Professional Documents

Culture Documents

Parker Ash Probe User Manual

Parker Ash Probe User Manual

Uploaded by

Daniel Alberto Reyes RamirezCopyright:

Available Formats

You might also like

- IO AB Utrient Cycles: BjectivesDocument7 pagesIO AB Utrient Cycles: BjectivesSalman KhanNo ratings yet

- Management Report On Tesla, Inc.Document7 pagesManagement Report On Tesla, Inc.Naveed IbrahimNo ratings yet

- Pinney, Photography and AnthropologyDocument172 pagesPinney, Photography and AnthropologypinoNo ratings yet

- VibproDocument624 pagesVibproStevanus Silaban100% (3)

- MEDISON SA-9900 Service Manual PDFDocument264 pagesMEDISON SA-9900 Service Manual PDFKhalil Issaad86% (7)

- Manual G36 O2 Analyzer - V.2.04 July 2017Document46 pagesManual G36 O2 Analyzer - V.2.04 July 2017Isidoros100% (3)

- Coinbase ApplicationDocument9 pagesCoinbase ApplicationAnonymous EBNbQRDNo ratings yet

- Red Flags For AutismDocument3 pagesRed Flags For AutismHemant KumarNo ratings yet

- Validation AutoclaveDocument638 pagesValidation AutoclaveWormInch100% (5)

- SURFv1.3 Operator ManualDocument54 pagesSURFv1.3 Operator ManualAli DiabNo ratings yet

- Winscope1000 Global GuideDocument32 pagesWinscope1000 Global GuideGilder GonzalezNo ratings yet

- APRIS Product ManualDocument129 pagesAPRIS Product ManualEswin Paico de la CruzNo ratings yet

- Hydrolux HL 500 Pro H2 1Document30 pagesHydrolux HL 500 Pro H2 1muhammad adibNo ratings yet

- MX300 E-Manual PDFDocument148 pagesMX300 E-Manual PDFRazaleigh Mohd AminNo ratings yet

- User Manual For Opacity MeterDocument25 pagesUser Manual For Opacity MeterEryf ADRNo ratings yet

- Presostato HEDEDocument48 pagesPresostato HEDEMoLNo ratings yet

- Aphex 320a ManualDocument41 pagesAphex 320a ManualfacebNo ratings yet

- Spider 8 User ManualDocument34 pagesSpider 8 User ManualJacob MillerNo ratings yet

- Powershift V2: Manual Resistance Installation GuidelineDocument27 pagesPowershift V2: Manual Resistance Installation GuidelinedklnfsdNo ratings yet

- HTV M ManualDocument40 pagesHTV M ManualmehdiNo ratings yet

- WorldCast Horizon Manual v2.0 - A4Document85 pagesWorldCast Horizon Manual v2.0 - A4Vincent MNo ratings yet

- User'S Manual: Surf-Amf Auto Start - Surf-Auto EnhancedDocument48 pagesUser'S Manual: Surf-Amf Auto Start - Surf-Auto EnhancedBelghennou Hadj AliNo ratings yet

- SmartCEM OPS BDocument38 pagesSmartCEM OPS BLeo MaximoNo ratings yet

- Canon BJC-8200 Service Manual PDFDocument105 pagesCanon BJC-8200 Service Manual PDFDuplessisNo ratings yet

- Bacharach MGS-408 - ManualDocument43 pagesBacharach MGS-408 - ManualChris DNo ratings yet

- Users GuideDocument70 pagesUsers GuideCARLOS100% (1)

- BlastCam Operations Manual PDFDocument64 pagesBlastCam Operations Manual PDFlxo08No ratings yet

- R423 Manual PDFDocument128 pagesR423 Manual PDFmanikandanNo ratings yet

- 98 Spartan-Controls Net-Oil Product DocumentDocument108 pages98 Spartan-Controls Net-Oil Product DocumentCarlos WotchoskiNo ratings yet

- Philips PM3380 Users ManualDocument297 pagesPhilips PM3380 Users ManualDRF2540% (1)

- RV Heincke ADCP Support 600kHzDocument22 pagesRV Heincke ADCP Support 600kHzJainner Salcedo SanchezNo ratings yet

- Uritek-720 Plus: Operator's ManualDocument41 pagesUritek-720 Plus: Operator's ManualHoang Nhi TranNo ratings yet

- Solids Control Programs: SchlumbergerDocument10 pagesSolids Control Programs: SchlumbergerMarkus LandingtonNo ratings yet

- SM Sa9900 V1.0 (E)Document277 pagesSM Sa9900 V1.0 (E)namNo ratings yet

- UNIPHOS FumiSense Pro PH3 0 2000 PPM MKII HIGH PDFDocument25 pagesUNIPHOS FumiSense Pro PH3 0 2000 PPM MKII HIGH PDFraushan mishraNo ratings yet

- Air SamplerDocument42 pagesAir SamplerKuldeepNo ratings yet

- PDK 204979 Software Aipex Pro v3 enDocument827 pagesPDK 204979 Software Aipex Pro v3 enggntb64fckNo ratings yet

- Filehost - Canon Fax L350 Service ManualDocument213 pagesFilehost - Canon Fax L350 Service ManualvNo ratings yet

- Linux As Assmebler CompilerDocument252 pagesLinux As Assmebler CompilerLuis D'ArdisNo ratings yet

- Maxtest SoftwareDocument47 pagesMaxtest SoftwareGMAR Comercializadora100% (1)

- DPA5 User Manual PDFDocument42 pagesDPA5 User Manual PDFcleverson ferreira100% (2)

- MSP 34x0G Multistandard Sound Processor Family: MicronasDocument106 pagesMSP 34x0G Multistandard Sound Processor Family: MicronasasistekNo ratings yet

- AMKASYN Device Description Controller Card KW-R06Document47 pagesAMKASYN Device Description Controller Card KW-R06Isao TomitaNo ratings yet

- 2016-06-30 PB-Inspektor NT Manual Revision 1Document42 pages2016-06-30 PB-Inspektor NT Manual Revision 1Pablo CelisNo ratings yet

- Teledyne EchoTrac E20 ManualDocument60 pagesTeledyne EchoTrac E20 ManuallazarusNo ratings yet

- PROFIBUS Fieldbus Coupler MVS3007Document114 pagesPROFIBUS Fieldbus Coupler MVS3007Diego MontanezNo ratings yet

- APC Portable Airborne Particle Counter: Operations Manual Version 2.01Document50 pagesAPC Portable Airborne Particle Counter: Operations Manual Version 2.01Juan Alejandro Cañas ColoradoNo ratings yet

- Sas Super 100 - Sas Super 180 Duo Sas Super 360: Instruction ManualDocument54 pagesSas Super 100 - Sas Super 180 Duo Sas Super 360: Instruction ManualDANIEL DOMINGUEZNo ratings yet

- Edacs 500M Radio Flash SoftwareDocument8 pagesEdacs 500M Radio Flash SoftwareViorel AldeaNo ratings yet

- Hitachi 917 Analyzer - User ManualDocument406 pagesHitachi 917 Analyzer - User Manualmylove2804100% (1)

- XCMG Iflex5 Operators ManualDocument69 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- Ancortek Manual V1.0 20150601Document21 pagesAncortek Manual V1.0 20150601Wesley GeorgeNo ratings yet

- MSP 44x0G Multistandard Sound Processor Family: MicronasDocument100 pagesMSP 44x0G Multistandard Sound Processor Family: MicronasAntonio AscanioNo ratings yet

- Aoc Le32a1330-61 Le40a1330-61 LCD TV PDFDocument87 pagesAoc Le32a1330-61 Le40a1330-61 LCD TV PDFtrietNo ratings yet

- M070010 Gasmaster III Manual Issue 2 UKDocument48 pagesM070010 Gasmaster III Manual Issue 2 UKPhạm Thế Hiệp100% (1)

- Canon mp730 - 700-smDocument167 pagesCanon mp730 - 700-smRon FultonNo ratings yet

- Sat - 33.Pdf - Recognition and Listing of Acute Stroke Progression Based On Oct Images Using Curvelet AnalysisDocument11 pagesSat - 33.Pdf - Recognition and Listing of Acute Stroke Progression Based On Oct Images Using Curvelet AnalysisVj KumarNo ratings yet

- GC Application Module For FB107Document52 pagesGC Application Module For FB107Mohammad Asif ZakriyyaNo ratings yet

- Pour Point Analyzer MPP 5GDocument102 pagesPour Point Analyzer MPP 5GimunNo ratings yet

- I Step 1 1 0 Global GuideDocument28 pagesI Step 1 1 0 Global GuideMahmoud SadikNo ratings yet

- Installation and Operating Manual FMTB 5000 Test Bench: 0.5 - 5000 m3 / HDocument36 pagesInstallation and Operating Manual FMTB 5000 Test Bench: 0.5 - 5000 m3 / HDaniel Oscar100% (1)

- Nt-Converter 1.5.0 Global GuideDocument14 pagesNt-Converter 1.5.0 Global GuideFanni Smidéliusz-OláhNo ratings yet

- Sudt Accessport Advanced Terminal / Monitor / Debugger Version 1.37 User ManualDocument53 pagesSudt Accessport Advanced Terminal / Monitor / Debugger Version 1.37 User ManualAlberto AvilaNo ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- HospitalDocument18 pagesHospitalJeffrey ViernesNo ratings yet

- Passion in EntrepreneurshipDocument12 pagesPassion in EntrepreneurshipCharisse WooNo ratings yet

- Makalah Huawei Learning Cloud User GuidDocument45 pagesMakalah Huawei Learning Cloud User GuidhazirafatmarinaNo ratings yet

- Preliminary Considerations Property v. Things: Real or ImmovableDocument8 pagesPreliminary Considerations Property v. Things: Real or ImmovableSZNo ratings yet

- 4 - Hydraulic Power Supply 2006-SeptDocument39 pages4 - Hydraulic Power Supply 2006-SeptПавел ШиряевNo ratings yet

- Technical Report Writing in The Maritime & Offshore IndustryDocument4 pagesTechnical Report Writing in The Maritime & Offshore IndustryIke MaduforoNo ratings yet

- Conformity (Majority Influence)Document11 pagesConformity (Majority Influence)Camille FernandezNo ratings yet

- Johnrey For Demo DLPDocument8 pagesJohnrey For Demo DLPmelany r. malvarosaNo ratings yet

- TC2971en-Ed01 Installation Procedure For OmniVista8770 R5.0.24.00Document88 pagesTC2971en-Ed01 Installation Procedure For OmniVista8770 R5.0.24.00K Mei.No ratings yet

- Aggravating CircumstanceDocument4 pagesAggravating CircumstanceMindalyn Muring AripNo ratings yet

- NMax Application DataDocument4 pagesNMax Application DataKenneth T. Guillermo0% (1)

- LBO ModelingDocument66 pagesLBO Modelingalexander ThielNo ratings yet

- Zombie: The Coil RulebookDocument137 pagesZombie: The Coil RulebookGnomeMadeIon100% (4)

- 114 Layout Secrets For Your Framing Square PDFDocument2 pages114 Layout Secrets For Your Framing Square PDFHomerSimsonnakis100% (1)

- Subhiksha Case StudyDocument24 pagesSubhiksha Case StudyJatin KakraniNo ratings yet

- Foodtopia Ba G04 FinalreviewDocument52 pagesFoodtopia Ba G04 FinalreviewPetru CucutăNo ratings yet

- Kusama Artist Presentation 1Document9 pagesKusama Artist Presentation 1api-592346261No ratings yet

- Skills Framework For Design Technical Skills and Competencies (TSC) Reference DocumentDocument2 pagesSkills Framework For Design Technical Skills and Competencies (TSC) Reference DocumentdianNo ratings yet

- Minutes of The Session: Presiding OfficerDocument3 pagesMinutes of The Session: Presiding OfficerCecille SaymoNo ratings yet

- Descriptive Survey ResearchDocument6 pagesDescriptive Survey ResearchAbdullah HashmiNo ratings yet

- The Economist 0912Document346 pagesThe Economist 0912Riaz kingNo ratings yet

- Link of Support Material Link 2020-21CLASSES 9 1 - 11 12Document2 pagesLink of Support Material Link 2020-21CLASSES 9 1 - 11 12naman mahawerNo ratings yet

- La Pecora Bianca MenuDocument2 pagesLa Pecora Bianca MenuNick SolaresNo ratings yet

Parker Ash Probe User Manual

Parker Ash Probe User Manual

Uploaded by

Daniel Alberto Reyes RamirezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Parker Ash Probe User Manual

Parker Ash Probe User Manual

Uploaded by

Daniel Alberto Reyes RamirezCopyright:

Available Formats

Portable Ash Instrument Analyser

Ash Probe & AshGraffix

User Manual - Overview

VERSION HISTORY

Issue Date Author Changes

1.00 January 2017 Kevin Corcoran First publication

DISCLAIMER

This document is provided “as is” without any representations or warranties, express or implied. Parker Hannifin

Manufacturing Limited makes no representations or warranties in relation to this User Guide or the information and

materials provided herein. Although we make a reasonable effort to include accurate and up to date information,

Parker Hannifin Manufacturing Limited does not warrant that the information in this User Guide is complete, true,

accurate or non-misleading.

The contents of this document shall not be copied, disclosed, or utilised without the written permission of Parker

Hannifin Manufacturing Limited.

TRADEMARK ACKNOWLEDGEMENTS

Microsoft®, Windows® and Excel® are registered trademarks of Microsoft Corporation in the United States and other

countries.

Bretby Gammatech

Parker Hannifin Manufacturing Limited Tel: +44 (0)114 224 0000

Instrumentation Products Division Europe Email: info@bretbygammatech.com

President Park, President Way Web: www.parker.com/ipd

Sheffield, S4 7UR

United Kingdom

Ash Probe & AshGraffix Overview 2 Issue 1.00

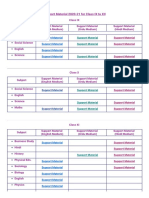

CONTENTS

VERSION HISTORY 2

DISCLAIMER 2

TRADEMARK ACKNOWLEDGEMENTS 2

CONTENTS 3

1 INTRODUCTION 5

1.1 MANUAL FORMAT 5

2 DESCRIPTION, MAINTENANCE AND OPERATION 6

2.1 EQUIPMENT DESCRIPTION 6

2.1.1 PROBE 6

2.1.2 ASHGRAFFIX DISPLAY UNIT 6

2.1.3 DISPLAY UNIT BATTERY CHARGER 6

2.1.4 ASH PROBE/DISPLAY UNIT CABLE 7

2.1.5 DATA DOWNLOAD CABLE 7

2.1.6 ASH PROBE UTILITY SOFTWARE 7

2.1.7 CALIBRATION SAMPLES GATHERING EQUIPMENT 7

2.1.8 OPERATOR’S MANUALS 7

2.2 CARE AND MAINTENANCE 8

2.2.1 PROBE 8

2.2.2 ASHGRAFFIX DISPLAY UNIT 8

2.2.3 FAULT FINDING 8

2.3 GENERAL PRINCIPLES OF OPERATION 9

2.4 CALIBRATION PROCEDURE 10

2.4.1 USING THE CALIBRATION SLEEVE 10

3 DISPLAY UNIT OPERATION 12

Ash Probe & AshGraffix Overview 3 Issue 1.00

3.1 OVERVIEW 12

3.2 HOME SCREEN DISPLAY 13

3.3 PROBE READING MAIN SCREEN 15

3.4 MODES OF OPERATION 15

3.4.1 PILES MODE 15

3.4.2 TRUCKS MODE 16

3.5 TAKING READINGS IN PILES MODE 16

3.5.1 INSERTING THE PROBE 17

3.5.2 TAKING THE READING 18

3.6 TAKING READINGS IN TRUCKS MODE 19

3.6.1 SETTING UP A NEW TRUCK RECORD 20

3.6.2 INSERTING THE PROBE 20

3.6.3 TAKING THE READINGS 21

3.7 DATA DISPLAY 23

3.7.1 PILE/TRUCK 23

3.7.2 MENU 24

3.7.2.1 Save/Export Data 24

3.7.2.2 Show Data for All Piles 24

3.7.2.3 Show Samples for Current Pile 25

3.8 EXPORT DATA 26

3.9 PROGRAM MENU 27

4 ASH PROBE UTILITY SOFTWARE 29

4.1 PROGRAM DESCRIPTION 29

4.2 PC REQUIREMENTS 29

Ash Probe & AshGraffix Overview 4 Issue 1.00

1 INTRODUCTION

The Ash Probe is a portable device simple to use device for measuring the ash content of coal in the field, whether it

be piles of coals or delivery trucks. It measures the natural gamma radiation produced by the impurities that form

the ash content and once suitably calibrated to the coal sources being measured, can determine the accuracy of the

ash content to 1% or better.

The Bretby Gammatech Ash Probe has been a world leader in portable coal quality monitoring for over 10 years,

with the unit accepted around the world as a standard in its field. The new version, incorporating the AshGraffix

display unit, follows on from that success and gives the unit a modern, multi-lingual, touch screen interface, making

the unit simpler to use and more feature rich, whilst still retaining the fundamental qualities of accurate ash content

measurement from its predecessor.

1.1 MANUAL FORMAT

The manual is broken into five sections that covers all aspects of operation of the system.

Part 1 is this introduction to the manual

Part 2 describes the Ash Probe and AshGraffix, gives operational procedures and guidance on routine maintenance.

Part 3 provides guidance on the use of the AshGraffix Display Unit with details of the menu structure.

Part 4 provides details on how to download data from the AshGraffix onto a PC or configure the unit from a PC using

the companion Microsoft Windows application software.

Ash Probe & AshGraffix Overview 5 Issue 1.00

2 DESCRIPTION, MAINTENANCE AND OPERATION

This section of the manual describes the individual piece of equipment that make up the Ash Probe and the relevant

maintenance and operation of those items.

2.1 EQUIPMENT DESCRIPTION

The Ash Probe system is comprised of the main battery powered AshGraffix display unit (from which the system is

controlled and results viewed), the actual probe used to be inserted into the coal piles and the cables used to

interconnect the two parts as well as connect to an external PC for data upload. Also include is a mains charger for

charging the display unit. The AshGraffix system can operate for over 8 hours typical operation on a full charge.

Other equipment is provided, as described below, to facilitate the calibration of the unit or provide optional

features.

2.1.1 PROBE

The probe consists of a stainless steel tube (53 mm diameter, 640 mm long) with a hard, anodised aluminium

pointed nose fitted at one end and an end cap of the same material fitted at the other end (a stainless steel nose

cone can be used where the coals are exceptionally hard and/or abrasive). Attached to the end cap is a LEMO six-

way socket for the connection of the cable from the display unit. Just below the end cap are two screwed bosses for

attachment of the handles to provide a grip for pushing the probe into coal piles.

Inside the stainless steel tube is housed a scintillation crystal/photo-multiplier tube (PMT) assembly and its

associated electronics. A carrying case is also provided for transportation and storage. The probe does not contain a

battery, as it is powered from the display unit. The total weight of the Probe is 2.9kg. The probe should be treated as

a delicate instrument, with extreme care being taken when in use, and always storing it in its carrying case when not

in use.

2.1.2 ASHGRAFFIX DISPLAY UNIT

The AshGraffix Display Unit is housed in a black metal case (220 mm x 168 mm x 55 mm), which has a protective

carrying case allowing the unit to be carried using the built in carrying strap. The main part of the console features a

7 inch high resolution TFT touch-screen display. On the side panel is a LEMO six-way socket for connection to the

probe, external PC or battery charger, a push-button switch with inbuilt LED indicator and also an industrial USB

socket to allow connection of a memory stick for data transfer.

The language of the text in the display unit can be selected from a list which currently includes: English, Spanish,

French, Polish, Russian, Turkish and Vietnamese. More languages can be added upon request.

2.1.3 DISPLAY UNIT BATTERY CHARGER

The Display Unit Battery Charger is a three stage plug-in unit for use on an 85 to 240-volt ac supply. It connects to

the LEMO connector on the side of the AshGraffix and takes approximately 4 hours to fully charge a unit from flat.

A bi-colour LED indicator on the charge indicates the state of the charging cycle. The meaning of the indicator

modes is explained on the front of the charger but the main indications are as follows:

LED flashes slowly in yellow – pre-charge sequence

LED flashes rapidly in green – rapid-charge sequence

LED flashes slowly in green – main charging sequence

Ash Probe & AshGraffix Overview 6 Issue 1.00

LED fully on in green – charging complete

2.1.4 ASH PROBE/DISPLAY UNIT CABLE

The cable, which is normally 3 metres long, has a LEMO 6-way plug attached at each end. One plug is right angled for

connecting to the Display Unit while the other is straight for connecting to the probe. Cables of other lengths can be

supplied on request. Cold climate cables can also be supplied on request.

The wiring for the cable is shown in Appendix A of this guide.

2.1.5 DATA DOWNLOAD CABLE

The cable, which is 2 metres long, has a LEMO 6-way plug attached at one end, and a USB (type A) plug the other.

This cable is used to download data to a PC or allow remote configuration using the supplied Ash Probe Utility

software. A cable with a 9 way D type plug for direction connection to an RS232 serial port is also available as an

option.

The wiring for the RS232 serial cable is shown in Appendix A of the User Manual.

2.1.6 ASH PROBE UTILITY SOFTWARE

This Windows application software, supplied on a CD or memory stick (with associated manual), can be used to

download data from an Ash Probe display unit and save to disk file as a generic spreadsheet (Comma Separated

Values or CSV format) which can be read by most office applications. The software also allows the display unit

parameters and calibration data to be viewed and edited using the connected PC rather than the on-board touch-

screen interface.

2.1.7 CALIBRATION SAMPLES GATHERING EQUIPMENT

The equipment consists of a stainless steel tube (240 mm diameter by 600 mm long) with a row of serrated teeth on

one end and two screw-on handles at the other. The device is used to push into the coal in order to extract the coal

sample around the probe. A stainless steel scoop is also provided to remove the coal.

2.1.8 OPERATOR’S MANUALS

This manual and the associated Ash Probe Utility Software manual are supplied on CD along with the Ash Probe

Utility software application.

Ash Probe & AshGraffix Overview 7 Issue 1.00

2.2 CARE AND MAINTENANCE

2.2.1 PROBE

IMPORTANT: The probe contains a very delicate crystal device which is easily damaged by physical impact. Great

care must be made not to drop or cause excessive vibration of the probe.

The crystal/photo-multiplier assembly and associated electronics are housed in a series of aluminium and mu-metal

joined up tubes. All the external surfaces of the assembly are covered with a 5mm layer of rubberised foam prior to

inserting in the stainless steel outer tube. The shock protection is necessary to safeguard the photo-multiplier tube,

which has a thin walled glass barrier mounted internally. For this reason, the ash probe should be treated as a

delicate instrument, with extreme care being taken when in use and always storing it in its carrying case when not in

use (which will offer some additional shock as well as thermal protection). Dropping the probe on a hard surface will

almost certainly result in serious damage. Also, never attempt to drive the probe into coal with a heavy object such

as a hammer. Hand pressure applied evenly to both handles should be the maximum force ever applied. If the coal is

compacted, use a spade to loosen it first. (Bretby Gammatech cannot be held responsible for any damage sustained

from improper use).

Before final assembly into the probe housing, the crystal/PMT assembly is temperature cycled between +35°C and -

10°C, to ensure that the unit can be used at temperatures within this range. Large temperature gradients however,

could be damaging to the crystal assembly and so should be avoided. In cold weather conditions, it is advisable to

store the probe in an unheated room to reduce the temperature difference when being used in a freezing cold coal

pile. Storing the probe in its carrying case when not in use will help to reduce the temperature gradients.

While in use, take care to ensure that dirt does not enter the LEMO connectors (on the probe and on the display

unit), and always wipe the probe to remove coal particles and moisture before storing in its case.

2.2.2 ASHGRAFFIX DISPLAY UNIT

As with the probe, the display unit should also be treated as a delicate instrument, although, the temperature

gradient restrictions on the probe do not apply.

The battery life of the display unit is displayed in a battery icon in the top right corner of the display as a percentage

figure. This is normally shown in green but will be shown in red as the percentage drops to 20% and below. At this

point the unit should be connected to the mains charger supply. To do this, insert the charger LEMO plug into the

LEMO socket on the console and connect the charger to the mains supply. A fully charged good condition battery

should give 8 to 10 hours typical operation. It is recommended that when not in use, the display unit be left on

charge. When not in use for extended periods, it is suggested that the battery be disconnected from the charger, but

that the unit is stored with the battery in a fully charged state.

2.2.3 FAULT FINDING

The display unit is equipped with a self-diagnostic function, which will attempt to determine which component if at

faulty in the event of a problem.

This involves using the Test Probe function, which will guide the user through the diagnostic process and determine

whether the problem lies with the probe itself (not producing counts of radiation), the cable (broken cable or short

circuit) or the display unit itself (faulty circuitry).

See section Error! Reference source not found. Test Probe of the User Manual for full details.

Ash Probe & AshGraffix Overview 8 Issue 1.00

If a cable is deemed to be faulty, it may be worth using a resistance/continuity meter to check that each pin of the

LEMO connector on one end of the cable is connected to the corresponding pin on the LEMO connector at the other

enable of the cable. The meter can also be used to check that there are no connections between pins on one end

and adjacent pins (i.e. a short circuit in the cable).

2.3 GENERAL PRINCIPLES OF OPERATION

This section of the manual describes the main principles of using the Ash Probe and AshGraffix display unit. The

details of the functions and AshGraffix user interface are covered in detail in Section 3 of this document.

There are two different modes of operation of the AshGraffix; Piles Mode and Trucks Mode. The default Piles mode

is designed to be used when the probe is being used to measure large piles of coal and many samples are to be taken

from around a pile to determine the overall average ash content. The Trucks mode, however, operates slightly

differently and is designed to be used when trucks of coal are being delivered and when only a few samples from the

carried coal will be used to calculate the overall average ash content.

When preparing to insert the Ash Probe into a pile or a truckload of coal, either to determine the ash content of the

coal or to measure the gamma counts for a calibration, the same general rules apply. These are as follows:

Where possible select a pile of coal of reasonable proportions, i.e. minimum 10 tons.

Avoid places in a pile or truck that are adjacent to (within 0.5 metres) the truck sides, concrete or brick walls

or any other objects. If there is a concrete floor, ensure that after insertion, the tip of the probe is in excess

of 0.5 metre above the ground. This is to avoid picking up background radiation from these surfaces.

Avoid peninsulas of coal. Select positions on the pile that provide access to the main body of the coal. The

final position of the tip of the probe after insertion should be in excess of 0.5 metre from any coal interface.

Avoid compacted coal where possible. If excessive force is necessary to insert the probe to its required

depth, select another location within the pile or loosen the coal with a spade first.

When inserting the probe, the elevation of the tube should be normal to the surface of the coal. If the

minimum distance above the floor (as described above) cannot be achieved, the elevation should be

modified to achieve this distance.

After having found a suitable location to use the probe, attach the two handles to the probe body and push the

probe into the coal to a depth of 600 mm. At this depth the array of four screws just below the handles should be

level with the coal surface.

Plug in the cable between the Ash Probe and the Display Unit and press the On/Off switch and when the screen

shows the home screen (displays shows one large icon and three small ones to access the main functions), press the

large icon to access the probe measurement screen.

Ash Probe & AshGraffix Overview 9 Issue 1.00

In the case of piles of coal, check that the required pile name/reference is indicated on the Display Unit, and that the

relevant calibration has been selected. In the case of trucks, the user will be prompted to enter details of the truck

to be measured prior to taking the first reading.

Press the START button on the touch-screen to start the counting procedure to obtain the gamma counts for the pile

or truckload of coal.

When the counting has been completed, the average gamma counts per second for that reading should be stored

unless there is a reason to discard the reading (perhaps it is significantly different to other sample readings due to

proximity to another surface say).

Select another position in the pile or truck, insert the Ash Probe, and repeat the above steps. If more than one

reading is taken in a pile or truck, the programme will average all the gamma counts in the pile or truck to calculate

the overall pile or truck ash content.

For more details on taking readings, see sections 3.5 or 3.6 depending upon the modem of operation.

2.4 CALIBRATION PROCEDURE

The purpose of a calibration is to establish the coefficients for a particular gamma/ash correlation that may be

associated with coal from a particular seam or area. The display unit can store 100 different sets of calibration

coefficients, and the user can select a specific calibration set to suit a given coal type or source being measured if

more than one source is used at site(s).

It is important during a calibration to use coals from the source that represents the whole range of ashes likely to be

sensed by the ash probe in practise. As a general rule, the wider the ash range the more stable the coefficients.

The calibration procedure largely consists of taking the readings from the Ash Probe with the probe inserted into a

variety of different piles from the same coal seam/source (and different locations within those piles) and taking coal

samples from each location. The physical samples should then be analysed in a laboratory to get definitive ash

content readings for each sample. The procedure for taking a sample using the Ash Probe is described in sections

3.5/3.6. All the readings should be associated with a unique “pile” on the Display Unit so that they are grouped

together for easy access to in data downloads.

The readings taken for that pile, can then be downloaded to a PC into a spreadsheet (by memory stick or using the

included Ash Probe Utility software and associated data cable). The collection of readings recorded by the ash probe

each contain the measured “counts-per-second” values from the sensor and it is this value that is plotted on a graph

(as the x axis) against the laboratory derived ash content values associated with each reading (on the y axis). This

will give a series of plots that will follow a roughly straight line on the graph. The calibration coefficients for this

source of coal are derived from this graph.

2.4.1 USING THE CALIBRATION SLEEVE

Having gone through the procedure for inserting the probe into a pile, as described in detail in section 3.5/3.6 of this

manual, an activity measurement is taken (see section 3). Once the activity measurement is complete and the data

stored, the cable is detached from the probe end, and the two handles unscrewed. The Calibration Tube, with

handles attached, is placed centrally over the end of the probe at the same elevation angle, and with a combination

of directly pushing and oscillating rotary motions is forced into the coal until the lower edge of the top rim just

touches the coal. It is essential that the calibration tube be maintained at the same elevation angle as the probe

ensuring that the probe remains centrally positioned within the calibration tube. This will guarantee that the sample

Ash Probe & AshGraffix Overview 10 Issue 1.00

of coal extracted for analysis will be the same coal sensed by the Ash Probe. The Probe is withdrawn from the coal,

and with the shovel provided, the first 150mm of coal is removed and discarded. The remainder of the coal down to

the bottom of the Calibration Tube is then dug out and put into an empty plastic bag. This sample of coal should be

labelled with the appropriate sample number and pile name, and kept for ash analysis.

The above procedure should then be repeated when gathering data for further calibration sample points. The user

should aim to collect data for at least 15 calibration sample points, more if several different sources of coal are to be

checked with the Ash Probe System.

IMPORTANT NOTE: It is vital that the date and time stamp are taken from the AshGraffix display unit and added to

the label of the sample to be sent to the lab so that the laboratory derived ash figured can be directly related to

each sample on the display unit so that the plotted calibration graph is correct.

Ash Probe & AshGraffix Overview 11 Issue 1.00

3 DISPLAY UNIT OPERATION

3.1 OVERVIEW

The heart of the Ash Probe is the AshGraffix Display Unit, which contains the main electronics and user interface. The

front panel consists of a 7 inch TFT touch screen display. The side panel consists of a power switch (with built in

green LED indicator) and a LEMO style connector for connecting the probe. This connector is protected by a dust cap

that lifts up on a hinge. This socket is also used to connect a battery charger or the data/PC interface cable. The side

panel also includes a USB (Type A) socket for connecting memory sticks to export data to (or to restore previously

backed up data).

When the unit is powered on, the opening screen will be displayed whilst the system is loaded. Once ready, touch

the screen at any location to move onto the Home screen display.

By default, to save power, the screen will dim after 150 seconds of no activity. After 5 minutes of no activity the

screen will be turned off completely. Touching the screen or, optionally, moving the display unit, will restore the

display to full brightness. These power saving features can be disabled or altered by the user to suit. See Section

Error! Reference source not found. for details).

The text of the display can be configured to be shown in several languages. At the time of publication, this included:

English, Spanish, French, Russian, Turkish, Polish and Vietnamese. Other languages may be added at a later stage.

Ash Probe & AshGraffix Overview 12 Issue 1.00

3.2 HOME SCREEN DISPLAY

When the unit it powered up, the main Home screen display will be shown (after the launch screens have been

displayed), allowing the user to access the main system functions via four touch-screen icons (taking readings,

showing data, exporting data and configuration).

The functions accessed by each icon are described below:

The largest icon gives access to the primary function of taking probe readings. On

pressing the icon, the user is taken to the probe readings pages (Section 3.3).

This displays a graph of the samples collected so far for the currently selected pile or

truck. It also can be used to view graphs for other piles/trucks and also to access the Data

Facilities menu. This provides facilities for viewing the data and allowing samples to be

removed or data to be exported.

This function gives direct access to the Export Data facility, which allows all collected data

to be exported as a spreadsheet file on an external USB memory stick. Data can also be

stored internally on the unit’s own flash memory. A special cable can be used which

allows the internal memory to appear as an eternal disk drive on a computer allowing any

data stored internally to be retrieved.

This function gives access to the system menu, where all other facilities can be accessed

and where the system configuration can be viewed and changed. The Data Facilities and

Export functions can also be accessed from this menu.

Ash Probe & AshGraffix Overview 13 Issue 1.00

This icon is not shown on the home screen but is instead displayed on most other screens, allowing quick

access back to the Home screen from any point in the program menu.

Ash Probe & AshGraffix Overview 14 Issue 1.00

3.3 PROBE READING MAIN SCREEN

This screen is the main screen for the primary function of taking measurements of ash content from piles or trucks.

It is accessed by selecting the large icon on the Home screen display.

On entry it shows the current calculated ash content as the average of all the samples taken for the current pile or

truck.

The main panel on the screen also shows the current Pile or Truck, the number of samples taken so far (for the

selected pile/truck) and the calibration being used.

Below the display panel are three touch screen buttons.

START – Press this button to take a reading. For details see sections 3.5/3.6.

Pile/Truck - Select/Edit the details of the current pile or truck (depending on the mode of operation). Use

this button to set up the pile or truck before taking the sample readings. See sections 3.5 and \3.6for details.

This final touch-screen button is actually the Home key icon, which returns to the Home screen display.

In additional to the information panel and function buttons, the top of the screen features the current time in the

top left corner and the battery life as a percentage display in the top right corner. These two displays are common to

almost all screens in the system.

3.4 MODES OF OPERATION

The display unit is designed to be used in one of two ways depending on the type of readings being taken. One

method is designed to be used with piles of coal where many samples would be taken from a single pile to get a

more accurate average value for the pile. The other is for use with trucks, where deliveries are being made and the

unit will take fewer samples of a particular truck to get the average for that delivery.

3.4.1 PILES MODE

This mode is the default mode of operation and is used where large piles of coal are to be measured. In this mode, it

is more likely that many samples will be taken from each pile to gain a more accurate average of the entire pile.

The system allows the user to define 99 separate piles. Each pile can have up to 99 individual samples/readings and

data can be exported to an external PC by data interface (using the Ash Probe Utility software) or to memory stick.

Ash Probe & AshGraffix Overview 15 Issue 1.00

A user may takes readings from different piles and can switch between selecting different piles to store readings

against at any time.

3.4.2 TRUCKS MODE

This mode is designed to be used at sites where deliveries of coal are made/received by vehicles such as trucks. As

such, the operation of taking samples is slightly different as fewer samples of any truck will be taken due to the

smaller overall size of the associated amount of coal within the truck.

Also, there are likely to be far more trucks that need to be recorded and as such, the system can store the readings

from up to 600 trucks with up to 12 samples for each truck.

When readings are taken, they are all associated with the current truck until the operation is finished. At which

point, the truck data is closed for that particular vehicle and the user must create a completely different truck to

start taking samples from the next vehicle.

3.5 TAKING READINGS IN PILES MODE

The most common way of using the unit is to take readings in piles mode. In this mode, a series of readings should

be taken from all over the pile to determine the average ash content of the entire pile. The more samples taken, the

more accurate the calculated average readings will be.

The first stage in taking a reading or set of readings therefore, is to select and set up the details of the pile to be

measured, so that all readings can be identified at a later stage. Of course, once the pile details have been

entered/selected, then this process does not need to be repeated until a different pile is to be measured.

To set up the pile, press the Pile button on the main screen display to show the Pile To Use screen. From here, a pile

can be selected from the list of the available ones (there are 99 piles available). Use the Up and Down arrow buttons

to either select an empty sot to define the details of a new pile (usually identified by having the name No Name Set)

or an existing pile to which more readings are to be added to. Press Edit when the desired pile is highlighted to

create or change the details of the selected pile.

NOTE: An existing pile can be selected, which can then be re-used for a new pile, deleting the previous samples for the

original pile. This might also be useful when an existing pile is being re-measured at a different date and therefore all

previous readings need to be discarded so as not to affect the new average ash calculation.

Ash Probe & AshGraffix Overview 16 Issue 1.00

The details that can be edited for each pile are:

Name The name of the pile used to identify it to the rest of the program and in the exported data. Touch

the data entry area of the panel to display a QWERTY touch-screen keypad to allow data entry.

Calibration – The calibration created specifically for the source of the coal in the pile to be measured. There

can be up to 100 calibrations to cater for the unit being used with many different coal sources. In many

cases, there will only be a single calibration used for the unit.

In additional to the fields above, the user can also press the Clear Data For This Pile button, which removes the

name and readings previously taken for this pile, effectively returning the pile the pool of unused ones to be used for

new sets of readings.

Once the desired parameters have been set, select the Save button to return to the Piles List and then press Select

to return to the main screen, ensuring that the chosen pile is selected for use.

With the pile set up, the actual readings can now be taken.

3.5.1 INSERTING THE PROBE

IMPORTANT: The probe should be treated as a delicate instrument. Extreme care should be taken when in use and

it should be stored in its carrying case when not in use.

When selecting a location to insert the probe in order to take a reading, bear in mind the following points:

Avoid places that are adjacent to (within 0.5 metres) concrete or brick walls or any other objects. If there is a

concrete floor, ensure that after insertion, the tip of the probe is in excess of 0.5 metre above the ground.

Avoid peninsulas of coal. Select positions on the pile that provide access to the main body of the coal. The

final position of the tip of the probe after insertion should be in excess of 0.5 metre from any coal interface.

Avoid compacted coal where possible. If excessive force is necessary to insert the probe to its required

depth, select another location within the pile or loosen the coal with a spade first.

When inserting the probe, the elevation of the tube should be normal to the surface of the coal. If the

minimum distance above the floor cannot be achieved, the elevation should be modified to achieve this

distance.

Attach the two handles to the probe body and push the probe into the coal to a depth of 600 mm. At this

depth the array of four screws just below the handles should be level with the coal surface. DO NOT USE

ANOTHER IMPLEMENT, SUCH AS A HAMMER TO FORCE THE PROBE INTO THE PILE.

Plug in the cable between the Ash Probe and the Display Unit

Ash Probe & AshGraffix Overview 17 Issue 1.00

3.5.2 TAKING THE READING

Once the probe has been inserted, connected to the display unit and the pile set up, press the START button to take

a reading. This will display the screen as shown below:

The screen is updated each second and continues to update until the unit determines that the signal is stable enough

to be recorded. This is usually determined by the Sigma (standard deviation) figure reaching a user defined minimum

level and the sampling having been active for a minimum of 60 second (a period of less than 60 seconds is not

deemed long enough to get a true figure, even if the variance is minimal).

The updates also can be stopped by user pressing the STOP or Abort buttons or when the maximum reading time has

elapsed. In these cases, the user is asked whether or not to save the reading determined so far (apart from the Abort

button, which abandons the current reading immediately).

The fields displayed are:

Seconds – The number of seconds that the reading has been measured for so far. The user set s a maximum

value that this value can reach after which the reading is stopped if it hasn’t already been stopped by the

Sigma reaching the selected value or the user pressing the Stop or Abort buttons.

Count – The count of pulses detected by the probe for the previous second

Average Count – The average counts per second since the reading was initiated

Sample – The sample number of the current pile that is being read

Ash – The average ash calculated from the calibration set associated with the currently selected pile and the

average counts per second.

Sigma – The standard deviation (square root of the variance) of the readings being taken from the average.

The lower the value, the more stable the readings are. Over time, this value should decrease as the average

becomes more representative. When this value reaches a minimum level, as defined by the user, the reading

is halted as it is deemed stable enough to be representative.

When the reading is complete (through the sigma level being reached, the maximum time having been passed or the

user having pressed the STOP button, the screen below is shown, which gives the user the opportunity to SAVE the

reading or abort without saving, should the reading appear to be invalid or out of kilter with other samples (possibly

due to the probe not being correctly inserted or picking up data from an unrelated source).

Ash Probe & AshGraffix Overview 18 Issue 1.00

Pressing either SAVE or Abort returns the user to the main screen display, where the average ash figure will have

been updated accordingly (if the last reading was saved that is).

3.6 TAKING READINGS IN TRUCKS MODE

The alternative operating mode for the Display Unit is Trucks Mode. This is primarily designed for use when coal

carrying vehicles are being received or dispatched carrying loads.

The big difference between modes is that the user will only be able to take readings for a particular truck at the time

the truck arrives/departs and can only take a limited number (twelve) of samples for any given truck. Once the set of

readings for a vehicle have been completed, then the truck cannot be “selected” in the same way as a pile in order

to add more readings.

In total, there are 600 “slots” for truck data, each having up to 12 samples (as opposed to 99 piles with up to 99

samples each in Piles mode).

The first step to take the samples in this mode is to press the Start button. This will display a pop-up window

prompting the user to set up a new Truck record or to continue saving readings to the currently selected truck

record.

If continuing to add more readings/samples from the same truck, ensure the probe has been placed appropriately

and press Continue. The unit will then start to take the reading as described in section 3.6.3. Prior to pressing the

New button, the probe should be inserted into position reading to take a measurement, as described in section 3.6.2

below.

Ash Probe & AshGraffix Overview 19 Issue 1.00

Selecting New takes the user to a page to set up the details for a new truck, as described below.

3.6.1 SETTING UP A NEW TRUCK RECORD

This page allows the user to enter a Name (or reference number) for the truck, select the set of calibration

coefficients to use and also to clear any previous data held for this record (allowing old records to be reused).

The details that can be edited for each truck are:

Name The name, registration index or other reference number of the truck used to identify it to the rest of

the program and in the exported data. Touch the data entry area of the panel to display a QWERTY touch-

screen keypad to allow data entry.

Calibration – The calibration created specifically for the source of the coal in the truck to be measured.

There can be up to 100 calibrations to cater for the unit being used with many different coal sources. In

many cases, there will only be a single calibration used for the unit.

In additional to the fields above, the user can also press the Clear Data For This Truck button, which removes the

name and readings previously taken for this record, effectively returning the record to the pool of unused ones to be

used for new sets of readings.

Once the desired parameters have been set, select the Save button to continue to take the reading as described in

section 3.6.3.

3.6.2 INSERTING THE PROBE

The probe should be treated as a delicate instrument. Extreme care should be taken when in use and it should be

stored in its carrying case when not in use.

When selecting a location to insert the probe in order to take a reading, bear in mind the following points:

Avoid places that are adjacent to (within 0.5 metre) the sides of the truck or any other objects.

Avoid peninsulas of coal. Select positions on the pile that provide access to the main body of the coal. The

final position of the tip of the probe after insertion should be in excess of 0.5 metre from any coal interface.

Avoid compacted coal where possible. If excessive force is necessary to insert the probe to its required

depth, select another location within the pile or loosen the coal with a spade first.

Ash Probe & AshGraffix Overview 20 Issue 1.00

When inserting the probe, the elevation of the tube should be normal to the surface of the coal. If the

minimum distance above the floor cannot be achieved, the elevation should be modified to achieve this

distance.

Attach the two handles to the probe body and push the probe into the coal to a depth of 600 mm. At this

depth the array of four screws just below the handles should be level with the coal surface.

Plug in the cable between the Ash Probe and the Display Unit

3.6.3 TAKING THE READINGS

Once the probe has been inserted into the coal and the truck record created/selected, then pressing the Save

button on the truck details edit screen or Continue on the Select Truck window, displays the window below and

initiates the first reading.

The screen is updated each second and continues to update until the unit determines that the signal is stable enough

to be recorded. This is usually determined by the Sigma (standard deviation) figure reaching a user defined minimum

level and the sampling having been active for a minimum of 60 second (a period less than 60 seconds is not deemed

long enough to get a true figure, even if the variance is minimal).

The updates also can be stopped by user pressing the STOP or Abort buttons or when the maximum reading time

has elapsed. In these cases, the user is asked whether or not to save the reading determined so far (apart from the

Abort button, which abandons the current reading immediately). The Home key will also abort the current reading

and return to the main Home screen.

The fields displayed are:

Seconds – The number of seconds that the reading has been measured for so far. The user set s a maximum

value that this figure can reach after which the reading is stopped if it hasn’t already been stopped by the

Sigma reaching the selected level or the user pressing the Stop or Abort buttons.

Count – The count of pulses detected by the probe for the previous second

Average Count – The average counts per second since the reading was initiated

Sample – The sample number of the current truck that is being read

Ash – The average ash calculated from the calibration set associated with the currently selected truck and

the average counts per second.

Sigma – The standard deviation (square root of the variance) of the readings being taken from the average.

The lower the value, the more stable the readings are. Over time, this value should decrease as the average

Ash Probe & AshGraffix Overview 21 Issue 1.00

becomes more representative. When this value reaches a minimum level, as defined by the, the reading is

halted as it is deemed stable enough to be representative.

Overall Average Ash – The average ash content calculated from this and any previous readings for the

selected truck.

When the reading is complete (through the sigma level being reached, the maximum time having been passed or the

user having pressed the STOP button, the screen below is shown, which gives the user the opportunity to SAVE the

reading or Discard it without saving should the reading appear to be invalid or out of kilter with other samples

(possibly due to the probe not being correctly inserted or picking up data from an unrelated source). The Abort

button will exit the window without saving the latest reading, although any previous readings will be retained.

Once Save or Discard are pressed, then screen below is shown allowing the user to relocate the probe and take

another reading by pressing REPEAT or to End the collection of readings for this truck and return to the main screen

display.

Ash Probe & AshGraffix Overview 22 Issue 1.00

3.7 DATA DISPLAY

The Data icon on the Home screen display will show the samples graph, which displays the

measured ash for each of the individual samples of the currently selected pile or truck. The graph

will be automatically scaled to cope with the number and range of the samples.

A red line is draw across the graph, which depicts the average ash value based upon all the samples.

The use of a graph allows the user to easily see the range of readings that make up the average and to easily spot

erroneous readings which may be skewing the overall result. These could be the result of foreign material near the

probe at the time of measurement or perhaps the metal of a truck container being detected during the reading.

The Menu facility can be then used to show the samples in a table which allows individual samples to be removed by

the user if deemed to be inappropriate. Returning to the graph page will re-draw the graph with the edited data.

3.7.1 PILE/TRUCK

The Pile or Truck button is used to select a different pile/truck to display the samples for. Scroll bars to the side of

the list of piles/trucks allow the user to move the list and selection if the number of items in the list is too big to

display on the screen.

Ash Probe & AshGraffix Overview 23 Issue 1.00

Pressing the Select button will choose the highlighted item in the list and return to the graph, which will be re-drawn

to show all the samples taken for the selected item.

3.7.2 MENU

The Menu button displays function buttons to allow access to the data display and exporting facilities, including the

ability to export the data to disk or memory stick, list the samples and allow data to be excised and also to show the

overall figures for all piles/or trucks that have been recorded by the device.

3.7.2.1 Save/Export Data

This function is used to export the data from one or all piles/trucks to a USB memory stick or to the internal memory

(which can be read by a PC using a suitable cable).

This function is identical to the Export Data function that can be accessed from the Home screen and is explained in

detail in Section 3.8 of this document.

3.7.2.2 Show Data for All Piles

This function shows a list of all the piles or trucks recorded in the system, showing the overall ash content of each

one.

Ash Probe & AshGraffix Overview 24 Issue 1.00

Each entry in the list shows the name of the pile or truck, the overall ash percentage calculated from the samples

taken for that pile/truck, the variance (Err) between the samples (the lower the number the better), the total

number of samples used to derive the ash figure and the reference number of the set of calibration coefficients used

to perform the calculations.

The Details button is used to show the details of the individual samples taken for the highlighted pile/truck, as

described in Section 3.7.2.3 below.

The Export function allows the data to be exported using the Export Data function as described in section 3.8 below.

If a pile/truck is highlighted, then the Export function will default to only exporting the data for that specific item

(although the user can change this within the function page). If no entry in the list is highlighted, then the Export

function will default to exporting data for all piles/trucks.

3.7.2.3 Show Samples for Current Pile

This page allows the user to view the individual samples for the selected pile/truck.

Each sample that has been recorded for this pile/truck is shown together with the calculated ash percentage for that

figure as well as the base counter per second, recorded by the ash probe and from which the ash is calculated.

Ash Probe & AshGraffix Overview 25 Issue 1.00

The display also shows the actual set of calibration coefficients used to calculate the ash just below the list of

samples.

The name of the pile/truck and the date/time at which the last sample was record is shown at the top of the list.

The functions available on this page are:

Change Pile/Truck – This function displays a list of the piles/trucks recorded by the unit, allowing a different

one to be selected to show the samples for.

Change Calibration – This allows the user to change the set of calibration coefficients used to derive the

individual ash percentages from the recorded counts per second for each sample.

Clear All/Sample – This button allows an individual sample to be removed from the list, for example when it

appears to be an erroneous figure that is skewing the overall average ash figure for the pile/truck. If no

individual sample is highlighted, then this button is used to clear all the samples for that pile/truck, which

allows the pile to re-used, for example when data for a pile is being re-recorded at a later date.

3.8 EXPORT DATA

The Export Data button displays a function page that allows the data from all piles/trucks or a

selected pile or truck to be exported to a USB memory stick or to an internal disk file (which can

be accessed using an optional cable linked to a PC).

Data is exported as a spreadsheet in order to analyse the data offline using a package such as Microsoft ® Excel.

The main data that is exported is the overall ash content reading of each of the piles or trucks. Additionally, the

details of the individual samples that were taken for each pile can be included, as can the details of the sets of

calibration coefficients stored and used to carry out the calculations.

NOTE: Aside from this function, data can be downloaded from the unit using the Ash Probe Utility Software

program for Windows PC computers and the provided data cable. See Section 4 for details.

The format of the exported data is Comma Separated Values format (CSV) file, which can be interpreted by almost

all spreadsheet and database programs.

The fields on the page are as follows:

Ash Probe & AshGraffix Overview 26 Issue 1.00

File Name – The name of the filename to create. Pressing the text entry box will display a QWERTY keyboard

to allow the name to be entered. The name should normally include the file extension .CSV to enable the file

to be easily identified and loaded correctly to other programs. The file will actually be stored in the root

directory of the selected device (memory stick or internal disk).

Include Calibrations - If selected (represented by a green square for the field), then the output file will

contain a table listing all the calibrations and their coefficient values stored in the unit.

Include Samples - If selected, then the details of the individual sample readings used to calculate the overall

average ash content for each pile/truck will be included for each pile in the output file.

Pile(s)/Truck(s) – This selection field determines if data for just one particular pile/truck will be exported or

if data for all the piles/trucks recorded by the unit will be exported.

Internal Disk/Memory Stick – Selects whether the output file will be stored to the unit’s internal memory or

to an external memory stick plugged into the USB port.

Pressing the Save button will create the output file according to the selected parameters.

3.9 PROGRAM MENU

The Configuration/Menu button on the Home screen gives access to all the additional functions

of the unit involved with setup and configuration, accessing and viewing data as well as

maintenance and general information.

The page contains a number of buttons that access the individual configuration and function pages

The individual functions are described in detail in the following chapters, but briefly the functions are:

Data Display/Output- View and export the collected readings for all or individual piles/trucks

Calibrations – Edit the names and coefficients of any of the calibration sets.

Configuration- General configuration functions, including setting the operating mode, interface language,

password access, power save options, clearing data files and other program options.

Test Probe – Diagnostics function that will test a connected probe and help troubleshoot any problems

detected.

Backup/Restore – Save or restore the settings and data from the unit to an internal backup or onto an

external memory stick.

Ash Probe & AshGraffix Overview 27 Issue 1.00

About – Display general information about the program and view contact details for the local

supplier/agent.

Ash Probe & AshGraffix Overview 28 Issue 1.00

4 ASH PROBE UTILITY SOFTWARE

IMPORTANT NOTE: For the very latest information on the Ash Probe Utility Software, consult the user manual on

the installation CD which may be more up to date that the instructions contained within this document.

The Ash Probe Utility, APU, is a software application for use with the Bretby Gammatech Ash Probe and Lab Ash

portable coal quality monitoring systems.

It allows the data recorded by the Display Units to be downloaded to a spreadsheet file for viewing/editing on a PC.

With the AshGraffix systems, the viewing and configuration of the unit’s parameters can also be made using this

utility software.

4.1 PROGRAM DESCRIPTION

The APU software connects to an Ash Probe or Lab Ash Display Unit using a serial communication cable, which allows

data to be passed between the software and the Display Unit.

The cable and software is supplied by Bretby Gammatech as part of the Ash Probe package. The cable itself is either

an RS232 serial cable with a 9 pin D type connector on the computer side or a USB serial cable, which connects

directly from a computer USB port to the AshGraffix Display Unit.

In the case of a USB connector, a suitable software driver is required for the cable, which can be installed when the

application itself is installed. The driver is included on the installation CD and can be installed manually at any later

point if required.

NOTE: When using an RS232 cable, if the computer does not have an RS232 serial port, it will need a USB to RS232

convertor, which will also require a driver to be installed. Please follow the manufacturer’s instructions to install this.

The software allows the computer to interrogate the unit and provide full configuration facilities and also to

download the readings data from the unit and present this in the generic spreadsheet format , Comma Separated

Values (CSV), which can be read by most spreadsheet and database applications.

4.2 PC REQUIREMENTS

The APU software requires a PC with the following minimum specification:

Microsoft Windows XP/Vista/7/8 Operating System

10MB Free Disk Space

1 free USB port or RS232 serial port.

The program also requires Microsoft .Net Framework 3.5 to be installed. This will be downloaded from Microsoft

and installed automatically during the APU software installation if it is not already present on the PC.

If a USB to RS232 serial port convertor is used, then the associated driver for that convertor cable must be installed.

If a USB cable is supplied by Bretby Gammatech, then the driver can be installed during the APU software

installation, where the option is given to install it or the driver can be installed directly from the APU Installation CD

at a later stage.

Some computers running the Windows 7 or 8 operating system may already have the driver installed by default.

Ash Probe & AshGraffix Overview 29 Issue 1.00

Parker Worldwide

Europe, Middle East, Africa HU – Hungary, Budaörs UK – United Kingdom, Warwick

Tel: +36 23 885 470 Tel: +44 (0)1926 317 878

AE – United Arab Emirates, parker.hungary@parker.com parker.uk@parker.com

Dubai

Tel: +971 4 8127100 IE – Ireland, Dublin ZA – South Africa, Kempton Park

parker.me@parker.com Tel: +353 (0)1 466 6370 Tel: +27 (0)11 961 0700

parker.ireland@parker.com parker.southafrica@parker.com

AT – Austria, Wiener Neustadt

Tel: +43 (0)2622 23501-0 IL – Israel

parker.austria@parker.com Tel: +39 02 45 19 21 North America

parker.israel@parker.com CA – Canada, Milton, Ontario

AT – Eastern Europe, Wiener

Neustadt IT – Italy, Corsico (MI) Tel: +1 905 693 3000

Tel: +43 (0)2622 23501 900 Tel: +39 02 45 19 21 US – USA, Cleveland

parker.easteurope@parker.com parker.italy@parker.com Tel: +1 216 896 3000

AZ – Azerbaijan, Baku KZ – Kazakhstan, Almaty

Tel: +994 50 2233 458 Tel: +7 7273 561 000 Asia Pacific

parker.azerbaijan@parker.com parker.easteurope@parker.com

AU – Australia, Castle Hill

BE/LU – Belgium, Nivelles NL – The Netherlands, Oldenzaal Tel: +61 (0)2-9634 7777

Tel: +32 (0)67 280 900 Tel: +31 (0)541 585 000

parker.belgium@parker.com parker.nl@parker.com CN – China, Shanghai

Tel: +86 21 2899 5000

BG – Bulgaria, Sofia NO – Norway, Asker

Tel: +359 2 980 1344 Tel: +47 66 75 34 00 HK – Hong Kong

parker.bulgaria@parker.com parker.norway@parker.com Tel: +852 2428 8008

BY – Belarus, Minsk PL – Poland, Warsaw IN – India, Mumbai

Tel: +48 (0)22 573 24 00 Tel: +48 (0)22 573 24 00 Tel: +91 22 6513 7081-85

parker.poland@parker.com parker.poland@parker.com JP – Japan, Tokyo

CH – Switzerland, Etoy PT – Portugal Tel: +81 (0)3 6408 3901

Tel: +41 (0)21 821 87 00 Tel: +351 22 999 7360 KR – South Korea, Seoul

parker.switzerland@parker.com parker.portugal@parker.com Tel: +82 2 559 0400

CZ – Czech Republic, Klecany RO – Romania, Bucharest MY – Malaysia, Shah Alam

Tel: +420 284 083 111 Tel: +40 21 252 1382 Tel: +60 3 7849 0800

parker.czechrepublic@parker.com parker.romania@parker.com

NZ – New Zealand, Mt Wellington

DE – Germany, Kaarst RU – Russia, Moscow Tel: +64 9 574 1744

Tel: +49 (0)2131 4016 0 Tel: +7 495 645-2156

parker.russia@parker.com SG – Singapore

parker.germany@parker.com

Tel: +65 6887 6300

DK – Denmark, Ballerup SE – Sweden, Spånga

Tel: +46 (0)8 59 79 50 00 TH – Thailand, Bangkok

Tel: +45 43 56 04 00

parker.sweden@parker.com Tel: +662 186 7000

parker.denmark@parker.com

SK – Slovakia, Banská Bystrica TW – Taiwan, Taipei

ES – Spain, Madrid

Tel: +421 484 162 252 Tel: +886 2 2298 8987

Tel: +34 902 330 001

parker.spain@parker.com parker.slovakia@parker.com

FI – Finland, Vantaa SL – Slovenia, Novo Mesto South America

Tel: +358 (0)20 753 2500 Tel: +386 7 337 6650 AR – Argentina, Buenos Aires

parker.finland@parker.com parker.slovenia@parker.com Tel: +54 3327 44 4129

FR – France, Contamine s/Arve TR – Turkey, Istanbul BR – Brazil, Sao Jose dos Campos

Tel: +33 (0)4 50 25 80 25 Tel: +90 216 4997081 Tel: +55 800 727 5374

parker.france@parker.com parker.turkey@parker.com

CL – Chile, Santiago

GR – Greece, Athens UA – Ukraine, Kiev Tel: +56 2 623 1216

Tel: +30 210 933 6450 Tel: +48 (0)22 573 24 00

MX – Mexico, Toluca

parker.greece@parker.com parker.poland@parker.com

Tel: +52 72 2275 4200

© 2017 Parker Hannifin Corporation. All rights reserved. Ash Probe User Manual-Overview Issue 1.00

Parker Hannifin Manufacturing Ltd.

Instrumentation Products Division,

Europe

President Park, President Way

Sheffield S4 7UR

Tel: +44 (0) 114 224 0200

www.parker.com/ipd

You might also like

- IO AB Utrient Cycles: BjectivesDocument7 pagesIO AB Utrient Cycles: BjectivesSalman KhanNo ratings yet

- Management Report On Tesla, Inc.Document7 pagesManagement Report On Tesla, Inc.Naveed IbrahimNo ratings yet

- Pinney, Photography and AnthropologyDocument172 pagesPinney, Photography and AnthropologypinoNo ratings yet

- VibproDocument624 pagesVibproStevanus Silaban100% (3)

- MEDISON SA-9900 Service Manual PDFDocument264 pagesMEDISON SA-9900 Service Manual PDFKhalil Issaad86% (7)

- Manual G36 O2 Analyzer - V.2.04 July 2017Document46 pagesManual G36 O2 Analyzer - V.2.04 July 2017Isidoros100% (3)

- Coinbase ApplicationDocument9 pagesCoinbase ApplicationAnonymous EBNbQRDNo ratings yet

- Red Flags For AutismDocument3 pagesRed Flags For AutismHemant KumarNo ratings yet

- Validation AutoclaveDocument638 pagesValidation AutoclaveWormInch100% (5)

- SURFv1.3 Operator ManualDocument54 pagesSURFv1.3 Operator ManualAli DiabNo ratings yet

- Winscope1000 Global GuideDocument32 pagesWinscope1000 Global GuideGilder GonzalezNo ratings yet

- APRIS Product ManualDocument129 pagesAPRIS Product ManualEswin Paico de la CruzNo ratings yet

- Hydrolux HL 500 Pro H2 1Document30 pagesHydrolux HL 500 Pro H2 1muhammad adibNo ratings yet

- MX300 E-Manual PDFDocument148 pagesMX300 E-Manual PDFRazaleigh Mohd AminNo ratings yet

- User Manual For Opacity MeterDocument25 pagesUser Manual For Opacity MeterEryf ADRNo ratings yet

- Presostato HEDEDocument48 pagesPresostato HEDEMoLNo ratings yet

- Aphex 320a ManualDocument41 pagesAphex 320a ManualfacebNo ratings yet

- Spider 8 User ManualDocument34 pagesSpider 8 User ManualJacob MillerNo ratings yet

- Powershift V2: Manual Resistance Installation GuidelineDocument27 pagesPowershift V2: Manual Resistance Installation GuidelinedklnfsdNo ratings yet

- HTV M ManualDocument40 pagesHTV M ManualmehdiNo ratings yet

- WorldCast Horizon Manual v2.0 - A4Document85 pagesWorldCast Horizon Manual v2.0 - A4Vincent MNo ratings yet

- User'S Manual: Surf-Amf Auto Start - Surf-Auto EnhancedDocument48 pagesUser'S Manual: Surf-Amf Auto Start - Surf-Auto EnhancedBelghennou Hadj AliNo ratings yet

- SmartCEM OPS BDocument38 pagesSmartCEM OPS BLeo MaximoNo ratings yet

- Canon BJC-8200 Service Manual PDFDocument105 pagesCanon BJC-8200 Service Manual PDFDuplessisNo ratings yet

- Bacharach MGS-408 - ManualDocument43 pagesBacharach MGS-408 - ManualChris DNo ratings yet

- Users GuideDocument70 pagesUsers GuideCARLOS100% (1)

- BlastCam Operations Manual PDFDocument64 pagesBlastCam Operations Manual PDFlxo08No ratings yet

- R423 Manual PDFDocument128 pagesR423 Manual PDFmanikandanNo ratings yet

- 98 Spartan-Controls Net-Oil Product DocumentDocument108 pages98 Spartan-Controls Net-Oil Product DocumentCarlos WotchoskiNo ratings yet

- Philips PM3380 Users ManualDocument297 pagesPhilips PM3380 Users ManualDRF2540% (1)

- RV Heincke ADCP Support 600kHzDocument22 pagesRV Heincke ADCP Support 600kHzJainner Salcedo SanchezNo ratings yet

- Uritek-720 Plus: Operator's ManualDocument41 pagesUritek-720 Plus: Operator's ManualHoang Nhi TranNo ratings yet

- Solids Control Programs: SchlumbergerDocument10 pagesSolids Control Programs: SchlumbergerMarkus LandingtonNo ratings yet

- SM Sa9900 V1.0 (E)Document277 pagesSM Sa9900 V1.0 (E)namNo ratings yet

- UNIPHOS FumiSense Pro PH3 0 2000 PPM MKII HIGH PDFDocument25 pagesUNIPHOS FumiSense Pro PH3 0 2000 PPM MKII HIGH PDFraushan mishraNo ratings yet

- Air SamplerDocument42 pagesAir SamplerKuldeepNo ratings yet

- PDK 204979 Software Aipex Pro v3 enDocument827 pagesPDK 204979 Software Aipex Pro v3 enggntb64fckNo ratings yet

- Filehost - Canon Fax L350 Service ManualDocument213 pagesFilehost - Canon Fax L350 Service ManualvNo ratings yet

- Linux As Assmebler CompilerDocument252 pagesLinux As Assmebler CompilerLuis D'ArdisNo ratings yet

- Maxtest SoftwareDocument47 pagesMaxtest SoftwareGMAR Comercializadora100% (1)

- DPA5 User Manual PDFDocument42 pagesDPA5 User Manual PDFcleverson ferreira100% (2)

- MSP 34x0G Multistandard Sound Processor Family: MicronasDocument106 pagesMSP 34x0G Multistandard Sound Processor Family: MicronasasistekNo ratings yet

- AMKASYN Device Description Controller Card KW-R06Document47 pagesAMKASYN Device Description Controller Card KW-R06Isao TomitaNo ratings yet

- 2016-06-30 PB-Inspektor NT Manual Revision 1Document42 pages2016-06-30 PB-Inspektor NT Manual Revision 1Pablo CelisNo ratings yet

- Teledyne EchoTrac E20 ManualDocument60 pagesTeledyne EchoTrac E20 ManuallazarusNo ratings yet

- PROFIBUS Fieldbus Coupler MVS3007Document114 pagesPROFIBUS Fieldbus Coupler MVS3007Diego MontanezNo ratings yet

- APC Portable Airborne Particle Counter: Operations Manual Version 2.01Document50 pagesAPC Portable Airborne Particle Counter: Operations Manual Version 2.01Juan Alejandro Cañas ColoradoNo ratings yet

- Sas Super 100 - Sas Super 180 Duo Sas Super 360: Instruction ManualDocument54 pagesSas Super 100 - Sas Super 180 Duo Sas Super 360: Instruction ManualDANIEL DOMINGUEZNo ratings yet

- Edacs 500M Radio Flash SoftwareDocument8 pagesEdacs 500M Radio Flash SoftwareViorel AldeaNo ratings yet

- Hitachi 917 Analyzer - User ManualDocument406 pagesHitachi 917 Analyzer - User Manualmylove2804100% (1)

- XCMG Iflex5 Operators ManualDocument69 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- Ancortek Manual V1.0 20150601Document21 pagesAncortek Manual V1.0 20150601Wesley GeorgeNo ratings yet

- MSP 44x0G Multistandard Sound Processor Family: MicronasDocument100 pagesMSP 44x0G Multistandard Sound Processor Family: MicronasAntonio AscanioNo ratings yet

- Aoc Le32a1330-61 Le40a1330-61 LCD TV PDFDocument87 pagesAoc Le32a1330-61 Le40a1330-61 LCD TV PDFtrietNo ratings yet

- M070010 Gasmaster III Manual Issue 2 UKDocument48 pagesM070010 Gasmaster III Manual Issue 2 UKPhạm Thế Hiệp100% (1)

- Canon mp730 - 700-smDocument167 pagesCanon mp730 - 700-smRon FultonNo ratings yet

- Sat - 33.Pdf - Recognition and Listing of Acute Stroke Progression Based On Oct Images Using Curvelet AnalysisDocument11 pagesSat - 33.Pdf - Recognition and Listing of Acute Stroke Progression Based On Oct Images Using Curvelet AnalysisVj KumarNo ratings yet

- GC Application Module For FB107Document52 pagesGC Application Module For FB107Mohammad Asif ZakriyyaNo ratings yet

- Pour Point Analyzer MPP 5GDocument102 pagesPour Point Analyzer MPP 5GimunNo ratings yet

- I Step 1 1 0 Global GuideDocument28 pagesI Step 1 1 0 Global GuideMahmoud SadikNo ratings yet

- Installation and Operating Manual FMTB 5000 Test Bench: 0.5 - 5000 m3 / HDocument36 pagesInstallation and Operating Manual FMTB 5000 Test Bench: 0.5 - 5000 m3 / HDaniel Oscar100% (1)

- Nt-Converter 1.5.0 Global GuideDocument14 pagesNt-Converter 1.5.0 Global GuideFanni Smidéliusz-OláhNo ratings yet

- Sudt Accessport Advanced Terminal / Monitor / Debugger Version 1.37 User ManualDocument53 pagesSudt Accessport Advanced Terminal / Monitor / Debugger Version 1.37 User ManualAlberto AvilaNo ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- HospitalDocument18 pagesHospitalJeffrey ViernesNo ratings yet

- Passion in EntrepreneurshipDocument12 pagesPassion in EntrepreneurshipCharisse WooNo ratings yet

- Makalah Huawei Learning Cloud User GuidDocument45 pagesMakalah Huawei Learning Cloud User GuidhazirafatmarinaNo ratings yet

- Preliminary Considerations Property v. Things: Real or ImmovableDocument8 pagesPreliminary Considerations Property v. Things: Real or ImmovableSZNo ratings yet

- 4 - Hydraulic Power Supply 2006-SeptDocument39 pages4 - Hydraulic Power Supply 2006-SeptПавел ШиряевNo ratings yet

- Technical Report Writing in The Maritime & Offshore IndustryDocument4 pagesTechnical Report Writing in The Maritime & Offshore IndustryIke MaduforoNo ratings yet

- Conformity (Majority Influence)Document11 pagesConformity (Majority Influence)Camille FernandezNo ratings yet

- Johnrey For Demo DLPDocument8 pagesJohnrey For Demo DLPmelany r. malvarosaNo ratings yet

- TC2971en-Ed01 Installation Procedure For OmniVista8770 R5.0.24.00Document88 pagesTC2971en-Ed01 Installation Procedure For OmniVista8770 R5.0.24.00K Mei.No ratings yet

- Aggravating CircumstanceDocument4 pagesAggravating CircumstanceMindalyn Muring AripNo ratings yet

- NMax Application DataDocument4 pagesNMax Application DataKenneth T. Guillermo0% (1)

- LBO ModelingDocument66 pagesLBO Modelingalexander ThielNo ratings yet