Professional Documents

Culture Documents

HARC

HARC

Uploaded by

Yaqoob Ibrahim0 ratings0% found this document useful (0 votes)

117 views8 pagesThe document is a hazard analysis and risk control record for standard well test operations. It identifies several hazards associated with spotting equipment, including dropped loads, fallen objects, and swinging loads. To control these risks, measures are in place such as using certified slings and lifting points, competent personnel, banksmen to guide cranes, and keeping people clear of lifting areas. With these controls, the residual risks are rated as low likelihood and low severity.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a hazard analysis and risk control record for standard well test operations. It identifies several hazards associated with spotting equipment, including dropped loads, fallen objects, and swinging loads. To control these risks, measures are in place such as using certified slings and lifting points, competent personnel, banksmen to guide cranes, and keeping people clear of lifting areas. With these controls, the residual risks are rated as low likelihood and low severity.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

117 views8 pagesHARC

HARC

Uploaded by

Yaqoob IbrahimThe document is a hazard analysis and risk control record for standard well test operations. It identifies several hazards associated with spotting equipment, including dropped loads, fallen objects, and swinging loads. To control these risks, measures are in place such as using certified slings and lifting points, competent personnel, banksmen to guide cranes, and keeping people clear of lifting areas. With these controls, the residual risks are rated as low likelihood and low severity.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 8

HARC

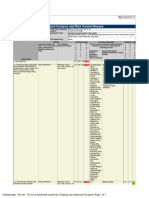

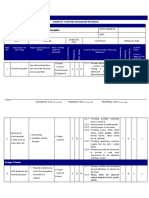

Hazard Analysis and Risk Control Record

Doc ref: 20170722190212 Task/Process Assessed: Standard Well Test Operations

Revision: 1.000 Location: RPI-TSW-TSWT Islamabad

Date: Jun 06, 2022 19:02 Assessment Team: Ullah Aman (Team Leader)

Hani Halim

Operation: TS Surface Testing (TS) Final Approved by: None)

HAZARD POTENTIAL RISK CONTROL MEASURES RESIDUAL RISK

Hazard Description and Worst Loss Category/ L S R List all Current and Planned Control L S R

Case Consequences with no Population Affected i e i Measures, taking into Account all i e i

Prevention or Mitigation Measures k v s Contributing and Escalating Factors k v s

in Place e e k e e k

l r l r

i i L Current and Current and i i L

h t e Planned Prevention Planned Mitigation h t e

o y v Measures to reduce Measures to reduce o y v

o e Likelihood Severity o e

Activity Steps d l d l

1. Spotting of equipment M (3) C (-4) H (-12) VL (1) M(-3) L (-3)

1.1. 1. Dropped load 2. Dropped/Fallen Objects (Potential Personnel-->Injury M (3) C (-4) H (-12) - Certified slings - All VL (1) M (-3) L (-3)

Swinging load 3. Falling Energy) Personnel (SLB, Client, 3rd Party) and Lifting personnel

objects Assets (Customer and SLB) Points. should

- know

Communication nearest

between crane escape

operator and route (for

Banksman. case of

- Competent falling

personnel load).

involved in lift -

(Rig crew Personnel

only). to know

- location

Compliance of nearest

with relevant first aid

authority box and

regulations nearest

- Dedicated rig phone

Banksmen to to contact

guide crane. medic

- No should

personnel that be

under load at required

any time. -

- Should

Non-essential load start

personnel kept swinging

clear of area. both

- Rig & guidelines

Client lifting to be

procedures to used to

be strictly control

adhered to. load

- Toolbox

talks prior to

lift.

- Two

guidelines to

be used for all

heavy lifts.

- Weight of

load clearly

marked.

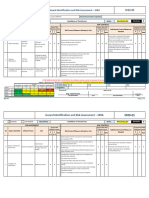

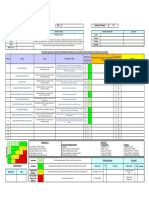

2. Rig up equipment H (4) S (-2) M (-8) L (2) L(-1) L (-2)

2.1. 1. Manual handling Dropped/Fallen Objects (Potential Personnel-->Injury H (4) S (-2) M (-8) - Use buddy - • At least all L (2) L (-1) L (-2)

of heavy equipment Energy) Personnel (SLB, Client, 3rd Party) system to upstream

Assets (Customer and SLB) share load. piping to have

Reputation (SLB)

- Use of safety/tie

crane for to down cables

avoid installed.

manual - • SIPP

lifting of (Schlumberger

heavy Injury

equipment. Prevention

program)

Compliance.

2.2. 2. Slip / trip/ pinch Noise/Nuisance Personnel-->Injury H (4) S (-2) M (-8) - Adequate lights - • Correct PPE L (2) L (-1) L (-2)

points / back strains / Personnel (SLB, Client, 3rd Party) provided for (ie steel toed

excessive noise from night time boots, gloves,

hammering

operations glasses and

- Adequate etc.)

personnel for - • SIPP

the job. (Schlumberger

- Communication Injury

between Prevention

personnel program)

involved Compliance.

- Crane utilized

when possible.

- Proper

housekeeping

at all times.

2.3. 3. Connecting Electrical Assets-->Equipment H (4) S (-2) M (-8) - All Surface - • L (2) L (-1) L (-2)

electrical equipment Assets (Customer and SLB) Well Test Correct

equipment to PPE

be properly

grounded

- Consult rig

electrician for

all electrical

connections.

- Rig

electrician to

be informed

not to power

off junction

supplying

Schlumberger

equipment.

3. Rig up surge tank to H (4) S (-2) M (-8) VL (1) S(-2) L (-2)

upright position

3.1. Load swing around Machinery/Equipment/Hand Tools Assets-->Equipment H (4) S (-2) M (-8) - Certified - • VL (1) S (-2) L (-2)

when lifting Personnel (SLB, Client, 3rd Party) slings and Maintain

Assets (Customer and SLB) lifting use of

points. tag lines

- Dedicated to control

Banksmen load from

to guide distance.

crane.

- Rig &

Client

lifting

procedures

to be

followed.

3.2. Falling objects Dropped/Fallen Objects (Potential Personnel-->Injury H (4) S (-2) M (-8) - Adequate - • All VL (1) S (-2) L (-2)

Energy) Personnel (SLB, Client, 3rd Party) cleared personnel

Reputation (SLB) space to know

land nearest

load. escape

- No route (for

personnel case of

under falling

load at load).

any time. - •

Personnel

to know

location

of nearest

first aid

box and

nearest

rig phone

to contact

medic

should

that be

required

3.3. Personnel falling Stepping, Handling, Manual Lifting Personnel-->Injury H (4) S (-2) M (-8) - Fall arrestor - • All VL (1) S (-2) L (-2)

down from surge tank and Falling (Person) Personnel (SLB, Client, 3rd Party) to be personnel

Reputation (SLB) permanently know

installed on nearest

top of surge escape

tank route (for

- Safety case of

harness to falling

be used load).

when - •

climbing on Personnel

surge tank. to know

location

of nearest

first aid

box and

nearest

rig phone

to contact

medic

should

that be

required

4. Flushing equipment VH (5) C (-4) E (-20) VL (1) C(-4) L (-4)

Pressure Testing

4.1. Pressure equipment Pressure Assets-->Equipment VH (5) C (-4) E (-20) - Equipment - • VL (1) C (-4) L (-4)

failure Personnel (SLB, Client, 3rd Party) qualified Correct

Assets (Customer and SLB) and PPE.

certified

- Permit to

work to be

raised.

- Toolbox

talk to be

held with

all relevant

personnel.

4.2. Unexpected Pressure Personnel-->Injury VH (5) C (-4) E (-20) - All equipment - • No entry VL (1) C (-4) L (-4)

pressure release, Personnel (SLB, Client, 3rd Party) and in to area

overpressure. Assets (Customer and SLB) interconnecting unless

pipework absolutely

anchored and necessary

secured. (for leak

- No equipment detection

tested on site only).

to higher than

stated working

pressure.

- Pressure

applied in

controlled

stages.

4.3. Accidental Pressure Assets-->Equipment VH (5) C (-4) E (-20) - Area to be - • No entry VL (1) C (-4) L (-4)

overpressurize Personnel (SLB, Client, 3rd Party) barriered off in to area

Assets (Customer and SLB) and warning unless

signs absolutely

positioned. necessary

- Detailed (for leak

program for detection

pressure only).

testing - • No

sequence hammering

stating method on lines

and under

pressures. pressure.

- Radio

communication

between

pumping unit

and Well Test

Supervisor

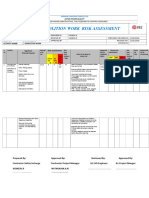

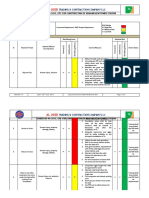

5. Flowing the well. VH (5) MC (-5) E (-25) VL (1) MC(-5) M

(-5)

5.1. Fire/Explosion Fire/Flammables Personnel-->Injury VH (5) MC (-5) E (-25) - Competent VL (1) MC (-5) M

Personnel (SLB, Client, 3rd Party) personnel (-5)

Assets (Customer and SLB) operating

with the

equipment - Barriers

- Safety erected to

meeting to minimize

be held prior access.

to open the - Emergency

well. drills and

- Well effluent exercises have

pressures already been

and performed by

temperatures all

anticipated crewmembers.

in advance. - Ensure enough

adequate fire

extinguishers

available.

- Responsibilities

of all personnel

are clearly

defined to all

crewmembers.

5.2. Over pressure Pressure Personnel-->Injury VH (5) MC (-5) E (-25) - Competent - Good VL (1) MC (-5) M

Personnel (SLB, Client, 3rd Party) personnel communication (-5)

Assets (Customer and SLB) operating - Responsibilities

with the of all personnel

equipment are clearly

- Lifting over defined to all

Well crewmembers.

Testing

equipment

is not

allowed,

even

during

build up.

5.3. Noise Noise/Nuisance Personnel-->Injury VH (5) MC (-5) E (-25) - All - Correct VL (1) MC (-5) M

Personnel (SLB, Client, 3rd Party) personnel PPE (-5)

Assets (Customer and SLB) to have

available

ear

protection.

5.4. Line Rupture Pressure Personnel-->Injury VH (5) MC (-5) E (-25) - High pressure - Correct PPE VL (1) MC (-5) M

Personnel (SLB, Client, 3rd Party) signs available - Good (-5)

Assets (Customer and SLB) and verbal communication

communication - Responsibilities

done before of all personnel

opening well. are clearly

defined to all

crewmembers.

5.5. Spill Toxic/Corrosive/Hazardous Environment-->Inappropriate Disposal VH (5) MC (-5) E (-25) - All piping - Correct PPE VL (1) MC (-5) M

Chemicals Personnel (SLB, Client, 3rd Party) to be - Good (-5)

Assets (Customer and SLB) certified: communication

pressure - Responsibilities

and of all personnel

thickness are clearly

tested defined to all

crewmembers.

5.6. Loss of instrument Pressure Other-->Process VH (5) M (-3) H (-15) - All air - Barriers VL (1) M (-3) L (-3)

air Personnel (SLB, Client, 3rd Party) connections erected

Reputation (SLB) to be to

secured by minimize

wip access.

checks.

5.7. Misalignment before Pressure Other-->Process VH (5) M (-3) H (-15) - Make - Good VL (1) M (-3) L (-3)

open the well Personnel (SLB, Client, 3rd Party) sure communication

Reputation (SLB) lines - Responsibilities

are of all personnel

properly are clearly

aligned defined to all

to open crewmembers.

the

well.

5.8. Lack of job program Information/Unsecured Data Other-->Reputation H (4) C (-4) H (-16) - Define with - Responsibilities VL (1) C (-4) L (-4)

Personnel (SLB, Client, 3rd Party) Client of all personnel

Reputation (SLB) representative are clearly

the job defined to all

program and crewmembers.

contingencies

planned

according to

well

conditions.

- Discuss

contingency

plan with crew

members

5.9. Equipment not Machinery/Equipment/Hand Tools Other-->Process H (4) C (-4) H (-16) - Barriers erected VL (1) C (-4) L (-4)

ready for well opening Personnel (SLB, Client, 3rd Party) to minimize

Reputation (SLB) access.

Emergency

- All drills and

equipment exercises have

pressure already been

tested performed by all

- ESD crew members.

Pilots - Good

ready communication.

- Make sure - Responsibilities

burner of all personnel

pilots are are clearly

“on” defined to all

- SSV crew members.

installed

and

pressure

tested

6. Separator Operations M (3) C (-4) H (-12) L (2) S(-2) L (-4)

6.1. Pressure, trapped Pressure Personnel-->Injury M (3) C (-4) H (-12) - • Check all - • L (2) S (-2) L (-4)

pressure. Personnel (SLB, Client, 3rd Party) valves, Monitor

Assets (Customer and SLB) ports and lines.

plugs prior

to

commence

the

operation.

- • Monitor

downstream

pressure

always.

6.2. Wrong level Machinery/Equipment/Hand Tools Assets-->Equipment M (3) C (-4) H (-12) - • Monitor - • Operator L (2) S (-2) L (-4)

indication. Loss of liquid Personnel (SLB, Client, 3rd Party) pressure at the

level or pressure Assets (Customer and SLB) and liquid equipment

level at all the

always. time.

- Flush sight

glass

continuously

to validate

level of

liquid.

- Safety

device for

sight glass

must be

operational.

6.3. Increase of level or Machinery/Equipment/Hand Tools Environment-->Inappropriate Disposal M (3) C (-4) H (-12) - Ensure - • Operator L (2) S (-2) L (-4)

pressure. Gas released Personnel (SLB, Client, 3rd Party) smooth at the

to atmosphere. Assets (Customer and SLB) Process operation equipment

(Customer and SLB) Reputation

of ACV. at all the

(SLB)

Manual time.

valves

opened.

6.4. Loss of air supply. Machinery/Equipment/Hand Tools Assets-->Equipment M (3) C (-4) H (-12) - Ensure that - • Operator L (2) S (-2) L (-4)

Problems with metering Personnel (SLB, Client, 3rd Party) main air at the

Assets (Customer and SLB) Process valve is equipment

(Customer and SLB) Reputation

identified & at all the

(SLB)

isolated and time.

labelled with - Flush air

"Don’t supply

operate". continously.

- Inform rig - Monitor air

personnel to pressure on

monitor & regular

keep the intervals.

compressors

run all the

time

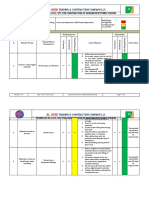

6.5. Oil carry over / gas Toxic/Corrosive/Hazardous Environment-->Inappropriate Disposal M (3) C (-4) H (-12) - Ensure - • Safety relief L (2) S (-2) L (-4)

carry under H2S gas Chemicals Personnel (SLB, Client, 3rd Party) that when valves

Assets (Customer and SLB) Process taking available on

(Customer and SLB) Reputation

samples separator for

(SLB)

personnel accidental

aware. vessel

Verify overpressure.

valves

closed

after

sampling.

- Frequent

checks to

be made

for carry

over and

carry

under.

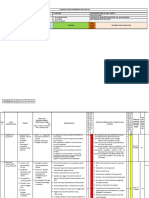

7. Surge tank M (3) M (-3) M (-9) L (2) S(-2) L (-4)

operations.

7.1. Overpressure of Pressure Assets-->Equipment M (3) M (-3) M (-9) - Make sure - Not allowed L (2) S (-2) L (-4)

surge tank Personnel (SLB, Client, 3rd Party) safety non-essential

Assets (Customer and SLB) Process is in place personnel in

(Customer and SLB) Reputation

the area.

(SLB)

- Safety relief

valves

available on

surge tank

7.2. Overflowing surge Fire/Flammables Environment-->Inappropriate Disposal M (3) M (-3) M (-9) - Flush the - Not allowed L (2) S (-2) L (-4)

tank Process (Customer and SLB) level non-essential

Reputation (SLB) indicator personnel in

continiously the area.

- Monitor

level

indicator of

surge tank

- Monitor tank

pumping

operation

7.3. Personnel falling Stepping, Handling, Manual Lifting Personnel-->Injury M (3) M (-3) M (-9) - Fall - Not allowed L (2) S (-2) L (-4)

from surge tank and Falling (Person) Personnel (SLB, Client, 3rd Party) arrestor non-essential

Reputation (SLB) installed personnel in

on top the area.

of tank. - Safety

harness and

fall arrestor

to be used

for every

climb on the

surge tank

7.4. Wrong level Machinery/Equipment/Hand Tools Other-->Process M (3) M (-3) M (-9) - Flush the - Not allowed L (2) S (-2) L (-4)

measurement on surge Process (Customer and SLB) level non-essential

tank Reputation (SLB) indicator personnel in

continiously the area.

- Monitor

level

indicator of

surge tank

8. Flaring Operations M (3) C (-4) H (-12) L (2) L(-1) L (-2)

8.1. Fire Fire/Flammables Personnel-->Injury M (3) C (-4) H (-12) - Ensure - • L (2) L (-1) L (-2)

Personnel (SLB, Client, 3rd Party) enough and Correct

Assets (Customer and SLB) adequate fire PPE to

Reputation (SLB)

extinguishers be

available. worn.

Fire monitors - • Raise

to be tested alarm

before in case

starting of fire

operations. and

shut

the

well

8.2. Spill Toxic/Corrosive/Hazardous Environment-->Inappropriate Disposal M (3) C (-4) H (-12) - Monitor - • L (2) L (-1) L (-2)

Chemicals Process (Customer and SLB) flare Emergency

Reputation (SLB) outlet. response

Monitor plan for oil

separator spill.

pressure - • Shut the

and well using

level. ESD

system or

choke

manifold.

8.3. Smoke pollution Toxic/Corrosive/Hazardous Environment-->Inappropriate Disposal M (3) C (-4) H (-12) - Monitor air - • L (2) L (-1) L (-2)

Chemicals Process (Customer and SLB) supply status Emergency

Reputation (SLB) continuously. response

plan for oil

spill.

9. Shutting in the Well VH (5) MC (-5) E (-25) VL (1) MC(-5) M

(-5)

9.1. Fire/explosion Fire/Flammables Personnel-->Injury VH (5) MC (-5) E (-25) - • - • VL (1) MC (-5) M

Personnel (SLB, Client, 3rd Party) Competent Barriers (-5)

Assets (Customer and SLB) personnel erected

Reputation (SLB)

operating to

equipment. minimize

access

- • Correct

PPE

9.2. Overpressure Machinery/Equipment/Hand Tools Assets-->Equipment VH (5) MC (-5) E (-25) - • All - • At least VL (1) MC (-5) M

Personnel (SLB, Client, 3rd Party) equipment one person (-5)

Assets (Customer and SLB) pressure to be

Reputation (SLB)

tested to permanently

MPWHP & stationed in

don’t well test

exceed area when

during there is

operation. pressure at

- • All Safety the choke

Systems manifold.

fully tested - • Barriers

and on erected to

line. minimize

- • Maximum access

shut in - • Correct

wellhead PPE

pressure

less than

working

pressure of

equipment.

9.3. Line rupture Pressure Personnel-->Injury VH (5) MC (-5) E (-25) - • All Safety - • At least VL (1) MC (-5) M

Personnel (SLB, Client, 3rd Party) Systems one person (-5)

Assets (Customer and SLB) fully tested to be

Reputation (SLB)

and on permanently

line. stationed in

- • Maximum well test

shut in area when

wellhead there is

pressure pressure at

less than the choke

working manifold.

pressure of - • Barriers

equipment. erected to

minimize

access

- • Correct

PPE

9.4. Spill Toxic/Corrosive/Hazardous Environment-->Inappropriate Disposal VH (5) MC (-5) E (-25) - • All Safety - • At least VL (1) MC (-5) M

Chemicals Personnel (SLB, Client, 3rd Party) Systems one person (-5)

Reputation (SLB) fully tested to be

and on permanently

line. stationed in

- • well test

Competent area when

personnel there is

operating pressure at

equipment. the choke

manifold

level.

- • Correct

PPE

10. Rigging down Well M (3) M (-3) M (-9) M (3) L(-1) L (-3)

Test equipment

10.1. Trips and falls Stepping, Handling, Manual Lifting Personnel-->Injury M (3) M (-3) M (-9) - • Adequate - • Correct M (3) L (-1) L (-3)

and Falling (Person) Personnel (SLB, Client, 3rd Party) personnel PPE (ie

Reputation (SLB) for steel toed

operation. boots,

- • Adequate gloves)

space to rig - • SIPP

down. Compliance

- • Adequate

time to be

allocated

for rigging

down.

- • Only

qualified rig

crew to be

involved

and back

loading

equipment

to trucks.

- • Planned

positioning

of baskets /

containers.

- • Use of

mechanical

lifting

devices

when

possible.

10.2. Hydrocarbon spill Toxic/Corrosive/Hazardous Environment-->Inappropriate Disposal M (3) M (-3) M (-9) - • - • Spill M (3) L (-1) L (-3)

Chemicals Process (Customer and SLB) Procedures cleaning

Reputation (SLB) to flush equipment

ALL available.

equipment

at end of

job prior to

rig down

(Standard

practice).

11. Flowing through L (2) M (-3) M (-6) VL (1) S(-2) L (-2)

Plant Production Line

11.1. Line Rupture due Pressure Environment-->Accidental Discharge L (2) M (-3) M (-6) - Appropriate - Contingency VL (1) S (-2) L (-2)

to over pressureAll or Spill sign boards plan

hydrocarbons venting Personnel - SLB, Client & 3rd - Authorized - ERP

through PRV line partyAssets - SLB equipment & lines

and competent - Line

causing line leakage

personnel only securing by

to operate safety belts

& weights

- Proper line

sizing for

- Good relief line

communication - Spill kit

with CCR via should be

Cisco phones available

provided by - Use of

OMV proper PPE

- Isolated vent

area

- Isolation of

source (well

head &

production

line) with SSVs

by HiLo pilots

- Isolation of the

area

- Minimum

number of

people

required

- Pressure

testing of line

and

equipment

- PRV @ DS to

relief the

pressure

- PTW

- Use of sac.

choke to

minimize the

flow rate from

single line

11.2. Line rupture due to Fire/Flammables Personnel-->Injury L (2) M (-3) M (-6) - ERP VL (1) L (-1) I (-1)

over pressure. Personnel - client, SLB & 3rd party should be

Production line (4.5Km Assets - SWT equipment & lines - Good available

lenght) hydrocarbon

communication and

venting through SWT

PRV relief line with Plant - Use discussed

of Cisco medium among the

to communicate crew

with CCR - First Aid

L-2

personnel

in each

shift

- Line

securing

- Isolation of the by safety

complete area belts &

weights

- Rig medic

and

ambulance

- Only authorized should be

personnel to at well

control and site

operate - Sac.

- Pressure testing choke to

at appropriate be used

pressure manually

- Proper sign in case of

boards to excessive

minimize flow

interaction through

- PRV @ DS of PRV relief

CMF@ line to

P=1100psi minimize

- PTW the flow

- SSV @ US rate

plant line to through

isolate the single line

production line - Spill kit

should be

available

- Use of

complete

PPE

Legend

Risk Level I - Insignificant,L - Low,M - Medium,H - High,E - Extreme

Likelihood VL - Very Low,L - Low,M - Medium,H - High,VH - Very High

Severity L - Light,S - Serious,M - Major,C - Catastrophic,MC - Multi Catastrophic

Schlumberger - Private - Not to be distributed outside the Company and authorized 3rd parties Page 8 of 8

You might also like

- 5-Pole Erection & Stringing PDFDocument2 pages5-Pole Erection & Stringing PDFAhmed Zai50% (4)

- RA Overhead CraneDocument5 pagesRA Overhead CraneRandy Adisyah100% (2)

- ABCIP Communication DriverDocument49 pagesABCIP Communication DriverGrébneva AlënaNo ratings yet

- ProTeus V User ManualDocument486 pagesProTeus V User ManualhuseyingulsanNo ratings yet

- Info Session On TAQADAM Startup AcceleratorDocument2 pagesInfo Session On TAQADAM Startup AcceleratorHamzaBaigNo ratings yet

- Egypt PEST AnalysisDocument34 pagesEgypt PEST AnalysisahmedmaeNo ratings yet

- Risk Assessment Rib Erection & FabricationDocument2 pagesRisk Assessment Rib Erection & FabricationAkash SharmaNo ratings yet

- Rusti AstralDocument2 pagesRusti AstralMungai123No ratings yet

- Top 10 Strategic Technologies For 2010Document3 pagesTop 10 Strategic Technologies For 2010nabilredascribdNo ratings yet

- Fast Maint Web ManualDocument158 pagesFast Maint Web ManualCarlosBertossiFerrariNo ratings yet

- A Fresh Approach To Gas Lift, Alan Brodie PTC VidDocument15 pagesA Fresh Approach To Gas Lift, Alan Brodie PTC VidÅhmëð ÏbråhïmNo ratings yet

- Revision: Task/Process Assessed: Date: Location: Operation: Assessment TeamDocument2 pagesRevision: Task/Process Assessed: Date: Location: Operation: Assessment TeamLenin DiazNo ratings yet

- DASABCIPDocument234 pagesDASABCIPericNo ratings yet

- Sontrach A1-BDocument48 pagesSontrach A1-BSaïd Ben AbdallahNo ratings yet

- Shiftbook and CMMS Interface User ManualDocument60 pagesShiftbook and CMMS Interface User ManualStokabaNo ratings yet

- CT2008 OilGasAutomation TechReport 2 1Document33 pagesCT2008 OilGasAutomation TechReport 2 1Vignesh RajanNo ratings yet

- Oil & Gas Industry in Africa 2Document30 pagesOil & Gas Industry in Africa 2Suleiman BaruniNo ratings yet

- Harc DST-TCP Shoot and Pull - 2015!09!21Document7 pagesHarc DST-TCP Shoot and Pull - 2015!09!21Christine RossNo ratings yet

- Software User Manual-1Document68 pagesSoftware User Manual-1AshishJaiswal100% (1)

- Global Digital Oil-Field (DOF) Market Analysis and ForecastDocument18 pagesGlobal Digital Oil-Field (DOF) Market Analysis and ForecastSanjay MatthewsNo ratings yet

- 23576israel 13191 SdgisraelDocument430 pages23576israel 13191 SdgisraelTaraNo ratings yet

- Pipesim 2006.1 Fundamentals GasliftDocument13 pagesPipesim 2006.1 Fundamentals GasliftamulyanaNo ratings yet

- Untapped Potential Digital Transformation in Mid & Downstream Industries 10th Oct 19 - FinalDocument2 pagesUntapped Potential Digital Transformation in Mid & Downstream Industries 10th Oct 19 - FinalashispNo ratings yet

- Oil and Gas Manifold - SchlumbergerDocument24 pagesOil and Gas Manifold - SchlumbergerMarwenNo ratings yet

- Digital TwinDocument3 pagesDigital TwinNavya RaturiNo ratings yet

- Market Line Industry Profile Oil Gasin PhilippiDocument42 pagesMarket Line Industry Profile Oil Gasin PhilippiTristan GarciaNo ratings yet

- Unicorn User ManualDocument584 pagesUnicorn User ManualMayuresh JagtapNo ratings yet

- Stimulsoft Reports and Dashboards User Manual - enDocument1,259 pagesStimulsoft Reports and Dashboards User Manual - enBrunoNo ratings yet

- Accenture Upstream Oil Gas Digital Energy Trends Survey Infographic FinalDocument1 pageAccenture Upstream Oil Gas Digital Energy Trends Survey Infographic Finalfightclub1234No ratings yet

- Petex DOF BrochureDocument15 pagesPetex DOF BrochureJeevan BabuNo ratings yet

- 8 Digital Knowledge Use Cases For Accelerating Oil & Gas ProfitabilityDocument16 pages8 Digital Knowledge Use Cases For Accelerating Oil & Gas ProfitabilityPrasad SreedheranNo ratings yet

- 16 Gas Lift OptimizationDocument3 pages16 Gas Lift OptimizationAhmed FahmyNo ratings yet

- Hazard Analysis and Risk Control RecordDocument7 pagesHazard Analysis and Risk Control RecordFernando OlaveoNo ratings yet

- Harc 20170301210927Document5 pagesHarc 20170301210927mmurunovNo ratings yet

- Risk Assessment SK GraphiteDocument8 pagesRisk Assessment SK GraphiteWasim KhanNo ratings yet

- Installation of TransformerDocument2 pagesInstallation of TransformerArsh NazarNo ratings yet

- Hira For DemolitionDocument3 pagesHira For DemolitionMokka SamaiyalNo ratings yet

- Risk Assessment - Rebar Shifting Using BHDocument4 pagesRisk Assessment - Rebar Shifting Using BHLeoniv Arviz LiboroNo ratings yet

- RA Cable PullingDocument3 pagesRA Cable PullingRandy Adisyah0% (1)

- 002 Excavation & TrenchingpdfDocument3 pages002 Excavation & Trenchingpdfghada gattouch100% (1)

- Long Terminvestments AuditproceduresDocument18 pagesLong Terminvestments Auditproceduressinra kongNo ratings yet

- 003 Material HandlingpdfDocument4 pages003 Material Handlingpdfghada gattouchNo ratings yet

- CE 30148331-Shallow Foundation: Performance RequirementsDocument22 pagesCE 30148331-Shallow Foundation: Performance RequirementsAhlam SarairahNo ratings yet

- Tug-Barge-Towing-Operations-Risk-Assessment SheetDocument12 pagesTug-Barge-Towing-Operations-Risk-Assessment SheetVM QHSE100% (1)

- Risk Assmeeint Cable PullingDocument1 pageRisk Assmeeint Cable PullingnoorNo ratings yet

- Task Based Risk Assessment Form: Briefing ResponsibilitiesDocument3 pagesTask Based Risk Assessment Form: Briefing ResponsibilitiesAriffZakariaNo ratings yet

- Ra-30 Asphalt WorksDocument15 pagesRa-30 Asphalt WorksAbdul LatheefNo ratings yet

- Hazard Identification Control Risk Assessment Risk Reduction Action PlanDocument4 pagesHazard Identification Control Risk Assessment Risk Reduction Action PlannoorNo ratings yet

- Hazard Identification Risk Assessment and Control: (Template)Document2 pagesHazard Identification Risk Assessment and Control: (Template)roland magoNo ratings yet

- Doc. No. Appendix D - HSE Risk Assessment 0 HDPE Pipe HydrotestDocument1 pageDoc. No. Appendix D - HSE Risk Assessment 0 HDPE Pipe Hydrotestsavanth jayaramNo ratings yet

- RA Installation of Air Distribution Ducts Rev. 00Document14 pagesRA Installation of Air Distribution Ducts Rev. 00M AzharNo ratings yet

- 103 Preparation For SeaDocument1 page103 Preparation For SeaMr-SmithNo ratings yet

- HIRAC CraneDocument2 pagesHIRAC CranetaufikNo ratings yet

- 004 Transformer InstallationDocument3 pages004 Transformer Installationghada gattouchNo ratings yet

- Concrete Repair RISK ASSESSMENTDocument5 pagesConcrete Repair RISK ASSESSMENTVimal ViswanathNo ratings yet

- HIRARC IBS Components Installation Rev 0Document21 pagesHIRARC IBS Components Installation Rev 0Suraindran ManoharanNo ratings yet

- 104 Preparation For Arrival at PortDocument1 page104 Preparation For Arrival at PortMr-SmithNo ratings yet

- Risk Assessment Form: Contracting W.L.LDocument7 pagesRisk Assessment Form: Contracting W.L.Lbelhareth seifeddineNo ratings yet

- 4-Cable Laying PDFDocument6 pages4-Cable Laying PDFAhmed ZaiNo ratings yet

- 10 ManliftDocument3 pages10 ManliftBalongNo ratings yet

- Energy Isolation High Voltage Electricity Work at Height Floor/Handrail Removal Confined Space Hot Work Excavation/Penetration Lifting/CraneageDocument4 pagesEnergy Isolation High Voltage Electricity Work at Height Floor/Handrail Removal Confined Space Hot Work Excavation/Penetration Lifting/CraneageJoanne Marie LagusNo ratings yet

- Proposed 6 Hole Logging StringDocument4 pagesProposed 6 Hole Logging StringYaqoob IbrahimNo ratings yet

- TLC ProceduresDocument14 pagesTLC ProceduresYaqoob IbrahimNo ratings yet

- Daily Production Report OMVDocument1 pageDaily Production Report OMVYaqoob IbrahimNo ratings yet

- Mdata Miano-26: 660256622Document14 pagesMdata Miano-26: 660256622Yaqoob IbrahimNo ratings yet

- 2-Phase With Sand TrapDocument2 pages2-Phase With Sand TrapYaqoob IbrahimNo ratings yet

- UEPL Miano-26 POWS 2.5in Perforation 16-June-2022 000Document14 pagesUEPL Miano-26 POWS 2.5in Perforation 16-June-2022 000Yaqoob IbrahimNo ratings yet

- Colour Code Assurance Hilong-5 Jugan-2Document6 pagesColour Code Assurance Hilong-5 Jugan-2Yaqoob IbrahimNo ratings yet

- Mexicos Deepest Well Drill String SPE-52822-MSDocument10 pagesMexicos Deepest Well Drill String SPE-52822-MSYaqoob IbrahimNo ratings yet

- Errata: Date of Issue: Affected PublicationDocument88 pagesErrata: Date of Issue: Affected PublicationYaqoob IbrahimNo ratings yet

- Hydraulic Jet PumpDocument2 pagesHydraulic Jet PumpYaqoob IbrahimNo ratings yet

- PDC Drill Bits: Manufacturer IADC Code Bit Name/model NumberDocument16 pagesPDC Drill Bits: Manufacturer IADC Code Bit Name/model NumberYaqoob IbrahimNo ratings yet

- Tube Move Calculation ParametersDocument1 pageTube Move Calculation ParametersYaqoob IbrahimNo ratings yet

- Color Coding Assurance at HL-09 (Qabul-2)Document13 pagesColor Coding Assurance at HL-09 (Qabul-2)Yaqoob IbrahimNo ratings yet

- IADC Classification ChartDocument2 pagesIADC Classification ChartYaqoob IbrahimNo ratings yet

- Color Code System For Lifting Equipment: Hilong-21Document3 pagesColor Code System For Lifting Equipment: Hilong-21Yaqoob IbrahimNo ratings yet

- PDC Drill BitsDocument22 pagesPDC Drill BitsYaqoob IbrahimNo ratings yet

- Colour Code System Compliance UET-1 KK-DT-4Document8 pagesColour Code System Compliance UET-1 KK-DT-4Yaqoob IbrahimNo ratings yet

- Drillers Istructions 21 Oct 2013 - BOP Pressure TestDocument2 pagesDrillers Istructions 21 Oct 2013 - BOP Pressure TestYaqoob IbrahimNo ratings yet

- Understanding Toolface: Angus JamiesonDocument32 pagesUnderstanding Toolface: Angus JamiesonYaqoob Ibrahim100% (2)

- Anti Stall Tool For Drilling BHA by ATSDocument4 pagesAnti Stall Tool For Drilling BHA by ATSYaqoob IbrahimNo ratings yet

- Safe Cards TCPDC-2001: Reported By: Dilawar KhanDocument8 pagesSafe Cards TCPDC-2001: Reported By: Dilawar KhanYaqoob IbrahimNo ratings yet

- Hazard Hunt Report TCPDC-2001 (Halipota-5)Document8 pagesHazard Hunt Report TCPDC-2001 (Halipota-5)Yaqoob Ibrahim0% (1)

- Stop Cards Excel Sheet 30th March Status (TCPDC 4001) (Korai 2)Document20 pagesStop Cards Excel Sheet 30th March Status (TCPDC 4001) (Korai 2)Yaqoob IbrahimNo ratings yet

- Daily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryDocument5 pagesDaily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryYaqoob IbrahimNo ratings yet

- Hazard Hunt Report TCPDC-2001 (Halipota-5)Document8 pagesHazard Hunt Report TCPDC-2001 (Halipota-5)Yaqoob Ibrahim0% (1)

- UEP-HL Stop Cards Feb - 2017Document59 pagesUEP-HL Stop Cards Feb - 2017Yaqoob Ibrahim100% (1)

- UEP-HL Stop Cards Jan - 2017Document54 pagesUEP-HL Stop Cards Jan - 2017Yaqoob IbrahimNo ratings yet

- Hazard Hunt Status 26-08-2017Document28 pagesHazard Hunt Status 26-08-2017Yaqoob IbrahimNo ratings yet

- Safe Cards TCPDC-2001: Reported By: Dilawar KhanDocument8 pagesSafe Cards TCPDC-2001: Reported By: Dilawar KhanYaqoob IbrahimNo ratings yet

- Daily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryDocument5 pagesDaily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryYaqoob IbrahimNo ratings yet

- What Is A SurveyDocument8 pagesWhat Is A SurveyPaisen YipNo ratings yet

- Spots Pbis MatrixDocument1 pageSpots Pbis Matrixapi-358900718No ratings yet

- Poultry Premix ManufacturerDocument11 pagesPoultry Premix ManufacturerSAHS LifesciencesNo ratings yet

- Colgate PalmoliveDocument7 pagesColgate PalmoliveHarshankNo ratings yet

- Ebm JurnalDocument198 pagesEbm Jurnalcamelia musaadNo ratings yet

- List of Secondary Tie-Up Hospitals in 22 Districts of Maharashtra RegionDocument6 pagesList of Secondary Tie-Up Hospitals in 22 Districts of Maharashtra RegionvinaykaambleNo ratings yet

- EPG Health Report The Future of HCP Engagement Impact 2023Document73 pagesEPG Health Report The Future of HCP Engagement Impact 2023paulilongereNo ratings yet

- AHDP Monthly Accomplishment Report 2019Document1 pageAHDP Monthly Accomplishment Report 2019Eduardo RodriguezNo ratings yet

- Asupan Gizi, Pola Makan Dan Kesehatan Gigi AnakDocument4 pagesAsupan Gizi, Pola Makan Dan Kesehatan Gigi AnakSri Gusnaini Milenia HNo ratings yet

- CPD Re-Orentation & Performance ReviewDocument24 pagesCPD Re-Orentation & Performance ReviewAhmed AdemNo ratings yet

- Limitations of Microbial Environmental Monitoring Methods in CleanroomsDocument13 pagesLimitations of Microbial Environmental Monitoring Methods in Cleanroomshealing hopeNo ratings yet

- Project Report: Ponds SmileDocument8 pagesProject Report: Ponds SmileAnasAhmedNo ratings yet

- Alpha Dry Adhesive-705438Document4 pagesAlpha Dry Adhesive-705438mohsinNo ratings yet

- IMGDocument4 pagesIMGGayathri KumarNo ratings yet

- Volume Homeostasis, Renal Function and Hypertension 1985Document14 pagesVolume Homeostasis, Renal Function and Hypertension 1985Debora OrnellasNo ratings yet

- VPB 111Document3 pagesVPB 111Dr-Ashok KeerNo ratings yet

- Rhythm Recognition - ACLS Medical Training 1Document9 pagesRhythm Recognition - ACLS Medical Training 1Catalina BorquezNo ratings yet

- Mozambique 2030 PDFDocument68 pagesMozambique 2030 PDFGray HouserNo ratings yet

- Guiding For HospitalDocument14 pagesGuiding For HospitalAnkit Bhatia100% (1)

- Lawson Products, Inc - Heavy Duty Chain LubricantDocument7 pagesLawson Products, Inc - Heavy Duty Chain Lubricantjaredf@jfelectric.comNo ratings yet

- Local Exhasut System - Design and LayoutDocument109 pagesLocal Exhasut System - Design and LayoutSreejit PillaiNo ratings yet

- Surrenderer Process Flow ChartDocument1 pageSurrenderer Process Flow ChartPingotMagangaNo ratings yet

- TANF Extension Reduces FundingDocument2 pagesTANF Extension Reduces FundingPatricia DillonNo ratings yet

- Ayurvedic Healing Covers Therapies and Medicine Treatments.: Bhagwan Mahavir College of ArchitectureDocument4 pagesAyurvedic Healing Covers Therapies and Medicine Treatments.: Bhagwan Mahavir College of Architectureaesha daveNo ratings yet

- How It Works - Human BodyDocument180 pagesHow It Works - Human BodyMargo Sun95% (39)

- Conditii - TRAVEL - Mod 403-Q-QSP-QP - Aprilie 2023 - ENDocument22 pagesConditii - TRAVEL - Mod 403-Q-QSP-QP - Aprilie 2023 - ENMihaela Iuliana MihaNo ratings yet

- Adulteration in Foods 1Document17 pagesAdulteration in Foods 1Aditya KumarNo ratings yet

- Jeevan Jyoti Hospital - A Brief Summary 2Document5 pagesJeevan Jyoti Hospital - A Brief Summary 2dexemar489No ratings yet

- Communication MidwiferyDocument11 pagesCommunication Midwiferygraham20No ratings yet