Professional Documents

Culture Documents

7 Setting Up and Commissioning 7.5 Installation Documentation

7 Setting Up and Commissioning 7.5 Installation Documentation

Uploaded by

Louis ChewOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 Setting Up and Commissioning 7.5 Installation Documentation

7 Setting Up and Commissioning 7.5 Installation Documentation

Uploaded by

Louis ChewCopyright:

Available Formats

7 SETTING UP AND COMMISSIONING

7.5 INSTALLATION DOCUMENTATION

7.5 INSTALLATION DOCUMENTATION

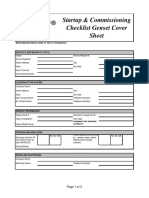

7.5.1 Installation Checklist

The Installation Checklist is a guide to the installing engineer and documents the installation pro-

cedure. The checklist is sequential and each stage of the procedure should be ticked once com-

pleted.

No. Machine Preparation Completed

1 Check Machine for Transit Damage

2 Check Accessories are Correct to the Packing list

3 Transport to Final Destination

4 Remove Grease Protection

5 Remove Transit Protection

6 Set Machine Height and Level

7 Fit Machine Light Tower

No. Power Up Sequence Completed

8 Carry Out Pre Power Up Checks

9 Measure Customer Factory Electrical Supply

10 Fit Electrical Plug for Customers Site

11 Set Time and Date

12 Check Correct Operation of E Stop Loop compon-

ents

13 Check Correct Operation of Cover Opening

14 Carry out Under Stencil Clean Function Check

15 Carry out Paste Dispenser Function Check

No. FMI Completed

16 Check Operation of Interface

No. Machine Performance Completed

17 Machine Alignment Capability:

Cp Cpk No Change

X Alignment

Y Alignment

ΘAlignment

Process Alignment Capability:

Cp Cpk No Change

X Alignment

Y Alignment

ΘAlignment

No. Machine Performance Upgrades (MPU's) Completed

18 Fit all MPU's and Record in the following table

(Record N/A for MPU's not supplied)

96 INSTRUCTION MANUAL DEK TQ SERIES 07/2020

7 SETTING UP AND COMMISSIONING

7.5 INSTALLATION DOCUMENTATION

MPU Number Description Fitted

No. Documentation Completed

19 Installation Report

20 Acceptance Certificate

No. Service Due Completed

21 Check the Next Service Due label has been filled in

(located on the rear panel)

No. Fifth Leg Completed

22 Check the fifth leg has been wound up (see warning

label located on the rear panel)

No. On Site Training Completed

23 Training at Installation

MACHINE MODEL

MACHINE SERIAL NUMBER

INSTRUCTION MANUAL DEK TQ SERIES 07/2020 97

7 SETTING UP AND COMMISSIONING

7.5 INSTALLATION DOCUMENTATION

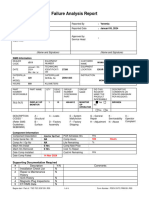

7.5.2 Installation Report

The Installation Report, on the next page, provides documentary evidence to ASM Assembly Sys-

tems that the printer delivered meets the ordered specification and was installed, and that customer

personnel have been instructed on the operational safety of the printer.

98 INSTRUCTION MANUAL DEK TQ SERIES 07/2020

7 SETTING UP AND COMMISSIONING

7.5 INSTALLATION DOCUMENTATION

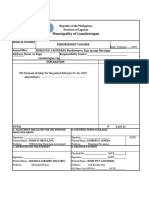

Installation Report über / for ASM SMT Solutions

Der Installation Report dokumentiert den gemeinsam von Service / In the installation report customer agrees that this document specifies

Systemabnahme und dem Kunden festgestellten Stand der Linie the installation of the equipment.

Kunde / Customer

Firma

Company Name

PLZ / Ort Telefon

Zip-Code / City Phone

Auftrag/Order No e-Mail

Installation

Name Abteilung

Setup Engineer Department

von [Datum] bis [Datum]

from [Date] until [Date]

Leistungsdaten / Performance data

Bestückprogrm. Rüstung

Program version Setup

Anzahl Leiterpl. BE/Leiterplatte Testlauf [min]

Number of Brds. Comp./Board Test Run [min]

Die sicherheitstechnischen Einrichtungen wurden überprüft Fragebogen "Customer Feedback" wurde übergeben

The safety devices have been inspected The "Customer Feedback" form was delivered

Die Aufstellung und die Inbetriebnahme beim Kunden sind erfolgt. Die Anlage steht zur produktiven Nutzung bereit.

The installation and the startup of the systems is complete. The systems are ready for productive use.

Die aufgeführten Personen wurden über die Sicherheitshinweise der Betriebsanleitung / Kapitel 2 "Betriebssicherheit" unterwiesen.

The listed persons have been instructed about the safety instructions of the user manual as detailed within "operational safety".

Der USB-Stick mit den Software-Sicherheitskopien und den Wartungsanleitungen/-filmen wurde übergeben

The software backup copies of the station-software / printer software and the maintainace-manuals/-movies has been delivered

Software Lizenzen wurden übergeben

The Software Licenses were submitted

Unterwiesenes Kundenpersonal / Instructed Customer Personnel

Bediener Einrichter Programmierer

Name Operator Line Engineer Programmer

1

Die Abnahme wurde NICHT ausgesprochen. Begründung bitte unter "Bemerkungen/offene Punkte" eintragen

The acceptance of the system was NOT agreed. Please record reasons below in "Comments, Work to be done"

Bemerkungen, offene Punkte / Comments, Work to be done

Fortsetzungsblatt

Additional sheet

Ort, Datum / Location, Date Unterschrift / Signature ASM AS Engineer Unterschrift Kunde / Signature Customer Unterschrift Vertrieb / Signature Sales

ASM Assembly Systems GmbH & Co KG

Rupert-Mayer-Str. 44

D-81379 Munich

Verteiler / Distribution Original :: Process-/ System Acceptance

Tel. +49 (89) 20800-48081 Fax +49 (89) 20800-28728

Kopie /Copy : Kunde / Customer Email: Feedback-SCM2.siplace@asmpt.com

r0164_anlage01.docx / ASM AS SCM 22 / Th. Kreiß / 12.06.2017

INSTRUCTION MANUAL DEK TQ SERIES 07/2020 99

7 SETTING UP AND COMMISSIONING

7.5 INSTALLATION DOCUMENTATION

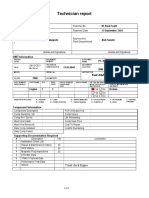

7.5.3 Acceptance Certificate

The Acceptance Certificate provides documentary evidence to ASM Assembly Systems that the

customer has received a satisfactory product. The document also enables the Customer Support

Group to provide support to the customer by having machine details close to hand in the event of a

query.

100 INSTRUCTION MANUAL DEK TQ SERIES 07/2020

7 SETTING UP AND COMMISSIONING

7.5 INSTALLATION DOCUMENTATION

Bearbeiter Tel. Lieferfreigabe

Prepared by Phone Customer Release / Pre Acceptance

Kunde / Customer

Firma Abnahmeprotokoll

Company Acceptance Certificate

Abteilung

Department über / for

Name ASM SMT Solutions

Telefon

Phone

Straße SAP-Auftragsnummer

Street SAP-Ordernumber

PLZ / Ort

Zip-Code / City

Kunden-Bestellzeichen / Customer's Order No.

Anlieferdatum Kunde / Date of Arrival at Customer's Site

Der aktuelle Auftragsumfang ist im Lieferschein dokumentiert Mitarbeiter des Bestellers sind in der Bedienung des

The current scope of orders is documented in the delivery note Automaten unterwiesen

Customer's personnel have been instructed in system

operation

Bemerkungen, offene Punkte / Comments, Work to be done

Fortsetzungsblatt

Additional sheet

Die Lieferfreigabe wird hiermit ausgesprochen

The release of the system is herewith agreed

Die Aufstellung und die Inbetriebnahme beim Kunden sind erfolgt

The installation and the startup of the system are completed

Ein produktiver Testlauf wurde durchgeführt Stunden

A test run was performed under working conditions hours

Die Anlage steht zur produktiven Nutzung bereit ab Datum

The system is ready for productive use since date

Unterschrift

Signature

Ort, Datum / Location, Date Unterschrift / Signature ASM AS Engineer Unterschrift Kunde / Signature Customer Unterschrift Vertrieb / Signature Sales

ASM Assembly Systems GmbH & Co KG

Rupert-Mayer-Str. 44

D-81379 Munich

Verteiler / Distribution Original :: Process-/ System Acceptance

Tel. +49 (89) 20800-48081 Fax +49 (89) 20800-28728

Kopie /Copy : Kunde / Customer Email: Feedback-SCM2.siplace@asmpt.com

r0164_anlage02.docx / ASM AS SCM 22 / Th. Kreiß / 12.06.2017

INSTRUCTION MANUAL DEK TQ SERIES 07/2020 101

You might also like

- The Hollywood Film Music Reader PDFDocument393 pagesThe Hollywood Film Music Reader PDFMarc100% (1)

- TEM 270 Installation and Operational Qualification Protocol Template SampleDocument5 pagesTEM 270 Installation and Operational Qualification Protocol Template SampleJoe Clarke100% (1)

- FAT ChecklistDocument17 pagesFAT ChecklistNoe Jimenez100% (2)

- Genset Startup and Commissioning Checklist C 175Document3 pagesGenset Startup and Commissioning Checklist C 175Dwi Mulyanti Dwimulyantishop100% (1)

- MOTOR INSTALLATION ChecklistDocument4 pagesMOTOR INSTALLATION ChecklistWisnu Hartono100% (2)

- DSRDocument2 pagesDSRJosé Carlos CarvalhoNo ratings yet

- AHU OQ & PQ DocumentDocument12 pagesAHU OQ & PQ DocumentAnurag KumbhareNo ratings yet

- Cooling Tower Construction ChecklistDocument6 pagesCooling Tower Construction ChecklistGopinath GopiNo ratings yet

- Income Inequality in Singapore: Causes, Consequences and Policy Options - Ishita DhamaniDocument31 pagesIncome Inequality in Singapore: Causes, Consequences and Policy Options - Ishita DhamaniJunyuan100% (1)

- Modbus Check Sheet ExampleDocument2 pagesModbus Check Sheet ExampleGuston SupriyadiNo ratings yet

- Tooo': oOO OO.Document28 pagesTooo': oOO OO.ediasianagriNo ratings yet

- 1.mechanical - Electrical Completion Inspection Checklist - E20812Document3 pages1.mechanical - Electrical Completion Inspection Checklist - E20812Lulu ChaniagoNo ratings yet

- 721-009-G1 i5RFDSA-InstallationReport 0 2Document4 pages721-009-G1 i5RFDSA-InstallationReport 0 2CaleNo ratings yet

- Pre-Commissioning Check Sheet: InstrumentsDocument1 pagePre-Commissioning Check Sheet: InstrumentshrimklimNo ratings yet

- Standard Commissioning Procedure For Building Exhaust Fans: General NotesDocument9 pagesStandard Commissioning Procedure For Building Exhaust Fans: General NotesAbdul Mohid SheikhNo ratings yet

- Blender IqDocument25 pagesBlender Iqmmm islamNo ratings yet

- Bacnet Verification System Pre-Functional Checklist: Statement of ReadinessDocument10 pagesBacnet Verification System Pre-Functional Checklist: Statement of Readinessnitroxx7No ratings yet

- Test and Inspection Data: Warning!Document2 pagesTest and Inspection Data: Warning!MuratOguz UcakNo ratings yet

- Pre-Commissioning Check Sheet: InstrumentsDocument1 pagePre-Commissioning Check Sheet: InstrumentshrimklimNo ratings yet

- A Check Format (With New Segmentation) Rev3 02082019Document17 pagesA Check Format (With New Segmentation) Rev3 02082019Anil KumarNo ratings yet

- Test and Inspection Data: Warning!Document2 pagesTest and Inspection Data: Warning!joam36No ratings yet

- GE E4879 Certified Component Verification BSDDocument12 pagesGE E4879 Certified Component Verification BSDEduardo RibasNo ratings yet

- COM J AI 001 R0 AnalogInputPreCommissioningDocument1 pageCOM J AI 001 R0 AnalogInputPreCommissioningAlessandro CamposNo ratings yet

- Eng GB SP A60h Stage IV V DDocument8 pagesEng GB SP A60h Stage IV V DYudha SetiawanNo ratings yet

- AppendixK PFC 262300LowVoltageSwitchgearDocument3 pagesAppendixK PFC 262300LowVoltageSwitchgearnitroxx7No ratings yet

- Checklist of Final Settings Review Rev01Document1 pageChecklist of Final Settings Review Rev01Santhosh Kumar VinayagamNo ratings yet

- AIAGDocument29 pagesAIAGGunNandaTianPurnamaNo ratings yet

- Exemple PPAPDocument62 pagesExemple PPAPmoezNo ratings yet

- Sample PPAP Level-3Document36 pagesSample PPAP Level-3Mr. Mafia BhargavNo ratings yet

- GM 1927 16 Process Control Plan Audit PCPADocument7 pagesGM 1927 16 Process Control Plan Audit PCPAMostafa Abd ElalemNo ratings yet

- IQ Template For StudentDocument9 pagesIQ Template For StudentYejin JangNo ratings yet

- Far ZBN41205Document4 pagesFar ZBN41205yeremia kristianNo ratings yet

- Electrical Commissioning Procedure: Document Number Version Number AuthorDocument16 pagesElectrical Commissioning Procedure: Document Number Version Number Authorizzy umandalNo ratings yet

- Dust Extractor IqoqpqDocument10 pagesDust Extractor Iqoqpqpinnacle qaNo ratings yet

- Adp-270523-007 r1 TV Services (Smatv) (A)Document28 pagesAdp-270523-007 r1 TV Services (Smatv) (A)saithu09janNo ratings yet

- CA10 20 DSI 12 02 en STDDocument183 pagesCA10 20 DSI 12 02 en STDDiego PietkowskyNo ratings yet

- 5x Engine Component Condition Report Gen AlignmentDocument15 pages5x Engine Component Condition Report Gen AlignmentSidik NopiansyahNo ratings yet

- FG Wilson India Operator (2 Cyl) PDFDocument69 pagesFG Wilson India Operator (2 Cyl) PDFviraj arjun ghadageNo ratings yet

- Process Flow/Control Plan WorksheetDocument4 pagesProcess Flow/Control Plan WorksheetVu NguyenNo ratings yet

- Report Genset TimbanganDocument4 pagesReport Genset TimbanganmahmudiNo ratings yet

- Precommissioning Checklist of Pa SystemDocument1 pagePrecommissioning Checklist of Pa SystemTamer EidNo ratings yet

- 3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommDocument10 pages3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommNishit KhuntNo ratings yet

- Generic Test & Acceptance ChecklistDocument24 pagesGeneric Test & Acceptance ChecklistM Kashif JunaidNo ratings yet

- 6ra7031 6dv62 0 Siomreg DC Converter Siemens ManualDocument234 pages6ra7031 6dv62 0 Siomreg DC Converter Siemens ManualBorislav ChavdarovNo ratings yet

- Testing Direct Digital Controls (DDC)Document11 pagesTesting Direct Digital Controls (DDC)efasaravananNo ratings yet

- VAL-SV - E-0170-P TD WSM 450 Wave Solder Machine Rev 1 Gabriel 2 Dec 2016 (1) - Edy4decDocument19 pagesVAL-SV - E-0170-P TD WSM 450 Wave Solder Machine Rev 1 Gabriel 2 Dec 2016 (1) - Edy4decarumNo ratings yet

- C-040 Annual Maintenance Checklist For Planmed ClarityDocument4 pagesC-040 Annual Maintenance Checklist For Planmed ClarityRomell DionaNo ratings yet

- 611 ConfigurationDocument432 pages611 ConfigurationchristianNo ratings yet

- Installation Bitling: t31S9 Ip &Document1 pageInstallation Bitling: t31S9 Ip &The Fashion CollectionsNo ratings yet

- TR Differential Ret670 Y YDocument19 pagesTR Differential Ret670 Y Ym khNo ratings yet

- TR Differential Ret670Document19 pagesTR Differential Ret670Mahdi AlamriNo ratings yet

- CCTV Method Statement Final Rev-01 PDFDocument33 pagesCCTV Method Statement Final Rev-01 PDFabdul wasay100% (2)

- eclipse Installation Checklist (Form A) and MDE-4227 Encore/Eclipse Start-Up Checklist (Form B)Document1 pageeclipse Installation Checklist (Form A) and MDE-4227 Encore/Eclipse Start-Up Checklist (Form B)Ahmed AbdoNo ratings yet

- Queue Management SystemDocument1 pageQueue Management SystemMuhammad MehboobNo ratings yet

- AQPP Check List NewDocument17 pagesAQPP Check List NewSuresh KumarNo ratings yet

- 5.2. Internal Light & Wiring Device Function TestDocument2 pages5.2. Internal Light & Wiring Device Function TestMariam AwadNo ratings yet

- Nternet Protocol Based CCTV CameraDocument1 pageNternet Protocol Based CCTV CameraJason SalazarNo ratings yet

- ISU - BBP - DM - 17 Meter InstallationDocument5 pagesISU - BBP - DM - 17 Meter InstallationBhasaar65No ratings yet

- Package Cover Sheet Line Maintenance: Certificate of Release To ServiceDocument6 pagesPackage Cover Sheet Line Maintenance: Certificate of Release To ServiceFemi AgbanaNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Multivariable Predictive Control: Applications in IndustryFrom EverandMultivariable Predictive Control: Applications in IndustryNo ratings yet

- ESCATEC TQ - STATUS (Update Oct)Document17 pagesESCATEC TQ - STATUS (Update Oct)Louis ChewNo ratings yet

- NuMotion Error ListsDocument53 pagesNuMotion Error ListsLouis ChewNo ratings yet

- Software Upgrade InstructionsDocument9 pagesSoftware Upgrade InstructionsLouis ChewNo ratings yet

- I.C.T Reflow Oven L8 Manual V1.0Document30 pagesI.C.T Reflow Oven L8 Manual V1.0Louis ChewNo ratings yet

- I.C.T Online Jet Dispensing MachineDocument4 pagesI.C.T Online Jet Dispensing MachineLouis ChewNo ratings yet

- I.C.T L Series Reflow OvenDocument3 pagesI.C.T L Series Reflow OvenLouis ChewNo ratings yet

- I.C.T SMT&DIP PCB Handling MachineDocument32 pagesI.C.T SMT&DIP PCB Handling MachineLouis ChewNo ratings yet

- I.C.T Upscale Inspection Conveyor V1.0 - HC1000 With LightDocument9 pagesI.C.T Upscale Inspection Conveyor V1.0 - HC1000 With LightLouis ChewNo ratings yet

- I.C.T Semi-Auto SMT PrinterDocument3 pagesI.C.T Semi-Auto SMT PrinterLouis ChewNo ratings yet

- I.C.T SMT Workshop Construction Requirements ListDocument8 pagesI.C.T SMT Workshop Construction Requirements ListLouis ChewNo ratings yet

- Introduction of MISDocument36 pagesIntroduction of MISdollyNo ratings yet

- Lesson 4. Statutory Monetary Benefits PDFDocument65 pagesLesson 4. Statutory Monetary Benefits PDFFranz LibreNo ratings yet

- H 046 006153 00 iPM Service Manual 1.0 PDFDocument130 pagesH 046 006153 00 iPM Service Manual 1.0 PDFSardhara TrusharNo ratings yet

- Acceleration PrincipleDocument2 pagesAcceleration PrincipleRashidAliNo ratings yet

- EDMDocument20 pagesEDMlogeshboy007No ratings yet

- CH 12 Consumer ProtectionDocument78 pagesCH 12 Consumer Protectionleena shijuNo ratings yet

- York VRF CatalogDocument52 pagesYork VRF CatalogVijay Kumar100% (2)

- Electronic Waste 1 1Document12 pagesElectronic Waste 1 1Harsha vardhanNo ratings yet

- Municipality of Camalaniugan: Amounting ToDocument3 pagesMunicipality of Camalaniugan: Amounting ToMelody Frac ZapateroNo ratings yet

- Saga of Indias Cold Chain DevelopmentDocument47 pagesSaga of Indias Cold Chain DevelopmentseadogNo ratings yet

- May Free Chapter - Middle School 2 by James PattersonDocument12 pagesMay Free Chapter - Middle School 2 by James PattersonRandomHouseAU43% (14)

- Buildings On RailsDocument3 pagesBuildings On RailsZachary RobinsonNo ratings yet

- Bridgeing The Gap Between Academia and IndustryDocument3 pagesBridgeing The Gap Between Academia and Industrypankaj_97No ratings yet

- Sil ReviewDocument19 pagesSil Reviewtrung2i100% (1)

- Iron Ore Exploration - Geology and Geophysics InvestigationDocument24 pagesIron Ore Exploration - Geology and Geophysics InvestigationAdrianto SetiadiNo ratings yet

- Differential Amplifier: Mrs.V.Srirenganachiyar, Ap/Ece Ramco Institute of Technology Academic Year:2017-2018 (Odd)Document13 pagesDifferential Amplifier: Mrs.V.Srirenganachiyar, Ap/Ece Ramco Institute of Technology Academic Year:2017-2018 (Odd)Hitlar MamaNo ratings yet

- Unit 2.1 FOREX MarketDocument39 pagesUnit 2.1 FOREX Markethannah0781No ratings yet

- RPAS Installation GuideDocument79 pagesRPAS Installation Guidevarachartered283No ratings yet

- 2 - How To Cretae PIRDocument8 pages2 - How To Cretae PIRSambit MohantyNo ratings yet

- Murray's Catering MenuDocument12 pagesMurray's Catering MenuMarketingNo ratings yet

- How Do I Manually Boot HP-UX On Integrity (Itanium) Based SystemsDocument6 pagesHow Do I Manually Boot HP-UX On Integrity (Itanium) Based Systemsnilu772008No ratings yet

- Dacasin Vs DacasinDocument1 pageDacasin Vs DacasinJulian DubaNo ratings yet

- 083 RFID Door Lock CodeDocument2 pages083 RFID Door Lock CodeWahyu RestuNo ratings yet

- Pic 16 F 1527Document354 pagesPic 16 F 1527Attila IllésNo ratings yet

- Rand Func in WordDocument3 pagesRand Func in WordEngr Binish RazaNo ratings yet

- EFHSIS MilestonesDocument26 pagesEFHSIS Milestoneszhei43No ratings yet

- Computer Science #3Document356 pagesComputer Science #3Sean s Chipanga100% (1)