Professional Documents

Culture Documents

Untitled

Untitled

Uploaded by

Glenn John Gasapo0 ratings0% found this document useful (0 votes)

10 views20 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

10 views20 pagesUntitled

Untitled

Uploaded by

Glenn John GasapoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 20

6.12 ARC FLASH HAZARDS

Arcing faults receive an increasing amount of attention as a particularly

damaging and potentially dangerous type of fault. The arcing fault is a flash-

over of low electric current that flows through the air (high impedance). It

releases a great deal of energy in the form of heat and pressure. The tempera-

ture can rise to 19,420°C (35,000°F [89]), and the intense heat from the are

can cause a sudden exp: of the air resulting in a blast with very strong

air pressure that can vaporize the materials and damage the equipment. The

arcing fault can persist longer and propagate. For example, a 3- to 4-in. arc in

an LV system can become “stabilized” and persist for an extended period of

time [90], and in enclosures the arc may propagate to the supply side of all

devices in the same enclosure (Fig. 6.29) [91]. On the other hand, the enclosure

magnifies blast that is forced to open its side, and the energy produced by the

arcis transmitted toward the worker causing burn injuries or death. Some burn.

injuries that may happen due to electric arcs are shown in Figure 6.30 [92].

‘The arc flash hazard is defined as “a dangerous condition associated with

possible release of energy caused by an electric arc” [93]. It is measured in

terms of arc flash incident energy (AFIE), which is used to determine the

appropriate level of personal protection equipment (PPE) and in terms of arc

flash protection boundary.

| Supply

J Are propagates to here

‘Are originates here

Figure 6.29 Are propagation [91].

oe (

@) ® °

Figure 6.30. Burn injuries due to electric ares {92}. (a) Leg burn; (b) hand burn;

(©) shoulder burn: (2) foot burn.

@)

6.12.1 Causes of Arcing Faults

Arcing faults are commonly caused by the following:

+ foreign tools dropped into equipment that may cause short-circuit,

produce sparks, and initiate arcs;

+ entry of foreign bodies (¢.g., rodent, snake, squirrel);

+ misalignment of moving contacts and corrosion of equipment parts. This,

weakens the contact between conductor terminals and increases the

contact resistance. So, heat is generated on the contacts and sparks may

be produced leading to arcing faults with nearby exposed conductors;

+ dirt contamination or dielectric breakdown. Dirt on insulating surfaces

can provide a path for current, allowing it to flashover creating arc dis-

charge across the surface. The flashover can also be created by condensa-

tion of vapor and water dripping on insulating surfaces;

+ careless cover or device removal that gives an opportunity for accidental

touching with live exposed parts producing arc faults;

+ overvoltages across narrow gaps If the air gap between conductors of

phases or phase conductor and earth is narrow enough, the electric field

intensity through the air gap may ionize the air during overvoltages pro-

ducing are faults; and

+ improper maintenance procedures.

6.12.2 Arc Flash Consequences

Nonhuman Consequences:

+ Process downtime due to accidents.

+ Loss of product and lost revenue.

+ Equipment damage.

+ Occupational Safety and Health Adi

fines.

tration (OSHA) citation and

Human Consequences:

+ Treatment of victims is very expensive. Victims may not retain their life

quality.

* Loss of skilled manpower and loss of morale.

+ Higher insurance costs.

6.12.3 Limits of Approach

For the safety of qualified persons who are working on energized equipment,

the flash and shock boundaries are broken down as indicated in Figure 6.31

according to the definition stated in Reference 93.

7 [E] net eee ney pe nt dts te

. ‘exposed live parts (arc source) within which the potcatial incident heat

\ Unt ‘energy from an arcing fault on the surface of skin is 12cal/em? and

‘ NS causing a curable second-degree burn (Fig, 6.32). Appropriate flash-flame.

la protection equipment must be utilized for persons entering the flash pro-

/ = \ fection region.

4 RES] + Limited Approach Boundary: Wis an approach limit at a distance from

lo sient the exposed live parts (are source) within which a shock hazard exists.

| ‘The person entering the limited approach boundary must be qualified to.

TH BS perform the job.

~~ own + Restricted Approach Boundary: It is an approach limit at a distance from

a the exposed live parts (arc source) withia which the risk of shock is

Some inereased, The person entering this boundary must use the appropriate

\ PPE and have an approved work plan from the authorized management.

Xs « Prohibied Approwsh Boundary: Kisan approach limit ata distance from

- ay the exposed live parts (are source) within which the work is considered

eT ‘the same as making contact with the live part. The person entering this

oo region must be well trained to work on live equipment.

Figure 6.31 Are lash approseh limit regions.

Figure 6.32 Flash protection boundary [91] (a person ata distance D from are source

Dp. isthe limit distance of the boundary)

eee itacrd

erry

eae

oes

Figure 6.3% Incident energy delivered by an are [91].

6.12.4 PPE Hazard Risk Categorles

Workers potentially exposed to arc flash hazard must be adequately protected.

‘The severity of this hazard is measured by the amount of energy that an arc

delivers to an exposed worker (Fig. 6.33). This “incident energy” is commonly

measured by calorie per square centimeter or joule per square centimeter and

its calculation provides a basis for selecting proper PPE (e.g., flash suits, arc

hoods, and flame-resistant [FR] clothing).

Incident energy and flash protection boundary vary based on different

parameters such as system voltage, arcing fault current, working distance from

arc source, and fault duration. The hazard level depends on many system vari-

ables including equipment type, prospective bolted fault currents, and charac-

teristics of upstream protective devices. Therefore, to properly select the levels

Of PPE to protect the workers, the potential arc flash hazard at a given system

location should be analyzed.

Both too little and too much PPE are undesirable as too little PPE is insuf-

ficient to protect the workers and too much PPE may hinder movement and

increase the risk level as well as increase the heat stress. The required PPE is

determined by comparing the calculated incident energy to the ratings for

specific combinations of PPE that are classified into five categories defined

by National Fire Protection Association (NFPA) 70E 2009 as an example in

Table 6.5.

For most protective clothing classes, other requirements for PPE are needed.

such as hard hat, safety glasses, hearing protection, leather gloves, work shoes,

and face shields. The arc rating of each is determined according to NFPA 70E-

As seen in Table 6.5, there is no PPE class of rating larger than 40cal/em*,

NFPA 70E does not intend for work to be performed at locations with such

high AFIE. Above these levels, arc blast may be as significant a concern as the

are flash where burn injuries are not the only concern but also hearing damage

and internal injuries (collapsed lung, concussion).

TABLE 6.5 Protective Clothing Characteristics (NEPA 70E 2009)

Hazard/Risk Minimum Are Rating

Category

a

of PPE (calcm’)

NIA

4

8

25

40

‘Typical Protective Clothing Description

Untreated cotton, wool, rayon or silk, or

blends of these materials with a fabric

weight of at least 4.50z/yd?

Arc rated FR shirt and FR pants or coverall

Cotton underwear plus FR shirt and FR pants

Arc rated FR shirt and pants or coverall, and

are flash suit selected so that the system are

rating meets the required minimum

Arc rated FR shirt and pants or coverall, and

are flash suit selected so that the system are

rating meets the required minimum

Note: Meltable fabrics and other similar synthetics are never permitted.

NIA = null

6.12.5 Calculation Methods

Several methods for calculating the arc flash hazard have been developed.

Three of these methods are briefly described below.

6.12.5.1 IEEE Standard 1584-2002 IEEE Standard 1584 [94] presents

the most comprehensive set of empirical equations for calculating incident

energy levels and flash protective boundaries. These equations are based on

the available bolted fault current, voltage, clearing time, equipment type,

earthing, and working distance. They cover systems at voltage levels ranging

from 208V to 15kV and for available bolted fault currents ranging from 700A

to 106A, to sufficiently cover the majority of LV and MV installations.

‘This method can also determine the impact of certain current limiting LV

fuses as well as certain types of LV breakers. The equations are rather complex

if calculations are to be performed by hand, though the equations are easily

implemented in a spreadsheet or in other computer software. The calculations

are summarized in four steps as below:

1. Arcing Current Estimation: For LV applications <1kV,

logl, = K +0.662 log Iv +0.0966V + 0.000526G + 0.5588V (log lis)

— 0,00304G(l0g Ie)

For applications >1kV,

log I, = 0.00402 +0.983log ler.

Converting from log,

1,= 10°",

where

J, = the arcing fault current (kA),

K =~0.153 for open configurations

= -0.097 for box configurations,

(6.14)

(6.15)

(6.16)

Jy; = rms of the bolted fault current for three-phase symmetrical faults

(KA),

fhe system voltage (kV),

fhe gap between conductors (mm) (Table 6.6).

v

2. Normalized Incident Energy Estimation: The normalized incident energy,

based on 0.2-s arc duration and 610-mm distance from the arc, is given as

log E, = K, + Kz + 1.081log /, +0.0011G (6.17)

and

E, = 10%", (6.18)

where

E, = incident energy normalized for time and distance (J/em’),

K, =-0.792 for open configurations

0.555 for box configurations,

Ky =0 for unearthed and high-resistance earthed systems

-0.113 for earthed systems, and

G = gap between conductors (mm) (Table 6.6).

3. Incident Energy Estimation: The incident energy at a normal surface at

a given distance and arcing time is calculated in terms of the normalized

incident energy by the relation

E=4184CEy (SIF . (6.19)

0.2, D

\cident energy (J/cm?),

calculation factor = 1.0 for voltage > 1kV

.5 for voltage < 1kV,

t =arcing time (s),

D = working distance from are (mm), and

x = distance exponent as given in Table 6.6.

4. Flash Protection Boundary: The flash protection boundary is the dis-

tance from an arcing fault at which the incident energy is equal to 1.2cal/

cm’, and a person without PPE may get a curable second-degree burn:

Dy =610 x|41sscie, Xe (6.20)

where

Dz = distance of the boundary from the arcing point (mm),

Cy = calculation factor = 1.0 for voltage > 1kV

= 15 for voltage < 1kV,

E, = incident energy normalized,

Ey = incident energy at the boundary distance (J/cm?); it can be set

at 5.0.J/em? (1.2cal/em’) for bare ski

t =arcing time (s),

Jyq = bolted fault current (kA), and

x =the distance exponent from Table 6.6.

6.12.5.2 NFPA 70E-2004 Equations for calculating arc current, incident

energy, and flash protection boundary are given below [93]:

1. Arc Current

For are in box:

).85 Iyp — 0.004 13, for V<1kV

928 le for 1kVSkV,

where

1, = are current (kA),

Io, = bolted fault current (kA), and

V =system voltage.

2. Incident Energy

For arc in open air, V < 0.6kV, 16-SOKA short-circuit current:

E=S271D [0.001615 —0.0076 lyr +0.8938]. (6.22)

For arc in box, V<0.6KV, 16-SOKA short-circuit current:

E=1038.7D*1[0,0093 fs — 0.3453). +5.9675]. (6.23)

For arc in open air, V > 0.6kV:

E=T3D?Viut, (6.24)

incident energy (cal/em’),

bolted fault current (kA), and

D = working distance from arc (inches).

3. Flash Protection Boundary

When the arc current is 70.7% of the bolted fault current, the theoretical

maximum arc power (MW) is half of the bolted three-phase fault MVA

[96]. This is the base on which the equation of flash boundary calculation

is deduced:

Dy = 2.65% 1,732 XV X Ine Xt (6.25)

where

Ds = distance of the boundary from the arcing point (inches),

rated system voltage line to line (kV),

bolted fault current (kA), and

arcing time (s).

jon, NFPA 70E-2004 contains a method for selecting PPE that

requires little or no calculation. Table 130.7(C) (9) (a) assigns “Hazard/Risk

Category” values for typical work tasks that might be performed on common

types of equipment, such as the insertion of starter buckets in a 600-V class

‘motor control center (MCC). The Hazard/Risk Category values correspond to

the five categories of PPE (Table 6.5) so that a worker may determine the

level of clothing that is required by simply finding the appropriate work task

in the table [97].

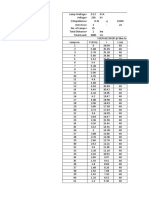

TABLE 6.6 Factors for Equipment and Voltage Classes [95]

System Voltage ‘Typical Gap between

(kV) Equipment Type Conductors (mm) —_Distance x Factor

0.208-1 Open air 10-40, 2.000

Switchgear 32, 1473

MCC and panels 25 ‘L641

Cable 13 2.000

>l tos Open air 102 2.000

Switchgear 13-102 0.973

Cable 13 2.000

>5 to 15 Open air 13-153 2.000

Switchgear 153 0.973

Cable B 2.000

MCC= motor control center.

6.12.5.3 Computer Software It is more powerful to use software that

provides an extensive array of capabilities to minimize the level of efforts

required to obtain accurate arc flash analysis in compliance with both IEEE

1584 Std. and NFPA 70E. The software should have the following features that

are essential for arc flash assessment:

+ calculation of short-circuit current at each point in the system as well as

the contributing currents from system branches:

+ protection coordination where the time-grading setting of different pro-

tective devices should ensure proper selectivity. Results of arc flash analy-

sis help to justify the setting of protective devices for both selectivity and

are flash protection;

+ capability of arc flash analysis for different system configuration or system

with changes in its parameters;

+ capability of graphical display for the system single-line diagram associ-

ated with results of arc flash analysis, short-circuit currents, and protection

units setting, and so on, at the different selected points in the system;

+ capability of arc flash analysis at different operating conditions; and

+ printing out the warning labels and required documents in compliance

with OSHA and NFPA standards.

‘Therefore, the procedure of arc flash calculation can be summarized by the

following steps:

+ collection of system and installation data,

+ determination of all system modes of operation,

+ calculation of bolted fault currents,

+ estimation of arc fault currents,

+ defining protective device characteristics and arc duration,

+ documentation of system voltages and equipment classes,

+ selection of working distances,

+ estimation of incident energy of all equipment, and

+ determination of flash protection boundary for all equipment.

6.12.7 Mitigation of Arc Flash Hazards

Different methods for arc flash hazard reduction such as reducing the arcing

current, increasing the working distance, reducing the fault clearing time, and

using arc flash detecting relays can be applied.

6.12.71 Arcing Current Reduction Use of current-limiting devices can

help limit the current available for a fault, which in turn reduces the corre-

sponding incident energy for clearing times of short duration (one to three

cycles). The fault current must be in the current limiting range for these

devices. Test data are required to provide the coefficients of IEEE 1584 simpli-

fied equations that can be used for determining the incident energy. Fault

currents below the current limiting range are treated in the same manner as

noncurrent limiting devices.

6.12.7.2. Increasing the Working Distance As in Equation 6.22, the inci-

dent energy is inversely proportional to approximately the square of the

working distance (in open air). Therefore, increasing the working distance will

highly reduce the incident energy. Working distance can be increased by using

remote racking devices, remote operating devices, and extension tools.

6.12.7.3_ Reducing the Clearing Time Reducing arc flash hazards means

reducing AFIE levels. It becomes an increasingly important consideration in

designing electric distribution systems. However, selective coordination of

overcurrent protective devices is equally important. The best solution is to

provide superior reduction of AFIE without sacrificing selectivity [98].

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FAULTDocument34 pagesFAULTGlenn John GasapoNo ratings yet

- Floor Plan:: Symbols & LegendsDocument1 pageFloor Plan:: Symbols & LegendsGlenn John GasapoNo ratings yet

- ESTECH030 Handouts 8: Prepared and Compiled By: Y.E. FernandezDocument8 pagesESTECH030 Handouts 8: Prepared and Compiled By: Y.E. FernandezGlenn John GasapoNo ratings yet

- System Single Line Diagram: Impedance Diagram - 1 Impedance Diagram - 2Document1 pageSystem Single Line Diagram: Impedance Diagram - 1 Impedance Diagram - 2Glenn John GasapoNo ratings yet

- Doe Road Light 2017 - Illumination Doe Road Light 2017 - IlluminationDocument53 pagesDoe Road Light 2017 - Illumination Doe Road Light 2017 - IlluminationGlenn John GasapoNo ratings yet

- Vs Vs Vs : Sending EndDocument3 pagesVs Vs Vs : Sending EndGlenn John GasapoNo ratings yet

- UntitledDocument21 pagesUntitledGlenn John GasapoNo ratings yet

- UntitledDocument16 pagesUntitledGlenn John GasapoNo ratings yet

- Basic Circuit Design: Presented By: Engr. Noel R. Angeles, Pee Acpe Ma EeDocument13 pagesBasic Circuit Design: Presented By: Engr. Noel R. Angeles, Pee Acpe Ma EeGlenn John GasapoNo ratings yet