - Final - PK3Document4 pagesMatrix For Piping Work - ITP - Final - PK3Trương Ngọc SơnNo ratings yet

- Production of Urea Formaldehyde UF85-947312 - 2Document66 pagesProduction of Urea Formaldehyde UF85-947312 - 2Sanzar Rahman 1621555030No ratings yet

- GHJDocument163 pagesGHJAbdul Gafoor ShaikhNo ratings yet

- One-Bath Dyeing of Blended FabricsDocument4 pagesOne-Bath Dyeing of Blended FabricsNguyễn Huy CườngNo ratings yet

- Pidicrrete CF 351.Document1 pagePidicrrete CF 351.nickdash09No ratings yet

- Padel Traditional Technical Data SheetDocument2 pagesPadel Traditional Technical Data SheetT SharnoubylNo ratings yet

- BOQ of Viaduct at Ch. 5+165 PDFDocument3 pagesBOQ of Viaduct at Ch. 5+165 PDFpreetcivilNo ratings yet

- Extraction From C4 HydrocarbonsDocument2 pagesExtraction From C4 HydrocarbonsAubrey TawandaNo ratings yet

- Mar 21 AvlDocument1 pageMar 21 AvlBala KrishnanNo ratings yet

- O-Ring Reference GuideDocument63 pagesO-Ring Reference GuideVenu Gopal100% (1)