Professional Documents

Culture Documents

CNG - Electrically Conductive Compressed Natural Gas Hose: Features Certifications

CNG - Electrically Conductive Compressed Natural Gas Hose: Features Certifications

Uploaded by

Percy Quispe - IVAFIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CNG - Electrically Conductive Compressed Natural Gas Hose: Features Certifications

CNG - Electrically Conductive Compressed Natural Gas Hose: Features Certifications

Uploaded by

Percy Quispe - IVAFICopyright:

Available Formats

Hose

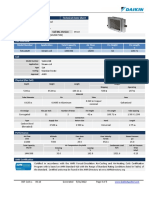

CNG – Electrically Conductive Compressed A

Natural Gas Hose

Features

Twin and multi-line available

Certifications

Conforms to:

Tubing

NFPA 52

ANSI/IAS NGV 4.2-1999

CSA12.52-M99 B

Applications/Markets

Coiled Air Hose

CNG Dispenser

& Fittings

Fleet transit

CNG Fuel transfer

Residential CNG refueling C

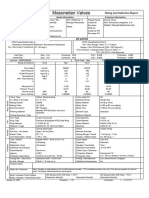

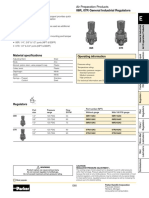

Maximum Minimum

Part Nominal Maximum Working Bend Weight

Number I.D. O.D. Pressure Radius

Transportation

lbs

inch mm inch mm psi MPa inch mm lbs./ft. kg./mtr.

5CNG-3 3/16 5 .43 11 5,000 34.5 1.50 38 .05 .07

5CNG-4 1/4 6 .62 16 5,000 34.5 2.00 51 .11 .16 D

5CNG-6 3/8 10 .65 16 5,000 34.5 3.00 76 .09 .13

5CNG-8 1/2 13 .90 23 5,000 34.5 4.00 102 .21 .31

5CNG-12 3/4 19 1.15 29 5,000 34.5 7.50 191 .24 .36

5CNG-16 1 25 1.59 40 5,000 34.5 10.00 254 .36 .53

Fittings

Construction Colors

Tube: Electrically conductive nylon Red E

Reinforcement: Fiber

Notes

Cover: Polyurethane

Perforated cover

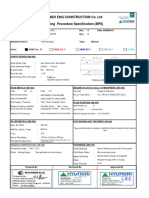

Operating Parameters CNG hose must be assembled at the factory or by a Parflex

approved facility

Tooling, Equipment

Temperature Range:

Wire spring guards must be used on ANSI/CSA design

& Accessories

-40°F to +180°F (-40°C to +82°C) certified CNG dispenser hose assembly sizes -3 through -8:

Min. Burst Pressure is 4x Max. Working Pressure at 73°F (23°C) single and multi-line bonded assemblies - pg. F-21

Fittings

Factory-made assemblies only F

55 Series – pg. E-12 58 Series – pg. E-12

58H Series – pg. E-41

For Crimp Die Selection charts see pgs. G-30 : G-41

General Technical

For detailed ordering information, please consult price list or contact Parflex® Division. G

Parker Hannifin Corporation | Parflex® Division | Ravenna, Ohio | parker.com/pfd A-53

You might also like

- Fluid Circuit Identification On AircraftDocument9 pagesFluid Circuit Identification On AircraftenglismanNo ratings yet

- FM 1-49 Sept 2009Document25 pagesFM 1-49 Sept 2009sancorzNo ratings yet

- 4660 CNG PDFDocument2 pages4660 CNG PDFdsanabraNo ratings yet

- CNG Hose and Fittings Tech Literature E-HOTH-TT001-E January 2016Document12 pagesCNG Hose and Fittings Tech Literature E-HOTH-TT001-E January 2016Iqbal Rusdan AriefNo ratings yet

- H2 CNG LNG Presentation For The NGV 22Document14 pagesH2 CNG LNG Presentation For The NGV 22jayendrapatilNo ratings yet

- 919/919B - PTFE Hose: FeaturesDocument1 page919/919B - PTFE Hose: Featureshoussem houssemNo ratings yet

- Testpoint.: The Compact, Quick Fastening Measurement CouplingDocument10 pagesTestpoint.: The Compact, Quick Fastening Measurement CouplingSamad A BakarNo ratings yet

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocument1 pageWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNo ratings yet

- 6143-MAR-EU-1028 - R0 (1) Approved MAR For PVC Warning Tape For Buried Cable-Galaxy PlasticDocument56 pages6143-MAR-EU-1028 - R0 (1) Approved MAR For PVC Warning Tape For Buried Cable-Galaxy PlasticNAVANEETHNo ratings yet

- 6143-MAR-EU-1027 - R0 (1) Approved MAR For Duct Sealing-Al Seeb TradingDocument44 pages6143-MAR-EU-1027 - R0 (1) Approved MAR For Duct Sealing-Al Seeb TradingNAVANEETHNo ratings yet

- MN 176323 24Document3 pagesMN 176323 24nawaz.ahmed.spnutra.comNo ratings yet

- DPL DripPanElbowDocument1 pageDPL DripPanElbowPartha Sarathi SadhukhanNo ratings yet

- 421 and 482TC/ST Braided Hydraulic HoseDocument1 page421 and 482TC/ST Braided Hydraulic HoseMiroslaw LabudaNo ratings yet

- CNG Solenoid Valve v5.0 PDFDocument1 pageCNG Solenoid Valve v5.0 PDFDavid EspinozaNo ratings yet

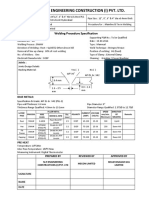

- Welding Procecure SpecificationDocument9 pagesWelding Procecure SpecificationNwoha PeterNo ratings yet

- 341 Series HoseDocument1 page341 Series Hoseprakhar tandonNo ratings yet

- Submittal-Weicco PS-Geco-BMW-03.10.23Document50 pagesSubmittal-Weicco PS-Geco-BMW-03.10.23senthilonline15No ratings yet

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocument1 pageWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNo ratings yet

- SL CableDocument2 pagesSL Cablehrramco1981No ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Inspection Checklist - HDPE Butt Fusion WeldingDocument1 pageInspection Checklist - HDPE Butt Fusion WeldingQasim Saeed KhanNo ratings yet

- Specification DNA-31734 Tracking Resistant ADSS CableDocument5 pagesSpecification DNA-31734 Tracking Resistant ADSS CableDerrick Kojo SenyoNo ratings yet

- EU Data Sheet Chainflex CF880Document7 pagesEU Data Sheet Chainflex CF880gaconlonton410No ratings yet

- MANGUERA 1-2 NYLON PARKER CAT 4660 - B-TubingDocument4 pagesMANGUERA 1-2 NYLON PARKER CAT 4660 - B-TubingJose Antonio GomezNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Pgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Document6 pagesPgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Manuel DizonNo ratings yet

- 5UPX0805F Product Specifications (Comprehensive)Document5 pages5UPX0805F Product Specifications (Comprehensive)oaguilar83No ratings yet

- Interloop Satellite Stitching Unit: RecommendationDocument13 pagesInterloop Satellite Stitching Unit: RecommendationFraz AhmadNo ratings yet

- Chainflex CF210ULDocument2 pagesChainflex CF210ULIVOR COSTANo ratings yet

- CNG Receptacle Tn5 WehDocument8 pagesCNG Receptacle Tn5 WehMassimo De LucaNo ratings yet

- PU-4116 (WSP Booster Pump)Document9 pagesPU-4116 (WSP Booster Pump)adha.priyawan17No ratings yet

- Rev 01 Mud Gas Separator of Oil ServiceDocument3 pagesRev 01 Mud Gas Separator of Oil ServiceKanti LakhankarNo ratings yet

- Data Sheet LLP Compressor's (Updated)Document8 pagesData Sheet LLP Compressor's (Updated)GioNo ratings yet

- Technical Specification - 2023 01 16 18 50 06Document10 pagesTechnical Specification - 2023 01 16 18 50 06abhishekgupta9990No ratings yet

- DNA-7609 Span 600Document2 pagesDNA-7609 Span 600Victor LeónNo ratings yet

- Pipeline Coatings PDFDocument29 pagesPipeline Coatings PDFAsimNo ratings yet

- BK-G10 and BK-G16: BK-G10T and BK-G16T Compact Commercial Diaphragm Gas MetersDocument2 pagesBK-G10 and BK-G16: BK-G10T and BK-G16T Compact Commercial Diaphragm Gas MetersAli ŞengülNo ratings yet

- A. List of Goods and Delivery ScheduleDocument3 pagesA. List of Goods and Delivery ScheduleAbdul Aziz FahadNo ratings yet

- Combustion Application Data Sheet - AT1021ADocument1 pageCombustion Application Data Sheet - AT1021AsendutdutNo ratings yet

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocument11 pagesDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- Dna-7231 24F V500 PDFDocument3 pagesDna-7231 24F V500 PDFjoaquicNo ratings yet

- EagleBurgmann - CobaDGS - Zero Emission Solution - ENDocument2 pagesEagleBurgmann - CobaDGS - Zero Emission Solution - ENUday GokhaleNo ratings yet

- Parker Hose 471-2SCDocument1 pageParker Hose 471-2SCMiroslaw LabudaNo ratings yet

- EU Data Sheet Chainflex CF890Document8 pagesEU Data Sheet Chainflex CF890gaconlonton410No ratings yet

- VV216A-109-A-801 - 1 Installation & Oper Main. Procedure PDFDocument253 pagesVV216A-109-A-801 - 1 Installation & Oper Main. Procedure PDFLê Phước PhúNo ratings yet

- Jis Piping HandbookDocument177 pagesJis Piping HandbookJerome100% (1)

- Commissioning Sheet 4Document1 pageCommissioning Sheet 4ABHISHEK SHARMANo ratings yet

- NGL Recovery Project at Badak LNG Plant: 23 World Gas Conference 5-9 June 2006 Amsterdam - The NetherlandsDocument20 pagesNGL Recovery Project at Badak LNG Plant: 23 World Gas Conference 5-9 June 2006 Amsterdam - The NetherlandsnefoussiNo ratings yet

- Truckfilling UnitDocument2 pagesTruckfilling Unitrieza_fNo ratings yet

- Design Clarification - 2Document1 pageDesign Clarification - 2Kacip BolaNo ratings yet

- HFY-3800-0000-PPL-PD-0009 - 0 Pipeline Crossings Procedure Including HDD, Code-ADocument11 pagesHFY-3800-0000-PPL-PD-0009 - 0 Pipeline Crossings Procedure Including HDD, Code-AYousif AlmusawiNo ratings yet

- Content 20240115185834Document2 pagesContent 20240115185834BLY YEDEKPA NOEL BENITONo ratings yet

- Syngas Valve Train Techno-Commercial Quote & Schematic: Mash MakesDocument9 pagesSyngas Valve Train Techno-Commercial Quote & Schematic: Mash MakesShamshuddin TanekhanNo ratings yet

- Cross Section of Cables PVC InsulatedDocument1 pageCross Section of Cables PVC InsulatedSuguna DeviNo ratings yet

- 123HAN BPS 02 - Rev.2Document1 page123HAN BPS 02 - Rev.2ABDUL RAHMAN ALI MIRNo ratings yet

- OMJ-MAN-SRT-QA-1964-Updated-AG FF Pipes. REPAIR WELDING PROCEDUREDocument10 pagesOMJ-MAN-SRT-QA-1964-Updated-AG FF Pipes. REPAIR WELDING PROCEDUREMostafa NabilNo ratings yet

- SC Org Ofc (13280PCM)Document2 pagesSC Org Ofc (13280PCM)Daniel AlonsoNo ratings yet

- Proposed WPS For API 5LDocument1 pageProposed WPS For API 5LMecon HyderabadNo ratings yet

- CableDocument5 pagesCableAbdelrahman ElshahedNo ratings yet

- MariGreen LNG 4.0 Doeksen - Standard Modular LNG SystemDocument8 pagesMariGreen LNG 4.0 Doeksen - Standard Modular LNG Systemwon choiNo ratings yet

- Comparison - ElmoDocument12 pagesComparison - ElmoBagus SigitNo ratings yet

- 7132 ParkerDocument1 page7132 ParkerPercy Quispe - IVAFINo ratings yet

- 17 Check Valves (VC Series)Document8 pages17 Check Valves (VC Series)Percy Quispe - IVAFINo ratings yet

- 62PLMBH 10MDocument1 page62PLMBH 10MPercy Quispe - IVAFINo ratings yet

- 07r313ac - ParkerDocument1 page07r313ac - ParkerPercy Quispe - IVAFINo ratings yet

- Alfa Laval Operating Instruction PDFDocument28 pagesAlfa Laval Operating Instruction PDFAndré Heunis100% (1)

- s5113 Mm39 F.O Supply UnitDocument408 pagess5113 Mm39 F.O Supply UnitJorge AguilarNo ratings yet

- 1Document65 pages1alif salmanNo ratings yet

- Ametek 241 PDFDocument2 pagesAmetek 241 PDFJaganathan KrishnanNo ratings yet

- SPM Chemistry Paper 2 ExerciseDocument16 pagesSPM Chemistry Paper 2 ExerciseMohd HaidilNo ratings yet

- Ms Ramya Swetha Paper For OUDocument7 pagesMs Ramya Swetha Paper For OUvempadareddyNo ratings yet

- Ingersoll Dresser - Flowserve - Bombas ESP2Document60 pagesIngersoll Dresser - Flowserve - Bombas ESP2Leonardo Enrqiue Moreno RamosNo ratings yet

- Landfill Leachate Treatment 2Document7 pagesLandfill Leachate Treatment 2Christian Mihai GNo ratings yet

- DAIKIN-VRVIII-S - Brochure - PCVSUSE11-02B - Daikin AC PDFDocument8 pagesDAIKIN-VRVIII-S - Brochure - PCVSUSE11-02B - Daikin AC PDFKagitha TirumalaNo ratings yet

- HVAC Check List - Indoor Air QualityDocument15 pagesHVAC Check List - Indoor Air QualityTurnerJoeNo ratings yet

- KineticsDocument10 pagesKineticsJohn CyrilNo ratings yet

- Naugatuck CT Odor Control EvaluationDocument133 pagesNaugatuck CT Odor Control EvaluationRepublican-American100% (2)

- Tech GuideDocument56 pagesTech GuideAlexander CiutiNo ratings yet

- Unit 1 Revision ChecklistDocument4 pagesUnit 1 Revision ChecklistShafkat Sakeebur Rahman100% (3)

- 13 Fin-Cat P166-180 enDocument15 pages13 Fin-Cat P166-180 enMorched TounsiNo ratings yet

- Industrial Grade HPMC PDFDocument5 pagesIndustrial Grade HPMC PDFnanoNo ratings yet

- Preparation 9 - Green Soan and Green Soap TincturesDocument4 pagesPreparation 9 - Green Soan and Green Soap TincturesAngela CastrilloNo ratings yet

- Toshiba MJ-5005 ManualDocument38 pagesToshiba MJ-5005 ManualFuriousBKNo ratings yet

- Working Process Woven & KnitDocument2 pagesWorking Process Woven & Knitmd. habibul islamNo ratings yet

- Turbo AirDocument20 pagesTurbo AirDavid SpinosoNo ratings yet

- Dextra Assembly InstructionsDocument16 pagesDextra Assembly InstructionsLenin MedinaNo ratings yet

- SCHEMADocument4 pagesSCHEMAMacsim CristianNo ratings yet

- CH 5. Calculation of Parameters For Non-Cutting OperationsDocument11 pagesCH 5. Calculation of Parameters For Non-Cutting OperationsSRI RAMNo ratings yet

- Flowtec Pump Manual 528Document20 pagesFlowtec Pump Manual 528icarus_fallenNo ratings yet

- Caleffi: Motorised Zone Valves Z-OneDocument4 pagesCaleffi: Motorised Zone Valves Z-OneBudoi Octav-AurelNo ratings yet

- Tree-Structure Canopy A Case Study in deDocument18 pagesTree-Structure Canopy A Case Study in deDrGanesh KameNo ratings yet

- 4.2.2 Polyesters and PolyamidesDocument7 pages4.2.2 Polyesters and PolyamidesttsNo ratings yet

- Use of Stainless Steel in Automobile SectorDocument11 pagesUse of Stainless Steel in Automobile SectorAyush goyalNo ratings yet