Professional Documents

Culture Documents

Radar Tank Gauge For Asphalt and Bitumen Tankers Gla 300 Asphalt

Radar Tank Gauge For Asphalt and Bitumen Tankers Gla 300 Asphalt

Uploaded by

Boris BirinCopyright:

Available Formats

You might also like

- HS6620D Data Sheet V3.0Document29 pagesHS6620D Data Sheet V3.0Homo Cyberneticus67% (3)

- ANT AQU4518R12 1831 DatasheetDocument3 pagesANT AQU4518R12 1831 DatasheetMuhammad Jamil AwanNo ratings yet

- Radar Tank Gauge For Gas Carriers GLA-310 - 5 PDFDocument2 pagesRadar Tank Gauge For Gas Carriers GLA-310 - 5 PDFEjaz Ahmed RanaNo ratings yet

- gt403 Ce2Document4 pagesgt403 Ce2SodaDrinkNo ratings yet

- Pressure Transmitter: Principle of OperationDocument4 pagesPressure Transmitter: Principle of OperationAranNo ratings yet

- Pressure Transmitter Gt405Document4 pagesPressure Transmitter Gt405ALEXIS RODRIGUEZNo ratings yet

- Alat Ukur LPGDocument4 pagesAlat Ukur LPGMj MargarethNo ratings yet

- 117position Monitor PDFDocument2 pages117position Monitor PDFJacob KalloorNo ratings yet

- MeasurIT KTek AT200 Level Transmitter 0910Document4 pagesMeasurIT KTek AT200 Level Transmitter 0910cwiejkowskaNo ratings yet

- TI266ten 0409Document12 pagesTI266ten 0409Keren ArteagaNo ratings yet

- Trend Master Galvanic IsolatorDocument6 pagesTrend Master Galvanic Isolatorrohitraj10No ratings yet

- Ex Single Data Sheet Wall Mounting Socket 63 A 8579-31-407 201390Document5 pagesEx Single Data Sheet Wall Mounting Socket 63 A 8579-31-407 201390Arthur BastosNo ratings yet

- 90 1199 10.4 (GT3000 Specifications)Document2 pages90 1199 10.4 (GT3000 Specifications)tipcigromeroNo ratings yet

- 9884 - Duct Temperature Sensor FK-TP - 200 - enDocument4 pages9884 - Duct Temperature Sensor FK-TP - 200 - enMinh nhut LưuNo ratings yet

- Specs SSGC-FP-PT-12537 Transformer RectifierDocument3 pagesSpecs SSGC-FP-PT-12537 Transformer RectifierIrfan AhmedNo ratings yet

- Pune Techtrol FGTDocument2 pagesPune Techtrol FGTBenjamin StricklandNo ratings yet

- Pressure Control BrochureDocument12 pagesPressure Control Brochurebkpaul3107No ratings yet

- 852-318 Data Sheet LoresDocument4 pages852-318 Data Sheet LoresDaniel SubelzaNo ratings yet

- GS 01f06a00-01e - 013Document36 pagesGS 01f06a00-01e - 013Gilang RomadhonNo ratings yet

- En 09 15 Eng Rev.5 Servo Gauge 854 XTGDocument6 pagesEn 09 15 Eng Rev.5 Servo Gauge 854 XTGJoaquin LunaNo ratings yet

- Meggitt Ipc704Document15 pagesMeggitt Ipc704Abdul Salam SagirNo ratings yet

- Data Sheet For Pressure Transmitter: Units:-Flow: Liquid-T/hr Gas-MMSCMD Steam - KG/HR Pressure - KG/CMDocument19 pagesData Sheet For Pressure Transmitter: Units:-Flow: Liquid-T/hr Gas-MMSCMD Steam - KG/HR Pressure - KG/CMrahul.adityaNo ratings yet

- Electrochemical Toxic Gas Detector GT3000 Series Includes Transmitter (GTX) and Sensor Module (GTS)Document2 pagesElectrochemical Toxic Gas Detector GT3000 Series Includes Transmitter (GTX) and Sensor Module (GTS)Vivekanandan FriendlieyNo ratings yet

- Ds Sf6 GDT Gd10cl en Us 27789Document4 pagesDs Sf6 GDT Gd10cl en Us 27789behnamatgNo ratings yet

- ACS713-Datasheet - Current Sensor ICDocument14 pagesACS713-Datasheet - Current Sensor ICphase90No ratings yet

- Product Specifications Product Specifications: Accuret Accuret - A20 A20Document2 pagesProduct Specifications Product Specifications: Accuret Accuret - A20 A20inikeapriliaputriNo ratings yet

- External Mounted Magnetostrictive Level TransmitterDocument6 pagesExternal Mounted Magnetostrictive Level Transmitterjuan vazquezNo ratings yet

- Catalogo Smart Servo 854 Ferrum Energy PDFDocument6 pagesCatalogo Smart Servo 854 Ferrum Energy PDFManuel De MatosNo ratings yet

- Petrotek LPG Gas Detection FlyerDocument3 pagesPetrotek LPG Gas Detection FlyerHuraira AliNo ratings yet

- WECO 1502 Connection DrawingDocument2 pagesWECO 1502 Connection Drawinghai minhNo ratings yet

- Aks 3000Document8 pagesAks 3000gatoluisNo ratings yet

- Smart Subcombiner US CEDocument2 pagesSmart Subcombiner US CEtalasubhanojiraogmaiNo ratings yet

- Rs-fs-9001 GT Flame SensorDocument18 pagesRs-fs-9001 GT Flame Sensorzakarianoui35No ratings yet

- Flexret: A Flexible, Integrated Solution For Adjusting The Electrical Downtilt of Kathrein Flexret AntennasDocument11 pagesFlexret: A Flexible, Integrated Solution For Adjusting The Electrical Downtilt of Kathrein Flexret AntennasиванNo ratings yet

- Flexret: A Flexible, Integrated Solution For Adjusting The Electrical Downtilt of Kathrein Flexret AntennasDocument10 pagesFlexret: A Flexible, Integrated Solution For Adjusting The Electrical Downtilt of Kathrein Flexret AntennasAdrian BrumeaNo ratings yet

- Crouse Hinds MTL tp48 Catalog PageDocument3 pagesCrouse Hinds MTL tp48 Catalog Pageinstrument.assist.slpNo ratings yet

- CA 134 Piezoelectric Accelerometer: Iecex Nepsi Tiis KGSDocument5 pagesCA 134 Piezoelectric Accelerometer: Iecex Nepsi Tiis KGSEliyanto E BudiartoNo ratings yet

- Medidor Caudal Kobold Aleta TSKDocument6 pagesMedidor Caudal Kobold Aleta TSKBase SistemasNo ratings yet

- Hornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetDocument2 pagesHornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetInstruTech, Inc.No ratings yet

- Datasheet For Pressure Transmitter - Stg74S: (No. RP19-009)Document4 pagesDatasheet For Pressure Transmitter - Stg74S: (No. RP19-009)Dhananjay BhaldandNo ratings yet

- En-09-14-Eng Rev.6 Servo Gauge 854 AtgDocument6 pagesEn-09-14-Eng Rev.6 Servo Gauge 854 AtgAsad NaeemNo ratings yet

- Catalog 27-512 Base Station AntennasDocument99 pagesCatalog 27-512 Base Station AntennasJocelyn DervainNo ratings yet

- AQU4518R0Document2 pagesAQU4518R0term1natorNo ratings yet

- Igbt 40N60 - 600V, 40aDocument10 pagesIgbt 40N60 - 600V, 40aLuis HuanqqueNo ratings yet

- Tdf3 NewDocument2 pagesTdf3 NewSơn Lê CaoNo ratings yet

- Tp65H050G4Bs: 650V Supergan Fet in To-263 (Source Tab)Document15 pagesTp65H050G4Bs: 650V Supergan Fet in To-263 (Source Tab)RobertoCarlosGiacchettaNo ratings yet

- Datasheet Andrew Antenna 7.3m C Band ES73 1Document14 pagesDatasheet Andrew Antenna 7.3m C Band ES73 1Angel Simo Morales0% (1)

- Material List: Produced On 23/11/2021 With Xpress Selection V9.6.1 - Database DIL 16.6.4Document13 pagesMaterial List: Produced On 23/11/2021 With Xpress Selection V9.6.1 - Database DIL 16.6.4Sicologo CimeNo ratings yet

- BTA08-600BW3G, BTA08-800BW3G Triacs: Silicon Bidirectional ThyristorsDocument6 pagesBTA08-600BW3G, BTA08-800BW3G Triacs: Silicon Bidirectional ThyristorsJoseZavalaNo ratings yet

- btw69 1200Document9 pagesbtw69 1200Kumar ShresthaNo ratings yet

- Tp65H150Lsg: 650V Gan Fet PQFN Series PreliminaryDocument9 pagesTp65H150Lsg: 650V Gan Fet PQFN Series PreliminaryWepa BizNo ratings yet

- Abb MT 5000Document12 pagesAbb MT 5000FIRMANSYAHNo ratings yet

- btw69 800Document9 pagesbtw69 800YusufNo ratings yet

- Ptronxonf 2Document2 pagesPtronxonf 2Procurement PardisanNo ratings yet

- RECLOSER-FARADAY-33KV Auto Recloser BrochureDocument9 pagesRECLOSER-FARADAY-33KV Auto Recloser BrochureJoel Alevxandr OsorttoNo ratings yet

- Dendimetro Endress Hauser Ti180fen - dg57Document8 pagesDendimetro Endress Hauser Ti180fen - dg57hubkenNo ratings yet

- Surge Protector and Filter Specifications: Technical DataDocument16 pagesSurge Protector and Filter Specifications: Technical DataJuan Esteban Benjumea BenjumeaNo ratings yet

- Datasheet Gps Clock Tcg01eDocument3 pagesDatasheet Gps Clock Tcg01esbmajor1970No ratings yet

- Pin Description Features: P-Channel Enhancement Mode MOSFETDocument0 pagesPin Description Features: P-Channel Enhancement Mode MOSFETShaher Bano KazmiNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- IGBT MODULE (N Series) : N N Outline DrawingDocument4 pagesIGBT MODULE (N Series) : N N Outline DrawingGabriel EscamillaNo ratings yet

- Bluetooth Antenna Design Guide BookDocument14 pagesBluetooth Antenna Design Guide BookAnatolii PulavskyiNo ratings yet

- C406-1 Series Emergency Locator Transmitter: Description, Operation, Installation and Maintenance ManualDocument67 pagesC406-1 Series Emergency Locator Transmitter: Description, Operation, Installation and Maintenance ManualRay Adrian CalinawanNo ratings yet

- TPS3809L30DBVR RG1608N-102-W-T1 Susumu RG1608N-222-W-T1 StackpoleDocument1 pageTPS3809L30DBVR RG1608N-102-W-T1 Susumu RG1608N-222-W-T1 StackpoleClaudio EspositoNo ratings yet

- Ap One Ax: Better Coverage and Speed With Wi-Fi 6Document4 pagesAp One Ax: Better Coverage and Speed With Wi-Fi 6Ángel LopezNo ratings yet

- Research Paper Topics On Wireless NetworksDocument7 pagesResearch Paper Topics On Wireless Networksefeh4a7z100% (1)

- Lab Report: 1 Title: ObjectiveDocument7 pagesLab Report: 1 Title: ObjectiveRojot Saha100% (1)

- Kezelesi Utmutato Q3 RF 2010 AngolDocument12 pagesKezelesi Utmutato Q3 RF 2010 AngolClaudiu AdamNo ratings yet

- EP17178223NWB1Document59 pagesEP17178223NWB1pxrxspxlxsxsNo ratings yet

- Q522.2he LaDocument123 pagesQ522.2he LaMarko Vujinović100% (1)

- Notes Arduino NanoDocument10 pagesNotes Arduino NanoManfredHNo ratings yet

- Logic GatesDocument10 pagesLogic GatesVicks TechnologyNo ratings yet

- (Mtech Ece) - 2012Document70 pages(Mtech Ece) - 2012Kumar VaibhavNo ratings yet

- 1945 Installation ManualDocument48 pages1945 Installation ManualSanti AnisaNo ratings yet

- IEC - Tests Set Tough Standards For Surge ImmunityDocument2 pagesIEC - Tests Set Tough Standards For Surge ImmunityHowk RiosNo ratings yet

- Jurnal Resti: Analisis Kinerja Skema MPEG Surround Pada Pengkodean Audio 22 Kanal Menggunakan Bitrate 1000 - 2000 KbpsDocument11 pagesJurnal Resti: Analisis Kinerja Skema MPEG Surround Pada Pengkodean Audio 22 Kanal Menggunakan Bitrate 1000 - 2000 KbpsMr. JokerNo ratings yet

- Module 01 PDFDocument26 pagesModule 01 PDFabs4everonlineNo ratings yet

- Activasi Modem TC301 - Inspection Guidance (For Distributor)Document5 pagesActivasi Modem TC301 - Inspection Guidance (For Distributor)Gold d Roger twoNo ratings yet

- RMPA Using Dielectric Optimization TechniqueDocument4 pagesRMPA Using Dielectric Optimization TechniqueijsretNo ratings yet

- SI 60E 6H - DatasheetDocument1 pageSI 60E 6H - DatasheetAbhinashNo ratings yet

- (BL - EN.U4ECE22022) Sandeep-Signals and Systems AssignmentDocument27 pages(BL - EN.U4ECE22022) Sandeep-Signals and Systems AssignmentdommarajurahulvarmaNo ratings yet

- Prime Time Shortwave Broadcasts in EnglishDocument12 pagesPrime Time Shortwave Broadcasts in Englishjohn7451No ratings yet

- 0001 Drive Impulse VG+ Series-2Document129 pages0001 Drive Impulse VG+ Series-2Jb100% (1)

- Ateme Kyrion Dr5000 Datasheet August 2017Document77 pagesAteme Kyrion Dr5000 Datasheet August 2017charrazcaNo ratings yet

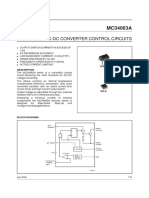

- DC-DC Converter Control Circuits: Description DIP-8Document15 pagesDC-DC Converter Control Circuits: Description DIP-8Полецкий ОлегNo ratings yet

- Chapter 7 ProblemsDocument17 pagesChapter 7 Problemsaaron lester yabut0% (1)

- Revised 4 C Btech 1 3 5 7 8 Jan 2023 19123Document7 pagesRevised 4 C Btech 1 3 5 7 8 Jan 2023 19123Raman dhimanNo ratings yet

- Earthig - Data Equipment - Texas InstrumentsDocument9 pagesEarthig - Data Equipment - Texas InstrumentsSandeep PartiNo ratings yet

- VNS3NV04DP e - VNS3NV04DPTR eDocument22 pagesVNS3NV04DP e - VNS3NV04DPTR eAlexander RodriguezNo ratings yet

Radar Tank Gauge For Asphalt and Bitumen Tankers Gla 300 Asphalt

Radar Tank Gauge For Asphalt and Bitumen Tankers Gla 300 Asphalt

Uploaded by

Boris BirinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Radar Tank Gauge For Asphalt and Bitumen Tankers Gla 300 Asphalt

Radar Tank Gauge For Asphalt and Bitumen Tankers Gla 300 Asphalt

Uploaded by

Boris BirinCopyright:

Available Formats

GLA-300/H

RADAR TANK GAUGE FOR CHEMICAL, ASPHALT AND BITUMEN TANKERS

The KONGSBERG GLA-300/H Radar Tank Gauge (RTG) is part of the GL-300 Tank Monitoring System.

Together with the GC-300 Cargo Temperature Unit (CTU) and the GLK-300 Signal Processing Unit (SPU),

the RTG introduces modern and flexible arrangements for simpler installation. The radar technology pro-

vides accurate measurement regardless of the atmospheric conditions inside the tank. The tank pressure

transmitter is fully integrated by means of both mechanics, electronics and cabling.

Principle of operation Tank pressure transmitter

The RTG employs the Frequency Modulated Continuous Wave The GT450 tank pressure transmitter is fully integrated in the

(FMCW) principle with dual sweep technology to eliminate Dop- RTG. The transmitter comes ready installed from the factory.

pler-effect caused by cargo movement. The distance (i.e. ullage)

The GT450 pressure transmitter is built around a dry, robust

is derived from the time delay of the reflected signal. The elec-

ceramic measurement capsule with internal capacitive sensing

tronic unit in the RTG includes a patented signal detection meth-

element and with a ratiometric output.

od that ensures optimum performance.

The pressure transmitter is connected to the GLK-300 SPU by a

A frequency sweeping microwave signal is emitted by the RTG, HART bus link (1-pair cable).

and by aid of the horn antenna directed vertically down the tank

either directly or by an angular adapter. The high frequency Tank installation

combined with the antenna design gives a very narrow beam

width of ±4 °. The RTG adapts to a gauge socket with a minimum inner diam-

eter of 200 mm (larger sockets can be used if straight type). The

The GLA-300/H is designed with a PTFE lense isolating the ra- gauge socket shall be welded to the top of the tank, preferably as

dar electronics from the tanks atmosphere and provide a clean close to the center of gravity of the tank as possible.

surface toward the tank contents. The clean surface ensures

easy cleaning of radar, which is regarded critical in the transport In high temperature applications, using a specially designed

of hazardous chemicals. angular gauge socket, the radar tank gauge avoids direct heat

radiation from the cargo. This reduces the exposure of the high

The radar are connected to a dedicated GLK-300 SPU by a RS- temperature and increases the lifetime of the electroncs inside

485 communication link (2-pair cable). the GLA-300/H housing.

The RTG housing includes a cable gland for cable connection

to the GC-300 Cargo Temperature Unit (1-pair cable).

FEATURES ORDER CODE

• Radar RMS accuracy 2 mm

• Measuring range 0 to 50 m

• Half power beam width1 8 ° (±4 °)

• Operating temperature -45 to +85 °C

• Ingress protection IP 66/67

• Intrinsically safe Ex ia IIC T4 Ga

• Stainless steel AISI 316 L

• Integrated tank pressure transmitter

1

For details about free space requirements, ref. Installation Manual.

TECHNICAL SPECIFICATIONS

Radar Tank Gauge

Measuring range: 0 to 50 meter

RMS accuracy*: 2 mm

Frequency: K-band (24 GHz)

Beam width: ±4°

Material: AISI 316L and PTFE

Tank Pressure Transmitter

Measuring range: 0.8 to 1.4 bar

(optional 0.8 to 1.8 bar)

Accuracy: ±1.0 % of FRO** (+20 °C to +85 °C)

±2.5 % of FRO** (-45 °C to +20 °C)

Material: AISI 316 and Titanium Figure 1: Dimensional drawing GLA-300/H

Common specification RTG unit housing

Cable specification: 3 x twisted pair common screen

Operating temperature: -45 ˚C to +85 ˚C

Protection grade: IP66/67

Weight: 17 kg

Inspection hatch

Ex-classification: II 1 G Ex ia IIC T4 Ga

Ex-certification: Sira 14ATEX2056X

IECEx SIR 14.0025X

Gauge socket

Environmental standards: IACS E10 (yard supply)

CISPR 22

Safety data

Max. input voltage: Ui = 14,3 VDC Figure 2: GLA-300/H installed on a Ø200 mm straight

Max. input power: Pi = 2,1 W socket. Inspection hatch mounted on the gauge socket.

Max. input current: Ii = 560 mA

Max. internal capacitance: Ci = 347 nF

Inspection hatch

Max. internal inductance: Li = negligible RTG unit housing

Type approvals: ABS, BV, CCS, DNV-GL, KRS,

LRS, NK, Rina

P-GLA300H/CE Rev. E

* RMS sensor accuracy at controlled environment

**FRO = Full Range Output Gauge socket

(yard supply)

Figure 3: GLA-300/H installed on a Ø200 mm angular

Specifications subject to change without any further notice.

socket. Inspection hatch mounted on the gauge socket.

KONGSBERG MARITIME

Switchboard: +47 815 73 700

Customer support: +47 815 35 355

E-mail sales: km.sales@km.kongsberg.com

E-mail support: km.support@kongsberg.com km.kongsberg.com

You might also like

- HS6620D Data Sheet V3.0Document29 pagesHS6620D Data Sheet V3.0Homo Cyberneticus67% (3)

- ANT AQU4518R12 1831 DatasheetDocument3 pagesANT AQU4518R12 1831 DatasheetMuhammad Jamil AwanNo ratings yet

- Radar Tank Gauge For Gas Carriers GLA-310 - 5 PDFDocument2 pagesRadar Tank Gauge For Gas Carriers GLA-310 - 5 PDFEjaz Ahmed RanaNo ratings yet

- gt403 Ce2Document4 pagesgt403 Ce2SodaDrinkNo ratings yet

- Pressure Transmitter: Principle of OperationDocument4 pagesPressure Transmitter: Principle of OperationAranNo ratings yet

- Pressure Transmitter Gt405Document4 pagesPressure Transmitter Gt405ALEXIS RODRIGUEZNo ratings yet

- Alat Ukur LPGDocument4 pagesAlat Ukur LPGMj MargarethNo ratings yet

- 117position Monitor PDFDocument2 pages117position Monitor PDFJacob KalloorNo ratings yet

- MeasurIT KTek AT200 Level Transmitter 0910Document4 pagesMeasurIT KTek AT200 Level Transmitter 0910cwiejkowskaNo ratings yet

- TI266ten 0409Document12 pagesTI266ten 0409Keren ArteagaNo ratings yet

- Trend Master Galvanic IsolatorDocument6 pagesTrend Master Galvanic Isolatorrohitraj10No ratings yet

- Ex Single Data Sheet Wall Mounting Socket 63 A 8579-31-407 201390Document5 pagesEx Single Data Sheet Wall Mounting Socket 63 A 8579-31-407 201390Arthur BastosNo ratings yet

- 90 1199 10.4 (GT3000 Specifications)Document2 pages90 1199 10.4 (GT3000 Specifications)tipcigromeroNo ratings yet

- 9884 - Duct Temperature Sensor FK-TP - 200 - enDocument4 pages9884 - Duct Temperature Sensor FK-TP - 200 - enMinh nhut LưuNo ratings yet

- Specs SSGC-FP-PT-12537 Transformer RectifierDocument3 pagesSpecs SSGC-FP-PT-12537 Transformer RectifierIrfan AhmedNo ratings yet

- Pune Techtrol FGTDocument2 pagesPune Techtrol FGTBenjamin StricklandNo ratings yet

- Pressure Control BrochureDocument12 pagesPressure Control Brochurebkpaul3107No ratings yet

- 852-318 Data Sheet LoresDocument4 pages852-318 Data Sheet LoresDaniel SubelzaNo ratings yet

- GS 01f06a00-01e - 013Document36 pagesGS 01f06a00-01e - 013Gilang RomadhonNo ratings yet

- En 09 15 Eng Rev.5 Servo Gauge 854 XTGDocument6 pagesEn 09 15 Eng Rev.5 Servo Gauge 854 XTGJoaquin LunaNo ratings yet

- Meggitt Ipc704Document15 pagesMeggitt Ipc704Abdul Salam SagirNo ratings yet

- Data Sheet For Pressure Transmitter: Units:-Flow: Liquid-T/hr Gas-MMSCMD Steam - KG/HR Pressure - KG/CMDocument19 pagesData Sheet For Pressure Transmitter: Units:-Flow: Liquid-T/hr Gas-MMSCMD Steam - KG/HR Pressure - KG/CMrahul.adityaNo ratings yet

- Electrochemical Toxic Gas Detector GT3000 Series Includes Transmitter (GTX) and Sensor Module (GTS)Document2 pagesElectrochemical Toxic Gas Detector GT3000 Series Includes Transmitter (GTX) and Sensor Module (GTS)Vivekanandan FriendlieyNo ratings yet

- Ds Sf6 GDT Gd10cl en Us 27789Document4 pagesDs Sf6 GDT Gd10cl en Us 27789behnamatgNo ratings yet

- ACS713-Datasheet - Current Sensor ICDocument14 pagesACS713-Datasheet - Current Sensor ICphase90No ratings yet

- Product Specifications Product Specifications: Accuret Accuret - A20 A20Document2 pagesProduct Specifications Product Specifications: Accuret Accuret - A20 A20inikeapriliaputriNo ratings yet

- External Mounted Magnetostrictive Level TransmitterDocument6 pagesExternal Mounted Magnetostrictive Level Transmitterjuan vazquezNo ratings yet

- Catalogo Smart Servo 854 Ferrum Energy PDFDocument6 pagesCatalogo Smart Servo 854 Ferrum Energy PDFManuel De MatosNo ratings yet

- Petrotek LPG Gas Detection FlyerDocument3 pagesPetrotek LPG Gas Detection FlyerHuraira AliNo ratings yet

- WECO 1502 Connection DrawingDocument2 pagesWECO 1502 Connection Drawinghai minhNo ratings yet

- Aks 3000Document8 pagesAks 3000gatoluisNo ratings yet

- Smart Subcombiner US CEDocument2 pagesSmart Subcombiner US CEtalasubhanojiraogmaiNo ratings yet

- Rs-fs-9001 GT Flame SensorDocument18 pagesRs-fs-9001 GT Flame Sensorzakarianoui35No ratings yet

- Flexret: A Flexible, Integrated Solution For Adjusting The Electrical Downtilt of Kathrein Flexret AntennasDocument11 pagesFlexret: A Flexible, Integrated Solution For Adjusting The Electrical Downtilt of Kathrein Flexret AntennasиванNo ratings yet

- Flexret: A Flexible, Integrated Solution For Adjusting The Electrical Downtilt of Kathrein Flexret AntennasDocument10 pagesFlexret: A Flexible, Integrated Solution For Adjusting The Electrical Downtilt of Kathrein Flexret AntennasAdrian BrumeaNo ratings yet

- Crouse Hinds MTL tp48 Catalog PageDocument3 pagesCrouse Hinds MTL tp48 Catalog Pageinstrument.assist.slpNo ratings yet

- CA 134 Piezoelectric Accelerometer: Iecex Nepsi Tiis KGSDocument5 pagesCA 134 Piezoelectric Accelerometer: Iecex Nepsi Tiis KGSEliyanto E BudiartoNo ratings yet

- Medidor Caudal Kobold Aleta TSKDocument6 pagesMedidor Caudal Kobold Aleta TSKBase SistemasNo ratings yet

- Hornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetDocument2 pagesHornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetInstruTech, Inc.No ratings yet

- Datasheet For Pressure Transmitter - Stg74S: (No. RP19-009)Document4 pagesDatasheet For Pressure Transmitter - Stg74S: (No. RP19-009)Dhananjay BhaldandNo ratings yet

- En-09-14-Eng Rev.6 Servo Gauge 854 AtgDocument6 pagesEn-09-14-Eng Rev.6 Servo Gauge 854 AtgAsad NaeemNo ratings yet

- Catalog 27-512 Base Station AntennasDocument99 pagesCatalog 27-512 Base Station AntennasJocelyn DervainNo ratings yet

- AQU4518R0Document2 pagesAQU4518R0term1natorNo ratings yet

- Igbt 40N60 - 600V, 40aDocument10 pagesIgbt 40N60 - 600V, 40aLuis HuanqqueNo ratings yet

- Tdf3 NewDocument2 pagesTdf3 NewSơn Lê CaoNo ratings yet

- Tp65H050G4Bs: 650V Supergan Fet in To-263 (Source Tab)Document15 pagesTp65H050G4Bs: 650V Supergan Fet in To-263 (Source Tab)RobertoCarlosGiacchettaNo ratings yet

- Datasheet Andrew Antenna 7.3m C Band ES73 1Document14 pagesDatasheet Andrew Antenna 7.3m C Band ES73 1Angel Simo Morales0% (1)

- Material List: Produced On 23/11/2021 With Xpress Selection V9.6.1 - Database DIL 16.6.4Document13 pagesMaterial List: Produced On 23/11/2021 With Xpress Selection V9.6.1 - Database DIL 16.6.4Sicologo CimeNo ratings yet

- BTA08-600BW3G, BTA08-800BW3G Triacs: Silicon Bidirectional ThyristorsDocument6 pagesBTA08-600BW3G, BTA08-800BW3G Triacs: Silicon Bidirectional ThyristorsJoseZavalaNo ratings yet

- btw69 1200Document9 pagesbtw69 1200Kumar ShresthaNo ratings yet

- Tp65H150Lsg: 650V Gan Fet PQFN Series PreliminaryDocument9 pagesTp65H150Lsg: 650V Gan Fet PQFN Series PreliminaryWepa BizNo ratings yet

- Abb MT 5000Document12 pagesAbb MT 5000FIRMANSYAHNo ratings yet

- btw69 800Document9 pagesbtw69 800YusufNo ratings yet

- Ptronxonf 2Document2 pagesPtronxonf 2Procurement PardisanNo ratings yet

- RECLOSER-FARADAY-33KV Auto Recloser BrochureDocument9 pagesRECLOSER-FARADAY-33KV Auto Recloser BrochureJoel Alevxandr OsorttoNo ratings yet

- Dendimetro Endress Hauser Ti180fen - dg57Document8 pagesDendimetro Endress Hauser Ti180fen - dg57hubkenNo ratings yet

- Surge Protector and Filter Specifications: Technical DataDocument16 pagesSurge Protector and Filter Specifications: Technical DataJuan Esteban Benjumea BenjumeaNo ratings yet

- Datasheet Gps Clock Tcg01eDocument3 pagesDatasheet Gps Clock Tcg01esbmajor1970No ratings yet

- Pin Description Features: P-Channel Enhancement Mode MOSFETDocument0 pagesPin Description Features: P-Channel Enhancement Mode MOSFETShaher Bano KazmiNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- IGBT MODULE (N Series) : N N Outline DrawingDocument4 pagesIGBT MODULE (N Series) : N N Outline DrawingGabriel EscamillaNo ratings yet

- Bluetooth Antenna Design Guide BookDocument14 pagesBluetooth Antenna Design Guide BookAnatolii PulavskyiNo ratings yet

- C406-1 Series Emergency Locator Transmitter: Description, Operation, Installation and Maintenance ManualDocument67 pagesC406-1 Series Emergency Locator Transmitter: Description, Operation, Installation and Maintenance ManualRay Adrian CalinawanNo ratings yet

- TPS3809L30DBVR RG1608N-102-W-T1 Susumu RG1608N-222-W-T1 StackpoleDocument1 pageTPS3809L30DBVR RG1608N-102-W-T1 Susumu RG1608N-222-W-T1 StackpoleClaudio EspositoNo ratings yet

- Ap One Ax: Better Coverage and Speed With Wi-Fi 6Document4 pagesAp One Ax: Better Coverage and Speed With Wi-Fi 6Ángel LopezNo ratings yet

- Research Paper Topics On Wireless NetworksDocument7 pagesResearch Paper Topics On Wireless Networksefeh4a7z100% (1)

- Lab Report: 1 Title: ObjectiveDocument7 pagesLab Report: 1 Title: ObjectiveRojot Saha100% (1)

- Kezelesi Utmutato Q3 RF 2010 AngolDocument12 pagesKezelesi Utmutato Q3 RF 2010 AngolClaudiu AdamNo ratings yet

- EP17178223NWB1Document59 pagesEP17178223NWB1pxrxspxlxsxsNo ratings yet

- Q522.2he LaDocument123 pagesQ522.2he LaMarko Vujinović100% (1)

- Notes Arduino NanoDocument10 pagesNotes Arduino NanoManfredHNo ratings yet

- Logic GatesDocument10 pagesLogic GatesVicks TechnologyNo ratings yet

- (Mtech Ece) - 2012Document70 pages(Mtech Ece) - 2012Kumar VaibhavNo ratings yet

- 1945 Installation ManualDocument48 pages1945 Installation ManualSanti AnisaNo ratings yet

- IEC - Tests Set Tough Standards For Surge ImmunityDocument2 pagesIEC - Tests Set Tough Standards For Surge ImmunityHowk RiosNo ratings yet

- Jurnal Resti: Analisis Kinerja Skema MPEG Surround Pada Pengkodean Audio 22 Kanal Menggunakan Bitrate 1000 - 2000 KbpsDocument11 pagesJurnal Resti: Analisis Kinerja Skema MPEG Surround Pada Pengkodean Audio 22 Kanal Menggunakan Bitrate 1000 - 2000 KbpsMr. JokerNo ratings yet

- Module 01 PDFDocument26 pagesModule 01 PDFabs4everonlineNo ratings yet

- Activasi Modem TC301 - Inspection Guidance (For Distributor)Document5 pagesActivasi Modem TC301 - Inspection Guidance (For Distributor)Gold d Roger twoNo ratings yet

- RMPA Using Dielectric Optimization TechniqueDocument4 pagesRMPA Using Dielectric Optimization TechniqueijsretNo ratings yet

- SI 60E 6H - DatasheetDocument1 pageSI 60E 6H - DatasheetAbhinashNo ratings yet

- (BL - EN.U4ECE22022) Sandeep-Signals and Systems AssignmentDocument27 pages(BL - EN.U4ECE22022) Sandeep-Signals and Systems AssignmentdommarajurahulvarmaNo ratings yet

- Prime Time Shortwave Broadcasts in EnglishDocument12 pagesPrime Time Shortwave Broadcasts in Englishjohn7451No ratings yet

- 0001 Drive Impulse VG+ Series-2Document129 pages0001 Drive Impulse VG+ Series-2Jb100% (1)

- Ateme Kyrion Dr5000 Datasheet August 2017Document77 pagesAteme Kyrion Dr5000 Datasheet August 2017charrazcaNo ratings yet

- DC-DC Converter Control Circuits: Description DIP-8Document15 pagesDC-DC Converter Control Circuits: Description DIP-8Полецкий ОлегNo ratings yet

- Chapter 7 ProblemsDocument17 pagesChapter 7 Problemsaaron lester yabut0% (1)

- Revised 4 C Btech 1 3 5 7 8 Jan 2023 19123Document7 pagesRevised 4 C Btech 1 3 5 7 8 Jan 2023 19123Raman dhimanNo ratings yet

- Earthig - Data Equipment - Texas InstrumentsDocument9 pagesEarthig - Data Equipment - Texas InstrumentsSandeep PartiNo ratings yet

- VNS3NV04DP e - VNS3NV04DPTR eDocument22 pagesVNS3NV04DP e - VNS3NV04DPTR eAlexander RodriguezNo ratings yet