Professional Documents

Culture Documents

Select 90c d2

Select 90c d2

Uploaded by

nateOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Select 90c d2

Select 90c d2

Uploaded by

nateCopyright:

Available Formats

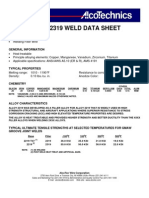

Select 90C-D2

Description:

Select 90C-D2 is a low alloy steel, composite metal cored electrode for gas-shielded arc welding.

This electrode is intended for single and multiple pass welding of certain high strength, low alloy steels

where a minimum tensile strength of 90,000 psi is required in the deposited metal. The recommended

shielding gas is 75-80% argon-balance carbon dioxide. Using shielding gases higher in argon typically

increases the strength of the weld deposit. A minimum dew point of -40F should be maintained with the

shielding gas, along with a minimum flow rate of 40-50 cfh.

Classification:

E90C-D2 per AWS A5.28, SFA 5.28.

Characteristics:

Select 90C-D2 is a metal cored electrode that can be substituted for ER90S-D2 solid wire. This

premium electrode operates in a smooth, spatter-free spray using 75-80% argon-balance carbon dioxide

shielding gas. Modern manufacturing technology ensures the best in weldability, feedability, and

consistency. In addition to better availability than the corresponding solid wires, Select 90C-D2 offers many

economic and quality advantages, such as less sensitivity to subsurface porosity, the elimination of lack of

fusion or “cold lap”, and 30-50% faster travel speeds for a given weldment size. This product is available in

an assortment of packages to suit most welding needs.

Applications:

Select 90C-D2 is ideal for those applications requiring weld metal which matches the mechanical

properties of high strength, low alloy pressure vessel steels such as ASTM A302 Grade B, HSLA steels and

manganese-molybdenum castings such as ASTM A49, A291, and A735.

Typical Mechanical Properties:

75%Ar/25%CO2 98%Ar/2%O2

Ultimate Tensile Strength 92,400 98,400

Yield Strength 81,300 86,900

Percent Elongation 26 27

CVN impact (ftlb ƒ) @ -20 F 42 35

Typical Deposit Composition:

Wt% C Mn Si P S Mo

.06 1.45 .54 .010 .010 .49

Recommended Welding Parameters*:

Optimum Range

Diam. (in.) Amperage WFS Voltage Amperage WFS Voltage ESO

.035 200 550 29-30 160-250 350-750 24-35 ½”-¾”

.045 255 410 29-30 180-330 240-600 27-33 ½”-1"

.052 300 350 29-30 220-460 220-620 25-35 ½”-1

1/16 360 300 29-30 240-520 175-500 26-37 ¾”-1¼

*With 75%Ar/25% CO2. For Ar/O2 blends, lower the voltage by 3 Volts.

Rev 1 (04/23/2015)

Notice: The results reported are based upon testing of the product under controlled laboratory conditions in accordance with American

Welding Society Standards. Actual use of the product may produce different results due to varying conditions. An example of such

conditions would be electrode size, plate chemistry, environment, weldment design, fabrication methods, welding procedure and service

requirements. Thus the results are not guarantees for use in the field.

You might also like

- Wickes UnderlayDocument2 pagesWickes UnderlayfloodanddrainageNo ratings yet

- Er70s 6Document1 pageEr70s 6sdsdsdnNo ratings yet

- Smoothcor 120T5 K4 (E120T5 K4C)Document1 pageSmoothcor 120T5 K4 (E120T5 K4C)brunizzaNo ratings yet

- Select 439tiDocument1 pageSelect 439tiHariPrasathNo ratings yet

- Selectwear 58: DescriptionDocument1 pageSelectwear 58: DescriptionEli FreemanNo ratings yet

- B SawcoDocument4 pagesB SawcoledystNo ratings yet

- SOW 09380SB2T SpecSheetDocument2 pagesSOW 09380SB2T SpecSheetAi NayNo ratings yet

- Pinnacle Alloys E81T1 Ni1Document2 pagesPinnacle Alloys E81T1 Ni1Santiago OrbeaNo ratings yet

- Pinnacle Alloys E11018 MDocument2 pagesPinnacle Alloys E11018 MMoch_adiganjarNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Datasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1Document3 pagesDatasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1laz_kNo ratings yet

- Midalloy ER80S B6 EB6Document1 pageMidalloy ER80S B6 EB6joel cisnerosNo ratings yet

- Pinnacle Alloys E8018-B6 Code and Specification DataDocument2 pagesPinnacle Alloys E8018-B6 Code and Specification DataMurad AlmoudiNo ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- Maxfil-12RJ D&H DetailsDocument1 pageMaxfil-12RJ D&H DetailsmriyazklNo ratings yet

- Class: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageDocument2 pagesClass: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageAditya PrajasNo ratings yet

- Lincolnweld LA-93, AWS EB3RDocument2 pagesLincolnweld LA-93, AWS EB3Rpratik charkhawalaNo ratings yet

- Pamphlet (DW 2594)Document1 pagePamphlet (DW 2594)Irvansyah RazadinNo ratings yet

- E6010 Data SheetDocument3 pagesE6010 Data SheetJuan Alberto PozoNo ratings yet

- A 2319 TdsDocument2 pagesA 2319 TdsSyam NathNo ratings yet

- FabCO 811N1 PDFDocument2 pagesFabCO 811N1 PDFAlejandroAcuñaMaureiraNo ratings yet

- Alloy C-4300MDocument1 pageAlloy C-4300Malex diazNo ratings yet

- Primacore MW 71Document2 pagesPrimacore MW 71rjan7peNo ratings yet

- Cellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499Document4 pagesCellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499ashwini shuklaNo ratings yet

- Tech Data Sheet: Dual Shield Ii 101H4MDocument2 pagesTech Data Sheet: Dual Shield Ii 101H4McarlosNo ratings yet

- Pinnacle Alloys E8018 C3Document2 pagesPinnacle Alloys E8018 C3Sajeev SivanandanNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel Weldingkdsenipah6667No ratings yet

- Ultra HT As PlatesDocument13 pagesUltra HT As PlatesavikNo ratings yet

- B-62 2507 Rev 06Document5 pagesB-62 2507 Rev 06Shaik ShahNo ratings yet

- Typical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Document20 pagesTypical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Samuel LatumahinaNo ratings yet

- Datasheet Sandvik 199l enDocument3 pagesDatasheet Sandvik 199l enpedro rojasNo ratings yet

- E7018 PDFDocument3 pagesE7018 PDFPrakash RajNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- Technical Report (CSF-81TM)Document5 pagesTechnical Report (CSF-81TM)matiasg.sanchezv95No ratings yet

- Echnical Ulletin: Used For Joining in Large Vehicle and Crane ManufacturingDocument1 pageEchnical Ulletin: Used For Joining in Large Vehicle and Crane ManufacturingSungJun ParkNo ratings yet

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- E6010 Data SheetDocument2 pagesE6010 Data SheetKhaled A MarashliNo ratings yet

- CSF-81T en 2014Document1 pageCSF-81T en 2014NGUYEN VINHNo ratings yet

- Pinnacle Alloys E7018 12.16Document3 pagesPinnacle Alloys E7018 12.16Saad AfzalNo ratings yet

- Pinnacle-Alloys-E6011-12.16Document3 pagesPinnacle-Alloys-E6011-12.16Steven Andres Rodriguez PulidoNo ratings yet

- Metalshield MC - 706: Conformances Key FeaturesDocument3 pagesMetalshield MC - 706: Conformances Key FeaturesGerson HenriquesNo ratings yet

- Pinnacle Alloys ER2594Document2 pagesPinnacle Alloys ER2594Federico Quintana100% (1)

- High Voltage 2xs FL 2y A2xs FL 2y 123kv Power CableDocument3 pagesHigh Voltage 2xs FL 2y A2xs FL 2y 123kv Power CableShailendra Kumar VermaNo ratings yet

- LINCOLN ER2594Document2 pagesLINCOLN ER2594dluquegaNo ratings yet

- E6011 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE6011 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- FCAW DocumentDocument19 pagesFCAW DocumentKentDemeterioNo ratings yet

- Pinnacle Alloys E9018-M Code and Specification DataDocument2 pagesPinnacle Alloys E9018-M Code and Specification DataPutra Panca WardhanaNo ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- Special Metal Korea Co., LTDDocument1 pageSpecial Metal Korea Co., LTDWelli E SNo ratings yet

- SM 385Document1 pageSM 385Arizal Nur ArdhiNo ratings yet

- Carelso 60/65: Steel For Pressure Equipment in Mild Sour ServiceDocument3 pagesCarelso 60/65: Steel For Pressure Equipment in Mild Sour ServicePeterWayNo ratings yet

- Datasheet Sandvik 2212htDocument2 pagesDatasheet Sandvik 2212htDarryl007No ratings yet

- SV Series - Special Medium Voltage Leaded Varistors: DescriptionDocument4 pagesSV Series - Special Medium Voltage Leaded Varistors: DescriptionIgor PNo ratings yet

- Macsteel VRN - Wear Abrasion Steels - Creusabro 8000Document4 pagesMacsteel VRN - Wear Abrasion Steels - Creusabro 8000jonodo89No ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeNguyen Anh TuanNo ratings yet

- E7018 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7018 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Idalloy: C MN Si CR Mo V P S CuDocument1 pageIdalloy: C MN Si CR Mo V P S CuiocephNo ratings yet

- Pinnacle Alloys E6013Document2 pagesPinnacle Alloys E6013rahulNo ratings yet

- Understanding Contact Tips For MIG WeldingDocument9 pagesUnderstanding Contact Tips For MIG WeldingnateNo ratings yet

- Stick To The Basics - Welding ProductivityDocument8 pagesStick To The Basics - Welding ProductivitynateNo ratings yet

- Quantum Arc 3Document2 pagesQuantum Arc 3nateNo ratings yet

- ADM4 LiteratureDocument2 pagesADM4 LiteraturenateNo ratings yet

- SM 70enDocument6 pagesSM 70ennateNo ratings yet

- Since We Opened Our Doors in 1907, National Standard Has Been Setting The Standard For Consistent Product QualityDocument48 pagesSince We Opened Our Doors in 1907, National Standard Has Been Setting The Standard For Consistent Product QualitynateNo ratings yet

- MIG Gun MythbustingDocument4 pagesMIG Gun MythbustingnateNo ratings yet

- Understanding Contact Tips For MIG WeldingDocument9 pagesUnderstanding Contact Tips For MIG WeldingnateNo ratings yet

- Choosing Shielding Gases For Arc Welding - The FabricatorDocument5 pagesChoosing Shielding Gases For Arc Welding - The FabricatornateNo ratings yet

- 7 Effects of Shielding Gas - The FabricatorDocument4 pages7 Effects of Shielding Gas - The FabricatornateNo ratings yet

- Down To The Wire - Welding ProductivityDocument4 pagesDown To The Wire - Welding ProductivitynateNo ratings yet

- How Customized MIG Guns Improve Welding - Industrial Equipment News (IEN)Document3 pagesHow Customized MIG Guns Improve Welding - Industrial Equipment News (IEN)nateNo ratings yet

- Doe 2016 TransformerDocument20 pagesDoe 2016 TransformerHugo Dennis Mattos EspinozaNo ratings yet

- Bill of Materials: See Iso 10-P-1202 SHT 02Document2 pagesBill of Materials: See Iso 10-P-1202 SHT 02Junaid AdnanNo ratings yet

- COBOL-64 Software SystemDocument163 pagesCOBOL-64 Software SystemRiccardo RicciNo ratings yet

- m250 First Network PDFDocument140 pagesm250 First Network PDFEstevam100% (1)

- Global Classic: Cost-Effective, All-Purpose Bridge CMMDocument12 pagesGlobal Classic: Cost-Effective, All-Purpose Bridge CMMMauricio SilvaNo ratings yet

- Gas Turbine Performance Acceptance Test Specification (Version 5) (TSMKO-00TG-T-30-TG0-321-A)Document91 pagesGas Turbine Performance Acceptance Test Specification (Version 5) (TSMKO-00TG-T-30-TG0-321-A)Anonymous kVwp7D67% (3)

- A Paper Written To Assist Those Who May Be Concerned in The Finishing of Concrete Swimming Pool'sDocument18 pagesA Paper Written To Assist Those Who May Be Concerned in The Finishing of Concrete Swimming Pool'sDavid Coulson100% (1)

- Failure of Chauras BridgeDocument8 pagesFailure of Chauras BridgeRitesh ChaurasiaNo ratings yet

- Heat Transfer White PaperDocument14 pagesHeat Transfer White PaperflitzzzNo ratings yet

- Thermocouple: VoltageDocument7 pagesThermocouple: Voltage9897856218No ratings yet

- Physics of Musical InstrumentsDocument30 pagesPhysics of Musical InstrumentsFernando CasaseusNo ratings yet

- API Filtration Test: API High-Pressure/High Temperature (HPHT) Filter PressDocument6 pagesAPI Filtration Test: API High-Pressure/High Temperature (HPHT) Filter PressAakriti Bhandari100% (2)

- ASME A17.1 Elevator RecallDocument6 pagesASME A17.1 Elevator Recalltushar1128No ratings yet

- Activiti User GuideDocument305 pagesActiviti User GuideyogaarsaNo ratings yet

- Series CouplingsDocument8 pagesSeries CouplingsEagle1968No ratings yet

- UR Relay Series: Revision 1.60 Release NotesDocument6 pagesUR Relay Series: Revision 1.60 Release NotesNima MahmoudpourNo ratings yet

- 09 Chapter 3Document41 pages09 Chapter 3Krishna GNo ratings yet

- Asme Sec Ix 2019 381Document1 pageAsme Sec Ix 2019 381Balkishan DyavanapellyNo ratings yet

- Es 22Document3 pagesEs 22saad rehmanNo ratings yet

- NA Vendor Analysis - PMT MethodsDocument248 pagesNA Vendor Analysis - PMT MethodsluispariniNo ratings yet

- Online Political Marketing in Greece - An Evaluation of The 2007Document9 pagesOnline Political Marketing in Greece - An Evaluation of The 2007bandi_2340No ratings yet

- Nadya Parameswari JasmineDocument9 pagesNadya Parameswari JasmineDianata Eka PutraNo ratings yet

- Course Pack On The Human Person Ourishing in Terms of Science and TechnologyDocument8 pagesCourse Pack On The Human Person Ourishing in Terms of Science and TechnologyBARRIENTOS, MARIE NICOLENo ratings yet

- 506 IngDocument2 pages506 IngleomyroNo ratings yet

- 14 References PDFDocument23 pages14 References PDFAgim KarajNo ratings yet

- Fortisalberta Inc. D02-06 Design Policies: Double Circuit Distribution LinesDocument18 pagesFortisalberta Inc. D02-06 Design Policies: Double Circuit Distribution LineskiyottaNo ratings yet

- Pump CoatingDocument45 pagesPump CoatingAmit Kumar GuptaNo ratings yet

- Surface Systems & Instruments, Inc.: Product OverviewDocument2 pagesSurface Systems & Instruments, Inc.: Product OverviewYENY HERNANDEZNo ratings yet