Professional Documents

Culture Documents

Zadaća 5

Zadaća 5

Uploaded by

AdmiirOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zadaća 5

Zadaća 5

Uploaded by

AdmiirCopyright:

Available Formats

Tehnički engleski jezik 2

Student: Admir Aščerić

Homework 5

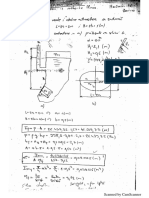

A) Besemerov proces je prva otkrivena metoda za masovnu proizvodnju čelika i

koristio je konverter kod kojeg se zrak upuhuje na dnu za prečišćavanje tečnog

željeza. Konverter se obično nagne na stranu kada se vruće željezo sipa u njeg.

Siemens-Martinova peć (SM) je tip peći koja koristi toplotu sagorijevanja gasova

ili tečnih goriva da konvertuje šaržu otpadnog željeza ili tečnog visokopećnog

željeza u tečni čelik.

Koji dio SM peći liči na veliku pravougaonu posudu koja može držati 50 do 175

tona željeza?

Za razliku od ognjišta SM peći, koje je pravougaonog oblika, ognjište elektro peći

je cilindrična zdjela koja je napravljena na taj način da olakša oboje, punjenje i

pražnjenje.

B) Pig iron is actually alloy of steel with carbon and it is produced by various

processes from which the eldest is the process in blast furnaces.

Usually after 2 hours, scrap is being almost totaly melted down, and in order to

continue the refinement process, the hot steel (pig iron) is added from the blast

furnace. Electric arcs which are positioned beetween movable carbon electrodes,

are producing heat which is necessary for this process to keep up proceeding.

In order to achieve high degree of purity and high quality of steel, the process

must be done in a right way.

One of the finale stages of this process is tilting or tipping over the furnace in

order to remove impure slag.

Answers on the questions:

1. The Bessemer process and the open-hearth process were important because the

production of steel started with them. Bessemer process is the first method

discovered for mass steel production and that is why it is so important.

2. One of the differences between those processes is in the shape of the furnace:

Pear-shaped vessel shape (Bessemer furnace), large rectangular basin shape

(open-hearth furnace) and the cilindrical bowl-shaped heart (electric arc furnace).

You might also like

- Steel AsiaDocument19 pagesSteel AsiamalynNo ratings yet

- Open Hearth FurnaceDocument19 pagesOpen Hearth Furnacemanikandan50% (2)

- Furances: Cupola FurnaceDocument7 pagesFurances: Cupola FurnaceMahmoud MerdanNo ratings yet

- Steel Making ProcessDocument8 pagesSteel Making ProcessDebanil ChakrabortyNo ratings yet

- Bessemer FurnaceDocument4 pagesBessemer FurnaceHariman El EmirNo ratings yet

- Metallurgy of MaterialDocument34 pagesMetallurgy of MaterialRehman TahirNo ratings yet

- Primary Steel MakingDocument56 pagesPrimary Steel MakingnitinrnnnNo ratings yet

- Open Hearth FurnaceDocument3 pagesOpen Hearth Furnacemibtisamnasih0000No ratings yet

- Steel Making HandoutDocument11 pagesSteel Making Handoutsivamett100% (1)

- Steel ManufacturingDocument23 pagesSteel ManufacturingIsrael HailuNo ratings yet

- E Mat: Engineering MaterialsDocument135 pagesE Mat: Engineering MaterialsStevenson CacNo ratings yet

- Steel Manufacture: Multicycled Steel Construction Products Material Properties of SteelDocument16 pagesSteel Manufacture: Multicycled Steel Construction Products Material Properties of SteeladhencandraNo ratings yet

- Steel Making Using Open Hearth Furnace-1Document9 pagesSteel Making Using Open Hearth Furnace-1victorymusa45No ratings yet

- Cupola Furnace eDocument5 pagesCupola Furnace eAshok PradhanNo ratings yet

- Steel MakingDocument28 pagesSteel Makingsatish_trivediNo ratings yet

- The Electric Arc FurnaceDocument21 pagesThe Electric Arc FurnaceKingsley Posiyano100% (1)

- Chapter5 SteelDocument28 pagesChapter5 SteelMUHAMMAD IZZAT AQMAL BIN MUSTAPHA KAMALNo ratings yet

- Crucible and High-Frequency MethodsDocument6 pagesCrucible and High-Frequency Methodsmaanka tuduNo ratings yet

- Unit 1 Metals and Melting Practices: StructureDocument45 pagesUnit 1 Metals and Melting Practices: StructureTapas BanerjeeNo ratings yet

- Steel 2Document11 pagesSteel 2Shawn BlueNo ratings yet

- Media-File-1 Downloadpages BluescopeDocument2 pagesMedia-File-1 Downloadpages Bluescopeapi-325627613No ratings yet

- + Engineering Materials II Note Chapter - 1 UpdatedDocument27 pages+ Engineering Materials II Note Chapter - 1 Updatedkerodsh2112No ratings yet

- Blast FurnaceDocument91 pagesBlast FurnaceSarbajitManna100% (1)

- Billets ProcessDocument5 pagesBillets ProcessWewey NuestroNo ratings yet

- Introduction To Steel MakingDocument44 pagesIntroduction To Steel MakingDrTrinath TalapaneniNo ratings yet

- Uses of Ferrous Metals & Alloys SteelsDocument55 pagesUses of Ferrous Metals & Alloys SteelsNoel AngeloNo ratings yet

- Iii. Ironmaking: Blast Furnace, A VerticalDocument7 pagesIii. Ironmaking: Blast Furnace, A VerticalGrezy MagnoNo ratings yet

- Zadaća 4Document1 pageZadaća 4AdmiirNo ratings yet

- Electric Arc Furnace Steel MakingDocument11 pagesElectric Arc Furnace Steel MakingM. Didik Suryadi100% (2)

- Steel MakingDocument5 pagesSteel MakingjonnelNo ratings yet

- How Is Steel Made Steel Production Process With PDFDocument4 pagesHow Is Steel Made Steel Production Process With PDFastronaut0303No ratings yet

- Smelting Is A Form Of: Blast FurnaceDocument31 pagesSmelting Is A Form Of: Blast FurnaceLalaine Arabit100% (1)

- Melting Furnaces: Cupola FurnaceDocument5 pagesMelting Furnaces: Cupola FurnaceAly RamadanNo ratings yet

- Electric Arc Furnace SteelmakingDocument3 pagesElectric Arc Furnace Steelmakingjanakiram2010No ratings yet

- Steel Making - Open-Hearth TehniqueDocument5 pagesSteel Making - Open-Hearth TehniqueMarcelo Rodriguez FujimotoNo ratings yet

- What Is Furnace ?Document21 pagesWhat Is Furnace ?BARUN BIKASH DENo ratings yet

- Metallurgical Industrial Furnaces 4Document5 pagesMetallurgical Industrial Furnaces 4Mining ReviewNo ratings yet

- FurnaceDocument2 pagesFurnacepushkarnath79No ratings yet

- Metallurgical Industrial Furnaces 5Document21 pagesMetallurgical Industrial Furnaces 5Mining ReviewNo ratings yet

- Air University Islamabad: Materials and Manufacturing Assignment # 3Document11 pagesAir University Islamabad: Materials and Manufacturing Assignment # 3danial shehroz khanNo ratings yet

- Electric Arc FurnaceDocument17 pagesElectric Arc FurnacePassmore DubeNo ratings yet

- Ironmaking in The Blast Furnace Plant: Sinter CokeDocument6 pagesIronmaking in The Blast Furnace Plant: Sinter CokeVij_78No ratings yet

- Meltingfurnace 170728094222Document31 pagesMeltingfurnace 170728094222Ninfa LansangNo ratings yet

- 2.15. Melting TechniquesDocument2 pages2.15. Melting Techniquesaman chaudharyNo ratings yet

- Report On Jindal Steel WorksDocument13 pagesReport On Jindal Steel WorksAmit DubeyNo ratings yet

- Ferrous Material Structure and Binary Alloy SystemDocument68 pagesFerrous Material Structure and Binary Alloy SystemUsman FarooqNo ratings yet

- Product and Industrial Designe MET 28-10-11Document31 pagesProduct and Industrial Designe MET 28-10-11Haider ManzoorNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Electric Arc Furnace: RefractoryDocument5 pagesElectric Arc Furnace: RefractoryAbhilash MallikarjunaNo ratings yet

- Melting FurnaceDocument37 pagesMelting FurnaceDr.S.Ravi CITNo ratings yet

- What Is A Melting FurnaceDocument11 pagesWhat Is A Melting FurnaceravivpsNo ratings yet

- Forging Processes MEE 3024 2014Document25 pagesForging Processes MEE 3024 2014Ali M. ElghawailNo ratings yet

- How's Steel Manufactured?: Raw Materials For IronmakingDocument6 pagesHow's Steel Manufactured?: Raw Materials For Ironmakingamitkhanna71No ratings yet

- Cast Iron Production & ClassificationDocument34 pagesCast Iron Production & ClassificationTanzir Musa100% (1)

- Document 123Document3 pagesDocument 123Adonis MiñanoNo ratings yet

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- Unit 2Document24 pagesUnit 2AdmiirNo ratings yet

- Zadaća 11Document1 pageZadaća 11AdmiirNo ratings yet

- Zadaća 10Document1 pageZadaća 10AdmiirNo ratings yet

- Tehnički Engleski Jezik 2 Student: Admir Aščerić Homework 5Document1 pageTehnički Engleski Jezik 2 Student: Admir Aščerić Homework 5AdmiirNo ratings yet

- Zadaća 4Document1 pageZadaća 4AdmiirNo ratings yet

- Zadaća 3Document2 pagesZadaća 3AdmiirNo ratings yet

- Remont Kanala Ugljene Prašine - ProjekatDocument2 pagesRemont Kanala Ugljene Prašine - ProjekatAdmiirNo ratings yet

- Fluidi Rokovi PDFDocument114 pagesFluidi Rokovi PDFAdmiirNo ratings yet