Professional Documents

Culture Documents

Zadaća 10

Zadaća 10

Uploaded by

AdmiirOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zadaća 10

Zadaća 10

Uploaded by

AdmiirCopyright:

Available Formats

Tehnički engleski jezik 2

Student: Admir Aščerić

Homework 10

1.)

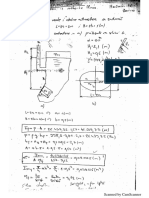

A) Parni i pneumatski čekići, udarni čekići i horizontalno operativne mašine koriste se za

hladno kovanje, dok se, hidraulične prese, koje sabijaju metal umjesto kovanja, koriste se

za presovanje.

Kalupi se koriste za dobijanje mašinskih otkovaka raznih oblika i veličina, dok se

kratkotrajni kalupi koriste za dobijanje relativno jednostavnijih oblika.

Kako bi napravili kompleksnije oblike u skladu sa konturama i dimenzijama finalnog

proizvoda, 2 ili više setova kalupa, često poznati kao zatvorene matrice, će biti potrebni.

Različiti faktori su od velike važnosti kada se radi o valjanju kao što je, pravac valjanja

(uzdužno, poprečno i valjanje vijaka), način rada valjaonice (kontinuiran ili

naizmjenični), stanje metala (vruče, toplo ili hladno valjanje), kao i oblik valjanog

proizvoda (tanki lim, puni ili šuplji profil).

Šta se desi kada se materijal izlije ili utisne u kalup?

B) Rollers could be smooth ones for sheet rolling or grooved ones which are used for

various types of sections. Plastic deformation of metal between two or more rotating rolls

is called rolling, and beside the plastic deformation, by rolling it can be improved grain

structure, mechanical properties of a material, as well as surface finish of material.

Secondary manufacturing processes are including processes which are responsible for the

final appearance of product (for example, its dimensions and surface finish) and

processes like heat treating, treatments where we achieve corrosion resistance, desired

hardness etc.

Screw cutting, tapping, thread milling, gear cutting and so on, are also secondary

processes.

2.) I) Casting is a primary manufacturing process in which the products (castings) are made

by pouring molten metal into molds or dies.

II) Extrusion is a fabrication process for producing rods, tubes, solid or hollow sections

from the billet or blank solid metal. There are 3 types of extrusion: direct, inverse and

impact extrusion.

You might also like

- Hot Working Processes Rolling Drawing Forging Extruding Piercing SpinningDocument26 pagesHot Working Processes Rolling Drawing Forging Extruding Piercing SpinningSarojKumarSinghNo ratings yet

- Metal Forming ProcessDocument10 pagesMetal Forming ProcessSiddharth ShahNo ratings yet

- Assignment: Submitted To: Miss Sobia Anwar Submitted By: Uzair Khan (2018-CH-01)Document12 pagesAssignment: Submitted To: Miss Sobia Anwar Submitted By: Uzair Khan (2018-CH-01)Uzair KhanNo ratings yet

- Hot Working: Forming Can Be Divided Into Two CategoriesDocument9 pagesHot Working: Forming Can Be Divided Into Two CategoriesNelson AlvarezNo ratings yet

- Manufacturing Processes: by Premchand Kumar Deoghar (Jharkhand)Document49 pagesManufacturing Processes: by Premchand Kumar Deoghar (Jharkhand)PremKumarNo ratings yet

- CastingDocument12 pagesCastingS V Garata ReddyNo ratings yet

- GR GNT 00166580000000717Document25 pagesGR GNT 00166580000000717ashoku24007No ratings yet

- MT 2nd AssignmentDocument72 pagesMT 2nd AssignmentDixitNo ratings yet

- Mt1 Unit 4 NotesDocument11 pagesMt1 Unit 4 Notesvelavansu100% (1)

- Manufacturing Process Paper 2Document5 pagesManufacturing Process Paper 2elisabetbertaniaNo ratings yet

- Rolling (Bulk Deformation Process)Document27 pagesRolling (Bulk Deformation Process)Kazal ArefinNo ratings yet

- Overview of Casting TechnologyDocument5 pagesOverview of Casting TechnologySK Kushwah RajputNo ratings yet

- Sheet Metal Forming An IntroductionDocument2 pagesSheet Metal Forming An Introductionanormal personNo ratings yet

- Pressure Die PPT InPDFDocument84 pagesPressure Die PPT InPDFSree RamichettyNo ratings yet

- Unit IV OrigionalDocument25 pagesUnit IV OrigionalPrakash SinghNo ratings yet

- 1) - Introduction:: Metal Forming ProcessesDocument10 pages1) - Introduction:: Metal Forming Processesphysics a2No ratings yet

- Manufacturing Engineering Blueprint ObjectivesDocument24 pagesManufacturing Engineering Blueprint Objectiveskidusabeje7No ratings yet

- Die Basics 101: Intro To Stamping: Stamping (Metalworking) Stamping PressingDocument30 pagesDie Basics 101: Intro To Stamping: Stamping (Metalworking) Stamping PressingAmitNo ratings yet

- Sheet Metalworking: ©2002 John Wiley & Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e"Document34 pagesSheet Metalworking: ©2002 John Wiley & Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e"Himanshu GuptaNo ratings yet

- Forging Is ADocument5 pagesForging Is ASahilNo ratings yet

- Metal ExtrusionDocument41 pagesMetal ExtrusionRashiqah RazlanNo ratings yet

- Sheet Metal Forming ProcessDocument5 pagesSheet Metal Forming ProcessAbdulbar kelilNo ratings yet

- Design of Dies - Unit 4Document149 pagesDesign of Dies - Unit 4210 SureshNo ratings yet

- Fabrication of MetalDocument22 pagesFabrication of MetalaurangzaibNo ratings yet

- Hot & Cold WorkingDocument23 pagesHot & Cold WorkingzackaiedaNo ratings yet

- Sheet Metal Working: Rudra Mani Ghimire Assistant Professor Department of Mechanical EngineeringDocument34 pagesSheet Metal Working: Rudra Mani Ghimire Assistant Professor Department of Mechanical EngineeringHimanshu GuptaNo ratings yet

- Differences Between Metal Forming Process and Casting ProcessDocument21 pagesDifferences Between Metal Forming Process and Casting ProcessFarhana Eyla75% (4)

- Dr. Chaitanya Sharma Phd. Iit RoorkeeDocument62 pagesDr. Chaitanya Sharma Phd. Iit RoorkeeTrung Quoc Le100% (1)

- Forming Processes MaterialDocument34 pagesForming Processes MaterialBALA GANESHNo ratings yet

- ME 212 Materials Processing-1Document15 pagesME 212 Materials Processing-1Favour LawrenceNo ratings yet

- FMP 221 Lecture 9 Cold WorkingDocument34 pagesFMP 221 Lecture 9 Cold WorkingSarojKumarSinghNo ratings yet

- Sheet Metal NotesDocument28 pagesSheet Metal NotesRingtone darbaarNo ratings yet

- Super Steel Industry..... 3Document31 pagesSuper Steel Industry..... 3erryNo ratings yet

- Forming Processes HAF NotesDocument10 pagesForming Processes HAF NotesZaky MuzaffarNo ratings yet

- Manufacturing Processes Midterm SheetDocument3 pagesManufacturing Processes Midterm SheetIvan MuñozNo ratings yet

- Basics of Continuous Casting of Steel - Copy-1Document4 pagesBasics of Continuous Casting of Steel - Copy-1Ghulam FareedNo ratings yet

- Labs-2 METAL FORMING Practice PDFDocument6 pagesLabs-2 METAL FORMING Practice PDFROYALNEWSSNo ratings yet

- Mechanical Working of Metals MaterialDocument40 pagesMechanical Working of Metals MaterialRoyalmechNo ratings yet

- AMT-Forming (Compatibility Mode)Document15 pagesAMT-Forming (Compatibility Mode)Abdulhmeed MutalatNo ratings yet

- Group 5 ScriptDocument28 pagesGroup 5 ScriptCarl Jay R. IntacNo ratings yet

- Fabrication of Automatic Spring Rolling MachineDocument45 pagesFabrication of Automatic Spring Rolling MachineANAND KRISHNANNo ratings yet

- Metal FormingDocument31 pagesMetal Formingswrd119No ratings yet

- Metal RollingDocument17 pagesMetal RollingkxalxoNo ratings yet

- Module 2 Activity No. 1Document6 pagesModule 2 Activity No. 1Benz DyNo ratings yet

- Metal Forming ProcessDocument5 pagesMetal Forming Processrk_kamatchi3483No ratings yet

- Unit IV 180208091907Document153 pagesUnit IV 180208091907tamilselvan nNo ratings yet

- Sheet MetalDocument34 pagesSheet MetalNirav SindhaNo ratings yet

- Manufacturing ProcessesDocument29 pagesManufacturing Processesemieel reegisNo ratings yet

- Sheet Metal BasicsDocument69 pagesSheet Metal Basicskiran_wakchaure50% (2)

- Metal Casting Dies: Thoguluva Raghavan VijayaramDocument4 pagesMetal Casting Dies: Thoguluva Raghavan VijayaramcombinationcoffeeNo ratings yet

- ExtrusionDocument9 pagesExtrusionOdebiyi StephenNo ratings yet

- Metal CastingDocument28 pagesMetal CastingAngel ChanteyNo ratings yet

- Design Study of Progressive Tool DesignDocument34 pagesDesign Study of Progressive Tool Designsudheer9289% (9)

- Unit - IV Drawing of Rods, Wires and TubesDocument13 pagesUnit - IV Drawing of Rods, Wires and TubesMaddipudi RamakrishnaNo ratings yet

- Hot & Cold WorkingDocument18 pagesHot & Cold WorkingMadushan MadushaNo ratings yet

- Universal Grinding - Machine - Report-FinalDocument48 pagesUniversal Grinding - Machine - Report-FinalGopuNo ratings yet

- Rolling Process Exp.: The Hashemite University Faculty of Engineering Industrial Engineering DepartmentDocument6 pagesRolling Process Exp.: The Hashemite University Faculty of Engineering Industrial Engineering DepartmentahmadalsayehNo ratings yet

- Extrusion FundamentalsDocument5 pagesExtrusion FundamentalsJoNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Unit 2Document24 pagesUnit 2AdmiirNo ratings yet

- Zadaća 11Document1 pageZadaća 11AdmiirNo ratings yet

- Tehnički Engleski Jezik 2 Student: Admir Aščerić Homework 5Document1 pageTehnički Engleski Jezik 2 Student: Admir Aščerić Homework 5AdmiirNo ratings yet

- Zadaća 5Document1 pageZadaća 5AdmiirNo ratings yet

- Zadaća 4Document1 pageZadaća 4AdmiirNo ratings yet

- Zadaća 3Document2 pagesZadaća 3AdmiirNo ratings yet

- Remont Kanala Ugljene Prašine - ProjekatDocument2 pagesRemont Kanala Ugljene Prašine - ProjekatAdmiirNo ratings yet

- Fluidi Rokovi PDFDocument114 pagesFluidi Rokovi PDFAdmiirNo ratings yet