Professional Documents

Culture Documents

Method Statment - Hdpe Pipe Welding and Installation Job

Method Statment - Hdpe Pipe Welding and Installation Job

Uploaded by

mitendra singhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statment - Hdpe Pipe Welding and Installation Job

Method Statment - Hdpe Pipe Welding and Installation Job

Uploaded by

mitendra singhCopyright:

Available Formats

FORMATE ID :

MSS/KCSA/DRA/MS/

REV NO. : 00

EFFECTIVE

DATE :08/03/2022

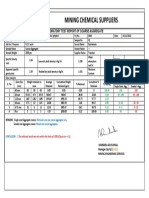

MINING SERVICES & SUPPLIES

DOCUMENT TITLE : METHOD STATEMENTS

PROJECT NAME : BURIED SERVICES

Page 1 of 3

NAME OF CLIENT : KAMOA COPPER SA

MINING SERVICES & SUPPLIES

CONTRACTOR

NAME:

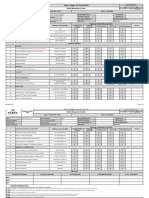

Mr PRADEEP (MSS) Mr. DIPESH ABHIJIT KHOKUTE(MSS) Reviewed By (KAMOA Approved By (KAMOA

(MANAGER QA/QC) SHARMA(MSS) (Sr. MANAGER) COPPER SA): COPPER SA) :

(DY MANAGER)

METHOD STATEMENTS

SR Mr Dipesh Mr. Pradeep Abhijit

. EFFECTIVE REV. Sharma Pushpala ( MSS KAMOA

KAMOA SQC

NO DATE NO. ( MSS DY ( MSS QA/QC CONSTRUCTIO SUPERVISOR

. MANAGER) Dy. Manager) N MANAGER)

01

02

03

04

Use Standard Flow Chart Symbols in Process approach Flowchart :

Process Flow Process Alternate Document Informatio

Start/End steps steps Decisio n

Step Process n /Data

Property of MSS – Approved (Controlled document in Document Repository)

FORMATE ID :

MSS/KCSA/DRA/MS/

REV NO. : 00

EFFECTIVE

DATE :08/03/2022

MINING SERVICES & SUPPLIES

DOCUMENT TITLE : METHOD STATEMENTS

PROJECT NAME : BURIED SERVICES

Page 2 of 3

NAME OF CLIENT : KAMOA COPPER SA

MINING SERVICES & SUPPLIES

CONTRACTOR

NAME:

Mr PRADEEP (MSS) Mr. DIPESH ABHIJIT KHOKUTE(MSS) Reviewed By (KAMOA Approved By (KAMOA

(MANAGER QA/QC) SHARMA(MSS) (Sr. MANAGER) COPPER SA): COPPER SA) :

(DY MANAGER)

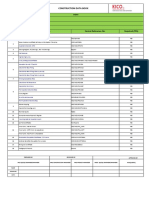

HDPE PIPE & SLEEVES INSTALLATION FROM BORE HOLE

TO TANK AREA

Excavation:-

1) Environmental clearance before the start of excavation of trench work.

2) Area clearance for excavation of trench and installation of HDPE pipes and sleeve.

3) Marking of area for excavation of trench and removing of excess soil.

4) By using TLB excavation of trench from bore hole 01 to 02 and from 02 bore hole to

start point of sleeves area.

5) Excavation of trenches to be carried out from start point of sleeves (river crossing) to

the tank area.

6) At River crossing Excavator and TLB both to be used for excavation of trench to maintain

proper and width of trench.

HDPE Pipe and Sleeves welding:-

7) HDPE Pipe and fitting to be connected to bore hole 01 and bore hole 02.

8) Welding of HDPE pipe Roll or 12 mtr length as per availability by use of HDPE welding

machine.

9) Laying of HDPE pipe from Bore hole 01 to 02 and then after laying of pipe 160 Dia till the

start point of the sleeves.

Use Standard Flow Chart Symbols in Process approach Flowchart :

Process Flow Process Alternate Document Informatio

Start/End steps steps Decisio n

Step Process n /Data

Property of MSS – Approved (Controlled document in Document Repository)

FORMATE ID :

MSS/KCSA/DRA/MS/

REV NO. : 00

EFFECTIVE

DATE :08/03/2022

MINING SERVICES & SUPPLIES

DOCUMENT TITLE : METHOD STATEMENTS

PROJECT NAME : BURIED SERVICES

Page 3 of 3

NAME OF CLIENT : KAMOA COPPER SA

MINING SERVICES & SUPPLIES

CONTRACTOR

NAME:

Mr PRADEEP (MSS) Mr. DIPESH ABHIJIT KHOKUTE(MSS) Reviewed By (KAMOA Approved By (KAMOA

(MANAGER QA/QC) SHARMA(MSS) (Sr. MANAGER) COPPER SA): COPPER SA) :

(DY MANAGER)

10) Welding of HDPE Sleeves 315 mm Dia and 160 mm Dia by use of HDPE welding machine.

11) Laying of HDPE pipe sleeves for river crossing 315 mm Dia 5 Nos and 160 mm Dia 2 Nos.

12) 2 Nos of HDPE pipe line from bore hole 01 and 02 to be welded and Slided through the

315mm Dia sleeves at river crossing to connect to the tank.

13) HDPE pipe from bore hole 01 and 02 to be connected to the tank for water storage.

14) Backfilling of laterite and earth soil be done from bore hole 01 to bore hole 02 area,

compaction to be done for the same area after backfilling job.

15) At river crossing 100 mm laterite to be compacted before HDPE sleeves laying.

16) After laying of HDPE Sleeves Concrete work to be done on sleeves for fixing the hdpe

pipe sleeves steady so that pipe does not move at the time of flood.

17) For the future provision HDPE sleeves the sleeves to be blinded so that no rain water or

soil enters into the HDPE pipe.

18) After the concerting layer on Sleeves a 200-300 layer of earth soil or laterite to be

backfilled and compaction at river crossing need to be done.

19) After completion of the backfilling and compaction of the line Bore hole line to be

connected at tank area and line needs to be tested.

Use Standard Flow Chart Symbols in Process approach Flowchart :

Process Flow Process Alternate Document Informatio

Start/End steps steps Decisio n

Step Process n /Data

Property of MSS – Approved (Controlled document in Document Repository)

You might also like

- Bi-Di PigDocument1 pageBi-Di PigrobyharyudhaNo ratings yet

- C1729 Is A New ASTM Standard For Aluminum JacketingDocument2 pagesC1729 Is A New ASTM Standard For Aluminum JacketingTushar Arekar100% (2)

- Underground Installation of Thermoplastic Pipe For Sewers and Other Gravity-Flow ApplicationsDocument10 pagesUnderground Installation of Thermoplastic Pipe For Sewers and Other Gravity-Flow ApplicationsDavid SolisNo ratings yet

- JFD 100Document1 pageJFD 100ecsuperalNo ratings yet

- Nitoproof 10Document2 pagesNitoproof 10Balasubramanian Ananth67% (3)

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- Kamoa Copper Sa: Quality Management System Non-Conformance ReportDocument2 pagesKamoa Copper Sa: Quality Management System Non-Conformance ReportMitendra Kumar ChauhanNo ratings yet

- Bunding of Storage Tanks and Transfer FacilitiesDocument4 pagesBunding of Storage Tanks and Transfer FacilitiesAjiri IvoviNo ratings yet

- Hdpe Pipe Butt Welding ProceduresDocument7 pagesHdpe Pipe Butt Welding ProceduresRodrigo CarizNo ratings yet

- Managing Concrete Washout: DEQ Rules Effective 12/15/15Document2 pagesManaging Concrete Washout: DEQ Rules Effective 12/15/15Jorge GutierrezNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- Concrete Waste GuidelineDocument8 pagesConcrete Waste GuidelineArvee VermaNo ratings yet

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocument1 page4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFabdullah amanullah0% (1)

- PVC CPVC Physical Properties and Astm Specifications For Piping PDFDocument1 pagePVC CPVC Physical Properties and Astm Specifications For Piping PDFShahfaraz AhmadNo ratings yet

- Klamflexproduct BrochureDocument24 pagesKlamflexproduct BrochureblindjaxxNo ratings yet

- Camx 2015 Vaidya UabDocument11 pagesCamx 2015 Vaidya UabJuNeng NigLtdNo ratings yet

- User'S Manual: MANUAL NO - GL240-UM-153Document150 pagesUser'S Manual: MANUAL NO - GL240-UM-153Ta100% (1)

- Quotation: Note: This Quotation Is Sent by Email and No Signature Is RequiredDocument1 pageQuotation: Note: This Quotation Is Sent by Email and No Signature Is RequiredSyazwan KhairulNo ratings yet

- Card Board BurstingDocument3 pagesCard Board BurstingParthiban Karuna100% (1)

- Oil-Water Separator Inspection and Maintenance ChecklistDocument2 pagesOil-Water Separator Inspection and Maintenance ChecklistHatta YasinNo ratings yet

- Fire Monitor Data Sheet - 3-3Document1 pageFire Monitor Data Sheet - 3-3Bagus PrambudiNo ratings yet

- EZR RegulatorDocument40 pagesEZR RegulatorBranko BabicNo ratings yet

- Nqd-Valve Installation ReportDocument21 pagesNqd-Valve Installation ReportprathameshNo ratings yet

- Application ProcedureDocument18 pagesApplication ProcedureTeguh SilaNo ratings yet

- Radiation Safety Distance DiagramDocument3 pagesRadiation Safety Distance DiagramEswaranNo ratings yet

- DOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Document2 pagesDOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Bharathi100% (1)

- Normas de Referencia - Fibra de VidroDocument12 pagesNormas de Referencia - Fibra de Vidroricardobor100% (1)

- Prosedure HEX & HPWJDocument131 pagesProsedure HEX & HPWJNaniura CreationNo ratings yet

- Method Statement: Hot TapDocument43 pagesMethod Statement: Hot TapJaldeep GiniyaNo ratings yet

- Lifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneDocument7 pagesLifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneHtin Lin Aung100% (1)

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- Materials System SpecificationDocument15 pagesMaterials System SpecificationAwais CheemaNo ratings yet

- PRE-QUALIFICATION - Pavers - Aalco GroupDocument75 pagesPRE-QUALIFICATION - Pavers - Aalco GroupJason RazatlabNo ratings yet

- Design of Obround Flange For Pressure Vessel Application by Analytical Method and FEA To Comply With ASME CodeDocument11 pagesDesign of Obround Flange For Pressure Vessel Application by Analytical Method and FEA To Comply With ASME CodeFelip PrietoNo ratings yet

- How To Select A Heat Shrink SleeveDocument2 pagesHow To Select A Heat Shrink SleeveLava SatNo ratings yet

- Hydrotest JHADocument29 pagesHydrotest JHABenjamin EmmanuelNo ratings yet

- Installation Procedure: Installation For CHEZY PP Inspection ChamberDocument1 pageInstallation Procedure: Installation For CHEZY PP Inspection Chambertaufik saari100% (1)

- CPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingDocument18 pagesCPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingAdil Ijaz100% (1)

- Method Statement For Static Equipment (T-4701, T-4302, D-4302, D-4304, D-4606) - 2 PDFDocument54 pagesMethod Statement For Static Equipment (T-4701, T-4302, D-4302, D-4304, D-4606) - 2 PDFNGUYEN VINHNo ratings yet

- G Series - ENG.MRISDocument4 pagesG Series - ENG.MRISMatsumura SokonNo ratings yet

- Lowering of PipelineDocument5 pagesLowering of PipelineLarry Ubu100% (1)

- Method StatementDocument7 pagesMethod StatementGerson FernandesNo ratings yet

- Inspection and Test Plan (ITP)Document7 pagesInspection and Test Plan (ITP)Zulfokar FahdawiNo ratings yet

- Method Statement-HDPE-MWSPDocument16 pagesMethod Statement-HDPE-MWSPKumar AbhishekNo ratings yet

- Ventilation Plan For Confined Space EntryDocument9 pagesVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- Inspection and Test Plan For Heat ExchangersDocument28 pagesInspection and Test Plan For Heat ExchangersHOMAYOUN KHADIVINo ratings yet

- Plumbness Check ReportDocument50 pagesPlumbness Check ReportYusuf KhoirNo ratings yet

- Installation Manual OXYFLEX® MF1100 October 2014 PDFDocument8 pagesInstallation Manual OXYFLEX® MF1100 October 2014 PDFRomuel PioquintoNo ratings yet

- Polyurethane Spray Foam Roofing - Hi-Rise Specialists, When The Storm ComesDocument5 pagesPolyurethane Spray Foam Roofing - Hi-Rise Specialists, When The Storm ComesWeathertightsystemsincNo ratings yet

- Released: Company Document No: Document ClassDocument32 pagesReleased: Company Document No: Document ClassShajahan AsanarNo ratings yet

- Torque Value DelmonDocument8 pagesTorque Value DelmonKhalid HaiderNo ratings yet

- Specification of Pipe InsulationDocument6 pagesSpecification of Pipe InsulationNoldz SantosNo ratings yet

- How Vci WorkDocument21 pagesHow Vci Work同道文档中心100% (1)

- u-PVC InchDocument46 pagesu-PVC Inchegemen7404612No ratings yet

- A.9.02 - CPCL Itp For Utility Boiler PackageDocument3 pagesA.9.02 - CPCL Itp For Utility Boiler PackageGanesh EshwarNo ratings yet

- GRP Lamination Processing - Instructions PDFDocument34 pagesGRP Lamination Processing - Instructions PDFmuhammadkashikNo ratings yet

- MSS-KKP-DCB - Method StatementsDocument8 pagesMSS-KKP-DCB - Method StatementsMitendra Kumar ChauhanNo ratings yet

- Mcs - Method StatementsDocument179 pagesMcs - Method StatementsMitendra Kumar ChauhanNo ratings yet

- Testing Procedure - Earth Works - DCPDocument3 pagesTesting Procedure - Earth Works - DCPmitendra singhNo ratings yet

- MOS PlasteringDocument7 pagesMOS PlasteringAhmad Fauzi Bin OmarNo ratings yet

- MOS DrainageDocument8 pagesMOS DrainageAhmad Fauzi Bin OmarNo ratings yet

- Company: MSS Activity Description: Construction of Village Potable Water Storage Tank Kamoa - 1 Date Compiled: 25/04/2023 Risk Assessment NumberDocument19 pagesCompany: MSS Activity Description: Construction of Village Potable Water Storage Tank Kamoa - 1 Date Compiled: 25/04/2023 Risk Assessment Numbermitendra singhNo ratings yet

- GCK Cement Test ReportsDocument1 pageGCK Cement Test Reportsmitendra singhNo ratings yet

- Sop's Marking Flotation-Milling-ConcentratorDocument2 pagesSop's Marking Flotation-Milling-Concentratormitendra singhNo ratings yet

- Katebi Soil Resistivity RepotDocument1 pageKatebi Soil Resistivity Repotmitendra singhNo ratings yet

- KC-CON-CERT-SO-01 - Setting Out Certificate-LatestDocument1 pageKC-CON-CERT-SO-01 - Setting Out Certificate-Latestmitendra singhNo ratings yet

- Concrete Mix Design C 30 For KamoaDocument9 pagesConcrete Mix Design C 30 For Kamoamitendra singhNo ratings yet

- ANNEXURE E - Acknowledgement of TenderDocument1 pageANNEXURE E - Acknowledgement of Tendermitendra singhNo ratings yet

- 254 - A.O.D - (A.o.d Duck)Document1 page254 - A.O.D - (A.o.d Duck)mitendra singhNo ratings yet

- BC301 Const Lab Surface Bed - 1Document7 pagesBC301 Const Lab Surface Bed - 1mitendra singhNo ratings yet

- Cube Test RegisterDocument2 pagesCube Test Registermitendra singhNo ratings yet

- Civils - Trenching - ExcavationsDocument2 pagesCivils - Trenching - Excavationsmitendra singhNo ratings yet

- CC305 Mini Sub SlabsDocument2 pagesCC305 Mini Sub Slabsmitendra singhNo ratings yet

- 0045-CI-255210 Rev 2Document1 page0045-CI-255210 Rev 2mitendra singhNo ratings yet

- Testing Procedure - Earth Works - DCPDocument3 pagesTesting Procedure - Earth Works - DCPmitendra singhNo ratings yet

- Sieve Analysis For Coarse Aggregates - Kico Project-091222Document1 pageSieve Analysis For Coarse Aggregates - Kico Project-091222mitendra singh100% (1)

- Civil - Laboratory Coasting Sheet (From 19.08.2022 To 19.09.2022)Document4 pagesCivil - Laboratory Coasting Sheet (From 19.08.2022 To 19.09.2022)mitendra singhNo ratings yet

- Mss-Method StatementsDocument864 pagesMss-Method Statementsmitendra singhNo ratings yet

- Weekly QMS Progress R of Mang.& Moladi Hous. KamoaDocument1 pageWeekly QMS Progress R of Mang.& Moladi Hous. Kamoamitendra singhNo ratings yet

- Concession RequestDocument1 pageConcession Requestmitendra singhNo ratings yet

- MCS - QCP-001 For Earth Work KKDocument6 pagesMCS - QCP-001 For Earth Work KKmitendra singhNo ratings yet

- Sotrafer-Quality Observation Complaince Tracking Record.Document63 pagesSotrafer-Quality Observation Complaince Tracking Record.mitendra singhNo ratings yet

- Imir - Incomming Material Inspection ReportDocument2 pagesImir - Incomming Material Inspection Reportmitendra singhNo ratings yet

- MCS - QCP - CONCRETE WORKS - Index - 03-12-22Document1 pageMCS - QCP - CONCRETE WORKS - Index - 03-12-22mitendra singhNo ratings yet

- MSS Data Book TrackerDocument16 pagesMSS Data Book Trackermitendra singhNo ratings yet

- Trail Mix-Mes-LubDocument5 pagesTrail Mix-Mes-Lubmitendra singhNo ratings yet

- Piping Fabrication and Construction PDFDocument61 pagesPiping Fabrication and Construction PDFMohamed AdelNo ratings yet

- General Presentation: Chemical Composition C Si MN Ni CR Cu Mo N P SDocument7 pagesGeneral Presentation: Chemical Composition C Si MN Ni CR Cu Mo N P SCan ERTANNo ratings yet

- Moisture BarriersDocument31 pagesMoisture BarriersraviciviltNo ratings yet

- 404 Superalloys: Y' 6, or Y"Document11 pages404 Superalloys: Y' 6, or Y"Kasia MazurNo ratings yet

- Additive Manufacturing of Bimetallic StructuresDocument40 pagesAdditive Manufacturing of Bimetallic StructuresJuan JimenezNo ratings yet

- Afp PNP 2 Stry Duplex 60 SQM Adopted Version 5Document18 pagesAfp PNP 2 Stry Duplex 60 SQM Adopted Version 5Christopher Greg PermisonNo ratings yet

- Mix Design of SCCDocument4 pagesMix Design of SCCDebaraj BailungNo ratings yet

- Float Glass PriceDocument3 pagesFloat Glass PricegtarasanNo ratings yet

- British Standards For Piping SystemDocument3 pagesBritish Standards For Piping SystemPradeep Sharma100% (1)

- El 05 PDFDocument1 pageEl 05 PDFRhobbie NolloraNo ratings yet

- 03 04 LewisDocument14 pages03 04 LewisDLM7No ratings yet

- Ronafix: Product DataDocument4 pagesRonafix: Product Datachong pak limNo ratings yet

- Design Criteria: GeneralDocument1 pageDesign Criteria: GeneralRolly Marc G. SoteloNo ratings yet

- Properties of Structure Steel As Per Limit State Method IS 800:2007, Mechanical Properties of SteelDocument19 pagesProperties of Structure Steel As Per Limit State Method IS 800:2007, Mechanical Properties of SteelRaju Sharma75% (4)

- Concrete - Part 14 - Protective Treatments For Concrete PDFDocument24 pagesConcrete - Part 14 - Protective Treatments For Concrete PDFshareyhouNo ratings yet

- Bug Holes in PrecastDocument5 pagesBug Holes in PrecastMichel DaoustNo ratings yet

- Butterfly Valves EgeplastDocument4 pagesButterfly Valves EgeplastdsyashankaNo ratings yet

- Wood Substitutes and Glasses: Multi Wood: Name:Asna Roll No: 13 Sem: S5 B Thejus College of ArchitectureDocument8 pagesWood Substitutes and Glasses: Multi Wood: Name:Asna Roll No: 13 Sem: S5 B Thejus College of ArchitectureAsna AbbasNo ratings yet

- QUS 104 Building ScienceDocument70 pagesQUS 104 Building ScienceOlagoke Habeeb Ademola100% (3)

- Brief About Kalzen Construction SystemDocument2 pagesBrief About Kalzen Construction Systemrakkesh01No ratings yet

- QQ B 654aDocument19 pagesQQ B 654astelioskoNo ratings yet

- Vietnam Oil and Gas Corporation (Petrovietnam) Dung Quat Refinery (DQR) ProjectDocument8 pagesVietnam Oil and Gas Corporation (Petrovietnam) Dung Quat Refinery (DQR) ProjectSudip ShresthaNo ratings yet

- Lec 2 Refractories Kiln Design 2011Document36 pagesLec 2 Refractories Kiln Design 2011venka07No ratings yet

- Recycling Aluminum Aerospace AlloysDocument5 pagesRecycling Aluminum Aerospace AlloysShamim HasanNo ratings yet

- Building Technologies 5: ResearchDocument12 pagesBuilding Technologies 5: ResearchclareableNo ratings yet

- Report RobotDocument10 pagesReport RobotAimy SufeaNo ratings yet

- CRSI Slabs On GroundDocument1 pageCRSI Slabs On GroundJason Gross100% (2)