Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

18 viewsDme - 1, Dom Question Paper

Dme - 1, Dom Question Paper

Uploaded by

varshitha srinivasCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ModelQp 18ME53 TM 2022-23Document3 pagesModelQp 18ME53 TM 2022-23varshitha srinivasNo ratings yet

- Turbo, Cad, Auto QPDocument25 pagesTurbo, Cad, Auto QPvarshitha srinivasNo ratings yet

- SATHISH S CADCAM 2022 23 Model 1Document2 pagesSATHISH S CADCAM 2022 23 Model 1varshitha srinivasNo ratings yet

- SATHISH S CADCAM 2022 23 Model 3Document2 pagesSATHISH S CADCAM 2022 23 Model 3varshitha srinivasNo ratings yet

Dme - 1, Dom Question Paper

Dme - 1, Dom Question Paper

Uploaded by

varshitha srinivas0 ratings0% found this document useful (0 votes)

18 views23 pagesOriginal Title

DME - 1, DOM QUESTION PAPER

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

18 views23 pagesDme - 1, Dom Question Paper

Dme - 1, Dom Question Paper

Uploaded by

varshitha srinivasCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 23

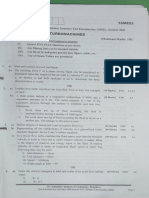

fal i 48ME51

FIETH Semester BLE, Degree Summer Semester End Examination (SSEK), October 2022

DESIGN OF MACHINE ELEMENTS-1

100}

{Maximum Marl

Anstructions to students:

@ Answer FIVE FULL Questions as per choice,

Gi) Any Missing Data can be assumed suitably.

(iil) Use BLACK ball point pen for text, figure, table, ete.

(iy) Use of Design data hand book is permitted

RBT

Marks CO Level

Sketch and explain Biaxial and ‘Triaxial stresses, stress tensor and principal 08 Marks} COL

Mb) A mild steel bracket shown in fig-I(b) is subjected to pull of 1OKN. The [12Marks| COL LS

bracket has a rectangular cross-section whose depth is twice the width, If the

is 80N/mm’, Determine the cross-section of

the bracket.

Discuss factors influencing selection of appropriate value for the factor of (04 Marks} COL L2

gram for the following materials [04 Marks} COL 12

ports a 9KN load and in addition is subjected [12 Marks] COL LS

Q N-m as shown fig-2(c). Determine the

‘of Technology, Bangalore

dito VIU, Belagavi, Karnataka, India)

oT

oe (06 Marks} cq

eories of failut

ve piling Ot

; - ne Maximum normal stress theory i :

H Dis orstion energy theory, “

: i ant’s theory

Paint verant’S at

i) Sant En emai foro® OF sas, AE isl A!

ay Ata pte bec ing gy vue Of 200MPa: Determine pee |

prey cast io

material yor of Sarety IS 25. :

of the plate Facto

R

SKN

‘

OR

; 4 a A Rectangular plate of 50mm wide with acircular hole of diameter 10mm in [08 Marks} CO2

the centre is subjected to a bending moment of 10N-miif the thickness of the

plate is 10mm. Determine the ‘maximum stress induced in the plate.

Be ae?

w ¢

'

Fig-4(@)

fe load that can be carried by a bar of rectangular cross

ig — 4(b). limiting the maximum stress to 130MPa, taking

b) Determine the sal [12 Marks} CO2

section shown in fi

stress concentration into account.

Fig-4(b)

Dr, Ambedkar Institute of Technology

(An Autonomous trun ttpeel et) Heea ae

tele) Page

Derive the soderberg’s Equation,

Determine the maxim

um load fi i

led as shown in fig, fits

-5(b). The ultimate strength is 700MPa. The yield point

All dimensions in mm

Fig-5(b)

OR

A hot rolled steel! shaft is subjected to a torsional load that varies fr

om

330_Nm (ew) to110 Nm (ccw) as an applied bending moment at the eritical

section varies from +440 N-m to — 220 Nm. The shaft is of uniform cross

section and no key way is present at the critical section. Determine the

required shaft diameter. The material has an ultimate strength of 5SOMN/m?

and yield strength of 410 MN/m?. Factor of safety=1.5. Size and surface

correction co-efficients are 0.85 and 0.62 respectively. Take the endurance

_ limit as half the ultimate strength.

‘A machine shaft turning at 600 rev/min is supported on bearings 750 mm

apart. 15 kW is supplied to the shaft through a 450 mm pulley located 250

mm to the right of right bearing. The power is transmitted from the shaft

through a 200 mm spur gear located 250 mm to the right of left bearing. The

belt drive is at an angle of 60 ° above the horizontal. The pulley weighs 800N

to provide some flywheel effect. The ratio of the belt tensions is 3:1. The gear

‘has a 20° tooth form and with another gear located directly above the shaft. If

the shaft material selected has an ultimate strength of 500 MPa and a yield

ethe necessary diameter using Ky=1.5 and K=1.0

OR

mm is used for the gear and the shaft

at 440rpm is transmitted by the spline

n the splines is limited to. 6.5 N/mm2.

i) The length of hub of the gear

[05 Marks}

(20 Marks}

[20 Marks}

107 Marks}

cos 13

Ply supported beam, cyclically [15 Marks} CO3 Ls

cos 1s

cos 6

cos 6

haft ofa motor and centrifugal pump [13 Marks] CO#

output =3000 liters/minute, total

f 10%. Select C-40 steel

%

10.

a) Explain Non Destructive testing to assess the condition of a pressure vessel,

'b) Design a double riveted Butt joint with two cover plates for the longitudinal

seam of a boiler shell 1.5m in diameter subjected to a steam pressure of

0.95N/mm?, Assume the efficiency of 75%. Allowable tensile stress in the

plate of 9ON/mm’, allowable compressive stress of 140 N/mm? and an

allowable shear stress in the rivet of 56 N/mm?

OR

a) A 16 mm thick plate is welded to a vertical support by two.

shown in fig-10(a), Determine the si

for the weld material is 75 MPa.

llet welds as

‘re of weld, if the permissible shear stress

Fig-10(a)

b) A solid circular shaft 25mm in diam

fillet weld as shown in fig-10(b). Determine the leg dimension of the weld if

the permissible shear stress is 9SN/mm?

100 mm

P=35KkN

Fig-10(b)

Petr orto

sn

USN

05Maria) glo

[15 Marks} Co

yr

{10 Marks} CO}

ter is welded to a support by means of | 10 Marks|_ COS

| USN ae

18MES1

FIFTH Semester BE Degree Semester End Examination (SEE), FEB/MAR-2022

DESIGN OF MACHINE ELEMENTS - 1

[Time: 3 Hours}

Instructions (0 students:

(@ Answer ANY FIVE FULL Questio

(ii) Any Missing Data can be assumed suitably.

Use BLACK ball point pen for text, figure, table, etc.

(iv) Use of design data handbook is permitted.

Marks

~ 8) Explain briefly different phases of design process. (06 Marks}

'b) Explain briefly mechanical properties of engineering materials [06 Marks}

©) Determine the required thickness of the steel bracket at section A-A, {08 Marks}

when loaded as shown in figure-le in order to limit tensile stress to

70MN/m’.

so

Figure-1e

OR

a) Explain briefly, i) Standards, ii) Codes and iii) Principal stress (06 Marks}

Bb) Define and explain factor of safety 104 Masa]

_ Determi ine the torque transmitted by the stepped shaft shown in [10 Marks}

eo - maximum shear stress limited to 60MPa,

ao

ma

[Maximum Marks: 100)

co BE

cor Lt

col

cor os

co 6

Olen ee

cor os

Page 1

3. a) Explain following theories of failure: i) Maximum Principal stress

theory ii) Maximum shear stress theory iii) Maximum normal stress

theory iv) Distortion energy theory v) Maximum elastic strain energy

theory : Pe

b) A round rod of 50mm diameter is to sustain an axial Pano

Joad of 20KN and twisting moment of 1.5KN-m. the rod is made 0

C40 steel of yield stress 328,6MPa. Determine the factor of a

under following conditions: i) Maximum Principal stress theory

Maximum elastic strain energy theory iii) Distortion energy theory

oR

4. a) Define stress concentration and explain methods of reducing stress

concentration,

b) A flat plate subjected to a tensile load of SKN is shown Lee oe

plate material is grey cast iron having maximum strength ° 7

Determine the thickness of the plate. Consider FOS is 2.5,

Figure-4b

§, a) Define endurance limit. State and explain the modifying factors of it.

A hot rolled steel shaft is subjected to torsion that varies from 330Nm

(CW) to 110Nm (CCW) as an applied bending moment at the critical

section varies from +440Nm to -220Nm, Determine the required

diameter of the shaft. o,=550MPa, 6,=410MPa, FOS=1.5, size and

surface correction factors are 0.85 and 0.62 respectively. Take

endurance limit is half of the ultimate Strength and consider the shaft

is of uniform cross section.

OR

6. Derive the expression for maximum stress due to axial impact load on

the bar.

A Power hammer weighing 4kN strikes the mid-point of the beam

simply supported at its end 4m

apart. The beam has a depth of

200mm and width 100mm, r .

. Determine hei; i

hammer weight can be allowed en ac

beam is limited to 120MPa, Ta

material is 206.8GPq

[10 Marks}

{10 Marks}

[10 Marks}

[10 Marks}

108 Marks}

[12 Maris}

[08 Marks}

{12 Marks}

©

Coy

cor

cor

co3

cos

co3

cos

u

1s

Ls

A shaft is supported by two bearing 1.5m apart, 4 keyed gear, 20!

involute and 175mm diameter is located at 400mm tothe let af tne

right bearing and is driven by @ gear directly behind it. A 600mm

diameter pulley is Keyed 10 the shaft 600mm to the Fight ofthe leh

bearing and drives « pulley with a horizontal bet directly behind it

The tension ratio of the belt is 3:1. The drive transmits 45kW at

330rpm. Assume Ci=1.5 and Cy=1.5,

OR

Design a rigid flange coupling to transmit 18kW at 1440xpm, The

allowable shear stress for CI flange is 4MPa. The shaf, keys and

bolts are made of annealed steel having allowable shear stress of

93MPa. Allowable crushing stress for key is 186MPa.

Design a double riveted butt joint with two cover plates of equal

width for the longitudinal seam of boiler shell of 1m diameter

subjected to a steam pressure of 2MPa. The rivet pitch is to be same

in all rows and zig-zag riveting is to be used. The allowable stress in

tensile, crushing and shear are 124MPa, 180MPa and 93MPa

respectively.

OR

‘The cylinder head of a steam engine is subjected to a steam pressure

‘of 0.7N/mm:. It is held in position by means of 12bolts. A soft copper

_ gasket is used to make the joint leak proof. The effective diameter of

‘eylinder is 300mm. find the size of the bolt so that the stress in

: 2

Joad that can be applied to a bracket loaded as

The size of the weld is 8mm and allowable

110 Marks}

[20 Marks}

[20 Marks}

[10 Marks}

{10 Marks}

cos

cos

2

[ | [| 18MES52/ MES2

Semester BE Degree Summer Semester End Examination (SSEE),

September-2021

DYNAMICS OF MACHINES

[Maximum Marks: 100]

Instructions to students:

(Answer ANY FIVE FULL Questions,

(ii) Any Missing Data can be assumed suitably.

(iii) Use BLACK Point pen for text, figure, table, ete.

RBT

Marts co fNN

Explain equilibrium of two force members and two force and torque [05 Marks] COL 2

‘members.

Im a four bar mechanism shown in figure 1(b),

value of torque and various forces on links for

system. AB=50mm, BC=60mm, CD=5

BAD=60" and AD=100mm.

calculate the required [1SMarks} CO1 3

the equilibrium of the

'Smm, CE=25mm, CF=30mm,

Figure 1(b) Four bar mechanism

Explain the principle of virtual work.

A four link mechanism with the following dimensions is acted upon

bya dey P80N on the link DC at an angle of 150°. AD=500mm,

. BC=1000mm, DC=750mm and DE=350mm.

"Ton the link AB for static equilibrium.

(08 Marks} COI 12

(12Marks} Cor L3

7

a)

Figure 3(a) Four bar mechanism

AB=500mm, BC=660mm, CD=560mm, AD=1000mm, AB=325mm,

BF=297mm, DG=373mm, F2-80N, Fi=144N, Fa=60N.

‘The four bar mechanism as shown in figure 4(a). The centre of [14 Marks} co

gravity of each link is at its midpoint. |

AD=500mm, AB=250mm, CD=300mm, BC=300mm.

Mass of the links

AB=1.52kg, BC=3, 06kg, DC=5.09kg.

Mass moment of inertia of the links

AB=0.012kg-m?, BC=0.036 kg-m?, CD=0.02 kg-m?. Find the inertia

forces on each link.

8

\ a

A Figure 4(a) Four bar mechanism F

~b) Discuss D Alembert's principle. 106 Marks} cor 4

'b) The sum of the diameters of two pulleys connected by flat belt is [1S Marks)

0.6m. If they run at 1400rpm and 2100rpm, determine the diameter of

each pulley. The centre distance between the pulleys is 1.5m and

of friction between belt and pulleys is 0.4. Determine the

n power that can be transmitted by the above open belt drive

maximum tension as restricted to 3000N.

and write a note on types of friction.

2 is used to connect to pulleys of equal

tomy! ns. Te se pee

i Speed of the belt,

ii Power transmitted,

iii Stress in slack fried of the belt.

a) A rotating shaft carries four masses | 2 3 and 4 which are radially [16 Marks] CO4

attached to it. The mass centres are 30mm, 38mm, 40mm, and 35mm

Tespectively from the axis of rotation. The masses 1, 3 and 4 are

7.5kg Skg and 4kg are respectively. The actual distance between the

planes | and 2 is 400mm and 2 and 3 is 500mm. The masses | and 3

are at right angles to each other. Find for complete balance,

i Angle between 1, 2 and 4.

li Axial distance between 3 and 4.

iii Magnitude of mass 2.

Explain the following: i,) Static Balancing

3

ii.) Dynamic Balancing. [04Marks} O04 LI

A single cylinder horizontal oil engine has crank 187.5mm and [20Marks| CO4 13

connecting rod 825mm. The revolving parts are equivalent to 5Skg at

crank radius and the mass of the piston and gudgeon pin is 45kg. The

connecting rod has its mass equal to 57.5kg and its mass centre is

located 262.5mm from the crankpin centre. The revolving balanced

masses are fixed to the extension of crank web at radius 21.25mm to

balance the revolving parts and half of reciprocating parts. Neglecting

obliquity of connecting rod, Find

i Balancing mass.

ii Residual unbalanced force at 300rpm.

A porter governor has all four arms 300mm long. The upper arms are [20Marks|_ COS 13

attached on the axis of rotation and the lower arms are fixed to the

sleeve at a distance of 30mm from the axis of rotation. The mass of

each ball is 4kg and the sleeve has a mass of 60kg. The extreme radii

of rotation are 160mm and 200mm. Determine the range of speed of

pe een automobile is travelling along a track of 100m ae {20Marks} COS 13

radius. Each of four road wheels has a moment of inertia of 2kg-m’

‘of 60cm. The rotating parts of the engine

of Ikg-m?. The engine axis is parallel to the

{ rotates in the same sense as the road

s engine to back axle is 3:1. The mass of

as it CG 500mm above road level. Width

vehicle around the curve for all

tre eke road surface if this is not

ee RER EERE EEEEE

EEE

| | | | | [ | 18MES52/ MES2

H Semester B E Degree Summer Semester End Examination (SSEE), September-2021

DYNAMICS OF MACHINES

3 Hours} {Maximum Marks: 100]

Instructions to students:

(@ — Answer ANY FIVE FULL Questions.

(ii) Any Missing Data can be assumed suitably.

(ii) _ Use BLACK ball point pen for text, figure, table, ete.

v

Mars CO Ey

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ModelQp 18ME53 TM 2022-23Document3 pagesModelQp 18ME53 TM 2022-23varshitha srinivasNo ratings yet

- Turbo, Cad, Auto QPDocument25 pagesTurbo, Cad, Auto QPvarshitha srinivasNo ratings yet

- SATHISH S CADCAM 2022 23 Model 1Document2 pagesSATHISH S CADCAM 2022 23 Model 1varshitha srinivasNo ratings yet

- SATHISH S CADCAM 2022 23 Model 3Document2 pagesSATHISH S CADCAM 2022 23 Model 3varshitha srinivasNo ratings yet