Professional Documents

Culture Documents

AISC Table-2

AISC Table-2

Uploaded by

Sakthi VasuCopyright:

Available Formats

You might also like

- Washer - Sizing - Chart - 12.16 Feltros de TrompeteDocument4 pagesWasher - Sizing - Chart - 12.16 Feltros de TrompeteLuciano AlvesNo ratings yet

- Fishing Tools For 12 and A Quarter HoleDocument1 pageFishing Tools For 12 and A Quarter Holehamid100% (1)

- BluestemLowMandoPlanFree PDFDocument1 pageBluestemLowMandoPlanFree PDFRoberthe NichanNo ratings yet

- Bolt Sizes & Length For Spade and DespadeDocument6 pagesBolt Sizes & Length For Spade and DespadeŠhiññ Šóhäï100% (1)

- (Woodworking) Workbench - Woodworking Plans - Workbench - Popular Mechanics - Hard Maple PDFDocument7 pages(Woodworking) Workbench - Woodworking Plans - Workbench - Popular Mechanics - Hard Maple PDFAntonio CompanyNo ratings yet

- 26 Manuals 3338, Anti-Aircraft Ammunition PDFDocument129 pages26 Manuals 3338, Anti-Aircraft Ammunition PDFKosta_g100% (1)

- 7 Grating PDFDocument2 pages7 Grating PDFSathish KumarNo ratings yet

- 7 Grating PDFDocument2 pages7 Grating PDFKomedianTunggalNo ratings yet

- AISC Important TablesDocument1 pageAISC Important TablesRavi Lohar100% (1)

- "Om-1" Kickover Tool: The "OM-1" Kickover Tool Is Used To Install and Retrieve Devices in 1 1/2" Side Pocket MandrelsDocument1 page"Om-1" Kickover Tool: The "OM-1" Kickover Tool Is Used To Install and Retrieve Devices in 1 1/2" Side Pocket MandrelsEdwin AbelloNo ratings yet

- Grate Frame Detail PDFDocument1 pageGrate Frame Detail PDFKreen132No ratings yet

- Envelope Size Chart: Standard BookletDocument1 pageEnvelope Size Chart: Standard BookletAkshay GatkalNo ratings yet

- Item Codigo Tipo de Ángulo Elemento CantidadDocument2 pagesItem Codigo Tipo de Ángulo Elemento CantidadJose Valdez NeyraNo ratings yet

- D 4358 - Duchesne - Depliant Treillis Et Barres Armature - Rev 10Document8 pagesD 4358 - Duchesne - Depliant Treillis Et Barres Armature - Rev 10Nikola MNo ratings yet

- Cameron Dual Bore RamsDocument1 pageCameron Dual Bore Ramsfarhad2004No ratings yet

- Catalogue Fasteners V2 OnlineDocument60 pagesCatalogue Fasteners V2 OnlineimsyndNo ratings yet

- MBMA-2012 (Section - Fabrication Tolerances)Document5 pagesMBMA-2012 (Section - Fabrication Tolerances)Phung - P. QC Phan MinhNo ratings yet

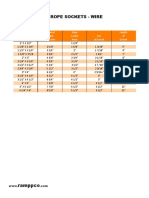

- Rope Socket DimensionsDocument1 pageRope Socket DimensionsmeryNo ratings yet

- Squareness MeasurementDocument1 pageSquareness Measurementgrd4No ratings yet

- Anexo B Ficha Técnica Caja Metalica 4X4 (CJ44)Document1 pageAnexo B Ficha Técnica Caja Metalica 4X4 (CJ44)Yandripm MenendezNo ratings yet

- Technical Services Digest November 2002Document3 pagesTechnical Services Digest November 2002pghasaeiNo ratings yet

- DCI StencilsDocument2 pagesDCI Stencilsprudvi100% (2)

- Equivalencias ElectromallaDocument2 pagesEquivalencias ElectromallaCésar Aguilar100% (1)

- CDR Tee StrainersDocument2 pagesCDR Tee StrainersM JohnNo ratings yet

- Tabel MurbautDocument1 pageTabel MurbautPrayoga AriNo ratings yet

- L3513 ModelRA-A FSDocument2 pagesL3513 ModelRA-A FSexpert1970No ratings yet

- Instructivo de Madera VerticalDocument5 pagesInstructivo de Madera VerticalGilmer Alarcon CañariNo ratings yet

- Grating AceroGrillDocument9 pagesGrating AceroGrillRafaelNo ratings yet

- Core-Type Junk Basket: When Ordering, Please SpecifyDocument2 pagesCore-Type Junk Basket: When Ordering, Please SpecifyBehrangNo ratings yet

- AMICO - Grating Stair Tread SectionDocument12 pagesAMICO - Grating Stair Tread SectionwijayanataNo ratings yet

- STC Rating Chart PDFDocument1 pageSTC Rating Chart PDFtroyel99No ratings yet

- Kant-Twist Clamps: Specifications SheetDocument3 pagesKant-Twist Clamps: Specifications SheetOmegacoolNo ratings yet

- UHMW Channel Profiles 2018Document2 pagesUHMW Channel Profiles 2018Jorge ArbelaezNo ratings yet

- Cementing ToolsDocument107 pagesCementing Toolswalter acero orpesaNo ratings yet

- Basket Sub-Product SheetDocument1 pageBasket Sub-Product SheetBehrangNo ratings yet

- 7 4GratingTreadDocument1 page7 4GratingTreadTanja DjordjevicNo ratings yet

- Tapping and Drilling ChartDocument3 pagesTapping and Drilling ChartChris HeydenrychNo ratings yet

- Minimum Bolt Tension Per AISC 360-16, Table J3.1: Bolt Diameter, In. A325 Bolts A490 BoltsDocument2 pagesMinimum Bolt Tension Per AISC 360-16, Table J3.1: Bolt Diameter, In. A325 Bolts A490 Boltsrob westoverNo ratings yet

- Key Steel Tolerances and Standards: Imperial (Inches)Document3 pagesKey Steel Tolerances and Standards: Imperial (Inches)Steven GerrardNo ratings yet

- Dremel 2012AccessoryPosterDocument1 pageDremel 2012AccessoryPosterwdowiuueNo ratings yet

- Drillstar Roller ReamerDocument2 pagesDrillstar Roller ReamerLOURIDOMICHELLENo ratings yet

- FMSI Tube Nut FlyerDocument2 pagesFMSI Tube Nut FlyerBillNo ratings yet

- Engineering Keys and Pins Boksburg South AfricaDocument15 pagesEngineering Keys and Pins Boksburg South AfricaCorneNo ratings yet

- 6064 - Catalog - PB-1.4 February 2006Document4 pages6064 - Catalog - PB-1.4 February 2006Alfonso López JiménezNo ratings yet

- Doron PVC WaterstopDocument3 pagesDoron PVC WaterstopSharmine AnibNo ratings yet

- Linear Bar GrillesDocument7 pagesLinear Bar GrillesmpwasaNo ratings yet

- Insulflex SizeDocument1 pageInsulflex SizeAnonymous ItzBhUGoiNo ratings yet

- Gland Spec.Document9 pagesGland Spec.Muthuvel GaneshNo ratings yet

- AB ClipsDocument1 pageAB ClipsARJONA_JGNo ratings yet

- Misura Tavolo LavoroDocument4 pagesMisura Tavolo LavoroCarlo N CastellanoNo ratings yet

- Astm A325 & A490 Bolts & NutsDocument6 pagesAstm A325 & A490 Bolts & NutsagusfitriyadiNo ratings yet

- Typical Single Plate Connection Schedule 7 Typical Double Angle Connection Schedule 8Document1 pageTypical Single Plate Connection Schedule 7 Typical Double Angle Connection Schedule 8Ravi LoharNo ratings yet

- Sandvik Rotary Tools: Drill String Components by RigDocument40 pagesSandvik Rotary Tools: Drill String Components by Rigwalther alcocer100% (1)

- Dremel Bit PosterDocument1 pageDremel Bit PosterPhil BooeNo ratings yet

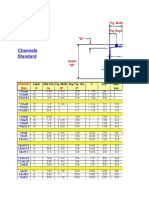

- ChannelsDocument4 pagesChannelsjcNo ratings yet

- Material List Summary Kitchen Cabinet (4-20-2024)Document2 pagesMaterial List Summary Kitchen Cabinet (4-20-2024)proengineer415No ratings yet

- 7.beam & Slab ScheduleDocument1 page7.beam & Slab ScheduleSoe Soe MonNo ratings yet

- Fishing Tools For 17 and Half Inch HoleDocument2 pagesFishing Tools For 17 and Half Inch Holehamid0% (1)

- Cabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsFrom EverandCabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsRating: 5 out of 5 stars5/5 (2)

- TIM WebSB Strip Flat BarDocument3 pagesTIM WebSB Strip Flat BarSakthi VasuNo ratings yet

- UntitledDocument3 pagesUntitledSakthi VasuNo ratings yet

- Rectangular and Square HSS Venting - American Galvanizers AssociationDocument4 pagesRectangular and Square HSS Venting - American Galvanizers AssociationSakthi VasuNo ratings yet

- Walkie Talkie - 10 Codes - CommUSADocument1 pageWalkie Talkie - 10 Codes - CommUSASakthi VasuNo ratings yet

- Slide FlexusDocument13 pagesSlide FlexusAmin SanimanNo ratings yet

- 6 Inclusion Strategies For Students With Autism Spectrum DisordersDocument8 pages6 Inclusion Strategies For Students With Autism Spectrum Disordersapi-268598032No ratings yet

- Flame Retardant For TextilesDocument23 pagesFlame Retardant For TextilesimranchemiNo ratings yet

- Words of PleasureDocument211 pagesWords of PleasureallendraNo ratings yet

- Compensatory Mechanism of Circulatory ShockDocument29 pagesCompensatory Mechanism of Circulatory ShockWan Razin Wan Hassan100% (1)

- CIS Electrical Standard Rev 001Document46 pagesCIS Electrical Standard Rev 001Tarek AbulailNo ratings yet

- Msds en Shell Tellus s2 M 68Document15 pagesMsds en Shell Tellus s2 M 68Debora Septania PurbaNo ratings yet

- Synopsis: Rajiv Gandhi University of Health Sciences Karnataka State, BangaloreDocument17 pagesSynopsis: Rajiv Gandhi University of Health Sciences Karnataka State, BangaloreSANANo ratings yet

- TC PRR021 51309288 225 DatasheetDocument133 pagesTC PRR021 51309288 225 DatasheetSalim MohamedNo ratings yet

- Ibadan - Nigeria - Reconnaissance - Visit - KopieDocument10 pagesIbadan - Nigeria - Reconnaissance - Visit - KopieAgung BudiantoNo ratings yet

- Nursing Care of The Client With High-Risk Labor and DeliveryDocument23 pagesNursing Care of The Client With High-Risk Labor and DeliveryMarie Ashley CasiaNo ratings yet

- The Miracle Plant Kalanchoe Pinnata A PhytochemicaDocument6 pagesThe Miracle Plant Kalanchoe Pinnata A PhytochemicaAboli GhateNo ratings yet

- Electrical Troubleshooting VespaDocument19 pagesElectrical Troubleshooting VespaMuch Abdulah NurhidayatNo ratings yet

- Design of Material Handling System For SpecificDocument14 pagesDesign of Material Handling System For SpecificKaran Virbhadre100% (3)

- Gun Water PDFDocument4 pagesGun Water PDFAlejandro MontecilloNo ratings yet

- 12.4 Voluntary & Involuntary Action, 12.6 Endocrine System - Google FormsDocument7 pages12.4 Voluntary & Involuntary Action, 12.6 Endocrine System - Google FormsHAJAR LENNo ratings yet

- Peroxide Cure of RubberDocument19 pagesPeroxide Cure of RubberVivek RainaNo ratings yet

- Antenatal HandoutDocument16 pagesAntenatal HandoutZahNo ratings yet

- ASTM E 1444 11 MT Magnetic Particle TestingDocument21 pagesASTM E 1444 11 MT Magnetic Particle TestingeliuNo ratings yet

- Exercise Test Weight Reps Set Interval Tonnage Cutoff 1Rm 5Rm Squat Bench Row Press Deadlift Smallest Plates Available Match Prs in Week #Document7 pagesExercise Test Weight Reps Set Interval Tonnage Cutoff 1Rm 5Rm Squat Bench Row Press Deadlift Smallest Plates Available Match Prs in Week #Chelsea ClarkNo ratings yet

- Calculos Torre de AireacionDocument8 pagesCalculos Torre de AireacionMonica Alexandra Rueda RamirezNo ratings yet

- Lung AbscessDocument28 pagesLung AbscessBobet ReñaNo ratings yet

- Mapping Kemuning 1 - 2 Maret 2023Document1 pageMapping Kemuning 1 - 2 Maret 2023josephNo ratings yet

- Pathology Lecture 2, Cell Injury (Notes/tafree3')Document18 pagesPathology Lecture 2, Cell Injury (Notes/tafree3')Ali Al-Qudsi100% (3)

- RLO CableDocument1 pageRLO CableLeiden O'SullivanNo ratings yet

- Sem - Ii Pharmacology Lab ManualDocument36 pagesSem - Ii Pharmacology Lab ManualLokesh MahataNo ratings yet

- Basic Offshore Safety Induction and Emergency Training: CtsiDocument72 pagesBasic Offshore Safety Induction and Emergency Training: Ctsiangel coazoNo ratings yet

- Life Cycle of FunariaDocument3 pagesLife Cycle of FunariaPalash Ghosh100% (1)

- Leavening Agents Lab ReportDocument5 pagesLeavening Agents Lab Reportapi-340581896100% (2)

AISC Table-2

AISC Table-2

Uploaded by

Sakthi VasuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISC Table-2

AISC Table-2

Uploaded by

Sakthi VasuCopyright:

Available Formats

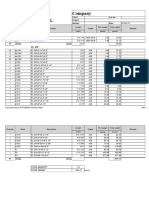

Minimum Bolt Rows Column Web Gages Minimum Edge Distance for Standard Round Holes

W6 1 Nominal Depth Gage Bolt Diameter 1/2" 5/8" 3/4" 7/8" 1" 1 1/8" 1 1/4" Over 1 1/4"

W8, W10, W12 2 W6 * 2 1/2" Sheared Edge 7/8" 1 1/8" 1 1/4" 1 1/2" * 1 3/4" * 2" 2 1/4" 1 3/4 x Bolt Diameter

W14, W16, W18 3 W8 * 3 1/2" Rolled or Gas Cut Edge 3/4" 7/8" 1" 1 1/8" 1 1/4" 1 1/2" 1 5/8" 1 1/4 x Bolt Diameter

W21, W24 4 W10 4 1/2" * These may be 1 1/4" at the ends of beam connection angles.

W27, W30 5 W12 and Larger 5 1/2" All edges that are rolled or gas cut may be reduced by 1/8" when the hole is at a point where stress does

W33, W36 6 * Flange holes must be staggered not exceed 25% of the maximum allowed stress.

from the web holes

Maximum Bolt Rows @ 3" Spacing Usual Gages for Angles

W6 1 Usual Gages for Channels Le g 8" 7" 6" 5" 4" 3 1/2" 3" 2 1/2" 2" 1 3/4" 1 1/2" 1 3/8" 1 1/4" 1"

W8, W10 2 Channel Size Usual Gage g 4 1/2" 4" 3 1/2" 3" 2 1/2" 2" 1 3/4" 1 3/8" 1 1/8" 1" 7/8" 7/8" 3/4" 5/8"

W12, W14 3 C15x50 2 1/4" g1 3" 2 1/2" 2 1/4" 2"

W16 4 C15x40 2" g2 3" 3" 2 1/2" 1 3/4"

W18 5 C15x33.9 2"

W21 6 C12x30 1 3/4" Nominal Hole Dimensions

W24 7 C12x25 1 3/4" Hole Dimensions

W27 8 C12x20.7 1 3/4" Bolt Diameter Short-Slot Long-Slot

Standard Diameter Oversized Diameter

W30 9 C10x30 1 3/4" (Width x Length) (Width x Length)

W33, W36 10 C10x25 1 3/4" 1/2" 9/16" 5/8" 9/16" x 11/16" 9/16" x 1 1/4"

C10x20 1 1/2" 5/8" 11/16" 13/16" 11/16" x 7/8" 11/16" x 1 9/16"

Anchor Bolt Hole Oversize C10x15.3 1 1/2" 3/4" 13/16" 15/16" 13/16" x 1" 13/16" x 1 7/8"

3/4" Diameter 9/16" C9x20 1 1/2" 7/8" 15/16" 1 1/16" 15/16" x 1 1/8" 15/16" x 2 3/16"

7/8" Diameter 111 /16" C9x15 1 3/8" 1" 1 1/16" 1 1/4" 1 1/16" x 1 5/16" 1 1/16" x 2 1/2"

Over 1" Diameter 13/16" C9x13.4 1 3/8" 1 1/8" and Larger Diameter + 1/16" Diameter + 5/16" (d+1/16") x (d+3/8") (d+1/16) x (dx2.5)

C8x18.75 1 1/2"

AWS/AISC Minimum Weld Size C8x13.75 1 3/8" Minimum Radius for Cold Bending

*Thicker/Thinner Part Weld Size C8x11.5 1 3/8" Thickness

ASTM Designation

To 1/4" Inclusive 1/8" C7x14.75 1 1/4" Up to 1/4" Over 1/4" to 1/2" Over 1/2" to 1" Over 1" to 1 1/2" Over 1 1/2" to 2"

Over 1/4" to 1/2" 3/16" C7x12.25 1 1/4" A36 1 1/2 x Thickness 1 1/2 x Thickness 2 x Thickness 3 x Thickness 4 x Thickness

Over 1/2" to 3/4" 1/4" C7x9.8 1 1/4" A572-50 2 1/2 x Thickness 2 1/2 x Thickness 4 x Thickness -a -a

Over 3/4" to 1 1/2" 5/16" C6x13 1 3/8" a

It is recommended that steel in this thickness range be bent hot. Hot bending, however, may result in a decrease in the as-rolled mechanical

Over 1 1/2" to 2 1/4" 3/8" C6x10.5 1 1/8"

properties.

Over 2 1/4" to 6" 1/2" C6x8.2 1 1/8"

Over 6" 5/8" C5x9 1 1/8"

* Thicker per 3rd and 9th edition C5x6.7 - Values of Edge Distance Increment Increase

* Thinner per 13th edition & AWS C4x7.25 1" Slotted Holes

Nominal Diameter of

C4x5.4 - Oversized Holes Perpendicular to Edge

Fastener Parallel to Edge

Usual Beam Gages C3x6 - Short Slots Long Slots

Flange Width Gage C3x5 - 7/8" and less 1/16" 1/8"

4" 2 1/4" C3x4.1 - 1" 1/8" 1/8" 3/4 d 0

4 1/16" to 6" 2 3/4" 1 1/8" and greater 1/8" 3/16"

6 1/16" to 7 15/16" 3 1/2"

8" and up 5 1/2"

ANCHOR ROD HOLES IN BASE PLATES

You might also like

- Washer - Sizing - Chart - 12.16 Feltros de TrompeteDocument4 pagesWasher - Sizing - Chart - 12.16 Feltros de TrompeteLuciano AlvesNo ratings yet

- Fishing Tools For 12 and A Quarter HoleDocument1 pageFishing Tools For 12 and A Quarter Holehamid100% (1)

- BluestemLowMandoPlanFree PDFDocument1 pageBluestemLowMandoPlanFree PDFRoberthe NichanNo ratings yet

- Bolt Sizes & Length For Spade and DespadeDocument6 pagesBolt Sizes & Length For Spade and DespadeŠhiññ Šóhäï100% (1)

- (Woodworking) Workbench - Woodworking Plans - Workbench - Popular Mechanics - Hard Maple PDFDocument7 pages(Woodworking) Workbench - Woodworking Plans - Workbench - Popular Mechanics - Hard Maple PDFAntonio CompanyNo ratings yet

- 26 Manuals 3338, Anti-Aircraft Ammunition PDFDocument129 pages26 Manuals 3338, Anti-Aircraft Ammunition PDFKosta_g100% (1)

- 7 Grating PDFDocument2 pages7 Grating PDFSathish KumarNo ratings yet

- 7 Grating PDFDocument2 pages7 Grating PDFKomedianTunggalNo ratings yet

- AISC Important TablesDocument1 pageAISC Important TablesRavi Lohar100% (1)

- "Om-1" Kickover Tool: The "OM-1" Kickover Tool Is Used To Install and Retrieve Devices in 1 1/2" Side Pocket MandrelsDocument1 page"Om-1" Kickover Tool: The "OM-1" Kickover Tool Is Used To Install and Retrieve Devices in 1 1/2" Side Pocket MandrelsEdwin AbelloNo ratings yet

- Grate Frame Detail PDFDocument1 pageGrate Frame Detail PDFKreen132No ratings yet

- Envelope Size Chart: Standard BookletDocument1 pageEnvelope Size Chart: Standard BookletAkshay GatkalNo ratings yet

- Item Codigo Tipo de Ángulo Elemento CantidadDocument2 pagesItem Codigo Tipo de Ángulo Elemento CantidadJose Valdez NeyraNo ratings yet

- D 4358 - Duchesne - Depliant Treillis Et Barres Armature - Rev 10Document8 pagesD 4358 - Duchesne - Depliant Treillis Et Barres Armature - Rev 10Nikola MNo ratings yet

- Cameron Dual Bore RamsDocument1 pageCameron Dual Bore Ramsfarhad2004No ratings yet

- Catalogue Fasteners V2 OnlineDocument60 pagesCatalogue Fasteners V2 OnlineimsyndNo ratings yet

- MBMA-2012 (Section - Fabrication Tolerances)Document5 pagesMBMA-2012 (Section - Fabrication Tolerances)Phung - P. QC Phan MinhNo ratings yet

- Rope Socket DimensionsDocument1 pageRope Socket DimensionsmeryNo ratings yet

- Squareness MeasurementDocument1 pageSquareness Measurementgrd4No ratings yet

- Anexo B Ficha Técnica Caja Metalica 4X4 (CJ44)Document1 pageAnexo B Ficha Técnica Caja Metalica 4X4 (CJ44)Yandripm MenendezNo ratings yet

- Technical Services Digest November 2002Document3 pagesTechnical Services Digest November 2002pghasaeiNo ratings yet

- DCI StencilsDocument2 pagesDCI Stencilsprudvi100% (2)

- Equivalencias ElectromallaDocument2 pagesEquivalencias ElectromallaCésar Aguilar100% (1)

- CDR Tee StrainersDocument2 pagesCDR Tee StrainersM JohnNo ratings yet

- Tabel MurbautDocument1 pageTabel MurbautPrayoga AriNo ratings yet

- L3513 ModelRA-A FSDocument2 pagesL3513 ModelRA-A FSexpert1970No ratings yet

- Instructivo de Madera VerticalDocument5 pagesInstructivo de Madera VerticalGilmer Alarcon CañariNo ratings yet

- Grating AceroGrillDocument9 pagesGrating AceroGrillRafaelNo ratings yet

- Core-Type Junk Basket: When Ordering, Please SpecifyDocument2 pagesCore-Type Junk Basket: When Ordering, Please SpecifyBehrangNo ratings yet

- AMICO - Grating Stair Tread SectionDocument12 pagesAMICO - Grating Stair Tread SectionwijayanataNo ratings yet

- STC Rating Chart PDFDocument1 pageSTC Rating Chart PDFtroyel99No ratings yet

- Kant-Twist Clamps: Specifications SheetDocument3 pagesKant-Twist Clamps: Specifications SheetOmegacoolNo ratings yet

- UHMW Channel Profiles 2018Document2 pagesUHMW Channel Profiles 2018Jorge ArbelaezNo ratings yet

- Cementing ToolsDocument107 pagesCementing Toolswalter acero orpesaNo ratings yet

- Basket Sub-Product SheetDocument1 pageBasket Sub-Product SheetBehrangNo ratings yet

- 7 4GratingTreadDocument1 page7 4GratingTreadTanja DjordjevicNo ratings yet

- Tapping and Drilling ChartDocument3 pagesTapping and Drilling ChartChris HeydenrychNo ratings yet

- Minimum Bolt Tension Per AISC 360-16, Table J3.1: Bolt Diameter, In. A325 Bolts A490 BoltsDocument2 pagesMinimum Bolt Tension Per AISC 360-16, Table J3.1: Bolt Diameter, In. A325 Bolts A490 Boltsrob westoverNo ratings yet

- Key Steel Tolerances and Standards: Imperial (Inches)Document3 pagesKey Steel Tolerances and Standards: Imperial (Inches)Steven GerrardNo ratings yet

- Dremel 2012AccessoryPosterDocument1 pageDremel 2012AccessoryPosterwdowiuueNo ratings yet

- Drillstar Roller ReamerDocument2 pagesDrillstar Roller ReamerLOURIDOMICHELLENo ratings yet

- FMSI Tube Nut FlyerDocument2 pagesFMSI Tube Nut FlyerBillNo ratings yet

- Engineering Keys and Pins Boksburg South AfricaDocument15 pagesEngineering Keys and Pins Boksburg South AfricaCorneNo ratings yet

- 6064 - Catalog - PB-1.4 February 2006Document4 pages6064 - Catalog - PB-1.4 February 2006Alfonso López JiménezNo ratings yet

- Doron PVC WaterstopDocument3 pagesDoron PVC WaterstopSharmine AnibNo ratings yet

- Linear Bar GrillesDocument7 pagesLinear Bar GrillesmpwasaNo ratings yet

- Insulflex SizeDocument1 pageInsulflex SizeAnonymous ItzBhUGoiNo ratings yet

- Gland Spec.Document9 pagesGland Spec.Muthuvel GaneshNo ratings yet

- AB ClipsDocument1 pageAB ClipsARJONA_JGNo ratings yet

- Misura Tavolo LavoroDocument4 pagesMisura Tavolo LavoroCarlo N CastellanoNo ratings yet

- Astm A325 & A490 Bolts & NutsDocument6 pagesAstm A325 & A490 Bolts & NutsagusfitriyadiNo ratings yet

- Typical Single Plate Connection Schedule 7 Typical Double Angle Connection Schedule 8Document1 pageTypical Single Plate Connection Schedule 7 Typical Double Angle Connection Schedule 8Ravi LoharNo ratings yet

- Sandvik Rotary Tools: Drill String Components by RigDocument40 pagesSandvik Rotary Tools: Drill String Components by Rigwalther alcocer100% (1)

- Dremel Bit PosterDocument1 pageDremel Bit PosterPhil BooeNo ratings yet

- ChannelsDocument4 pagesChannelsjcNo ratings yet

- Material List Summary Kitchen Cabinet (4-20-2024)Document2 pagesMaterial List Summary Kitchen Cabinet (4-20-2024)proengineer415No ratings yet

- 7.beam & Slab ScheduleDocument1 page7.beam & Slab ScheduleSoe Soe MonNo ratings yet

- Fishing Tools For 17 and Half Inch HoleDocument2 pagesFishing Tools For 17 and Half Inch Holehamid0% (1)

- Cabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsFrom EverandCabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsRating: 5 out of 5 stars5/5 (2)

- TIM WebSB Strip Flat BarDocument3 pagesTIM WebSB Strip Flat BarSakthi VasuNo ratings yet

- UntitledDocument3 pagesUntitledSakthi VasuNo ratings yet

- Rectangular and Square HSS Venting - American Galvanizers AssociationDocument4 pagesRectangular and Square HSS Venting - American Galvanizers AssociationSakthi VasuNo ratings yet

- Walkie Talkie - 10 Codes - CommUSADocument1 pageWalkie Talkie - 10 Codes - CommUSASakthi VasuNo ratings yet

- Slide FlexusDocument13 pagesSlide FlexusAmin SanimanNo ratings yet

- 6 Inclusion Strategies For Students With Autism Spectrum DisordersDocument8 pages6 Inclusion Strategies For Students With Autism Spectrum Disordersapi-268598032No ratings yet

- Flame Retardant For TextilesDocument23 pagesFlame Retardant For TextilesimranchemiNo ratings yet

- Words of PleasureDocument211 pagesWords of PleasureallendraNo ratings yet

- Compensatory Mechanism of Circulatory ShockDocument29 pagesCompensatory Mechanism of Circulatory ShockWan Razin Wan Hassan100% (1)

- CIS Electrical Standard Rev 001Document46 pagesCIS Electrical Standard Rev 001Tarek AbulailNo ratings yet

- Msds en Shell Tellus s2 M 68Document15 pagesMsds en Shell Tellus s2 M 68Debora Septania PurbaNo ratings yet

- Synopsis: Rajiv Gandhi University of Health Sciences Karnataka State, BangaloreDocument17 pagesSynopsis: Rajiv Gandhi University of Health Sciences Karnataka State, BangaloreSANANo ratings yet

- TC PRR021 51309288 225 DatasheetDocument133 pagesTC PRR021 51309288 225 DatasheetSalim MohamedNo ratings yet

- Ibadan - Nigeria - Reconnaissance - Visit - KopieDocument10 pagesIbadan - Nigeria - Reconnaissance - Visit - KopieAgung BudiantoNo ratings yet

- Nursing Care of The Client With High-Risk Labor and DeliveryDocument23 pagesNursing Care of The Client With High-Risk Labor and DeliveryMarie Ashley CasiaNo ratings yet

- The Miracle Plant Kalanchoe Pinnata A PhytochemicaDocument6 pagesThe Miracle Plant Kalanchoe Pinnata A PhytochemicaAboli GhateNo ratings yet

- Electrical Troubleshooting VespaDocument19 pagesElectrical Troubleshooting VespaMuch Abdulah NurhidayatNo ratings yet

- Design of Material Handling System For SpecificDocument14 pagesDesign of Material Handling System For SpecificKaran Virbhadre100% (3)

- Gun Water PDFDocument4 pagesGun Water PDFAlejandro MontecilloNo ratings yet

- 12.4 Voluntary & Involuntary Action, 12.6 Endocrine System - Google FormsDocument7 pages12.4 Voluntary & Involuntary Action, 12.6 Endocrine System - Google FormsHAJAR LENNo ratings yet

- Peroxide Cure of RubberDocument19 pagesPeroxide Cure of RubberVivek RainaNo ratings yet

- Antenatal HandoutDocument16 pagesAntenatal HandoutZahNo ratings yet

- ASTM E 1444 11 MT Magnetic Particle TestingDocument21 pagesASTM E 1444 11 MT Magnetic Particle TestingeliuNo ratings yet

- Exercise Test Weight Reps Set Interval Tonnage Cutoff 1Rm 5Rm Squat Bench Row Press Deadlift Smallest Plates Available Match Prs in Week #Document7 pagesExercise Test Weight Reps Set Interval Tonnage Cutoff 1Rm 5Rm Squat Bench Row Press Deadlift Smallest Plates Available Match Prs in Week #Chelsea ClarkNo ratings yet

- Calculos Torre de AireacionDocument8 pagesCalculos Torre de AireacionMonica Alexandra Rueda RamirezNo ratings yet

- Lung AbscessDocument28 pagesLung AbscessBobet ReñaNo ratings yet

- Mapping Kemuning 1 - 2 Maret 2023Document1 pageMapping Kemuning 1 - 2 Maret 2023josephNo ratings yet

- Pathology Lecture 2, Cell Injury (Notes/tafree3')Document18 pagesPathology Lecture 2, Cell Injury (Notes/tafree3')Ali Al-Qudsi100% (3)

- RLO CableDocument1 pageRLO CableLeiden O'SullivanNo ratings yet

- Sem - Ii Pharmacology Lab ManualDocument36 pagesSem - Ii Pharmacology Lab ManualLokesh MahataNo ratings yet

- Basic Offshore Safety Induction and Emergency Training: CtsiDocument72 pagesBasic Offshore Safety Induction and Emergency Training: Ctsiangel coazoNo ratings yet

- Life Cycle of FunariaDocument3 pagesLife Cycle of FunariaPalash Ghosh100% (1)

- Leavening Agents Lab ReportDocument5 pagesLeavening Agents Lab Reportapi-340581896100% (2)