Professional Documents

Culture Documents

Untitled

Untitled

Uploaded by

Issam LahlouOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Untitled

Untitled

Uploaded by

Issam LahlouCopyright:

Available Formats

P ROCTER & GAMBLE FABRIC & HOME CARE

Supersedes: 95238780.002 GCAS: 95238780.003

R AW MATERIAL PLANT INSTRUCTION

Date: 11 April 2019

*** RESTRICTED ***

C AUSTIC SODA

OBJECTIVE

This standard covers the storage and handling of the materials listed above. The information herewithin is important and should

be followed for reasons of safety and quality. This standard applies to any P&G site using the materials listed above.

For safety specifics and detailed chemical behaviour of the material, the appropriate supplier’s MSDS (Material Safety Data

Sheet) should be referred to.

This standard serves to form the basis for more detailed plant specific standard operating procedures and manufacturing standards.

MATERIAL DESCRIPTION

Caustic Soda is a liquid raw material. It is used in the neutralisation of HLAS Acid to produce NaLAS Surfactant Paste which is

used in the detergent industry. It is also used to adjust pH directly to formula. The typical concentration used in P&G is about 50%

and about 32%.

Caustic Soda is a colourless to slightly blue clear solution of Sodium Hydroxide.

Caustic Soda is a strong alkali and highly corrosive liquid. Refer to MSDS before handling. Restrictions on shipment may be

imposed.

MATERIAL CHARACTERISTICS

To note, the following are typical characteristics. If in any doubt or for more specific information, the relevant supplier should be

contacted.

Boiling Point : 115°C – 145°C (e.g. 50% NaOH = 140◦C, 30% NaOH=115◦C)

Freezing Point : 12°C for concentration about 50%; 5°C for concentration around 32%

Flash Point : n/a

Handling Temperatures : 20°C min, 50°C max

Decomposition : If stored correctly it will not decompose over time

Reactivity : Exothermic dilution with water. Violent reactions with acids, chlorine and oxidising agents in

aqueous solutions. Hydrogen liberation by contact with certain metals (explosive hazards)

Density : 1.5g/cm3 @ 20°C

Vapour Pressure : 1.45 – 2.00 mbar @ 15°C

Viscosity : 23 – 30 cP @ 20°C

STORAGE & HANDLING

Unloading

Before unloading, check that material meets Appearance Criteria from IRMS (Colour, Clarity etc.).

Handling

Caustic is highly corrosive. Proper PPE should be weared before handling the material. Supplier MSDS should be read and

followed.

Material of Construction

Tanks: 304SS, CS lined (Amercoat 75), FRP

Gasket: Teflon, PE, PP

Lines: 304SS, CS lined

Material Temperature

Recommended temperature for storage:

LSL (°C) LCL(°C) UCL(°C) USL(°C)

40-50% NaOH 10 20 50 60

32% NaOH 5 10 50 60

Changes to this issue: update on material temperature and extend the RMPI to cover broad caustic soda specs.

Originator: Lizhu Wang Function: Materials Location: BJIC

Business Use - P&G AUTHORIZED 95238780 Rev 003 Effective Date 2019-04-12 Printed 2023-04-19 Page 1 of 2

P ROCTER & GAMBLE FABRIC & HOME CARE

Supersedes: 95238780.002 GCAS: 95238780.003

R AW MATERIAL PLANT INSTRUCTION

Date: 11 April 2019

*** RESTRICTED ***

C AUSTIC SODA

Plant should follow control limit for the best of material quality. Mateiral can be stored between control limit and spec limit for a

short period (e.g. 1 week) in case a sudden temperature shift.

Storing long term above the maximum temperature can lead to iron pick up and caustic embrittlement/caustic stress corrosion.

Storing long term below minimum temperature can lead to crystallisation/freezing. If freezing happened, it is necessary to heat the

material to melt.

Transfer / Addition to Process

Tanks and lines tracing needs to be kept on at all times to avoid crystallisation. Once formed, caustic crystals are very difficult to

dissolve.

Protection From Environment

Follow temperature guidelines above.

Line Clearance

Cleaning of pipes and tanks must be done with air, except for SS systems, where steam cleaning may be used.

Where caustic is manufactured by the Mercury Cell Process, there is a high probability that Mercury will settle out on the

bottom of the storage tanks.

Because of the vapour pressure of mercury, exposure to individuals who enter confined spaces such as tanks could become

high. In addition, any heat or steam could increase the mercury exposure level.

Any tank that needs to be entered must be tested prior to entry with a Mercury Draeger Tube with a measuring range from 0.1

to 2.0 mg/m3. If any mercury is found, consult local HS&E Department immediately for additional instructions on PPE and

air sampling which may be needed. This procedure should also be added to the current tank entry permit forms used for

entering caustic tanks.

Shelf-life

12 months from date of manufacture. To extend the shelf life, re-test assay of NaOH to confirm meeting spec, and shelf life can be

extended for 6months.

Changes to this issue: update on material temperature and extend the RMPI to cover broad caustic soda specs.

Originator: Lizhu Wang Function: Materials Location: BJIC

Business Use - P&G AUTHORIZED 95238780 Rev 003 Effective Date 2019-04-12 Printed 2023-04-19 Page 2 of 2

You might also like

- Billy The Unicorn RainbowDocument5 pagesBilly The Unicorn Rainbowtheyjunky100% (1)

- R P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREDocument3 pagesR P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- Rev004Document2 pagesRev004Issam LahlouNo ratings yet

- UntitledDocument3 pagesUntitledIssam LahlouNo ratings yet

- Sodium Percarbonate All Grades Raw Material Handling: Procter & Gamble Manufacturing StandardsDocument5 pagesSodium Percarbonate All Grades Raw Material Handling: Procter & Gamble Manufacturing StandardsIssam LahlouNo ratings yet

- Rev004Document3 pagesRev004Issam LahlouNo ratings yet

- 22Cr MDSDocument6 pages22Cr MDSabhi1648665No ratings yet

- P & G F & H C R M P I RESTRICTED : Rocter Amble Abric OME AREDocument2 pagesP & G F & H C R M P I RESTRICTED : Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- Detail Engineering Services For Engen Tank X368 RebuildDocument9 pagesDetail Engineering Services For Engen Tank X368 RebuildpavanNo ratings yet

- P & G F & H C R M P I: Carboxymethyl Cellulose Sodium Salt (CMC)Document2 pagesP & G F & H C R M P I: Carboxymethyl Cellulose Sodium Salt (CMC)Issam LahlouNo ratings yet

- P & G F & H C R M P I R: Rocter Amble Abric OME AREDocument2 pagesP & G F & H C R M P I R: Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- Pala 652 e 02 15Document3 pagesPala 652 e 02 15Carmen LinaresNo ratings yet

- StackGard 255SQWDocument2 pagesStackGard 255SQWKrisna JAPEKELEVATEDNo ratings yet

- Ivan Wan ResinDocument3 pagesIvan Wan ResinmuhannadNo ratings yet

- Duraplate Uhs EnglishDocument4 pagesDuraplate Uhs EnglishLuis JaraNo ratings yet

- Sm13crs 95 enDocument6 pagesSm13crs 95 enhorstiillingNo ratings yet

- Description Packaging Product Data SheetDocument2 pagesDescription Packaging Product Data SheetRonald Fernandez ManubuluNo ratings yet

- Material Martensitic 13%CR S 110Document6 pagesMaterial Martensitic 13%CR S 110Jaya DiNo ratings yet

- Tar ProductsDocument14 pagesTar ProductsShaival JhaNo ratings yet

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- SABIC® LLDPE - MG500026 - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - MG500026 - Global - Technical - Data - Sheetabhimanyu.xplastNo ratings yet

- 2 1PackerSystem MechanicalPackersDocument17 pages2 1PackerSystem MechanicalPackersalabedNo ratings yet

- ULTRADUR Sup ® Sup +B4520+FC+AQUADocument3 pagesULTRADUR Sup ® Sup +B4520+FC+AQUACanchindoNo ratings yet

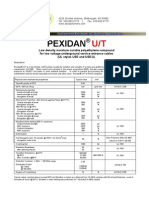

- Pexidan Ut Saco 0510Document2 pagesPexidan Ut Saco 0510Eddy BrentonNo ratings yet

- Asrene (Hdpe SP4808)Document2 pagesAsrene (Hdpe SP4808)AgusPurwantoNo ratings yet

- TDS Chemflake Glass Flake SuggestedDocument5 pagesTDS Chemflake Glass Flake SuggestedShankar Pl GowdaNo ratings yet

- Coal Tar PDFDocument4 pagesCoal Tar PDFMohammadreza AsheghNo ratings yet

- 0400GF Amerlock 400 GF PDSMay 08Document2 pages0400GF Amerlock 400 GF PDSMay 08amadan64No ratings yet

- Water TreatmentDocument2 pagesWater Treatmentmahmoud4871No ratings yet

- Ea 934naDocument4 pagesEa 934nalacsmm982No ratings yet

- Caradol sc48 08Document2 pagesCaradol sc48 08GİZEM DEMİRNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Intan Moisture Sensitive Device GuideDocument1 pageIntan Moisture Sensitive Device GuideAdair NettoNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake Specialmajmor-1No ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Sigmacover 522Document4 pagesSigmacover 522Asela BollegalaNo ratings yet

- Crestomer, Adhesivo Estructural de Alta ResistenciaDocument3 pagesCrestomer, Adhesivo Estructural de Alta ResistenciaTommy VargasNo ratings yet

- Tankguard Zinc Jotun PaintDocument5 pagesTankguard Zinc Jotun PaintGurdeep Sungh AroraNo ratings yet

- Wellcare Oil Tools PVT LTD: Product IndexDocument22 pagesWellcare Oil Tools PVT LTD: Product IndexParag PadoleNo ratings yet

- Chemflake Special: Technical Data SheetDocument5 pagesChemflake Special: Technical Data SheetSalmanNo ratings yet

- General Description: Coupling: Yellow, Yellow, Orange Pipe Body: Yellow, Yellow, OrangeDocument5 pagesGeneral Description: Coupling: Yellow, Yellow, Orange Pipe Body: Yellow, Yellow, OrangesunnyNo ratings yet

- TL425Document2 pagesTL425Sajeesh KrishnanNo ratings yet

- MSDS 4020170100Document18 pagesMSDS 4020170100patchar.mayNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetSantosh JayasavalNo ratings yet

- by Regd. Post With Ack. Due.: Ktpsstagev - Depur@apgenco - Gov.inDocument3 pagesby Regd. Post With Ack. Due.: Ktpsstagev - Depur@apgenco - Gov.inrecruitsaNo ratings yet

- Preventing De-Skulling Problems in A Tundish - Measurement and Modelling ExperienceDocument5 pagesPreventing De-Skulling Problems in A Tundish - Measurement and Modelling Experienceakanksha kumariNo ratings yet

- TDS LF-371 - Dec22Document2 pagesTDS LF-371 - Dec22ofershochetNo ratings yet

- Sensirion Humidity SHTC1 Application GuideDocument4 pagesSensirion Humidity SHTC1 Application GuidesugneshhirparaNo ratings yet

- Carbomastic 15 PDS 2013Document2 pagesCarbomastic 15 PDS 20134508366279No ratings yet

- Korepox H.S. EH4158 (Two-Component) : Product DescriptionDocument2 pagesKorepox H.S. EH4158 (Two-Component) : Product DescriptionTrịnh Minh KhoaNo ratings yet

- TDS Mfe 711 (New)Document2 pagesTDS Mfe 711 (New)Wahyudi Rendiana NyotoNo ratings yet

- TI CP 1327 e Methyl Acrylate 190419 SCREEN 01Document2 pagesTI CP 1327 e Methyl Acrylate 190419 SCREEN 01Vallen ChemNo ratings yet

- Green Tutorial 2Document19 pagesGreen Tutorial 2hoocheeleong234No ratings yet

- Neoprene Rubber Lining: Technical Data SheetDocument2 pagesNeoprene Rubber Lining: Technical Data SheetinfoNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Tds Radilon S Rv300k 333 Ner EngDocument2 pagesTds Radilon S Rv300k 333 Ner EngAshishNo ratings yet

- RAK Poxy 200HB MIO TiecoatDocument3 pagesRAK Poxy 200HB MIO Tiecoatqc_531040655No ratings yet

- UntitledDocument3 pagesUntitledIssam LahlouNo ratings yet

- The Art of Lead Burning: A practical treatise explaining the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatise explaining the apparatus and processesNo ratings yet

- The Art of Lead Burning: A practical treatisening the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatisening the apparatus and processesNo ratings yet

- Restricted P & G F & H C R M P I: ChlorideDocument3 pagesRestricted P & G F & H C R M P I: ChlorideIssam LahlouNo ratings yet

- P & G F & H C R M P I RESTRICTED : Rocter Amble Abric OME AREDocument1 pageP & G F & H C R M P I RESTRICTED : Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- R M P I P (90% A) : AW Aterial Lant NstructionDocument7 pagesR M P I P (90% A) : AW Aterial Lant NstructionIssam LahlouNo ratings yet

- UntitledDocument3 pagesUntitledIssam LahlouNo ratings yet

- P & G F & H C R M P I: Carboxymethyl Cellulose Sodium Salt (CMC)Document2 pagesP & G F & H C R M P I: Carboxymethyl Cellulose Sodium Salt (CMC)Issam LahlouNo ratings yet

- UntitledDocument3 pagesUntitledIssam LahlouNo ratings yet

- UntitledDocument3 pagesUntitledIssam LahlouNo ratings yet

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- The Procter & Gamble Co.: Issue Date: See TS FormDocument7 pagesThe Procter & Gamble Co.: Issue Date: See TS FormIssam LahlouNo ratings yet

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- R P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREDocument3 pagesR P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- Sodium Percarbonate All Grades Raw Material Handling: Procter & Gamble Manufacturing StandardsDocument5 pagesSodium Percarbonate All Grades Raw Material Handling: Procter & Gamble Manufacturing StandardsIssam LahlouNo ratings yet

- Rev004Document3 pagesRev004Issam LahlouNo ratings yet

- P & G F & H C R M P I RESTRICTED : Rocter Amble Abric OME AREDocument2 pagesP & G F & H C R M P I RESTRICTED : Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- P & G F & H C R M P I R: Rocter Amble Abric OME AREDocument2 pagesP & G F & H C R M P I R: Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- P & G F & H C R M P I R: Rocter Amble Abric OME AREDocument4 pagesP & G F & H C R M P I R: Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- Rev004Document2 pagesRev004Issam LahlouNo ratings yet

- UntitledDocument6 pagesUntitledIssam LahlouNo ratings yet

- Physical Metallurgy-18 Heat Treatment of SteelDocument7 pagesPhysical Metallurgy-18 Heat Treatment of SteelDSGNo ratings yet

- Buildings of Earth and StrawDocument2 pagesBuildings of Earth and StrawEmmanuel Marcelo MoreyraNo ratings yet

- 036-CEN Copper and Copper Alloys - CEN TC 133Document6 pages036-CEN Copper and Copper Alloys - CEN TC 133mini p shendeNo ratings yet

- Geofaom Supplier - StyrofillGeofoam - Geofoam Manufacture and SupplierDocument11 pagesGeofaom Supplier - StyrofillGeofoam - Geofoam Manufacture and SupplierMohamed Ismail ShehabNo ratings yet

- F 1476 - 95 Rje0nzytotvbDocument14 pagesF 1476 - 95 Rje0nzytotvbCHRISTIAN ZAVALANo ratings yet

- Shoki The Dog: Things You Need To Know About This ProjectDocument15 pagesShoki The Dog: Things You Need To Know About This ProjectAlina Turcan100% (1)

- ShapesDocument9 pagesShapesMatthew RobsonNo ratings yet

- Reducing Flange Manufacturers, Reducing Flange Dimensions, Reducing Threaded FlangeDocument29 pagesReducing Flange Manufacturers, Reducing Flange Dimensions, Reducing Threaded FlangesubashNo ratings yet

- Fosroc Concure A99 TDSDocument2 pagesFosroc Concure A99 TDSRaj BalakrisNo ratings yet

- Yoo 2013Document8 pagesYoo 2013Katherine AlvarezNo ratings yet

- Huck C50LDocument4 pagesHuck C50LchristianNo ratings yet

- Electrostatic PrecipitorsDocument2 pagesElectrostatic PrecipitorsTeererai KaguraNo ratings yet

- Lenggah Purwandari PPT SEMINARDocument21 pagesLenggah Purwandari PPT SEMINARlenggah purwandariNo ratings yet

- Vaseline Presntation Nikhil Patel D-21-336Document7 pagesVaseline Presntation Nikhil Patel D-21-336NikhilNo ratings yet

- GAS TUNGSTEN ARC WELDED AA 2219 ALLOY W SCANDIUM PDFDocument9 pagesGAS TUNGSTEN ARC WELDED AA 2219 ALLOY W SCANDIUM PDFXto PeregrinNo ratings yet

- Fretting Wear PDFDocument8 pagesFretting Wear PDFbd54No ratings yet

- Welding Handbook 14Document554 pagesWelding Handbook 14szystNo ratings yet

- Deltech DK60 and AboveDocument4 pagesDeltech DK60 and Abovesales-admin.bdgNo ratings yet

- Finding of The Iraqi Natural Pozzolana in Injana Area, Hemrin South, Central IraqDocument13 pagesFinding of The Iraqi Natural Pozzolana in Injana Area, Hemrin South, Central IraqaliNo ratings yet

- PREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)Document5 pagesPREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)vinsmoke1No ratings yet

- Chemical Composition: Copper Alloy DataDocument11 pagesChemical Composition: Copper Alloy DataLin DouaiNo ratings yet

- KTTM Yarn Quality and End Breakage ControlDocument22 pagesKTTM Yarn Quality and End Breakage ControlJigneshSaradava100% (1)

- Physical Science - CH 11Document5 pagesPhysical Science - CH 11suhughes100% (5)

- Materials For Intensified Alkaline Water Electrolysis - NouryonDocument15 pagesMaterials For Intensified Alkaline Water Electrolysis - NouryonWei TengNo ratings yet

- Astm A606Document4 pagesAstm A606tiwariNo ratings yet

- Surtec 930: Demulsifying AgentDocument3 pagesSurtec 930: Demulsifying AgentАлексей КубасовNo ratings yet

- Cera Matizante Fa-110Document2 pagesCera Matizante Fa-110alfosoa5505No ratings yet

- Mold Making Techniques 3Document22 pagesMold Making Techniques 3murali21oct100% (3)

- 919-Article Text-10875-1-10-20121101Document5 pages919-Article Text-10875-1-10-20121101Suyash KumarNo ratings yet