Professional Documents

Culture Documents

Wavistrong Installation Guide - Part26

Wavistrong Installation Guide - Part26

Uploaded by

gfhf dgdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wavistrong Installation Guide - Part26

Wavistrong Installation Guide - Part26

Uploaded by

gfhf dgdCopyright:

Available Formats

WAVISTRONG

Installation

Guide

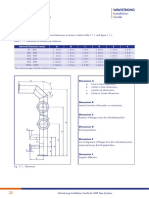

6.4.2. Channel crossing

The common method to install channel crossings is by

sinking of the channel crossing, after having assembled

this section on the bank of the canal or river. The pipe

section can be lowered using a floating crane or other

lifting equipment; care should be taken to ensure sufficient

pipe supports.

The process starts by sealing the ends of the pipe and

then launching this section; the pipe keeps floating. Then,

the pipe is filled and carefully sunk into its final position.

If the installation is performed using a cofferdam

construction then flexible joints can be used for

underwater piping; this makes the installation similar to Fig. 6.12. Launching of a channel crossing

an onshore assembly.

Note that underwater pipes should be covered sufficiently

to prevent floating and damage (e.g. by anchors).

6.5. Alignment

Undulating land levels with minor difference in height can

be followed by the flexibility of the system.

Bending of a joint of an installed pipeline shall be

avoided, unless allowable by system design.

6.6. Settlement

Fig. 6.13. Pipe alignment

Flexible joints have to be installed in pairs; one joint is

placed at the beginning of the deviation while the other is

located at the end of this area in order to create a rocker

pipe. The rocker pipe will act as a hinge.

The longer the rocker pipe, the higher the loads on the

joints. This can be avoided by adding more joints that

are flexible. Based on the soil parameters, the number of

joints is determined.

Note that the length of the sections shall be limited in

order to avoid excessive bending which may result in

failure of pipe or joint.

Mechanical O-ring joints shall be installed at both ends to Fig. 6.14. Settlement

accommodate further settlements.

The allowable angular deflection shall not be exceeded.

20 Wavistrong Installation Guide for GRE Pipe Systems

You might also like

- Metod StatementDocument10 pagesMetod StatementMamy R.67% (3)

- Method Statement For Valve InstallationDocument11 pagesMethod Statement For Valve InstallationKhang Hồ Lê100% (2)

- Installation PipeDocument57 pagesInstallation PipeSayan Manna100% (2)

- Wavistrong Installation Guide - Part23Document1 pageWavistrong Installation Guide - Part23gfhf dgdNo ratings yet

- Wavistrong Installation Guide - Part21Document1 pageWavistrong Installation Guide - Part21gfhf dgdNo ratings yet

- LECTURE No.8 Pipe Laying Vessels: Fig.1. Types of Pipe Lay Vessel Submarine PipelinesDocument14 pagesLECTURE No.8 Pipe Laying Vessels: Fig.1. Types of Pipe Lay Vessel Submarine PipelinesMiruna Clinciu100% (1)

- Wavistrong Installation Guide - Part29Document1 pageWavistrong Installation Guide - Part29gfhf dgdNo ratings yet

- Sclairpipe Marine PDFDocument16 pagesSclairpipe Marine PDFjeedanNo ratings yet

- OffshoreDocument3 pagesOffshorelaleye_olumideNo ratings yet

- Ipc2008 64247Document10 pagesIpc2008 64247dmlsfmmNo ratings yet

- Installation & Operation ManualDocument12 pagesInstallation & Operation ManualGlendinning Products, LLC.No ratings yet

- Method Statement For HV Cables Laying at Multi Storey Car Park Building at BWTC ComplexDocument9 pagesMethod Statement For HV Cables Laying at Multi Storey Car Park Building at BWTC Complexfibin haneefaNo ratings yet

- QuickStream PE - Manual Wavin PresiuneDocument40 pagesQuickStream PE - Manual Wavin PresiuneIonut SomneaNo ratings yet

- Product Selection Guide: Tube & Clamp ScaffoldDocument10 pagesProduct Selection Guide: Tube & Clamp ScaffoldGanesh Eshwar100% (1)

- IPC2014 33552 Structural Reliability Free SpansDocument11 pagesIPC2014 33552 Structural Reliability Free SpansfrvdabeeNo ratings yet

- Safety Valve InstallationDocument3 pagesSafety Valve InstallationEN IDNo ratings yet

- Omae2008 57486Document8 pagesOmae2008 57486dmlsfmmNo ratings yet

- How Does Offshore Pipeline Installation WorkDocument5 pagesHow Does Offshore Pipeline Installation Workrezhaeka100% (3)

- Check Dams: Design Manual Chapter 1 - General Provisions 7E - Design Information For ESC MeasuresDocument4 pagesCheck Dams: Design Manual Chapter 1 - General Provisions 7E - Design Information For ESC MeasuresIbrahim DanishNo ratings yet

- Offshore Pipeline Installation and RepairDocument36 pagesOffshore Pipeline Installation and Repairsjktnknsjgrg100% (4)

- A Simple Method For Simultaneously Tensi PDFDocument8 pagesA Simple Method For Simultaneously Tensi PDFAmit R. GhuleNo ratings yet

- SddsaDocument11 pagesSddsaAllswell ElleNo ratings yet

- Flow Over NotchDocument15 pagesFlow Over NotchMan Made Man100% (14)

- 8' MPV User's Manual For Side Port PDFDocument20 pages8' MPV User's Manual For Side Port PDFdavibrenoNo ratings yet

- 064 Method Statement For Construction of Air-Cooled CondensDocument13 pages064 Method Statement For Construction of Air-Cooled CondensMohd NasharuddinNo ratings yet

- Bottom Hole Completion TechniquesDocument9 pagesBottom Hole Completion Techniquesakshitppe11No ratings yet

- SaltandSwim3C Owner Manual SASDocument24 pagesSaltandSwim3C Owner Manual SASkarkoxcmpcNo ratings yet

- Cable Pulling MethodsDocument15 pagesCable Pulling MethodsRene RomeroNo ratings yet

- Rehabilitation of Bridge at AgarwadaDocument57 pagesRehabilitation of Bridge at AgarwadaBalan-Nogi DanNo ratings yet

- slotted drain brochureDocument12 pagesslotted drain brochureGodwin IwekaNo ratings yet

- Chapter 9 Pipelaying: 9.1 Pipeline RoutingDocument14 pagesChapter 9 Pipelaying: 9.1 Pipeline Routingmanuel cabarcas100% (2)

- Chapter 14 - Duct and Conduit-2Document2 pagesChapter 14 - Duct and Conduit-2vinaycltNo ratings yet

- SPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Document24 pagesSPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Eduardo OchaitaNo ratings yet

- Pap ADocument6 pagesPap AHarmoni AndreasNo ratings yet

- A New Way To Revive Old Gas WellsDocument7 pagesA New Way To Revive Old Gas WellsАлексей ЯковлевNo ratings yet

- Mooring Systems For Floaters - FPSO Mooring System 1Document24 pagesMooring Systems For Floaters - FPSO Mooring System 1apis14No ratings yet

- Guide For Installing RTR Pipe Courtesy Bondstrand For InfoDocument4 pagesGuide For Installing RTR Pipe Courtesy Bondstrand For InfoHafiz Ali Alvi100% (1)

- Sea Met - Self Installing Meteorological MastDocument11 pagesSea Met - Self Installing Meteorological MastLewis LackNo ratings yet

- Erection Procedure For 6.6 KV Bus DuctDocument7 pagesErection Procedure For 6.6 KV Bus DuctAnmohieyNo ratings yet

- Opgw StringingDocument3 pagesOpgw StringingNiraj SinhaNo ratings yet

- General Installation Guidelines: 1.0 Barrier FoundationDocument9 pagesGeneral Installation Guidelines: 1.0 Barrier FoundationMaruskLuluNo ratings yet

- Deepwater Riser InstallationDocument9 pagesDeepwater Riser InstallationekhwanhakimNo ratings yet

- Seam5 FinalsDocument17 pagesSeam5 FinalsRenefrid TejeroNo ratings yet

- Autonomous Subsea Tie in SystemDocument8 pagesAutonomous Subsea Tie in SystemAnonymous YSxTGQmD5No ratings yet

- Naval ArchitectureDocument36 pagesNaval ArchitectureAnshuman SharmaNo ratings yet

- Wavistrong Installation Guide - Part33Document1 pageWavistrong Installation Guide - Part33gfhf dgdNo ratings yet

- Pipeline INSTALLATIONDocument4 pagesPipeline INSTALLATIONJemar Lim100% (1)

- Instalación de Tuberías EnterradasDocument4 pagesInstalación de Tuberías EnterradasYana ParravanoNo ratings yet

- CH6 Water PassagesDocument76 pagesCH6 Water PassagesDAWIT GIRMANo ratings yet

- Advance Pipeline Crossing AnalysisDocument7 pagesAdvance Pipeline Crossing AnalysisAmmarul NafikNo ratings yet

- Geh 5876Document8 pagesGeh 5876anon_336518291No ratings yet

- Pumpguard PsDocument2 pagesPumpguard PsBehnamNo ratings yet

- Anchoring SystemDocument29 pagesAnchoring Systemintan nNo ratings yet

- CMT350Document9 pagesCMT350Mohamad Aiman Hakim bin Abdul Rahim100% (1)

- IJRAR2001610Document6 pagesIJRAR2001610GEOGINo ratings yet

- TCS P 104.06 R0Document20 pagesTCS P 104.06 R0Arnie100% (2)

- Pe Handbook Chapter 10 Marine Applications PDFDocument38 pagesPe Handbook Chapter 10 Marine Applications PDFAbhiNo ratings yet

- Appendix 9.B 9.B.1 Inverted Siphon: Sag CulvertsDocument21 pagesAppendix 9.B 9.B.1 Inverted Siphon: Sag CulvertsJulia DiazNo ratings yet

- Installation of Shore ApproachesDocument20 pagesInstallation of Shore ApproachesMohamed MustafaNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Approved Contractors ListDocument1 pageApproved Contractors Listgfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part49Document1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part49gfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part47Document1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part47gfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part52Document1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part52gfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part48 PDFDocument1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part48 PDFgfhf dgdNo ratings yet

- Pages From Pages From Hvac-Equations-Data-And-Rules-Of-Thumb - pdf02Document1 pagePages From Pages From Hvac-Equations-Data-And-Rules-Of-Thumb - pdf02gfhf dgdNo ratings yet

- District Cooling System DCS - Part12Document1 pageDistrict Cooling System DCS - Part12gfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part54 PDFDocument1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part54 PDFgfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part53Document1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part53gfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part58Document1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part58gfhf dgdNo ratings yet

- Wavistrong: Installation GuideDocument1 pageWavistrong: Installation Guidegfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part57 PDFDocument1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part57 PDFgfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part78 PDFDocument1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part78 PDFgfhf dgdNo ratings yet

- UntitledDocument1 pageUntitledgfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part77 PDFDocument1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part77 PDFgfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part59Document1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part59gfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part7Document1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part7gfhf dgdNo ratings yet

- UntitledDocument1 pageUntitledgfhf dgdNo ratings yet

- Demonstration VideoDocument1 pageDemonstration Videogfhf dgdNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part76 PDFDocument1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part76 PDFgfhf dgdNo ratings yet

- Credits: Principal-In-Charge Project Manager and Editor-In-Chief Project Team MembersDocument1 pageCredits: Principal-In-Charge Project Manager and Editor-In-Chief Project Team Membersgfhf dgdNo ratings yet

- District Cooling System DCS - Part3Document1 pageDistrict Cooling System DCS - Part3gfhf dgdNo ratings yet

- District Cooling System DCS - Part2Document1 pageDistrict Cooling System DCS - Part2gfhf dgdNo ratings yet

- District Cooling System DCS - Part1Document1 pageDistrict Cooling System DCS - Part1gfhf dgdNo ratings yet

- District Cooling System DCS - Part5Document1 pageDistrict Cooling System DCS - Part5gfhf dgdNo ratings yet

- District Cooling System DCS - Part4Document1 pageDistrict Cooling System DCS - Part4gfhf dgdNo ratings yet

- Better Utilization of Building Space Benefits To The District Environment Savings in Electricity ConsumptionDocument1 pageBetter Utilization of Building Space Benefits To The District Environment Savings in Electricity Consumptiongfhf dgdNo ratings yet

- Wavistrong Installation Guide - Part37Document1 pageWavistrong Installation Guide - Part37gfhf dgdNo ratings yet

- Wavistrong Installation Guide - Part38Document1 pageWavistrong Installation Guide - Part38gfhf dgdNo ratings yet

- Wavistrong Installation Guide - Part36Document1 pageWavistrong Installation Guide - Part36gfhf dgdNo ratings yet

- Batch 1 - Notes (2022)Document17 pagesBatch 1 - Notes (2022)jcxdsr956mNo ratings yet

- NASA Space Shuttle Orbiter Thermal Protection System Flight ExperienceDocument22 pagesNASA Space Shuttle Orbiter Thermal Protection System Flight ExperienceNguyen Duc BinhNo ratings yet

- Neural Networks For Machine Learning: Lecture 14A Learning Layers of Features by Stacking RbmsDocument39 pagesNeural Networks For Machine Learning: Lecture 14A Learning Layers of Features by Stacking RbmsTyler RobertsNo ratings yet

- Static Pressure and Pressure Head in FluidsDocument8 pagesStatic Pressure and Pressure Head in Fluidsyarzar17No ratings yet

- Screw Conveyor CalculationDocument14 pagesScrew Conveyor Calculationvvijaybhan100% (2)

- Further Computer-Analyzed D Ata of T H E Wageningen B-Screw SeriesDocument12 pagesFurther Computer-Analyzed D Ata of T H E Wageningen B-Screw SeriesS. M. MUNAWAR MAHTAB 1603061No ratings yet

- TWP Oracledatabasebackupservice 2183633Document21 pagesTWP Oracledatabasebackupservice 2183633Mwangi WanjohiNo ratings yet

- Zero Memory WidgetsDocument13 pagesZero Memory WidgetsKristineNo ratings yet

- Evaluation of Response Reduction Factor and Ductility Factor of RC Braced FrameDocument10 pagesEvaluation of Response Reduction Factor and Ductility Factor of RC Braced Framewidayat81No ratings yet

- Precommissioning Check of H.V., Indoor Board L.V. Power Control CentreDocument3 pagesPrecommissioning Check of H.V., Indoor Board L.V. Power Control CentreShameer BasheerNo ratings yet

- 500 Watt PWR Phase CombinerDocument6 pages500 Watt PWR Phase CombinerRaghil SotoyNo ratings yet

- Boarding Pass Bangkok PDFDocument4 pagesBoarding Pass Bangkok PDFLink KhoNo ratings yet

- 2 Way Valves: Fluid Control Division Europe Geneva - Switzerland General Catalogue FCDE/0110/UK/V1.0Document34 pages2 Way Valves: Fluid Control Division Europe Geneva - Switzerland General Catalogue FCDE/0110/UK/V1.0houssem houssemNo ratings yet

- Grid1 - MIGUEL GRAU - GR1S - Input DataDocument2 pagesGrid1 - MIGUEL GRAU - GR1S - Input DataCarlos CastilloNo ratings yet

- Expetiment 1 AIC (KTU)Document7 pagesExpetiment 1 AIC (KTU)Kirti ArunNo ratings yet

- Tectyl Multipurpose Clear 12 - 400 ML 000000000000816702 Spain (GHS) - EnglishDocument25 pagesTectyl Multipurpose Clear 12 - 400 ML 000000000000816702 Spain (GHS) - EnglishDavid P MNo ratings yet

- Jotun Tankguard HBDocument5 pagesJotun Tankguard HBrheriNo ratings yet

- MC8085Document7 pagesMC8085Bhavani BhavanNo ratings yet

- Light-Transmitting Fiber Optic Posts An in Vitro EvaluationDocument8 pagesLight-Transmitting Fiber Optic Posts An in Vitro EvaluationDanny Eduardo RomeroNo ratings yet

- A Complete Document For Dunning Procedure With Smartform - SAP BlogsDocument11 pagesA Complete Document For Dunning Procedure With Smartform - SAP BlogsRamki P0% (1)

- Moisture ContentDocument8 pagesMoisture ContentHafrizDaniel0% (1)

- Pnap App 024Document9 pagesPnap App 024bobbyccwNo ratings yet

- Law of Friction: Surface Between Two Bodies Oppose Relative MotionDocument11 pagesLaw of Friction: Surface Between Two Bodies Oppose Relative Motionpradeep kumarNo ratings yet

- Requirements Specification TemplateDocument6 pagesRequirements Specification TemplateArup DasNo ratings yet

- WSAWLD002Document29 pagesWSAWLD002Nc BeanNo ratings yet

- Chapter 3Document17 pagesChapter 3Huzairee IsmailNo ratings yet

- Electrical Engineering and Computer Science 6.685 Electric Machines, Fall 2005Document1 pageElectrical Engineering and Computer Science 6.685 Electric Machines, Fall 2005Lisandro ZaguilanNo ratings yet

- Psa RecordDocument66 pagesPsa RecordMurugesan ArumugamNo ratings yet

- High Tech Tool CatalogDocument40 pagesHigh Tech Tool CatalogMadirley PimentaNo ratings yet

- Worls First CNG Ship in Indonesia Presentation by Bima PSDocument20 pagesWorls First CNG Ship in Indonesia Presentation by Bima PSAnonymous icnhaNsF100% (2)