Professional Documents

Culture Documents

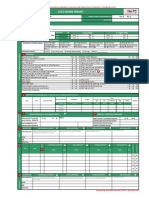

More Than One Energy Source Affected Person(s) Potential Exposure To Energy Group LOTO Conditions

More Than One Energy Source Affected Person(s) Potential Exposure To Energy Group LOTO Conditions

Uploaded by

saran985Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

More Than One Energy Source Affected Person(s) Potential Exposure To Energy Group LOTO Conditions

More Than One Energy Source Affected Person(s) Potential Exposure To Energy Group LOTO Conditions

Uploaded by

saran985Copyright:

Available Formats

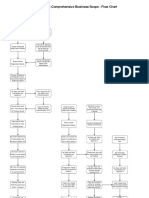

Train Affected

persons

Control of Hazardous EHS57

Energy [LOTO]

D0000116280

Inspections & Periodical Review for

Audits Conitnual Improvement

Implementation [5.1]

Guide D0000210410 Implement Site specific

Procedure for LOTO

Potential

stored, residual,

re-accumulation

of energy after

shutdown Affected

[5.2]

Equipment person(s) Follow Safe

Maintain Inventory More than one

Requiring potential Work

of Equipment requiring energy source

exposure to

LOTO practice

LOTO energy

Group LOTO

Conditions

[5.3] Equipment Inventory

Complete Equipment D0000210423

Specific LOTO

Procedure

Complete

Training EHS58 Equipment Specific

[5.4] LOTO Procedure

Identify Authorized Training D0000210418

Persons

Complete

equipment

training

Isolate &

[5.5] Plan & Shutdown Verify

LOTO energy

Follow LOTO Sequence Prepare equipment lockout

sources

[5.6] Restore/

Use Standard LOTO Notify Service

start-up.

device(s) and provide

appropriate Signage

Authorized

[5.7] person is

Ensure LOTO is absent

maintained for all shift Emeregncy LOTO

changes Device Removal Form

D0000210430

Lock key is

[5.8]

missing

Ensure standard

practice for emergency

LOTO Removal

a. Site Specific LOTO Procedure. e. Inspection Checklist.

b. Equipment Specific LOTO f. Audit report(s).

Procedure. g. Improvement plan(s).

c. LOTO Equipment Inventory. h. Training record(s).

d. Emergency LOTO Device i. Incident report(s) and

Removal Form (as applicable). corrective action(s).

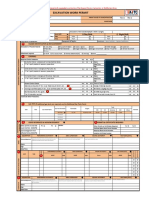

Powered Industrial Truck [PIT]

Train Affected

persons

Powered Industrial

Truck [PIT]

D0000xxxx

Periodical Review for

Audits

Conitnual Improvement

Implementation Control

Guide [5.1] Preventive

Roles & Equipment Measures &

D0000xxxx Implement Site specific Responsibilities Selection Safe Work

Maintenance &

Procedure for PIT Inspections

Practices

PIT Inventory

[5.2] D0000210423

Maintain PIT Inventory

[5.3] Conduct Risk Control Measures

Identify PIT Hazards Assessment & Safe Work

Practices

[5.4] Complete Trained Operator Pre-Start

Ensure Trained & Training as per Person(s) Inspection

Authorized Persons local Authorized to D0000xxx

Operate PIT regulations operate PIT

Operator Use Equipment for

Pre-Start Operations

[5.5] Inspection

Equipment Yes

Develop & Implement Fit to work

Ongoing Program

Management Process

No Do Not use

Preventive

Equipment.

Maintenance Fix Defect.

Develop & Implement Follow Safe

Traffic Management Work

Plan practice

f. Inspection report(s)

a. Site Specific PIT Procedure

g.Audit report(s)

b. PIT - Equipment Inventory

h. Improvement plan(s)

c. Pre-Start Operator Checklist

i. Training record(s)

d. Preventive maintenance report(s)

j. Incident report(s) and corrective

e. PIT-Traffic Management Layout

action(s)

Legend: Roles | Responsibilities

Standard Owner Managers & Supervisors EHS Point of Contact

Advanced Operations /

Engineering / R&D / Affected Person(s) Authorized Person(s)

Facility Maintenance

You might also like

- ISO - Machine Guard14120-2015Document13 pagesISO - Machine Guard14120-2015saran985100% (1)

- UnileverDocument23 pagesUnileverasees_abid67% (3)

- Session PlanDocument12 pagesSession PlanJheng Delos Reyes Pantoja100% (2)

- Pal EtopsDocument47 pagesPal EtopsVishal50% (2)

- OCSO Inventory Turnover AuditDocument160 pagesOCSO Inventory Turnover AuditOKCFOXNo ratings yet

- Investigation of Lockout/Tagout Procedure Failure in Machine Maintenance ProcessDocument6 pagesInvestigation of Lockout/Tagout Procedure Failure in Machine Maintenance ProcessHaniatul HidayahNo ratings yet

- Iasimp qs019 - en PDocument396 pagesIasimp qs019 - en Pluis.chuquimiaNo ratings yet

- Notice: Advisory Circulars Availability, Etc.: Extended Operations and Polar OperationsDocument35 pagesNotice: Advisory Circulars Availability, Etc.: Extended Operations and Polar OperationsJustia.comNo ratings yet

- CAMTECH Recommendations On Syllabus For Initial Training Course For SSE-JE - TRSDocument24 pagesCAMTECH Recommendations On Syllabus For Initial Training Course For SSE-JE - TRSmukesh lachhwaniNo ratings yet

- Iasimp Qs034 en PDocument278 pagesIasimp Qs034 en PÁgost VitaNo ratings yet

- EE-212-L ECD Lab 5Document2 pagesEE-212-L ECD Lab 5Saad KarimNo ratings yet

- Lista IOSA VS EASADocument3 pagesLista IOSA VS EASACareli ValdésNo ratings yet

- Industrial Electrical Machines and Drives Servicing Level 2Document56 pagesIndustrial Electrical Machines and Drives Servicing Level 2ኮኾብ ጽባሕ100% (2)

- Lockout-Tagout (LOTO) Frequently Asked Questions (FAQ)Document2 pagesLockout-Tagout (LOTO) Frequently Asked Questions (FAQ)Khuda BukshNo ratings yet

- Lock Out Tag Out (LOTO)Document43 pagesLock Out Tag Out (LOTO)ganesamoorthy1987No ratings yet

- Camtech Recommendations: Maharajpur, Gwalior - 474005Document20 pagesCamtech Recommendations: Maharajpur, Gwalior - 474005ashwaniNo ratings yet

- WIP Component Pick ReleaseDocument87 pagesWIP Component Pick ReleaseVikram IyerNo ratings yet

- Mics Kerys - Basic Reminders: Titre de La DiapositiveDocument65 pagesMics Kerys - Basic Reminders: Titre de La DiapositiveOunna PechNo ratings yet

- Upset Prevention Recovery Training UPRT PDFDocument2 pagesUpset Prevention Recovery Training UPRT PDFKonstantinos AIRMANNo ratings yet

- LOTOTODocument17 pagesLOTOTOjustice100% (1)

- UL 508A Control Panel Design GuideDocument36 pagesUL 508A Control Panel Design Guideravindra_058No ratings yet

- D82167GC10-Practices For Lesson 4Document20 pagesD82167GC10-Practices For Lesson 4ChristianQuirozPlefkeNo ratings yet

- EDTO Module 5 - Maintenance ConsiderationsDocument88 pagesEDTO Module 5 - Maintenance ConsiderationsTeh Xiang Jie0% (1)

- How To Establish Quality Sys QMS FTO-TRTODocument27 pagesHow To Establish Quality Sys QMS FTO-TRTODriss El FahliNo ratings yet

- A Review of Overall Equipment Effectiveness: Gavriluță AnaDocument5 pagesA Review of Overall Equipment Effectiveness: Gavriluță AnaIoana BiticaNo ratings yet

- 1.1 SMP For Mechanical Maintance of AirtubeDocument2 pages1.1 SMP For Mechanical Maintance of AirtubePRANAV KUMAR GAUTAMNo ratings yet

- MPA - Energy Iso LOTOTO 32pg Handbook V8 Final Print Copy - BookletDocument10 pagesMPA - Energy Iso LOTOTO 32pg Handbook V8 Final Print Copy - BookletMadalin DaniliucNo ratings yet

- Practices For Lesson 3: ODI Topology Concepts Chapter 3 - Page 1Document24 pagesPractices For Lesson 3: ODI Topology Concepts Chapter 3 - Page 1ChristianQuirozPlefkeNo ratings yet

- MPI - LAB - 4 (Spring - 2024)Document4 pagesMPI - LAB - 4 (Spring - 2024)Muhammad AbdullahNo ratings yet

- MPI - LAB - 6 (Spring - 2024)Document5 pagesMPI - LAB - 6 (Spring - 2024)Muhammad AbdullahNo ratings yet

- EEXI CII SEEMP Part 3 Eaglestar IMO Emission Regulations 2023Document17 pagesEEXI CII SEEMP Part 3 Eaglestar IMO Emission Regulations 2023Syamesh SeaNo ratings yet

- SWECs External 15 June 2020Document230 pagesSWECs External 15 June 2020Hamzah ZakiNo ratings yet

- Least Mastered Topic Per TeacherDocument2 pagesLeast Mastered Topic Per TeacherHelen DV. ArellanoNo ratings yet

- F-35 Weapon System OverviewDocument25 pagesF-35 Weapon System OverviewSzERG100% (3)

- Winahyo Setyowibowo: Fields of Competence Key AssignmentsDocument2 pagesWinahyo Setyowibowo: Fields of Competence Key AssignmentsAhmad Arif SaktiNo ratings yet

- Exploiting Log4j VulnerabilityDocument1 pageExploiting Log4j Vulnerabilityshrutiresearch15No ratings yet

- 15 - 09 LOTO TrainingDocument34 pages15 - 09 LOTO Trainingghada gattouchNo ratings yet

- MTVol9Nr2Art 4Document8 pagesMTVol9Nr2Art 4Dilan BandusenaNo ratings yet

- FOMCON Toolbox Fractional Order MathlabDocument26 pagesFOMCON Toolbox Fractional Order MathlabVu MinhNo ratings yet

- D82167GC10-Practices For Lesson 5Document14 pagesD82167GC10-Practices For Lesson 5ChristianQuirozPlefkeNo ratings yet

- Winter 17 TTDocument1 pageWinter 17 TTSrirevathi BalapattabiNo ratings yet

- Lac Implementation Plan Template..namiaDocument5 pagesLac Implementation Plan Template..namiaHazel VelosoNo ratings yet

- Actionable Items Summary of GapsDocument1 pageActionable Items Summary of GapsMPD Forensic UnitNo ratings yet

- Algo TMO18315-V4.1-SG-Ed8Document640 pagesAlgo TMO18315-V4.1-SG-Ed8SABER1980No ratings yet

- 09 Apostila Sistemas Eletricos Residenciais Industriais eDocument29 pages09 Apostila Sistemas Eletricos Residenciais Industriais eamadeusvcNo ratings yet

- TVM54064 - 7510MG Rel.4.2 OAM - Com - CFG - Ed2 - Print - 3Document34 pagesTVM54064 - 7510MG Rel.4.2 OAM - Com - CFG - Ed2 - Print - 3kmalNo ratings yet

- Lock Out Tag Out-Permit To Work Process Flow Chart: EPC Sub-ContractorDocument1 pageLock Out Tag Out-Permit To Work Process Flow Chart: EPC Sub-ContractorShailendraNo ratings yet

- Ay 2020-21 Eto Ts-SyllabusDocument22 pagesAy 2020-21 Eto Ts-SyllabusSaim HoonaNo ratings yet

- Step-by-Step Assembly Diagram: To Learn More About Human Spaceflight at NASA VisitDocument8 pagesStep-by-Step Assembly Diagram: To Learn More About Human Spaceflight at NASA VisitJuan OllNo ratings yet

- Model Site OLT Blade - BenhilDocument25 pagesModel Site OLT Blade - Benhilfajar prastyoNo ratings yet

- MC 10206954 0001Document4 pagesMC 10206954 0001Linh NguyenNo ratings yet

- Actionable Items Summary of GapsDocument1 pageActionable Items Summary of GapsMPD Forensic UnitNo ratings yet

- AKZ9 Instruction ManualDocument48 pagesAKZ9 Instruction ManualsunhuynhNo ratings yet

- OXOCXTE300ENDocument458 pagesOXOCXTE300ENsandraNo ratings yet

- Modul Pre Filter OWSDocument32 pagesModul Pre Filter OWSRokhmatuSivaNo ratings yet

- F Ti LST M Iitilo I Functional Setup Manager: Initial OverviewDocument10 pagesF Ti LST M Iitilo I Functional Setup Manager: Initial OverviewFeras AhmadNo ratings yet

- SWECs External 9 Apr 2021Document230 pagesSWECs External 9 Apr 2021Fisah WanNo ratings yet

- 15 RepDocument584 pages15 RepAVNo ratings yet

- Fuel & Energy Planning: Implementation Within An AOCDocument13 pagesFuel & Energy Planning: Implementation Within An AOCValerio GuitaroNo ratings yet

- NExT Course Catalog - Reservoir-EngineeringDocument2 pagesNExT Course Catalog - Reservoir-EngineeringNana TwumNo ratings yet

- NExT Course Catalog - Reservoir-EngineeringDocument2 pagesNExT Course Catalog - Reservoir-EngineeringNana TwumNo ratings yet

- Hot Work PermitDocument1 pageHot Work Permitsaran985100% (1)

- Cold Work PermitDocument1 pageCold Work Permitsaran985No ratings yet

- Excvation Work PermitDocument1 pageExcvation Work Permitsaran985No ratings yet

- Energy Thershold Value LOTODocument2 pagesEnergy Thershold Value LOTOsaran985No ratings yet

- Forklifts Getting On and Off SafelyDocument1 pageForklifts Getting On and Off Safelysaran985No ratings yet

- Confined Space Work PermitDocument1 pageConfined Space Work Permitsaran985No ratings yet

- SAFETYOFFICE IndustrialTruckSafetyDocument11 pagesSAFETYOFFICE IndustrialTruckSafetysaran985No ratings yet

- Powered Industrial Truck Best Practices: ResponsibilitiesDocument18 pagesPowered Industrial Truck Best Practices: Responsibilitiessaran985No ratings yet

- Hazards Associaed With PITsmall - Bus - Chap23Document2 pagesHazards Associaed With PITsmall - Bus - Chap23saran985No ratings yet

- Pre-Operation Inspection - Electronic Forklift - Electric ITA Class IDocument1 pagePre-Operation Inspection - Electronic Forklift - Electric ITA Class Isaran985No ratings yet

- Safety and Operational Risk Update: Mark Bly Executive Vice President, S &ORDocument10 pagesSafety and Operational Risk Update: Mark Bly Executive Vice President, S &ORsaran985No ratings yet

- Work InstructionDocument8 pagesWork Instructionsaran985No ratings yet

- Risk Assessment & Risk Management PlanDocument18 pagesRisk Assessment & Risk Management Plansaran985No ratings yet

- ICAM Investigation TechniqueDocument1 pageICAM Investigation Techniquesaran985No ratings yet

- ICAM Basic CauseDocument1 pageICAM Basic Causesaran985No ratings yet

- ICAM SeverityDocument1 pageICAM Severitysaran985No ratings yet

- ICAM Risk PotentialDocument1 pageICAM Risk Potentialsaran985No ratings yet

- Confined Space Equipment Inventory ListDocument2 pagesConfined Space Equipment Inventory Listsaran985No ratings yet

- ICAM Incident ClassificationDocument1 pageICAM Incident Classificationsaran985No ratings yet

- Oil and GasDocument93 pagesOil and Gassaran985No ratings yet

- Tazimul Alam: Work Experience SkillsDocument1 pageTazimul Alam: Work Experience Skillstazimul alamNo ratings yet

- WEEK 8: Lecture 8: ROR Multiple Alternatives: October 26-30, 2020Document29 pagesWEEK 8: Lecture 8: ROR Multiple Alternatives: October 26-30, 2020Aziezah PalintaNo ratings yet

- Supply Chains Management (SCM) Batu Mulia Khas Nusantara Di KotamadyaDocument18 pagesSupply Chains Management (SCM) Batu Mulia Khas Nusantara Di KotamadyaPara Pencari NafkahNo ratings yet

- Certificate: No. Q5 030821 0010 Rev. 00 Holder of Certificate: Leica Microsystems Ltd. ShanghaiDocument2 pagesCertificate: No. Q5 030821 0010 Rev. 00 Holder of Certificate: Leica Microsystems Ltd. ShanghaiKaito M. YoshihiroNo ratings yet

- BUSINESS PLAN FISH FARM REPUBLIC OF GUINEA AACD 07 01 2024.es - enDocument23 pagesBUSINESS PLAN FISH FARM REPUBLIC OF GUINEA AACD 07 01 2024.es - enDecour Paul-JeanNo ratings yet

- Regulation of Payment Aggregator - Cross BorderDocument6 pagesRegulation of Payment Aggregator - Cross BorderBharath HariharanNo ratings yet

- Ansoff MatrixDocument6 pagesAnsoff MatrixKuldeep KoyateNo ratings yet

- Adani Enterprises Limited IPO PDFDocument1 pageAdani Enterprises Limited IPO PDFvasanthkumar.santhu2100% (1)

- BSC 17 Sri Lanka - BMGT3003L (Operations Management)Document4 pagesBSC 17 Sri Lanka - BMGT3003L (Operations Management)priyamali jayarathnaNo ratings yet

- VRIO FrameworkDocument7 pagesVRIO FrameworkAhmed El ZareiNo ratings yet

- Dominos 2021 Annual ReportDocument204 pagesDominos 2021 Annual ReportAtif NaumanNo ratings yet

- E-Platform Comprehensive Flow DiagramDocument4 pagesE-Platform Comprehensive Flow DiagramSwetha SrikanthiNo ratings yet

- Cash-Flow Analysis Training PresentationDocument18 pagesCash-Flow Analysis Training PresentationJerry Sarabia JordanNo ratings yet

- Aakhliya Chouraha Se Jalori Gate Area: Jodhpur-IDocument76 pagesAakhliya Chouraha Se Jalori Gate Area: Jodhpur-IBasant MathurNo ratings yet

- Question 1 FaDocument6 pagesQuestion 1 Fajavariah irshadNo ratings yet

- The ISO 31 000 Standard On Risk Management: Eric MarsdenDocument43 pagesThe ISO 31 000 Standard On Risk Management: Eric MarsdenEndiaz L.A DevNo ratings yet

- Risk Assessment - Welding WorksDocument2 pagesRisk Assessment - Welding WorksSarfraz Randhawa100% (4)

- Tata Multi Cap FundDocument1 pageTata Multi Cap FundJeremiah SolomonNo ratings yet

- Peter Drucker - Alma Dariana Hernandez SeguraDocument1 pagePeter Drucker - Alma Dariana Hernandez SeguraMartin LopezNo ratings yet

- LESSON PLAN of NEP All Subjects 2021-22Document20 pagesLESSON PLAN of NEP All Subjects 2021-22sumeshmirashiNo ratings yet

- Stages of International Marketing InvolvementDocument7 pagesStages of International Marketing InvolvementRochelle Martirez100% (1)

- CH 03Document88 pagesCH 03Azka ShaukatNo ratings yet

- Portic is-PODocument2 pagesPortic is-POJeremiah v macaraegNo ratings yet

- Chapter12 - Estimating Cost of CapitalDocument29 pagesChapter12 - Estimating Cost of CapitalAntonio Jose DuarteNo ratings yet

- December 2022 Question Paper ACCA AFM (Vifhe - Com Taha Popatia Whatsapp +923453086312)Document10 pagesDecember 2022 Question Paper ACCA AFM (Vifhe - Com Taha Popatia Whatsapp +923453086312)Kevin100% (1)

- RFP-RVM-Amritsar Smart City PDFDocument54 pagesRFP-RVM-Amritsar Smart City PDFICT WalaNo ratings yet

- MGT 124 Final Exam ANSWERSDocument6 pagesMGT 124 Final Exam ANSWERSjoanne libedNo ratings yet

- Process Costing: AACSB: AnalyticDocument35 pagesProcess Costing: AACSB: AnalyticJyasmine Aura V. AgustinNo ratings yet