Professional Documents

Culture Documents

Technyl Star S 218 V30 BK 31N

Technyl Star S 218 V30 BK 31N

Uploaded by

ratz23695Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technyl Star S 218 V30 BK 31N

Technyl Star S 218 V30 BK 31N

Uploaded by

ratz23695Copyright:

Available Formats

caring is our formula

TECHNICAL DATA SHEET

TECHNYL STAR S 218 V30 BK 31N

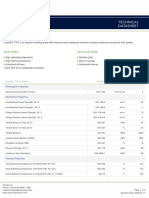

TECHNYL STAR S 218 V30 BK 31N is based on a patented high flow polyamide 6 resin (TechnylStar), heat stabilized, reinforced with 30% of

glass fibre, for injection moulding. Due to its outstanding flow caracteristics, this grade provides a significant productivity improvement and

allows more freedom in mould and part design versus a standard polyamide solutions.

General

Feature Heat-aging stabilized Very high flow

Excellent surface finish

Polymer type PA6 (Polyamide 6)

Processing technology Injection molding

Certification RoHS

Applications Consumer good application home & office furniture

Industrial Applications General Purpose

PC / laptop / tablet

Colors available Black

Forms Pellets

Product identification

ISO 1043 abbreviation PA6-GF30

Condition Standard Unit Value

Physical properties

Density ISO 1183 g/cm³ 1.35

Humidity absorption T=23°C, 50% RH ISO 62 % 1.68

Water absorption 24 hr, 23°C ISO 62 % 0.95

Molding shrinkage, parallel ISO 294-4, 2577 % 0.15

Molding shrinkage, normal ISO 294-4, 2577 % 0.8

DOMO Engineering Plastics | Technical Service

TechnicalService@domo.org | www.domochemicals.com

Date of issue: 04/2023

Page 1

caring is our formula

TECHNICAL DATA SHEET TECHNYL STAR S 218 V30 BK 31N

Condition Standard Unit Value

Mechanical properties dam / cond.*

Tensile modulus 1 mm/min ISO 527-1/-2 MPa 10000 / 6000

Stress at break ISO 527-1/-2 MPa 185 / 105

Strain at break ISO 527-1/-2 % 2.9 / 4.8

Flexural modulus, ISO 178 2 mm/min ISO 178 MPa 9000 / 5300

Flexural modulus, ASTM D790 2 mm/min ASTM D790 MPa 8650 / 5000

Flexural strength, ISO 178 2 mm/min ISO 178 MPa 250 / 165

Flexural strength, ASTM D790 2 mm/min ASTM D790 MPa - / 140

Charpy impact strength, +23°C +23°C ISO 179/1eU kJ/m² 70 / 75

Charpy impact strength, -30°C -30°C ISO 179/1eU kJ/m² 40 / -

Charpy notched impact strength, +23°C +23°C ISO 179/1eA kJ/m² 11 / 14

Charpy notched impact strength, -30°C -30°C ISO 179/1eA kJ/m² 7/-

Izod impact strength, +23°C +23°C ISO 180/1U kJ/m² 68 / -

Izod notched impact strength, +23°C +23°C ISO 180/1A kJ/m² 11 / 15

Izod notched impact strength, -30°C -30°C ISO 180/1A kJ/m² 11 / 14

Thermal properties

Melting temperature, 10°C/min ISO 11357-1 °C 221

Temp. of deflection under load, 1.80 MPa 1.80 MPa ISO 75 °C 208

Electrical properties

Comparative tracking index Solution A IEC 60112 V 400

Burning behaviour

Flammability, 3.0 mm 3.0 mm UL 94 HB

Glow-wire flammability index, GWFI, 1.5 1.5 mm IEC 60695-2-12 °C 650

mm

Burning rate, FMVSS, Thickness 1 mm FMVSS 302 <100

*: conditioned according to ISO 1110

DOMO Engineering Plastics | Technical Service

TechnicalService@domo.org | www.domochemicals.com

Date of issue: 04/2023

Page 2

caring is our formula

TECHNICAL DATA SHEET TECHNYL STAR S 218 V30 BK 31N

Processing conditions

Drying temperature/time 80°C

Suggested max moisture 0.2 %

Rear temperature 230 - 235 °C

Middle temperature 235 - 240 °C

Front temperature 240 - 245 °C

Recommended mould temperature 60 - 90 °C

Injection notes

The material is supplied in airtight bags, ready for use. In case that the virgin material has absorbed moisture, it must be dried with a

dehumidified air drying equipment, dew point minimum -20°C. Recommended time 2-4h.

Injection advice

For reinforced polyamides, Domo recommends the use of steel with a high content of carbon, and purified for polishing, to avoid or limit

the abrasion. For example: X38CrMoV5-1 (EN Norm) - 1.2367 /1.2343 (DIN Norm) or X160CrMoV12 (EN Norm) - 1.2601 /1.2379 (DIN Norm).

In the case of high requirements on surface quality a mould temperature of up to 120°C can be considered. The processing parameters

like processing temperatures are a recommendation and can be adjusted in function of injection machine size, part geometry / design.

Disclaimer

The information provided in this documentation corresponds to our technical knowledge at the date of its publication and do not

constitute a specification. This information may be subject to revision at our discretion. Domo cannot anticipate all conditions under which

this information and our products of other manufactures in combination with our products may be used. Domo accepts no responsibility

for results obtained by the application of this information or for the safety and suitability of our products alone or in combination with

other products. Users are advised to make their own tests to determine the safety and suitability of each product or product combination

for their own purposes. Unless otherwise agreed in writing, Domo sells the product without warranties. Buyers and users assume all

responsibility and liability for loss or damage arising from handling and use of our products, whether used alone or in combination with

other products. Unless specifically indicated, the grades mentioned are not suitable for applications in the pharmaceutical/medical

sector.

DOMO Engineering Plastics | Technical Service

TechnicalService@domo.org | www.domochemicals.com

Date of issue: 04/2023

Page 3

You might also like

- A - Level Project Work Insights & ReflectionsDocument3 pagesA - Level Project Work Insights & ReflectionsKou Uraki0% (1)

- 05 RRR Calculation Method v2Document14 pages05 RRR Calculation Method v2ratz23695No ratings yet

- Wifi Jammer: Winter Semester 2020-21 Analog Circuits Ece 2028Document10 pagesWifi Jammer: Winter Semester 2020-21 Analog Circuits Ece 2028Sathwik YadalamNo ratings yet

- Mineral Reinforced PP: Features ApplicationsDocument2 pagesMineral Reinforced PP: Features ApplicationskatolokchokNo ratings yet

- Prelim ExamDocument17 pagesPrelim Examsaci PTNo ratings yet

- 4 Corners Gold Rush Lesson PlanDocument3 pages4 Corners Gold Rush Lesson Planapi-267003013No ratings yet

- Ultramid A205fDocument3 pagesUltramid A205fSATHISH KUMAR SNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- ARYA_SASOL_LIM1922[2]Document3 pagesARYA_SASOL_LIM1922[2]Murat DalgicNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Datasheet-Ultra Hh-4115-Hi-IsoDocument3 pagesDatasheet-Ultra Hh-4115-Hi-IsoDiegoTierradentroNo ratings yet

- ULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Document2 pagesULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Luis Enrique Ramos PérezNo ratings yet

- Elix Ultra hh4115Document3 pagesElix Ultra hh4115DiegoTierradentroNo ratings yet

- ALTECH ABS A 2020/100 GF20: Technical Data SheetDocument1 pageALTECH ABS A 2020/100 GF20: Technical Data SheetarmandoNo ratings yet

- Econamid FL 6B30Document2 pagesEconamid FL 6B30Jagadeesh WaranNo ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- Elix Pc-Abs 5130Document4 pagesElix Pc-Abs 5130DiegoTierradentroNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- Domamid 6hvi4h2 BK - en TDSDocument1 pageDomamid 6hvi4h2 BK - en TDSMadhav RajpurohitNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Econamid FL 6M20 - Pa6 M2oDocument1 pageEconamid FL 6M20 - Pa6 M2omuthuNo ratings yet

- 000273-TECHNYL-C-102-NCDocument3 pages000273-TECHNYL-C-102-NCGiampietro PiccoliNo ratings yet

- Latigloss 66 H2 G 50 F2 PDFDocument4 pagesLatigloss 66 H2 G 50 F2 PDFBadis ChemaliNo ratings yet

- CovestroDocument2 pagesCovestroRonaldo CamargoNo ratings yet

- Glass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesDocument2 pagesGlass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesmuthuNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- LTH 1922Document4 pagesLTH 1922mohamad mostafaviNo ratings yet

- Data SheetDocument2 pagesData SheetDridi BadreddineNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- Styrolution 3 G55Document3 pagesStyrolution 3 G55John EduardoNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- Styrolution TDS300600621530Document2 pagesStyrolution TDS300600621530seguridadehigieneseguridadehigNo ratings yet

- Abs (Basf Terluran Gp22)Document1 pageAbs (Basf Terluran Gp22)hakangokceNo ratings yet

- Plexiglas Satinice Df21 8n - enDocument3 pagesPlexiglas Satinice Df21 8n - enjonathan6657No ratings yet

- Technical Data Sheet ADFLEX F 500Document2 pagesTechnical Data Sheet ADFLEX F 500leftpowtaNo ratings yet

- Radilon A Cp300K 333 BK: Product InformationDocument4 pagesRadilon A Cp300K 333 BK: Product InformationmuthuNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- ALTECH PE-HD A 2010/550 GF10: Technical Data SheetDocument2 pagesALTECH PE-HD A 2010/550 GF10: Technical Data SheetPhung LucNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- Desmopan 3059D - en - 00898365 00000542 20011347Document2 pagesDesmopan 3059D - en - 00898365 00000542 20011347sosal salvadosNo ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- TDS Mafill CRHT6344Document1 pageTDS Mafill CRHT6344marcohang00No ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- 300.024 Lustran Elite 1891Document2 pages300.024 Lustran Elite 1891Enrique ChavezNo ratings yet

- Ultradur: Product InformationDocument3 pagesUltradur: Product InformationirisNo ratings yet

- K300 TDSDocument2 pagesK300 TDSM. Kürşad ArslanNo ratings yet

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouNo ratings yet

- Pa66-G30 Ahbk003 Tds-Iso-EngDocument2 pagesPa66-G30 Ahbk003 Tds-Iso-EngVinoth SekarNo ratings yet

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraNo ratings yet

- Adflex Q100FDocument2 pagesAdflex Q100FAna Maria MuresanNo ratings yet

- Domamid 6g30st1Document1 pageDomamid 6g30st1shahin_723No ratings yet

- Green Cast Setacryl UKDocument4 pagesGreen Cast Setacryl UKgillestalbotNo ratings yet

- Radiflam A Rv250 Af 375 BK: Product InformationDocument3 pagesRadiflam A Rv250 Af 375 BK: Product InformationLucas Valentim MendesNo ratings yet

- Hdpe p702bk DatasheetDocument1 pageHdpe p702bk Datasheetphanplastic299No ratings yet

- Vesbo PPR EnglishDocument50 pagesVesbo PPR Englishcool.boys4200No ratings yet

- Pi Covestro Annual General Meeting 2023 enDocument3 pagesPi Covestro Annual General Meeting 2023 enratz23695No ratings yet

- UntitledDocument79 pagesUntitledratz23695No ratings yet

- Final Report Canadian Circular Economy For RubberDocument141 pagesFinal Report Canadian Circular Economy For Rubberratz23695No ratings yet

- Compensation Practice Cathy Alonso Strayer University (BUS409008VA016-1174-001) Compensation Management Anthony Jacob April 29, 2017Document8 pagesCompensation Practice Cathy Alonso Strayer University (BUS409008VA016-1174-001) Compensation Management Anthony Jacob April 29, 2017Srestha ChatterjeeNo ratings yet

- Background of The StudyDocument13 pagesBackground of The Studyjeffrey rodriguezNo ratings yet

- Final LIST OF IMPORTANT GRID ELEMENTS Updated On May 2020 PDFDocument74 pagesFinal LIST OF IMPORTANT GRID ELEMENTS Updated On May 2020 PDFbhargavNo ratings yet

- Thesis Van Ende FinalDocument277 pagesThesis Van Ende FinalArtem KravchenkoNo ratings yet

- Barcode v1Document31 pagesBarcode v1Desinta OctavianiNo ratings yet

- BIOLOGY HOTS Questions Class 12thDocument68 pagesBIOLOGY HOTS Questions Class 12thAkshatha Nayak50% (2)

- Criticism Herzberg TheoryDocument3 pagesCriticism Herzberg TheoryCaroline NerbasNo ratings yet

- Dec. 4 2021 Bldg. Tech ReviewDocument58 pagesDec. 4 2021 Bldg. Tech Reviewadyjoy antonioNo ratings yet

- To, The Medical Superintendent, Services Hospital LahoreDocument1 pageTo, The Medical Superintendent, Services Hospital LahoreAfraz AliNo ratings yet

- Economics 9732/01: Pioneer Junior College, Singapore Preliminary Examinations 2014 Higher 2Document8 pagesEconomics 9732/01: Pioneer Junior College, Singapore Preliminary Examinations 2014 Higher 2Yvette LimNo ratings yet

- Riko Technical Brochure PDFDocument29 pagesRiko Technical Brochure PDFGrigoreOzonNo ratings yet

- Screenshot 2022-10-07 at 9.15.02 PMDocument1 pageScreenshot 2022-10-07 at 9.15.02 PMoNo ratings yet

- Implications of Operating Boilers at Lower Pressures Than Design PressureDocument2 pagesImplications of Operating Boilers at Lower Pressures Than Design PressureAu TagolimotNo ratings yet

- Bence Bays Resume July 2015Document2 pagesBence Bays Resume July 2015api-292242662No ratings yet

- India Bulls Housing Finance LimitedDocument67 pagesIndia Bulls Housing Finance LimitedslohariNo ratings yet

- Building An Effective Safety Management System For Airlines: James J.H. Liou, Leon Yen, Gwo-Hshiung TzengDocument7 pagesBuilding An Effective Safety Management System For Airlines: James J.H. Liou, Leon Yen, Gwo-Hshiung Tzengzatul hasniNo ratings yet

- Lock Out Tag Out: Review QuestionsDocument37 pagesLock Out Tag Out: Review QuestionsMansoor AliNo ratings yet

- Bicycle ProjectDocument4 pagesBicycle Projectgaming channelNo ratings yet

- Assessment of Antioxidant Capacity For Scavenging Free Radicals in Vitro A Rational Basis and Practical ApplicationDocument11 pagesAssessment of Antioxidant Capacity For Scavenging Free Radicals in Vitro A Rational Basis and Practical Applicationngoclien93No ratings yet

- Lecture 4Document22 pagesLecture 4SUNDAS FATIMANo ratings yet

- Surgical Operation PDFDocument64 pagesSurgical Operation PDFshifna.latheefNo ratings yet

- GRES Integrated Energy Storage SystemDocument33 pagesGRES Integrated Energy Storage SystemVadim PopovichNo ratings yet

- Department of Education: Learning Activity SheetDocument7 pagesDepartment of Education: Learning Activity SheetKaren May UrlandaNo ratings yet

- WWW - Livelaw.In: in The Supreme Court of India Criminal Appellate JurisdictionDocument10 pagesWWW - Livelaw.In: in The Supreme Court of India Criminal Appellate JurisdictionSheetalNo ratings yet

- Corn Growth StagesDocument33 pagesCorn Growth StagesIvan JovanovićNo ratings yet

- Material HPLCDocument19 pagesMaterial HPLCIsmil ImamaNo ratings yet

![ARYA_SASOL_LIM1922[2]](https://imgv2-1-f.scribdassets.com/img/document/749034700/149x198/2086297215/1720509621?v=1)