Professional Documents

Culture Documents

SS Inspection by UT-Mike - Wechsler - MISTRAS - CINDE - Canada - 2019

SS Inspection by UT-Mike - Wechsler - MISTRAS - CINDE - Canada - 2019

Uploaded by

sheldonCopyright:

Available Formats

You might also like

- Ph3 Programming KG UpdatedDocument52 pagesPh3 Programming KG UpdatedMohamed Elhabib CheqriNo ratings yet

- Wire Rope Test CertificateDocument2 pagesWire Rope Test CertificateDustin Xender60% (5)

- Effect of Notch Shape and Dimension in Ultrasonic Testing of Seamless Steel Tubes1Document5 pagesEffect of Notch Shape and Dimension in Ultrasonic Testing of Seamless Steel Tubes1Anonymous 4APvkrc6No ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pressure VesselsDocument9 pagesPressure VesselsSajal KulshresthaNo ratings yet

- Quotation For Repair Work at Ramp G PDFDocument2 pagesQuotation For Repair Work at Ramp G PDFSURIA ROAD TRADE SDN BHDNo ratings yet

- Manual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukDocument16 pagesManual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukdarouichNo ratings yet

- Profile RadiogarphyDocument24 pagesProfile RadiogarphySantosh Kumar100% (1)

- Advanced NDT 2Document56 pagesAdvanced NDT 2Anonymous ffje1rpa83% (6)

- Presented by Marie-Pierre Despaux SonatestDocument31 pagesPresented by Marie-Pierre Despaux SonatestPetrNo ratings yet

- Improving Small Diameter Pipe Weld Inspections With Phased Arrays NDT For ManagersDocument34 pagesImproving Small Diameter Pipe Weld Inspections With Phased Arrays NDT For Managerssriraj.kadabaNo ratings yet

- On Qualification of TOFD Technique For Austenitic Stainless Steel Welds InspectionDocument8 pagesOn Qualification of TOFD Technique For Austenitic Stainless Steel Welds InspectionprabuNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- h07rn F Bs en 50525 2 21 Flexible Rubber CableDocument6 pagesh07rn F Bs en 50525 2 21 Flexible Rubber CableManny DummyNo ratings yet

- Hil Renukoot Ut 2022-2023Document249 pagesHil Renukoot Ut 2022-2023duttcon engineeringNo ratings yet

- Digital Profile Radiography - Practical Uses and LimitationsDocument24 pagesDigital Profile Radiography - Practical Uses and LimitationsMohan RajNo ratings yet

- Neugroschl 2017Document31 pagesNeugroschl 2017Ujjwal SinghNo ratings yet

- Ultrasonic Examination Report: Discharge DamperDocument1 pageUltrasonic Examination Report: Discharge DamperSaurav RoyNo ratings yet

- Successful Ultrasonic Inspection of Austenitic WeldsDocument6 pagesSuccessful Ultrasonic Inspection of Austenitic WeldsAnonymous 5qPKvmuTWCNo ratings yet

- Technician: TNT Focus: Pressure Vessel CodeDocument6 pagesTechnician: TNT Focus: Pressure Vessel CodePDDELUCANo ratings yet

- Ultrasonic Testing 2Document19 pagesUltrasonic Testing 2Vijayakumar ChandranNo ratings yet

- Modelled and Visualised Sound-Fields of 1.5D Phased-Array ProbesDocument23 pagesModelled and Visualised Sound-Fields of 1.5D Phased-Array ProbesRicardoSchayerSabinoNo ratings yet

- Ultrasonic Crack PDFDocument11 pagesUltrasonic Crack PDFHector BeaujonNo ratings yet

- As-Nzs Cispr32 - BT820Document27 pagesAs-Nzs Cispr32 - BT820wulanluvspinkNo ratings yet

- Test Report: Work Order No. JSA-19-05651Document3 pagesTest Report: Work Order No. JSA-19-05651SantoshNo ratings yet

- Ultrasonic Phased Array Technique For Austenitic Weld Inspection PDFDocument4 pagesUltrasonic Phased Array Technique For Austenitic Weld Inspection PDFRAFAEL ANDRADENo ratings yet

- 3-Eddy CuRRENT WORKSHOP 2016Document51 pages3-Eddy CuRRENT WORKSHOP 2016Asif Hameed100% (4)

- Surface Properties and Gloss of CAD/CAM Composites After Toothbrush AbrasionDocument7 pagesSurface Properties and Gloss of CAD/CAM Composites After Toothbrush Abrasionshargunan11No ratings yet

- Comparison Between - 6 DB and - 12 DB Amplitude Drop Techniques For Length SizingDocument8 pagesComparison Between - 6 DB and - 12 DB Amplitude Drop Techniques For Length SizingJuliooooNo ratings yet

- Conventional Radiography: A Few Challenging Applications: Founder'S DayDocument9 pagesConventional Radiography: A Few Challenging Applications: Founder'S DayWan Muhammad GhazaliNo ratings yet

- Page: 1 of 1: M/S.Rolon SealsDocument1 pagePage: 1 of 1: M/S.Rolon SealsRahul SamalaNo ratings yet

- Surface Mounting TechnlogyDocument161 pagesSurface Mounting Technlogyhariharasankar100% (2)

- Guidance 1GDocument5 pagesGuidance 1GWahyu HaryadiNo ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Cs-Rites-Door Link Mechanism (Single Link)Document3 pagesCs-Rites-Door Link Mechanism (Single Link)sohelNo ratings yet

- Application of ACFM-1Document5 pagesApplication of ACFM-1NILESHNo ratings yet

- Irjet V4i877Document6 pagesIrjet V4i877Roselle LasagasNo ratings yet

- Radiography of Thin Section Welds - Part 1 Practical Approach - TWIDocument11 pagesRadiography of Thin Section Welds - Part 1 Practical Approach - TWIKolusu SivakumarNo ratings yet

- 005 Journal TMT 2015Document5 pages005 Journal TMT 2015Sotu KdaptNo ratings yet

- Abs 0678Document11 pagesAbs 0678Jorge OrtegaNo ratings yet

- August 2020 SynergistDocument44 pagesAugust 2020 Synergistwernecksantos2952100% (1)

- Ultrasonic Phased Array Approach To Detection and Measurement of Corrosion at Pipe SupportsDocument10 pagesUltrasonic Phased Array Approach To Detection and Measurement of Corrosion at Pipe SupportsPetrNo ratings yet

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- Product Type Report: S.C. Halley Cables, S.R.LDocument4 pagesProduct Type Report: S.C. Halley Cables, S.R.LCristian FieraruNo ratings yet

- B574 Plfy402430879val PDFDocument6 pagesB574 Plfy402430879val PDFCarlosIkedaNo ratings yet

- Patch Cord Data SheetDocument4 pagesPatch Cord Data Sheetgeorgeta.dumitrache50No ratings yet

- Paut Paper PDFDocument7 pagesPaut Paper PDFAyesha GeNo ratings yet

- Ursi2018 Laila Final 3Document15 pagesUrsi2018 Laila Final 3lailamarzallNo ratings yet

- Optimization and Characterization of Ni-B Coating of Using RSM MethodDocument10 pagesOptimization and Characterization of Ni-B Coating of Using RSM MethodIJRASETPublicationsNo ratings yet

- Accurate Defect Sizing Using Phased Array and Signal ProcessingDocument10 pagesAccurate Defect Sizing Using Phased Array and Signal ProcessingMalolan VasudevanNo ratings yet

- 920 - Sand, Cr. Metal (Sie - Flaki) KarDocument93 pages920 - Sand, Cr. Metal (Sie - Flaki) Karrahul pardeshiNo ratings yet

- EAST+NDT+CHINA Calibration BlocksDocument6 pagesEAST+NDT+CHINA Calibration BlocksmgmqroNo ratings yet

- ThaiHoa Cleanroom Nitrile Gloves Brochure PDFDocument6 pagesThaiHoa Cleanroom Nitrile Gloves Brochure PDFHoàng Anh NgôNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Ttransition JointsDocument15 pagesTtransition JointsAdil HasanovNo ratings yet

- API Standards For Pipe Inspections PDFDocument38 pagesAPI Standards For Pipe Inspections PDFajayghosh3140100% (8)

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Proceedings of the 41st International Conference on Advanced Ceramics and CompositesFrom EverandProceedings of the 41st International Conference on Advanced Ceramics and CompositesWaltraud M. KrivenNo ratings yet

- Millimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyFrom EverandMillimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Thermographic Inspection of Insulation Installations in Envelope Cavities of Frame BuildingsDocument7 pagesThermographic Inspection of Insulation Installations in Envelope Cavities of Frame BuildingssheldonNo ratings yet

- Evaluation of Moisture Corrosion Resistance of Automotive Gear LubricantsDocument27 pagesEvaluation of Moisture Corrosion Resistance of Automotive Gear LubricantssheldonNo ratings yet

- BS en Iec 60068-3-3-2019Document54 pagesBS en Iec 60068-3-3-2019sheldon100% (1)

- BS en 583-6-2008Document26 pagesBS en 583-6-2008sheldonNo ratings yet

- KW 18KWH Canada Interim Letters - KWUSDocument2 pagesKW 18KWH Canada Interim Letters - KWUSMecano PadNo ratings yet

- Summary Sheet: Client Consultant Contractor Project: Package Ii: Document Name: Document No. 2 REVDocument42 pagesSummary Sheet: Client Consultant Contractor Project: Package Ii: Document Name: Document No. 2 REVPramod B.Wankhade100% (1)

- S.No Description Qty Unit Assumed by HWPL: Scope of Work - Supply PSSDocument14 pagesS.No Description Qty Unit Assumed by HWPL: Scope of Work - Supply PSSASR REDDYNo ratings yet

- Envision Math 3th GR Topic 5Document28 pagesEnvision Math 3th GR Topic 5Anna K. RiveraNo ratings yet

- Arrow Metal Brochure - Perforated MetalDocument12 pagesArrow Metal Brochure - Perforated MetalSterlingNo ratings yet

- Instruments Obs & Gynea PDFDocument19 pagesInstruments Obs & Gynea PDFVibes Usmlee100% (1)

- Definition of The CaribbeanDocument2 pagesDefinition of The CaribbeanBrianna AllenNo ratings yet

- Sample SpecsDocument137 pagesSample Specsprince francisNo ratings yet

- Guia de Aprendizaje-QuantifiersDocument8 pagesGuia de Aprendizaje-Quantifiersangelita berdugoNo ratings yet

- Turbine Cat SolarDocument2 pagesTurbine Cat SolarAbid Lakhani100% (1)

- Top-Down Triage Method For SimulationDocument3 pagesTop-Down Triage Method For SimulationrajuhaveriNo ratings yet

- Monterey Garden Insect Spray: Directions For UseDocument6 pagesMonterey Garden Insect Spray: Directions For Usejoe leeNo ratings yet

- Nage Waza (Throwing) : HIP THROWS (Koshi Waza)Document5 pagesNage Waza (Throwing) : HIP THROWS (Koshi Waza)Stuart WalshNo ratings yet

- JSW New Final ProjetDocument48 pagesJSW New Final ProjetRajender SinghNo ratings yet

- 168 ProjectDocument2 pages168 Projectfrederique.retailNo ratings yet

- Allowable Stress Design of Concrete Masonry PilastersDocument7 pagesAllowable Stress Design of Concrete Masonry PilastersReinaldo Andrei SalazarNo ratings yet

- Surveying 1Document2 pagesSurveying 1haes.sisonNo ratings yet

- Hows The Soil? Maniyar Village Has Red Soil and Black Soil For Its Villages. (Document4 pagesHows The Soil? Maniyar Village Has Red Soil and Black Soil For Its Villages. (Chinmay KaranNo ratings yet

- 978 1 5275 0785 2 SampleDocument30 pages978 1 5275 0785 2 SampleJacob AlonzoNo ratings yet

- Narrative 236k TreesDocument1 pageNarrative 236k TreesDinah r. De guzmanNo ratings yet

- The Elephant and FriendsDocument2 pagesThe Elephant and FriendsENGLISHCLASS SMKN1SRKNo ratings yet

- Why Use Preheat and Post Weld Heat Treatments Brochure PDFDocument2 pagesWhy Use Preheat and Post Weld Heat Treatments Brochure PDFErick HoganNo ratings yet

- Wipro Ge Healthcare Private Limited PDFDocument13 pagesWipro Ge Healthcare Private Limited PDFMandal TusharNo ratings yet

- Vitamin E, Wonder Worker of The 70'S - Adams, Ruth, 1911 - Murray, FrankDocument132 pagesVitamin E, Wonder Worker of The 70'S - Adams, Ruth, 1911 - Murray, FrankAnonymous gwFqQcnaXNo ratings yet

- Zero Gravity Chairs - ErgoQuest Zero Gravity Chairs and WorkstationsDocument6 pagesZero Gravity Chairs - ErgoQuest Zero Gravity Chairs and Workstationsnitouch3564No ratings yet

- Things That Make You Go HMMDocument2 pagesThings That Make You Go HMMmckee_jemNo ratings yet

SS Inspection by UT-Mike - Wechsler - MISTRAS - CINDE - Canada - 2019

SS Inspection by UT-Mike - Wechsler - MISTRAS - CINDE - Canada - 2019

Uploaded by

sheldonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SS Inspection by UT-Mike - Wechsler - MISTRAS - CINDE - Canada - 2019

SS Inspection by UT-Mike - Wechsler - MISTRAS - CINDE - Canada - 2019

Uploaded by

sheldonCopyright:

Available Formats

Mike Wechsler

Technical Director, MISTRAS Group, Inc.

ULTRASONIC INSPECTION

UT has become a very effective inspection tool for a variety of things including:

Thickness Points (TMLs) for establishing corrosion rates.

Code Inspection for New Weld Integrity (In-Lieu of Radiography)

In-Service Crack Sizing and Detection

Non-Intrusive Alternatives

Supporting RBI Needs or Fitness-for-Service (FFS) evaluations

Bottom Line:

Ultrasonics are an integral part of our programs. These inspections are being used to

allow for longer run times, extended life, and fewer internal inspections.

NDT in Canada 2019 | June 18-20 | Edmonton, AB

ULTRASONIC TECHNIQUES

Available Tools in the box vary by application:

Standard 0 degree

Shear Wave

High Angle Longitudinal Waves

Time of Flight Diffraction

Phased Array

Sectorial

Linear

Dual Matrix

TFM

Full Matrix Capture

Adaptive Focusing

All great advancements and tools to help us verify integrity, reduce risk,

and increase profitability.

NDT in Canada 2019 | June 18-20 | Edmonton, AB

ULTRASONIC VARIABLES

Variables that can affect the effectiveness of an inspection include:

Velocity

Material Type

Age

Thickness

Heat Treatment

Temperature

Acoustic Impedance

Wave Modes

Plate Differences

Grain Structure

Some of these are controllable and verifiable, but which ones?

And is this being done on all inspections?

NDT in Canada 2019 | June 18-20 | Edmonton, AB

CODE

Some variables that the code addresses are:

Calibration Block Material

Acoustically similar

Same product form, and/or equivalent P Number

Heat Treatment

Minimum tempering by material spec for type, grade, and

PWHT if there are welds involved

Surface Finish

Shall be representative

Austenitic Materials

Those that exhibit coarse grained or directionally-orientated

grain structure that can cause reflection and refraction at grain

boundaries as well as velocity changes within the grains……

NDT in Canada 2019 | June 18-20 | Edmonton, AB

STAINLESS STEEL APPLICATION

Customer request inspection in-service cracking of typical 304SS Material.

Typical approach would be:

Calibration Block Material

Acoustically similar

Range of Diameters

Calibration Flaw Sizes

EDM Notches, and SDH’s

Reference Blocks

304 SS Naviships/IIW

Probe/Frequency Selections

Procedural Development/Scan Plans

IF coarse grained – weld mockups according to T150

NDT in Canada 2019 | June 18-20 | Edmonton, AB

STAINLESS STEEL APPLICATION

And as a last resort…….

Request “cut out sample” of problem areas

NDT in Canada 2019 | June 18-20 | Edmonton, AB

VERIFICATION

Sample piece was provided with damage.

Inspection began with the normal process

Longitudinal (0 degree) Wave

Lower Frequency,

Larger Aperture (diameter)

Sampling of similar thickness/material Actual piece revealed this:

calibration block revealed:

NDT in Canada 2019 | June 18-20 | Edmonton, AB

VERIFICATION

Sample piece was provided with damage.

Inspection began with the normal process.

Shear Wave

Lower Frequency,

Larger Aperture (diameter)

Quick Screening with Shear wave results revealed the following:

Reflection from Corner Reflection from Corner of Sample

of Calibration block

NDT in Canada 2019 | June 18-20 | Edmonton, AB

VERIFICATION

Taking one step further, SDHs were introduced into the sample piece.

Quick Screening of the holes with Shearwave revealed the following:

Reflection from SDH Reflection from SDH Reflection from SDH

Calibration block Base material (Sample) In weld (Sample)

NDT in Canada 2019 | June 18-20 | Edmonton, AB

GRAIN SIZE DISCREPANCY

Typical 304SS Grain Size Typical 304SS Grain Size

Microstructural Analysis revealed that grain sizes were off the microscopic

grain chart in ASTM E112.

It is believed that this was due to extreme temperatures (2000 -2200 F°).

NDT in Canada 2019 | June 18-20 | Edmonton, AB

GRAIN SIZE VISIBLE

Grain Size is actually visible to the NAKED EYE!

NDT in Canada 2019 | June 18-20 | Edmonton, AB

SELECTION

Due to previous steps, it was clear that a different selection of probes was necessary.

Shear waves were not offering a good solution to the problem.

Next step was to evaluate DMA (Dual Matrix Array) probes with varying

frequencies/sizes to compare effectiveness and come up with an inspection plan.

These probes operate by producing longitudinal waves, but in a T/R Mode.

Benefits of these types probes are typically:

Ability to penetrate coarse grain structures

Higher signal to noise ratio

Near Surface Resolution

Potential Drawbacks:

1st Leg information only

Mode converted signals can be difficult to interpret

Oversizing/Distortion due to low frequency and large aperture size.

NDT in Canada 2019 | June 18-20 | Edmonton, AB

DIFFERENCE BETWEEN

DMA’s versus Shear wave on large coarse grain materials

NDT in Canada 2019 | June 18-20 | Edmonton, AB

SENSITIVITY COMPARISON IMAGES

To better understand probe performance on different sections

of the block, we gathered data and comparison of each, some

from corners, SDHs, and OD notches.

NDT in Canada 2019 | June 18-20 | Edmonton, AB

SENSITIVITY COMPARISON IMAGES (CORNER)

DMA Position 10 DMA Position 8 DMA Position 11

NDT in Canada 2019 | June 18-20 | Edmonton, AB

SENSITIVITY COMPARISON IMAGES (SDH)

Shear Ref Position 2

DMA Ref Position 2

NDT in Canada 2019 | June 18-20 | Edmonton, AB

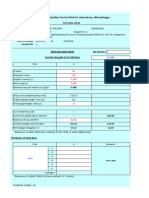

RESULTS

Pulse Echo 0 Degree

Reference sample=2" T 304 SS, Shear wave DMA-1 DMA-2

PA base material

Field Sample=1.5” T 304 SS

1.5Mhz x 0.75" x 4Mhz x 0.625" x 2Mhz x 0.75" x

2.25Mhz x 1/2" Dia 2Mhz x 1.0" Dia

.050" 0.238" 0.80"

Commercially produced

Reference Weld Sample, 4% 0 0 0 0 0

Notches/ 0.125"SDH

Sample Side A SDH (BM) -5.4 db -5.9 db -7.4 db -4.3 db -15 db

Sample Side B SDH (BM) -23 db -13.3 db -16.2 db -20.8 db -20 db

Weld SDH -21 db -9.7 db -12 db -18.7 db -

Sample Corner A (BM) -11 db -3.8 db -6.4 db -4.8 db -

Sample Corner B (BM) -39 db -14.5 db -17.7 db -24.8 db -

NDT in Canada 2019 | June 18-20 | Edmonton, AB

POTENTIAL OUTCOME

We need to open up our thought process and ask ourselves:

Have similar inspections been conducted, in which nothing was found?

How do we ensure that nothing means nothing?

Have all the proper processes been followed to ensure we didn’t mistake

a good inspection for a “bad” one?

NDT in Canada 2019 | June 18-20 | Edmonton, AB

TAKEAWAYS

Inspection results might not reflect reality

Expectations on time to complete inspections need to be understood better

Focus on the result, rather then a result

Don’t forget that results are feeding remaining life calculations or inspection intervals.

There are ways to validate materials to raise level of awareness including:

Attenuation

Graininess

Beam Redirection

Velocities

NDT in Canada 2019 | June 18-20 | Edmonton, AB

Questions or Comments?

NDT in Canada 2019 | June 18-20 | Edmonton, AB

You might also like

- Ph3 Programming KG UpdatedDocument52 pagesPh3 Programming KG UpdatedMohamed Elhabib CheqriNo ratings yet

- Wire Rope Test CertificateDocument2 pagesWire Rope Test CertificateDustin Xender60% (5)

- Effect of Notch Shape and Dimension in Ultrasonic Testing of Seamless Steel Tubes1Document5 pagesEffect of Notch Shape and Dimension in Ultrasonic Testing of Seamless Steel Tubes1Anonymous 4APvkrc6No ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pressure VesselsDocument9 pagesPressure VesselsSajal KulshresthaNo ratings yet

- Quotation For Repair Work at Ramp G PDFDocument2 pagesQuotation For Repair Work at Ramp G PDFSURIA ROAD TRADE SDN BHDNo ratings yet

- Manual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukDocument16 pagesManual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukdarouichNo ratings yet

- Profile RadiogarphyDocument24 pagesProfile RadiogarphySantosh Kumar100% (1)

- Advanced NDT 2Document56 pagesAdvanced NDT 2Anonymous ffje1rpa83% (6)

- Presented by Marie-Pierre Despaux SonatestDocument31 pagesPresented by Marie-Pierre Despaux SonatestPetrNo ratings yet

- Improving Small Diameter Pipe Weld Inspections With Phased Arrays NDT For ManagersDocument34 pagesImproving Small Diameter Pipe Weld Inspections With Phased Arrays NDT For Managerssriraj.kadabaNo ratings yet

- On Qualification of TOFD Technique For Austenitic Stainless Steel Welds InspectionDocument8 pagesOn Qualification of TOFD Technique For Austenitic Stainless Steel Welds InspectionprabuNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- h07rn F Bs en 50525 2 21 Flexible Rubber CableDocument6 pagesh07rn F Bs en 50525 2 21 Flexible Rubber CableManny DummyNo ratings yet

- Hil Renukoot Ut 2022-2023Document249 pagesHil Renukoot Ut 2022-2023duttcon engineeringNo ratings yet

- Digital Profile Radiography - Practical Uses and LimitationsDocument24 pagesDigital Profile Radiography - Practical Uses and LimitationsMohan RajNo ratings yet

- Neugroschl 2017Document31 pagesNeugroschl 2017Ujjwal SinghNo ratings yet

- Ultrasonic Examination Report: Discharge DamperDocument1 pageUltrasonic Examination Report: Discharge DamperSaurav RoyNo ratings yet

- Successful Ultrasonic Inspection of Austenitic WeldsDocument6 pagesSuccessful Ultrasonic Inspection of Austenitic WeldsAnonymous 5qPKvmuTWCNo ratings yet

- Technician: TNT Focus: Pressure Vessel CodeDocument6 pagesTechnician: TNT Focus: Pressure Vessel CodePDDELUCANo ratings yet

- Ultrasonic Testing 2Document19 pagesUltrasonic Testing 2Vijayakumar ChandranNo ratings yet

- Modelled and Visualised Sound-Fields of 1.5D Phased-Array ProbesDocument23 pagesModelled and Visualised Sound-Fields of 1.5D Phased-Array ProbesRicardoSchayerSabinoNo ratings yet

- Ultrasonic Crack PDFDocument11 pagesUltrasonic Crack PDFHector BeaujonNo ratings yet

- As-Nzs Cispr32 - BT820Document27 pagesAs-Nzs Cispr32 - BT820wulanluvspinkNo ratings yet

- Test Report: Work Order No. JSA-19-05651Document3 pagesTest Report: Work Order No. JSA-19-05651SantoshNo ratings yet

- Ultrasonic Phased Array Technique For Austenitic Weld Inspection PDFDocument4 pagesUltrasonic Phased Array Technique For Austenitic Weld Inspection PDFRAFAEL ANDRADENo ratings yet

- 3-Eddy CuRRENT WORKSHOP 2016Document51 pages3-Eddy CuRRENT WORKSHOP 2016Asif Hameed100% (4)

- Surface Properties and Gloss of CAD/CAM Composites After Toothbrush AbrasionDocument7 pagesSurface Properties and Gloss of CAD/CAM Composites After Toothbrush Abrasionshargunan11No ratings yet

- Comparison Between - 6 DB and - 12 DB Amplitude Drop Techniques For Length SizingDocument8 pagesComparison Between - 6 DB and - 12 DB Amplitude Drop Techniques For Length SizingJuliooooNo ratings yet

- Conventional Radiography: A Few Challenging Applications: Founder'S DayDocument9 pagesConventional Radiography: A Few Challenging Applications: Founder'S DayWan Muhammad GhazaliNo ratings yet

- Page: 1 of 1: M/S.Rolon SealsDocument1 pagePage: 1 of 1: M/S.Rolon SealsRahul SamalaNo ratings yet

- Surface Mounting TechnlogyDocument161 pagesSurface Mounting Technlogyhariharasankar100% (2)

- Guidance 1GDocument5 pagesGuidance 1GWahyu HaryadiNo ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Cs-Rites-Door Link Mechanism (Single Link)Document3 pagesCs-Rites-Door Link Mechanism (Single Link)sohelNo ratings yet

- Application of ACFM-1Document5 pagesApplication of ACFM-1NILESHNo ratings yet

- Irjet V4i877Document6 pagesIrjet V4i877Roselle LasagasNo ratings yet

- Radiography of Thin Section Welds - Part 1 Practical Approach - TWIDocument11 pagesRadiography of Thin Section Welds - Part 1 Practical Approach - TWIKolusu SivakumarNo ratings yet

- 005 Journal TMT 2015Document5 pages005 Journal TMT 2015Sotu KdaptNo ratings yet

- Abs 0678Document11 pagesAbs 0678Jorge OrtegaNo ratings yet

- August 2020 SynergistDocument44 pagesAugust 2020 Synergistwernecksantos2952100% (1)

- Ultrasonic Phased Array Approach To Detection and Measurement of Corrosion at Pipe SupportsDocument10 pagesUltrasonic Phased Array Approach To Detection and Measurement of Corrosion at Pipe SupportsPetrNo ratings yet

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- Product Type Report: S.C. Halley Cables, S.R.LDocument4 pagesProduct Type Report: S.C. Halley Cables, S.R.LCristian FieraruNo ratings yet

- B574 Plfy402430879val PDFDocument6 pagesB574 Plfy402430879val PDFCarlosIkedaNo ratings yet

- Patch Cord Data SheetDocument4 pagesPatch Cord Data Sheetgeorgeta.dumitrache50No ratings yet

- Paut Paper PDFDocument7 pagesPaut Paper PDFAyesha GeNo ratings yet

- Ursi2018 Laila Final 3Document15 pagesUrsi2018 Laila Final 3lailamarzallNo ratings yet

- Optimization and Characterization of Ni-B Coating of Using RSM MethodDocument10 pagesOptimization and Characterization of Ni-B Coating of Using RSM MethodIJRASETPublicationsNo ratings yet

- Accurate Defect Sizing Using Phased Array and Signal ProcessingDocument10 pagesAccurate Defect Sizing Using Phased Array and Signal ProcessingMalolan VasudevanNo ratings yet

- 920 - Sand, Cr. Metal (Sie - Flaki) KarDocument93 pages920 - Sand, Cr. Metal (Sie - Flaki) Karrahul pardeshiNo ratings yet

- EAST+NDT+CHINA Calibration BlocksDocument6 pagesEAST+NDT+CHINA Calibration BlocksmgmqroNo ratings yet

- ThaiHoa Cleanroom Nitrile Gloves Brochure PDFDocument6 pagesThaiHoa Cleanroom Nitrile Gloves Brochure PDFHoàng Anh NgôNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Ttransition JointsDocument15 pagesTtransition JointsAdil HasanovNo ratings yet

- API Standards For Pipe Inspections PDFDocument38 pagesAPI Standards For Pipe Inspections PDFajayghosh3140100% (8)

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Proceedings of the 41st International Conference on Advanced Ceramics and CompositesFrom EverandProceedings of the 41st International Conference on Advanced Ceramics and CompositesWaltraud M. KrivenNo ratings yet

- Millimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyFrom EverandMillimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Thermographic Inspection of Insulation Installations in Envelope Cavities of Frame BuildingsDocument7 pagesThermographic Inspection of Insulation Installations in Envelope Cavities of Frame BuildingssheldonNo ratings yet

- Evaluation of Moisture Corrosion Resistance of Automotive Gear LubricantsDocument27 pagesEvaluation of Moisture Corrosion Resistance of Automotive Gear LubricantssheldonNo ratings yet

- BS en Iec 60068-3-3-2019Document54 pagesBS en Iec 60068-3-3-2019sheldon100% (1)

- BS en 583-6-2008Document26 pagesBS en 583-6-2008sheldonNo ratings yet

- KW 18KWH Canada Interim Letters - KWUSDocument2 pagesKW 18KWH Canada Interim Letters - KWUSMecano PadNo ratings yet

- Summary Sheet: Client Consultant Contractor Project: Package Ii: Document Name: Document No. 2 REVDocument42 pagesSummary Sheet: Client Consultant Contractor Project: Package Ii: Document Name: Document No. 2 REVPramod B.Wankhade100% (1)

- S.No Description Qty Unit Assumed by HWPL: Scope of Work - Supply PSSDocument14 pagesS.No Description Qty Unit Assumed by HWPL: Scope of Work - Supply PSSASR REDDYNo ratings yet

- Envision Math 3th GR Topic 5Document28 pagesEnvision Math 3th GR Topic 5Anna K. RiveraNo ratings yet

- Arrow Metal Brochure - Perforated MetalDocument12 pagesArrow Metal Brochure - Perforated MetalSterlingNo ratings yet

- Instruments Obs & Gynea PDFDocument19 pagesInstruments Obs & Gynea PDFVibes Usmlee100% (1)

- Definition of The CaribbeanDocument2 pagesDefinition of The CaribbeanBrianna AllenNo ratings yet

- Sample SpecsDocument137 pagesSample Specsprince francisNo ratings yet

- Guia de Aprendizaje-QuantifiersDocument8 pagesGuia de Aprendizaje-Quantifiersangelita berdugoNo ratings yet

- Turbine Cat SolarDocument2 pagesTurbine Cat SolarAbid Lakhani100% (1)

- Top-Down Triage Method For SimulationDocument3 pagesTop-Down Triage Method For SimulationrajuhaveriNo ratings yet

- Monterey Garden Insect Spray: Directions For UseDocument6 pagesMonterey Garden Insect Spray: Directions For Usejoe leeNo ratings yet

- Nage Waza (Throwing) : HIP THROWS (Koshi Waza)Document5 pagesNage Waza (Throwing) : HIP THROWS (Koshi Waza)Stuart WalshNo ratings yet

- JSW New Final ProjetDocument48 pagesJSW New Final ProjetRajender SinghNo ratings yet

- 168 ProjectDocument2 pages168 Projectfrederique.retailNo ratings yet

- Allowable Stress Design of Concrete Masonry PilastersDocument7 pagesAllowable Stress Design of Concrete Masonry PilastersReinaldo Andrei SalazarNo ratings yet

- Surveying 1Document2 pagesSurveying 1haes.sisonNo ratings yet

- Hows The Soil? Maniyar Village Has Red Soil and Black Soil For Its Villages. (Document4 pagesHows The Soil? Maniyar Village Has Red Soil and Black Soil For Its Villages. (Chinmay KaranNo ratings yet

- 978 1 5275 0785 2 SampleDocument30 pages978 1 5275 0785 2 SampleJacob AlonzoNo ratings yet

- Narrative 236k TreesDocument1 pageNarrative 236k TreesDinah r. De guzmanNo ratings yet

- The Elephant and FriendsDocument2 pagesThe Elephant and FriendsENGLISHCLASS SMKN1SRKNo ratings yet

- Why Use Preheat and Post Weld Heat Treatments Brochure PDFDocument2 pagesWhy Use Preheat and Post Weld Heat Treatments Brochure PDFErick HoganNo ratings yet

- Wipro Ge Healthcare Private Limited PDFDocument13 pagesWipro Ge Healthcare Private Limited PDFMandal TusharNo ratings yet

- Vitamin E, Wonder Worker of The 70'S - Adams, Ruth, 1911 - Murray, FrankDocument132 pagesVitamin E, Wonder Worker of The 70'S - Adams, Ruth, 1911 - Murray, FrankAnonymous gwFqQcnaXNo ratings yet

- Zero Gravity Chairs - ErgoQuest Zero Gravity Chairs and WorkstationsDocument6 pagesZero Gravity Chairs - ErgoQuest Zero Gravity Chairs and Workstationsnitouch3564No ratings yet

- Things That Make You Go HMMDocument2 pagesThings That Make You Go HMMmckee_jemNo ratings yet