Professional Documents

Culture Documents

HMT Unideck Generic 2015 - 04 - 02

HMT Unideck Generic 2015 - 04 - 02

Uploaded by

DeonCopyright:

Available Formats

You might also like

- Astm F567Document4 pagesAstm F567RUI MIGUEL SILVANo ratings yet

- Ductile Details To Seismic Forces - Is 13920Document4 pagesDuctile Details To Seismic Forces - Is 13920MUTHUKKUMARAMNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Mels Constuction Limitada: Commercial Management Mechanical Completion CertificateDocument1 pageMels Constuction Limitada: Commercial Management Mechanical Completion CertificateDeonNo ratings yet

- Final Handover Certificate EarthworksDocument1 pageFinal Handover Certificate EarthworksDeonNo ratings yet

- Electrical - Completion CertificateDocument1 pageElectrical - Completion CertificateDeon100% (1)

- 8DIO Majestica User ManualDocument27 pages8DIO Majestica User ManualDavid BenavidesNo ratings yet

- Cable TraysDocument6 pagesCable TrayssallammohamedNo ratings yet

- Inland Transport Committee: INF.47 Economic Commission For EuropeDocument7 pagesInland Transport Committee: INF.47 Economic Commission For EuropeStan HonNo ratings yet

- RCC Member Design TipsDocument8 pagesRCC Member Design TipsAbhishek ChaudhariNo ratings yet

- Specs For Aluminum Geodesic Batten Domes 2012Document5 pagesSpecs For Aluminum Geodesic Batten Domes 2012RaghNo ratings yet

- SECTION 15070 Mechanical Sound, Vibration, and Seismic ControlDocument8 pagesSECTION 15070 Mechanical Sound, Vibration, and Seismic ControlAbdel HamidNo ratings yet

- RCC Design TipsDocument9 pagesRCC Design Tipssatoni12No ratings yet

- Ductile Detailing of Beam As Per IS 13920Document4 pagesDuctile Detailing of Beam As Per IS 13920Civil FundaNo ratings yet

- Structural TipsDocument7 pagesStructural Tipsbalacr3No ratings yet

- Frame Supported Membrane Structure Part 1 - General 1.1 Related DocumentsDocument13 pagesFrame Supported Membrane Structure Part 1 - General 1.1 Related Documentsloc nguyenNo ratings yet

- RCC Member Design TipsDocument9 pagesRCC Member Design TipsNaren ViratNo ratings yet

- SECTION 02822 Chain Link Fences and Gates Part 1 - GeneralDocument4 pagesSECTION 02822 Chain Link Fences and Gates Part 1 - GeneralEmad KhanNo ratings yet

- Civil Scope of WorkDocument19 pagesCivil Scope of WorkNazeer NNo ratings yet

- Pages From Civil EngineeringDocument50 pagesPages From Civil EngineeringRagavanNo ratings yet

- FloodBreak 3 Part Specification ROADWAY REV 07-27-2018Document7 pagesFloodBreak 3 Part Specification ROADWAY REV 07-27-2018Bayu Aji PamungkasNo ratings yet

- 2015 FSAE Chassis Rules Quick RefDocument7 pages2015 FSAE Chassis Rules Quick RefAnonymous Ms8nYcbxY2No ratings yet

- QCS Section 22Document12 pagesQCS Section 22hvacsriniNo ratings yet

- Petrex Specs For Honeycomb Internal Floating RoofsDocument5 pagesPetrex Specs For Honeycomb Internal Floating Roofszafarbadal0% (1)

- RCC Thumb RuleDocument7 pagesRCC Thumb RuleRahat ullah100% (6)

- Structural Tips / Thumb RulesDocument7 pagesStructural Tips / Thumb Ruleswindspace3No ratings yet

- Designed and Detailed According To IS 456 As An Ordinary Moment Resisting Frame Also Called Ordinary Concrete FrameDocument3 pagesDesigned and Detailed According To IS 456 As An Ordinary Moment Resisting Frame Also Called Ordinary Concrete FrameAnonymous Gye18jNo ratings yet

- Section-8A-Hardware ACSR BisonDocument9 pagesSection-8A-Hardware ACSR BisonSaroj ShresthaNo ratings yet

- Design Consideration For Metal Forming: 1.extrusionDocument2 pagesDesign Consideration For Metal Forming: 1.extrusionyeswanthNo ratings yet

- Division 23 Hvac: 230548: Vibration Isolation / 230549: Seismic/Wind Restraints Section 230548: Vibration IsolationDocument10 pagesDivision 23 Hvac: 230548: Vibration Isolation / 230549: Seismic/Wind Restraints Section 230548: Vibration IsolationTengku Azaha Tengku IsmailNo ratings yet

- Stainless Steel Flap Gate SpecificationDocument4 pagesStainless Steel Flap Gate SpecificationreluNo ratings yet

- Pontoon IFR Technical Specifications 07-18-06 PDFDocument15 pagesPontoon IFR Technical Specifications 07-18-06 PDFdndudcNo ratings yet

- 233300-AIR DUCT ACCESSORIESDocument15 pages233300-AIR DUCT ACCESSORIESMohamed SokarNo ratings yet

- 2010.1.10 Stitch Rivets and Bolts.Document10 pages2010.1.10 Stitch Rivets and Bolts.minedataNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 pagesSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlNo ratings yet

- Economics For Structural Steel Plate GirdersDocument10 pagesEconomics For Structural Steel Plate Girdersthomas kilianNo ratings yet

- Floating Roof DesinDocument5 pagesFloating Roof Desindimdaliak_985662241No ratings yet

- Specification For Chain Link Fence and GatesDocument8 pagesSpecification For Chain Link Fence and GatesSuresh BabuNo ratings yet

- Bostik Paneltack HM Dekton Tds en 2020Document5 pagesBostik Paneltack HM Dekton Tds en 2020Miguel ZuzaNo ratings yet

- CivbridgeprojectreportDocument7 pagesCivbridgeprojectreportapi-354416115No ratings yet

- Gate ConditionDocument18 pagesGate ConditionkiranrauniyarNo ratings yet

- Wellhead Selection - SummaryDocument5 pagesWellhead Selection - SummaryaaputraNo ratings yet

- Bolted ConnectionsDocument23 pagesBolted ConnectionsNaresh ReddyNo ratings yet

- Civil Work Specification Part 44Document10 pagesCivil Work Specification Part 44AM MANo ratings yet

- Installation Guidelines For Sports & High Mast Lighting StructuresDocument4 pagesInstallation Guidelines For Sports & High Mast Lighting StructuresKenny KenzoNo ratings yet

- Ulc I523-Cfs JoistDocument2 pagesUlc I523-Cfs JoistSumeet patelNo ratings yet

- Ductile Detailing For Earthquake Resistant RCC StrsDocument52 pagesDuctile Detailing For Earthquake Resistant RCC StrsManoj SharmaNo ratings yet

- BSD - CE3103 - Pangilinan, Abel Francis A. - Activity 3Document13 pagesBSD - CE3103 - Pangilinan, Abel Francis A. - Activity 3Shayne Rose OrtegaNo ratings yet

- Design of Connections GateDocument25 pagesDesign of Connections GateShaik Mastan ValiNo ratings yet

- PED AssignmentProblems 2017 PDFDocument10 pagesPED AssignmentProblems 2017 PDFSwapnil GudmalwarNo ratings yet

- General Guidelines InsulationDocument56 pagesGeneral Guidelines InsulationPadmanaban SoundirarajanNo ratings yet

- SECTION 16114 Cable Tray: Part 1 - General Related DocumentsDocument5 pagesSECTION 16114 Cable Tray: Part 1 - General Related DocumentsAhmed GamalNo ratings yet

- 07 Ductile Detailing RC BuildingsDocument52 pages07 Ductile Detailing RC BuildingsManju BirjeNo ratings yet

- Corbon Content Steel 1Document75 pagesCorbon Content Steel 1Aditya GadhaviNo ratings yet

- Reinforcement Detailing in Concrete StructuresDocument6 pagesReinforcement Detailing in Concrete StructurescherogonyaNo ratings yet

- AN BoltsDocument8 pagesAN BoltsAnthony McfayNo ratings yet

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Append 1 Vs Append 2 Comparison ChartDocument16 pagesAppend 1 Vs Append 2 Comparison ChartDeonNo ratings yet

- Soiltech Company ProfileDocument10 pagesSoiltech Company ProfileDeonNo ratings yet

- Specifications: M-60 MetersDocument2 pagesSpecifications: M-60 MetersDeonNo ratings yet

- Product Piping ListDocument1 pageProduct Piping ListDeonNo ratings yet

- Pnadg 949Document98 pagesPnadg 949DeonNo ratings yet

- Denso Butyl S43HT R23 Tape System Rev-01Document2 pagesDenso Butyl S43HT R23 Tape System Rev-01DeonNo ratings yet

- Unideck 2012-10-30Document11 pagesUnideck 2012-10-30DeonNo ratings yet

- Lanele Environmental-Authorisation - Letter FinalDocument44 pagesLanele Environmental-Authorisation - Letter FinalDeonNo ratings yet

- 1 Moze A 2020001Document46 pages1 Moze A 2020001DeonNo ratings yet

- MC Certificate Structural SteelDocument1 pageMC Certificate Structural SteelDeonNo ratings yet

- Final Handover Certificate ITDocument1 pageFinal Handover Certificate ITDeon100% (1)

- ACCEPTANCE Certificate - OFFLOADINGDocument2 pagesACCEPTANCE Certificate - OFFLOADINGDeonNo ratings yet

- Continuous Arabic Sign Language Recognition in User Dependent ModeDocument9 pagesContinuous Arabic Sign Language Recognition in User Dependent ModeTaipe Lopez AndyNo ratings yet

- Manual Dark LegionsDocument31 pagesManual Dark Legionskrycov100% (2)

- Techrite Siemens Siemens Lme Series Burner Controls 013060320901Document28 pagesTechrite Siemens Siemens Lme Series Burner Controls 013060320901Kang KamalNo ratings yet

- Pressure Releif ValveDocument24 pagesPressure Releif Valvemtalha_loveNo ratings yet

- Numerical DifferentiationDocument2 pagesNumerical DifferentiationChang Jae LeeNo ratings yet

- FF S 325Document61 pagesFF S 325chopanalvarezNo ratings yet

- Flashcards Exam 2 ReviewerDocument125 pagesFlashcards Exam 2 ReviewerJhoanie Marie CauanNo ratings yet

- On The Eurocode 8 Limited Damage Criteria For Non-Structural Elements - Analysis and RequirementsDocument10 pagesOn The Eurocode 8 Limited Damage Criteria For Non-Structural Elements - Analysis and RequirementsSoós MártiNo ratings yet

- Exploring C (Recovered)Document494 pagesExploring C (Recovered)navin bamane0% (1)

- Energy Performance of Indian Commercial Buildings 11Document17 pagesEnergy Performance of Indian Commercial Buildings 11vasheena mittalNo ratings yet

- CV Edvin Skaljo PMFDocument4 pagesCV Edvin Skaljo PMFAjdin HalilovicNo ratings yet

- Lee Colortran Status 12-24 & 24-48 Control Console Brochure 1990Document4 pagesLee Colortran Status 12-24 & 24-48 Control Console Brochure 1990Alan Masters100% (1)

- Ulysse 3.4.2 Release NotesDocument3 pagesUlysse 3.4.2 Release NotesDavid Santiago Daza QuirogaNo ratings yet

- Marks of ESE 2023 Qualified CandidatesDocument10 pagesMarks of ESE 2023 Qualified Candidatesthunderbuddy2222No ratings yet

- Lubigan Residence Working Drawings - Bidding DocumentsDocument23 pagesLubigan Residence Working Drawings - Bidding Documentsklent jalecoNo ratings yet

- Thermodyne Boiler BibleDocument144 pagesThermodyne Boiler BibleRicardas KragnysNo ratings yet

- BOSCH-REXROTH - RE18302-09 - VS241-245-246-247 F - NloDocument10 pagesBOSCH-REXROTH - RE18302-09 - VS241-245-246-247 F - Nloaron.maticNo ratings yet

- Cinnetic 2014 PDFDocument60 pagesCinnetic 2014 PDFOscar SpinningaliciaNo ratings yet

- X24C44 256 Bit 16 X 16 Bit: Features DescriptionDocument16 pagesX24C44 256 Bit 16 X 16 Bit: Features DescriptionMarinaBogaoNo ratings yet

- MANUALDocument12 pagesMANUALmimi lrNo ratings yet

- Shaft Hub Connections PDFDocument64 pagesShaft Hub Connections PDFTrung DũngNo ratings yet

- IIT Bombay Recruitment of Jr. Technical Superintendent & Assistant Security Officer Bombay - Last Date: 30th December 2011Document3 pagesIIT Bombay Recruitment of Jr. Technical Superintendent & Assistant Security Officer Bombay - Last Date: 30th December 2011Freshers Plane IndiaNo ratings yet

- Uninstalling and Reinstalling The Windows 2012R2 Failover Clustering FeatureDocument6 pagesUninstalling and Reinstalling The Windows 2012R2 Failover Clustering FeatureNavneetMishraNo ratings yet

- Duty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerDocument3 pagesDuty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerHawaz BeyeneNo ratings yet

- Bezema Acrylate Styrene BasisDocument3 pagesBezema Acrylate Styrene BasisClub classic 350No ratings yet

- Thesis ReportDocument15 pagesThesis ReportTabish ShibliNo ratings yet

- Optical MicrometerDocument2 pagesOptical MicrometerrubensNo ratings yet

- Bare Nickel Chromium Resistance Wire 80%Document1 pageBare Nickel Chromium Resistance Wire 80%energiayservicioNo ratings yet

- 058-9331 MC Air Chisel Manual enDocument25 pages058-9331 MC Air Chisel Manual enIrfan F. WibisonoNo ratings yet

HMT Unideck Generic 2015 - 04 - 02

HMT Unideck Generic 2015 - 04 - 02

Uploaded by

DeonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HMT Unideck Generic 2015 - 04 - 02

HMT Unideck Generic 2015 - 04 - 02

Uploaded by

DeonCopyright:

Available Formats

HMT Unideck Generic 2015_04_02

HMT Unideck – Aluminum Internal Floating Roof

Shell Types: Butt-Welded, Lap-Welded & Riveted

Tanks Types: Internal & Covered

Floating Roof Type: Aluminum Skin & Pontoon (conventional)

Specification

Part 1 – General D. Connections

1.01 Description of Work 1. Hex head AB bolts, ¼” diameter (minimum), shall be

used for structural connections; bolts shall not

The scope of this specification shall include the entire

aluminum internal floating roof system, which may consist of penetrate the structural girder in such a manner that

would extend into the vapor space.

the following: structure, deck sheeting, rim, pontoons,

connections, hardware, gaskets, and accessories. 2. All fasteners shall be austenitic stainless steel, Grade

18-8.

1.02 Design Criteria

3. Beam member splices shall be accomplished by

A. Flotation

utilizing an extruded member that inserts inside the

1. Minimum buoyancy ratio of 2.0 against the roof dead girder member and is fastened in such a manner that

load plus friction force exerted by perimeter seals provides an effective moment-resisting connection,

using a drag coefficient of no less than 3 lbs/ft while distributing the load over a minimum length of no less

floating on a product with a specific gravity of 0.70 than 4.5 inches from each spliced end.

(maximum).

4. Deck sheeting seams shall consist of a 1” minimum lap

2. Roofs shall be capable of staying afloat while having joint and a sufficient clamp beam with thru-fasteners

any two pontoons flooded with a concentrated load of that connect securely within an integral screw slot on

2

500 lbf over a 1 ft area while floating on a product with the primary girder member extrusion.

a specific gravity of 0.70 (maximum).

5. Interior support connections shall be located at the

3. The peripheral rim, as well as all appurtenances and ends of pontoons. Each pontoon end cap shall be no

openings shall submerge a minimum of 4” into the less than 0.09375 inches in thickness and shall be

stored product while floating. equipped with a welded gusset, 0.090 inches thick

B. Structure (minimum) providing a minimum of two (2) ½” diameter

1. Composite beam section shall be of sufficient bolts at the leg housing connection.

modulus to support a concentrated load of 500 lbf 6. Perimeter supports shall be connected directly to the

2

(minimum) within a 1 ft area without exceeding the rim member at the intersection of each individual rim

material yield stress as provided by the Aluminum segment via pre-assembled housings, effectively

Design Manual. serving as the rim splice connection.

2. Clamp beam shall contribute no more than 34% to the 7. Girder-to-rim connections shall be achieved utilizing

total area of the composite beam cross-section. through bolts and a beam seat that connects securely

3. Girder splice members shall be extruded members to the rim utilizing pem stud fasteners.

providing a total cross-sectional area of no less than E. Pontoons / Pontoon Attachment

60% of that provided by the beam member. 1. Pontoons shall be the primary structural member(s),

4. Perimeter rim member shall be an extruded aluminum and of sufficient cross-section to resist all design

alloy open shaped section, symmetric about the x-axis, loading without exceeding the material yield stress.

with sufficient properties to resist forces induced during 2. Pontoons shall have gusseted end caps that connect

regular operation of the roof. directly to either an interior structural support or the rim

C. Support System member. The gussets shall be secured to the pontoon

1. Minimum design loads as determined per Appendix H end cap with a 1/8” (min.) single-side fillet weld and

of the latest edition of API Standard 650. two vertical tab braces (top and bottom of gusset).

2. Underside support members shall be fabricated from 3. Pontoon tubular stock shall be pressure tested to 150

pipe or tube of sufficient cross-section to provide a psig; completed pontoon assemblies shall be pressure

slenderness ratio against local buckling of no more tested to 5 psig. Test couplings shall be welded into

than 17 and an interaction ratio against bi-axial one end cap and plugged with stainless steel threaded

bending of no more than 0.75. plugs.

2. When top-side suspension systems are utilized, the 4. The extruded saddle shall be of sufficient detail to

allowable load on the suspension members shall distribute any load transfer to the pontoon over a

provide a minimum safety factor of 5 against the sector length equivalent to a 59° inside angle

ultimate/breaking strength of the members (3,700 lbs (minimum) and weigh no more than 1 lb.

minimum, per member) and associated connections.

Revision 1, 04/02/2015 Page 1 of 2

HMT Unideck Generic 2015_04_02

Part 2 – Products

2.01 Manufacturer(s)

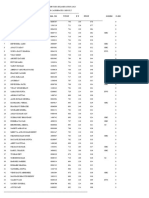

The standard for design, characteristics and performance is 2.03 Accessories

the HMT Unideck as manufactured by HMT, Inc. A. Wells (Ladder / Gauge / Column)

2.02 Components B. Manways, all-aluminum, gasketed and vapor-tight, 24”

A. Extruded Members diameter (minimum)

1. Girders C. Drains, check-ball actuated

• AA6061-T6 / AA6005-T5 D. Anti-rotation Cables, 3/16” diameter (minimum), flexible

• Integral screw slot in top flange stainless steel

• Semi-closed section with no more than 9% of the E. Anti-static Cables, 1/8” diameter (minimum), flexible

cross-section outside circumference open stainless steel

2. Clamp Beam F. Pressure / Vacuum Vents (Leg Actuated and Non-Leg

Actuated)

• AA6061-T6 / AA6005-T5

3. Rim

• AA6063-T5 / AA6005-T5

• Open section with minimum depth of 12”

• Minimum thickness of 0.125”

4. Pontoon Saddles

• AA6061-T6 / AA6005-T5

5. Supports

• AA6061-T6 / AA6063-T6

• Minimum 1.5NPS Schedule 5

B. Plate / Sheet

1. Deck Sheeting

• AA3003-H14 / AA3105-H14 or H16

• Minimum thickness of 0.020”

2. Pontoons

• AA3004-H26

• Minimum thickness of 0.051”

• 8” and/or 10” diameter

3. Pontoon End Caps and Gussets

• AA5052-H32

• End Cap minimum thickness of 0.09375”

• Gusset minimum thickness of 0.090”

• Gusset tab brace minimum thickness 0.125”

4. Pontoon Support Straps

• Support Straps: AA3003-H14

C. Hardware

1. Bolting / Fasteners

• Grade 18-8 stainless steel or Aluminum.

• ¼” or 3/8” diameter (minimum)

2. Pem Studs

• Grade 18-8 stainless steel

• 3/8” -16 UNC, 7/8” length (minimum)

2.02 Dimensions

A. Pontoon diameter: 8”, 10”

B. Pontoon thickness: 0.051” (minimum)

C. Girders: 1.098” x 1.54” (minimum, extents)

D. Pontoon Saddles: 4 7/8” width (minimum)

E. Pontoon Straps: 0.0625” thick x 1.25” width (minimum)

F. Bolts / Fasteners: 1” length (minimum)

Revision 1, 04/02/2015 Page 2 of 2

You might also like

- Astm F567Document4 pagesAstm F567RUI MIGUEL SILVANo ratings yet

- Ductile Details To Seismic Forces - Is 13920Document4 pagesDuctile Details To Seismic Forces - Is 13920MUTHUKKUMARAMNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Mels Constuction Limitada: Commercial Management Mechanical Completion CertificateDocument1 pageMels Constuction Limitada: Commercial Management Mechanical Completion CertificateDeonNo ratings yet

- Final Handover Certificate EarthworksDocument1 pageFinal Handover Certificate EarthworksDeonNo ratings yet

- Electrical - Completion CertificateDocument1 pageElectrical - Completion CertificateDeon100% (1)

- 8DIO Majestica User ManualDocument27 pages8DIO Majestica User ManualDavid BenavidesNo ratings yet

- Cable TraysDocument6 pagesCable TrayssallammohamedNo ratings yet

- Inland Transport Committee: INF.47 Economic Commission For EuropeDocument7 pagesInland Transport Committee: INF.47 Economic Commission For EuropeStan HonNo ratings yet

- RCC Member Design TipsDocument8 pagesRCC Member Design TipsAbhishek ChaudhariNo ratings yet

- Specs For Aluminum Geodesic Batten Domes 2012Document5 pagesSpecs For Aluminum Geodesic Batten Domes 2012RaghNo ratings yet

- SECTION 15070 Mechanical Sound, Vibration, and Seismic ControlDocument8 pagesSECTION 15070 Mechanical Sound, Vibration, and Seismic ControlAbdel HamidNo ratings yet

- RCC Design TipsDocument9 pagesRCC Design Tipssatoni12No ratings yet

- Ductile Detailing of Beam As Per IS 13920Document4 pagesDuctile Detailing of Beam As Per IS 13920Civil FundaNo ratings yet

- Structural TipsDocument7 pagesStructural Tipsbalacr3No ratings yet

- Frame Supported Membrane Structure Part 1 - General 1.1 Related DocumentsDocument13 pagesFrame Supported Membrane Structure Part 1 - General 1.1 Related Documentsloc nguyenNo ratings yet

- RCC Member Design TipsDocument9 pagesRCC Member Design TipsNaren ViratNo ratings yet

- SECTION 02822 Chain Link Fences and Gates Part 1 - GeneralDocument4 pagesSECTION 02822 Chain Link Fences and Gates Part 1 - GeneralEmad KhanNo ratings yet

- Civil Scope of WorkDocument19 pagesCivil Scope of WorkNazeer NNo ratings yet

- Pages From Civil EngineeringDocument50 pagesPages From Civil EngineeringRagavanNo ratings yet

- FloodBreak 3 Part Specification ROADWAY REV 07-27-2018Document7 pagesFloodBreak 3 Part Specification ROADWAY REV 07-27-2018Bayu Aji PamungkasNo ratings yet

- 2015 FSAE Chassis Rules Quick RefDocument7 pages2015 FSAE Chassis Rules Quick RefAnonymous Ms8nYcbxY2No ratings yet

- QCS Section 22Document12 pagesQCS Section 22hvacsriniNo ratings yet

- Petrex Specs For Honeycomb Internal Floating RoofsDocument5 pagesPetrex Specs For Honeycomb Internal Floating Roofszafarbadal0% (1)

- RCC Thumb RuleDocument7 pagesRCC Thumb RuleRahat ullah100% (6)

- Structural Tips / Thumb RulesDocument7 pagesStructural Tips / Thumb Ruleswindspace3No ratings yet

- Designed and Detailed According To IS 456 As An Ordinary Moment Resisting Frame Also Called Ordinary Concrete FrameDocument3 pagesDesigned and Detailed According To IS 456 As An Ordinary Moment Resisting Frame Also Called Ordinary Concrete FrameAnonymous Gye18jNo ratings yet

- Section-8A-Hardware ACSR BisonDocument9 pagesSection-8A-Hardware ACSR BisonSaroj ShresthaNo ratings yet

- Design Consideration For Metal Forming: 1.extrusionDocument2 pagesDesign Consideration For Metal Forming: 1.extrusionyeswanthNo ratings yet

- Division 23 Hvac: 230548: Vibration Isolation / 230549: Seismic/Wind Restraints Section 230548: Vibration IsolationDocument10 pagesDivision 23 Hvac: 230548: Vibration Isolation / 230549: Seismic/Wind Restraints Section 230548: Vibration IsolationTengku Azaha Tengku IsmailNo ratings yet

- Stainless Steel Flap Gate SpecificationDocument4 pagesStainless Steel Flap Gate SpecificationreluNo ratings yet

- Pontoon IFR Technical Specifications 07-18-06 PDFDocument15 pagesPontoon IFR Technical Specifications 07-18-06 PDFdndudcNo ratings yet

- 233300-AIR DUCT ACCESSORIESDocument15 pages233300-AIR DUCT ACCESSORIESMohamed SokarNo ratings yet

- 2010.1.10 Stitch Rivets and Bolts.Document10 pages2010.1.10 Stitch Rivets and Bolts.minedataNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 pagesSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlNo ratings yet

- Economics For Structural Steel Plate GirdersDocument10 pagesEconomics For Structural Steel Plate Girdersthomas kilianNo ratings yet

- Floating Roof DesinDocument5 pagesFloating Roof Desindimdaliak_985662241No ratings yet

- Specification For Chain Link Fence and GatesDocument8 pagesSpecification For Chain Link Fence and GatesSuresh BabuNo ratings yet

- Bostik Paneltack HM Dekton Tds en 2020Document5 pagesBostik Paneltack HM Dekton Tds en 2020Miguel ZuzaNo ratings yet

- CivbridgeprojectreportDocument7 pagesCivbridgeprojectreportapi-354416115No ratings yet

- Gate ConditionDocument18 pagesGate ConditionkiranrauniyarNo ratings yet

- Wellhead Selection - SummaryDocument5 pagesWellhead Selection - SummaryaaputraNo ratings yet

- Bolted ConnectionsDocument23 pagesBolted ConnectionsNaresh ReddyNo ratings yet

- Civil Work Specification Part 44Document10 pagesCivil Work Specification Part 44AM MANo ratings yet

- Installation Guidelines For Sports & High Mast Lighting StructuresDocument4 pagesInstallation Guidelines For Sports & High Mast Lighting StructuresKenny KenzoNo ratings yet

- Ulc I523-Cfs JoistDocument2 pagesUlc I523-Cfs JoistSumeet patelNo ratings yet

- Ductile Detailing For Earthquake Resistant RCC StrsDocument52 pagesDuctile Detailing For Earthquake Resistant RCC StrsManoj SharmaNo ratings yet

- BSD - CE3103 - Pangilinan, Abel Francis A. - Activity 3Document13 pagesBSD - CE3103 - Pangilinan, Abel Francis A. - Activity 3Shayne Rose OrtegaNo ratings yet

- Design of Connections GateDocument25 pagesDesign of Connections GateShaik Mastan ValiNo ratings yet

- PED AssignmentProblems 2017 PDFDocument10 pagesPED AssignmentProblems 2017 PDFSwapnil GudmalwarNo ratings yet

- General Guidelines InsulationDocument56 pagesGeneral Guidelines InsulationPadmanaban SoundirarajanNo ratings yet

- SECTION 16114 Cable Tray: Part 1 - General Related DocumentsDocument5 pagesSECTION 16114 Cable Tray: Part 1 - General Related DocumentsAhmed GamalNo ratings yet

- 07 Ductile Detailing RC BuildingsDocument52 pages07 Ductile Detailing RC BuildingsManju BirjeNo ratings yet

- Corbon Content Steel 1Document75 pagesCorbon Content Steel 1Aditya GadhaviNo ratings yet

- Reinforcement Detailing in Concrete StructuresDocument6 pagesReinforcement Detailing in Concrete StructurescherogonyaNo ratings yet

- AN BoltsDocument8 pagesAN BoltsAnthony McfayNo ratings yet

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Append 1 Vs Append 2 Comparison ChartDocument16 pagesAppend 1 Vs Append 2 Comparison ChartDeonNo ratings yet

- Soiltech Company ProfileDocument10 pagesSoiltech Company ProfileDeonNo ratings yet

- Specifications: M-60 MetersDocument2 pagesSpecifications: M-60 MetersDeonNo ratings yet

- Product Piping ListDocument1 pageProduct Piping ListDeonNo ratings yet

- Pnadg 949Document98 pagesPnadg 949DeonNo ratings yet

- Denso Butyl S43HT R23 Tape System Rev-01Document2 pagesDenso Butyl S43HT R23 Tape System Rev-01DeonNo ratings yet

- Unideck 2012-10-30Document11 pagesUnideck 2012-10-30DeonNo ratings yet

- Lanele Environmental-Authorisation - Letter FinalDocument44 pagesLanele Environmental-Authorisation - Letter FinalDeonNo ratings yet

- 1 Moze A 2020001Document46 pages1 Moze A 2020001DeonNo ratings yet

- MC Certificate Structural SteelDocument1 pageMC Certificate Structural SteelDeonNo ratings yet

- Final Handover Certificate ITDocument1 pageFinal Handover Certificate ITDeon100% (1)

- ACCEPTANCE Certificate - OFFLOADINGDocument2 pagesACCEPTANCE Certificate - OFFLOADINGDeonNo ratings yet

- Continuous Arabic Sign Language Recognition in User Dependent ModeDocument9 pagesContinuous Arabic Sign Language Recognition in User Dependent ModeTaipe Lopez AndyNo ratings yet

- Manual Dark LegionsDocument31 pagesManual Dark Legionskrycov100% (2)

- Techrite Siemens Siemens Lme Series Burner Controls 013060320901Document28 pagesTechrite Siemens Siemens Lme Series Burner Controls 013060320901Kang KamalNo ratings yet

- Pressure Releif ValveDocument24 pagesPressure Releif Valvemtalha_loveNo ratings yet

- Numerical DifferentiationDocument2 pagesNumerical DifferentiationChang Jae LeeNo ratings yet

- FF S 325Document61 pagesFF S 325chopanalvarezNo ratings yet

- Flashcards Exam 2 ReviewerDocument125 pagesFlashcards Exam 2 ReviewerJhoanie Marie CauanNo ratings yet

- On The Eurocode 8 Limited Damage Criteria For Non-Structural Elements - Analysis and RequirementsDocument10 pagesOn The Eurocode 8 Limited Damage Criteria For Non-Structural Elements - Analysis and RequirementsSoós MártiNo ratings yet

- Exploring C (Recovered)Document494 pagesExploring C (Recovered)navin bamane0% (1)

- Energy Performance of Indian Commercial Buildings 11Document17 pagesEnergy Performance of Indian Commercial Buildings 11vasheena mittalNo ratings yet

- CV Edvin Skaljo PMFDocument4 pagesCV Edvin Skaljo PMFAjdin HalilovicNo ratings yet

- Lee Colortran Status 12-24 & 24-48 Control Console Brochure 1990Document4 pagesLee Colortran Status 12-24 & 24-48 Control Console Brochure 1990Alan Masters100% (1)

- Ulysse 3.4.2 Release NotesDocument3 pagesUlysse 3.4.2 Release NotesDavid Santiago Daza QuirogaNo ratings yet

- Marks of ESE 2023 Qualified CandidatesDocument10 pagesMarks of ESE 2023 Qualified Candidatesthunderbuddy2222No ratings yet

- Lubigan Residence Working Drawings - Bidding DocumentsDocument23 pagesLubigan Residence Working Drawings - Bidding Documentsklent jalecoNo ratings yet

- Thermodyne Boiler BibleDocument144 pagesThermodyne Boiler BibleRicardas KragnysNo ratings yet

- BOSCH-REXROTH - RE18302-09 - VS241-245-246-247 F - NloDocument10 pagesBOSCH-REXROTH - RE18302-09 - VS241-245-246-247 F - Nloaron.maticNo ratings yet

- Cinnetic 2014 PDFDocument60 pagesCinnetic 2014 PDFOscar SpinningaliciaNo ratings yet

- X24C44 256 Bit 16 X 16 Bit: Features DescriptionDocument16 pagesX24C44 256 Bit 16 X 16 Bit: Features DescriptionMarinaBogaoNo ratings yet

- MANUALDocument12 pagesMANUALmimi lrNo ratings yet

- Shaft Hub Connections PDFDocument64 pagesShaft Hub Connections PDFTrung DũngNo ratings yet

- IIT Bombay Recruitment of Jr. Technical Superintendent & Assistant Security Officer Bombay - Last Date: 30th December 2011Document3 pagesIIT Bombay Recruitment of Jr. Technical Superintendent & Assistant Security Officer Bombay - Last Date: 30th December 2011Freshers Plane IndiaNo ratings yet

- Uninstalling and Reinstalling The Windows 2012R2 Failover Clustering FeatureDocument6 pagesUninstalling and Reinstalling The Windows 2012R2 Failover Clustering FeatureNavneetMishraNo ratings yet

- Duty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerDocument3 pagesDuty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerHawaz BeyeneNo ratings yet

- Bezema Acrylate Styrene BasisDocument3 pagesBezema Acrylate Styrene BasisClub classic 350No ratings yet

- Thesis ReportDocument15 pagesThesis ReportTabish ShibliNo ratings yet

- Optical MicrometerDocument2 pagesOptical MicrometerrubensNo ratings yet

- Bare Nickel Chromium Resistance Wire 80%Document1 pageBare Nickel Chromium Resistance Wire 80%energiayservicioNo ratings yet

- 058-9331 MC Air Chisel Manual enDocument25 pages058-9331 MC Air Chisel Manual enIrfan F. WibisonoNo ratings yet