Professional Documents

Culture Documents

Screw Compressors: S 151 To S 341, SL 270 To SL 481 and SLF 221 To SLF 271

Screw Compressors: S 151 To S 341, SL 270 To SL 481 and SLF 221 To SLF 271

Uploaded by

hendra matatiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Screw Compressors: S 151 To S 341, SL 270 To SL 481 and SLF 221 To SLF 271

Screw Compressors: S 151 To S 341, SL 270 To SL 481 and SLF 221 To SLF 271

Uploaded by

hendra matatiaCopyright:

Available Formats

Screw compressors S 151 to S 341,

SL 270 to SL 481 and SLF 221 to SLF 271

Effective FAD: 5.46 – 43.70 m³/min, 508 – 1590 cfm

Pressure range: 7.5 – 13 bar, 110 – 190 psig

Power range: 110 – 355 kW, 150 – 480 hp

MULTIFUNCTIONAL SUCTION VIBRATION-DECOUPLED EFFICIENCY EASY TO CONTROL

REGULATOR COMPRESSOR UNIT The unique BOGE airend allows As an optional extra, for the S

This closes hermetically, Noise emissions are reduced as the high free air delivery with a low series, the new modular focus

preventing oil vapours from compressor unit is isolated from power requirement, ensuring a control 2.0 makes its debut*:

escaping. Energy savings are vibration. A rigid base frame with reliable and effi cient compressed This most advanced control system

achieved by a fully unloaded start. access from either side, makes it air supply. within the industry not only spoils

Intrinsically safe, operational easy to move using a forklift or users with an intuitive user

reliability is ensured in the event pallet truck. interface. In addition to efficiency

of a fault by automatic closure of displays and the BOGE leakage

the regulator. monitor, it even offers RFID access

for the first time.

* standard with focus control

Compressed air for large delivery volumes: Screw

BOGE Compressed Air Systems

compressors in the S, SL and SLF series are able to GmbH & Co. KG

meet even high demands for compressed air reliably P. O. Box 10 07 13 · 33507 Bielefeld

Otto-Boge-Straße 1–7 · 33739 Bielefeld

and efficiently. Their intelligent design guarantees Tel. +49 5206 601-0 · Fax +49 5206 601-200

costeffective operation and maximum info@boge.com · www.boge.com

operating reliability.

BOGE Max. Effective free air Motor power Dimensions1) Dimensions2) Com- Weight Weight

Model pressure** delivery* Main Fan silenced super silenced pressed silenced super

drive motor WxDxH WxDxH silenced

bar psig m3/min cfm kW hp kW hp mm mm air kg kg

S 151 7,5 110 19,98 706 110 150 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3100 3200

S 151 8 115 19,40 685 110 150 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3100 3200

S 151 10 150 17,00 600 110 150 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3100 3200

S 151 13 190 14,40 508 110 150 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3100 3200

S 180 7,5 110 24,00 850 132 180 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3200 3300

S 180 8 115 23,30 825 132 180 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3200 3300

S 180 10 150 20,80 735 132 180 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3200 3300

S 180 13 190 17,80 630 132 180 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3200 3300

S 220 7,5 110 28,74 1020 160 220 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3200 3300

S 220 8 115 27,90 990 160 220 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3200 3300

S 220 10 150 25,10 890 160 220 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3200 3300

S 220 13 190 21,70 770 160 220 4 5,5 2265x1585x2005 2565x1585x2505 DN 80 3200 3300

S 271 7,5 110 35,74 1262 200 270 7,5 10 3100x1910x2145 3500x1910x2645 DN 100 4500 4600

S 271 8 115 34,70 1225 200 270 7,5 10 3100x1910x2145 3500x1910x2645 DN 100 4500 4600

S 271 10 150 30,50 1077 200 270 7,5 10 3100x1910x2145 3500x1910x2645 DN 100 4500 4600

S 271 13 190 24,73 872 200 270 7,5 10 3100x1910x2145 3500x1910x2645 DN 100 4500 4600

S 341 7,5 110 41,99 1484 250 340 11 15 3100x1910x2145 3500x1910x2645 DN 100 5000 5100

S 341 8 115 40,77 1441 250 340 11 15 3100x1910x2145 3500x1910x2645 DN 100 5000 5100

S 341 10 150 37,10 1310 250 340 11 15 3100x1910x2145 3500x1910x2645 DN 100 5000 5100

S 341 13 190 31,70 1119 250 340 11 15 3100x1910x2145 3500x1910x2645 DN 100 5000 5100

SL 270 7,5 110 33,5 1212 200 270 5,5 7,5 3100x1910x2145 3100x1910x2645 DN 100 3900 4000

SL 270 8 115 33,3 1177 200 270 5,5 7,5 3100x1910x2145 3100x1910x2645 DN 100 3900 4000

SL 340 10 150 33,2 1173 250 340 7,5 10 3100x1910x2145 3100x1910x2645 DN 100 4500 4600

380-EN-BI-0.5-07.2015/d · Technical changes and errors reserved.

SL 340 13 190 33,0 1166 250 340 7,5 10 3100x1910x2145 3100x1910x2645 DN 100 4500 4600

SL 341 7,5 110 44,0 1590 250 340 7,5 10 3100x1910x2145 3100x1910x2645 DN 100 5000 5100

SL 341 8 115 43,7 1544 250 340 7,5 10 3100x1910x2145 3100x1910x2645 DN 100 5000 5100

SL 431 10 150 43,4 1533 315 430 7,5 10 3100x1910x2145 3100x1910x2645 DN 100 5000 5100

SL 481 13 190 42,7 1508 355 480 7,5 10 3100x1910x2145 3500x1910x2645 DN 100 5600 5700

SLF 221 7,5 110 6,65 –29,06 235 –1026 160 220 4,0 5,5 3145x1910x2145 3145x1910x2645 DN 100 4500 4600

SLF 221 8 115 6,46 –28,21 228 – 996 160 220 4,0 5,5 3145x1910x2145 3145x1910x2645 DN 100 4500 4600

SLF 221 10 150 6,18 –25,06 218 – 885 160 220 4,0 5,5 3145x1910x2145 3145x1910x2645 DN 100 4500 4600

SLF 221 13 190 5,46 –20,36 193 – 719 160 220 4,0 5,5 3145x1910x2145 3145x1910x2645 DN 100 4500 4600

SLF 271 7,5 110 6,65 –35,74 235 –1262 200 270 7,5 10 3145x1910x2145 3145x1910x2645 DN 100 4700 4800

SLF 271 8 115 6,46 –34,70 228 –1225 200 270 7,5 10 3145x1910x2145 3145x1910x2645 DN 100 4700 4800

SLF 271 10 150 6,18 –30,50 218 –1077 200 270 7,5 10 3145x1910x2145 3145x1910x2645 DN 100 4700 4800

SLF 271 13 190 5,46 –24,70 193 – 872 200 270 7,5 10 3145x1910x2145 3145x1910x2645 DN 100 4700 4800

* Free air delivery for the complete package in accordance with ISO 1217, Appendix C, at 20°C ambient temperature and maximum pressure. Emitted sound pressure values from 76 dB(A) according

to DIN EN ISO 2151:2009.

** Max. pressure of the compressor. The 7.5 bar indications are provided as reference values. The machines are designed for 8 bar.

1)

super-silenced on the intake side 2)

super-silenced on the intake and on the exhaust air side

You might also like

- ABAC Smart Screw CompressorDocument6 pagesABAC Smart Screw CompressorDaniel Arbeláez0% (1)

- Air-Compressor User ManualDocument67 pagesAir-Compressor User ManualSAMIR BEL HADJ HMIDANo ratings yet

- Boge Piston Air CompressorsDocument28 pagesBoge Piston Air CompressorsAir Repair, LLCNo ratings yet

- HDB BreakersDocument89 pagesHDB BreakersJohn Louie Mazon100% (6)

- BD35F-HD Heavy Duty Direct Current Compressor R134a, 12-24V DCDocument2 pagesBD35F-HD Heavy Duty Direct Current Compressor R134a, 12-24V DCNaba94No ratings yet

- Air Compressor Troubleshooting Guide PDFDocument1 pageAir Compressor Troubleshooting Guide PDFhexzy fliraNo ratings yet

- 344 en Bluekat - 2Document4 pages344 en Bluekat - 2MAZENNo ratings yet

- HW29 Boiler Datasheet Nov 19Document2 pagesHW29 Boiler Datasheet Nov 19AlkaBoiler WTS - Saudi ArabiaNo ratings yet

- DENAIR Screw Air CompressorDocument10 pagesDENAIR Screw Air Compressormoussadjouadi93No ratings yet

- Cadenas Métricas FBDocument15 pagesCadenas Métricas FBjurgen_01No ratings yet

- 387 EN EO SeriesDocument2 pages387 EN EO SeriesGhufran KhanNo ratings yet

- Leaflet Utility ENDocument4 pagesLeaflet Utility ENFso servicio tecnico 2021No ratings yet

- Dunham-Bush Ducted Split R410a df16251.0Document2 pagesDunham-Bush Ducted Split R410a df16251.0AntoinetteNo ratings yet

- Standards Pillars and Bushes2Document136 pagesStandards Pillars and Bushes2sansagithNo ratings yet

- Bloomfoss Hydraulic Actuatos Product-Manual - BT-SeriesDocument7 pagesBloomfoss Hydraulic Actuatos Product-Manual - BT-SeriesSady KanettiNo ratings yet

- Qualified Solutions For The Transmission IndustryDocument22 pagesQualified Solutions For The Transmission Industryanrsrinivasan100% (1)

- AG Aluminium Filter Housing DatasheetDocument4 pagesAG Aluminium Filter Housing DatasheetMiroslavNo ratings yet

- (Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Document16 pages(Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Mahendra Tyre Works RaigarhNo ratings yet

- Condenser BushingsDocument6 pagesCondenser BushingsNix4crazyNo ratings yet

- VALVES Technical Catalog: Catálogo Técnico ValvoleDocument11 pagesVALVES Technical Catalog: Catálogo Técnico ValvoleMohamed Raafat0% (1)

- High Tech For Highest Pressures: The BOGE SRHV 470-10 Booster.Document2 pagesHigh Tech For Highest Pressures: The BOGE SRHV 470-10 Booster.Air Repair, LLCNo ratings yet

- Becker Brochure PDFDocument20 pagesBecker Brochure PDFMiraNo ratings yet

- Daemo Eng (2ba)Document20 pagesDaemo Eng (2ba)Jairresistenciagt123No ratings yet

- Aerius Brochure enDocument8 pagesAerius Brochure enbiberiusNo ratings yet

- HDB BreakersDocument88 pagesHDB Breakersmargotsilva96No ratings yet

- HDB Breakers ManualDocument89 pagesHDB Breakers ManualJoseph Emmanuel ParedesNo ratings yet

- Rexnord-Viva Vs enDocument2 pagesRexnord-Viva Vs enDenis AugustoNo ratings yet

- AMF Zero Point 2007 3GBDocument40 pagesAMF Zero Point 2007 3GBIon Vasilica BrosuNo ratings yet

- Air Tight DamperDocument2 pagesAir Tight Damperfire123123123No ratings yet

- En Nex AirlineDocument52 pagesEn Nex AirlineJoão SilvaNo ratings yet

- Cooling Tower CatalogueDocument21 pagesCooling Tower Catalogueaadil_thakur45100% (1)

- Belt Drive Type: 7,5kW - 45kW 22kW - 250kW 15kW - 250kW 10 - 500 HPDocument2 pagesBelt Drive Type: 7,5kW - 45kW 22kW - 250kW 15kW - 250kW 10 - 500 HPAriantoNo ratings yet

- Gearbox For Control Valves and Pneumatic ActuatorsDocument7 pagesGearbox For Control Valves and Pneumatic ActuatorsKi Ho ChungNo ratings yet

- Cooling Tower (Genius)Document7 pagesCooling Tower (Genius)JeghiNo ratings yet

- Single and Two-Stage Industrial Reciprocating Air CompressorsDocument4 pagesSingle and Two-Stage Industrial Reciprocating Air CompressorsGeetesh MakadiaNo ratings yet

- Ball Mill Standard Product Definition-Rev0Document12 pagesBall Mill Standard Product Definition-Rev0krishnabijuNo ratings yet

- Filter Press HPHT 175R PDFDocument3 pagesFilter Press HPHT 175R PDFHamed NazariNo ratings yet

- CXU 613 MP8 2008 2017 ADocument2 pagesCXU 613 MP8 2008 2017 AGustavo MosqueraNo ratings yet

- Mechanical Pinch Valves of OV SeriesDocument5 pagesMechanical Pinch Valves of OV SeriesDaniel SanNo ratings yet

- FAMAT Cold Reheat Check Valves 2013 PDFDocument11 pagesFAMAT Cold Reheat Check Valves 2013 PDFAMITNo ratings yet

- 38.reduction 4p-25.02.16Document4 pages38.reduction 4p-25.02.16adigesimurgNo ratings yet

- Ingersoll RandDocument12 pagesIngersoll RandBultaNo ratings yet

- Q9 006 E - Knife Gate Valves DN 50-400 PDFDocument7 pagesQ9 006 E - Knife Gate Valves DN 50-400 PDFJORGE HUARAYA LABRANo ratings yet

- Octagonal Blender Catalogue.Document2 pagesOctagonal Blender Catalogue.vk.brijeshNo ratings yet

- Oil-Injected Rotary Screw Compressors: Features & Bene TsDocument2 pagesOil-Injected Rotary Screw Compressors: Features & Bene TsВладислав СередаNo ratings yet

- ALUP Largo 31-45 Sales Leaflet EN 6999640400Document2 pagesALUP Largo 31-45 Sales Leaflet EN 6999640400Bosznay ZoltánNo ratings yet

- حلزونى ١٥بار FINIDocument5 pagesحلزونى ١٥بار FINIradwan.hueckmakmaxNo ratings yet

- Elgi Compressor CatalogDocument4 pagesElgi Compressor CatalogMOKSH MEWANo ratings yet

- BD GD CatalogDocument10 pagesBD GD CatalogjosueNo ratings yet

- Econosto Butterfly Valves, 4622, Range 50 - 400mmDocument2 pagesEconosto Butterfly Valves, 4622, Range 50 - 400mmMitul ClaudieiNo ratings yet

- DELTA IA-Robot DRV C EN 20190516 WebDocument20 pagesDELTA IA-Robot DRV C EN 20190516 WebKishan TalawattaNo ratings yet

- (GRE) Installation Manual For MarineDocument37 pages(GRE) Installation Manual For MarineQuy RomNo ratings yet

- GC Liners InsertsDocument4 pagesGC Liners InsertsmagicianchemistNo ratings yet

- Gfps-Dk-Technical Data Metal Butterfly Valve Type 039Document7 pagesGfps-Dk-Technical Data Metal Butterfly Valve Type 039Omar GuillenNo ratings yet

- Gmv5 - Ducted Hi Esp VRFDocument1 pageGmv5 - Ducted Hi Esp VRFAvk SanjeevanNo ratings yet

- Din Reactors CEDocument3 pagesDin Reactors CEvallamreddyNo ratings yet

- Customised Engineered Packages: Reciprocating Air CompressorsDocument4 pagesCustomised Engineered Packages: Reciprocating Air Compressorsmogwai71No ratings yet

- Compresoras de Tornillo KAISHAN Serie LGDocument8 pagesCompresoras de Tornillo KAISHAN Serie LGcecoelsacNo ratings yet

- Deltabeam EngDocument20 pagesDeltabeam EngAmir OmeraševićNo ratings yet

- BSB Series BRCDocument6 pagesBSB Series BRCsamiNo ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Designed To Take The LeadDocument7 pagesDesigned To Take The Leadhendra matatiaNo ratings yet

- A Profitable Solution! Alunova Recycling: Relies On Compressed Air From BOGE When Recycling Composite WasteDocument1 pageA Profitable Solution! Alunova Recycling: Relies On Compressed Air From BOGE When Recycling Composite Wastehendra matatiaNo ratings yet

- SO 61-2 W SO 126-2 W Oil-Free Compressors: A Clean Efficiency Boost: ToDocument2 pagesSO 61-2 W SO 126-2 W Oil-Free Compressors: A Clean Efficiency Boost: Tohendra matatiaNo ratings yet

- 359 Flexpet En-Bi 170209Document2 pages359 Flexpet En-Bi 170209hendra matatiaNo ratings yet

- Screw Compressors Oil-Injection Cooled: 40 Product Line 41 System ConceptDocument15 pagesScrew Compressors Oil-Injection Cooled: 40 Product Line 41 System Concepthendra matatiaNo ratings yet

- 404 en K15n2boosterDocument2 pages404 en K15n2boosterhendra matatiaNo ratings yet

- Screw Compressors Oil-Injection Cooled: 40 Product Line 41 System Concept 42 AssembliesDocument11 pagesScrew Compressors Oil-Injection Cooled: 40 Product Line 41 System Concept 42 Assemblieshendra matatiaNo ratings yet

- Screw Compressors Oil-Injection Cooled: 50 Product LineDocument5 pagesScrew Compressors Oil-Injection Cooled: 50 Product Linehendra matatiaNo ratings yet

- Baureihe SODocument3 pagesBaureihe SOhendra matatiaNo ratings yet

- Screw Compressors Oil-Injection Cooled: 40 Product LineDocument2 pagesScrew Compressors Oil-Injection Cooled: 40 Product Linehendra matatiaNo ratings yet

- Screw Compressors Oil-Injection Cooled: Index of KeywordsDocument1 pageScrew Compressors Oil-Injection Cooled: Index of Keywordshendra matatiaNo ratings yet

- Ingersol PDFDocument8 pagesIngersol PDFFadhila Ahmad AnindriaNo ratings yet

- Catalogo Compresor Galileo - Presion Aspiracion 12barDocument1 pageCatalogo Compresor Galileo - Presion Aspiracion 12barJorgeNo ratings yet

- BOOK 09 - MaintananceDocument15 pagesBOOK 09 - MaintananceShau WilliamNo ratings yet

- Airframe 358Document46 pagesAirframe 358Josapha Bass BlackNo ratings yet

- OLAER - PARKER - ACDAP Catalogue HY10-7000-OT Rev2 EN 2016Document59 pagesOLAER - PARKER - ACDAP Catalogue HY10-7000-OT Rev2 EN 2016Rafael GoulartNo ratings yet

- Kriwan Ops 1 Oil Pressure SensorDocument1 pageKriwan Ops 1 Oil Pressure Sensoralasad4everNo ratings yet

- York Packaged Unit 291626-YTG-B-0807Document48 pagesYork Packaged Unit 291626-YTG-B-0807gerardoddNo ratings yet

- PSD 01 2022 61af B 030 105Document22 pagesPSD 01 2022 61af B 030 105PedroNo ratings yet

- 50ton Voyaguer E Stage 72KWDocument10 pages50ton Voyaguer E Stage 72KWCarlos MartinezNo ratings yet

- Air Conditioner With Refrigerant R134aDocument178 pagesAir Conditioner With Refrigerant R134aArierep OdariesmeNo ratings yet

- 7 Gas Turbine Power PlantDocument7 pages7 Gas Turbine Power Plantyanyan100% (1)

- Multi V S 220v, 3ph, 60hz HP CsaDocument78 pagesMulti V S 220v, 3ph, 60hz HP CsaFERNANDO CORREANo ratings yet

- CTX (R-410A) SeriesDocument31 pagesCTX (R-410A) SeriesZaid SamhaNo ratings yet

- Centrifugal Compressor CommissioningDocument20 pagesCentrifugal Compressor CommissioningservignafNo ratings yet

- Cryostar Magazine9 Training CentreDocument7 pagesCryostar Magazine9 Training CentreNarayan Marndi0% (1)

- 6B Advanced Gas Path (AGP) : Output, Efficiency, and Availability SolutionDocument1 page6B Advanced Gas Path (AGP) : Output, Efficiency, and Availability SolutionMahesh MishraNo ratings yet

- Surface Profile Measurement by Replica Tape SSPC-SP10-Nace 2-Near - WhiteDocument5 pagesSurface Profile Measurement by Replica Tape SSPC-SP10-Nace 2-Near - WhiteClyde CoopperNo ratings yet

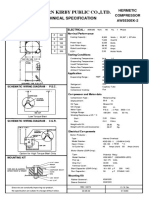

- Kulthorn Kirby Public Co.,Ltd.: Technical SpecificationDocument2 pagesKulthorn Kirby Public Co.,Ltd.: Technical SpecificationZikko FirmansyahNo ratings yet

- F860 V5 PDFDocument4 pagesF860 V5 PDFMudasir SahoNo ratings yet

- Asy Lmacaw Aoy Lmak2 Lmam2smDocument21 pagesAsy Lmacaw Aoy Lmak2 Lmam2smEmil EremiaNo ratings yet

- Atlas Copco Portable Air: The New Drillair™ Range of CompressorsDocument2 pagesAtlas Copco Portable Air: The New Drillair™ Range of CompressorsAsad AijazNo ratings yet

- BRR Ref Components MoodleDocument29 pagesBRR Ref Components MoodleNani PusuluriNo ratings yet

- MDVN EnglishDocument2 pagesMDVN EnglishKhaled KamelNo ratings yet

- Bearing Technology For Pumps and CompressorsDocument12 pagesBearing Technology For Pumps and Compressorsmans2014No ratings yet

- Compressor Analysis-Surge Protection PDFDocument42 pagesCompressor Analysis-Surge Protection PDFAnonymous a4Jwz14WNo ratings yet

- Project Standard Specification: Compressed-Air Equipment 15465 - Page 1/9Document9 pagesProject Standard Specification: Compressed-Air Equipment 15465 - Page 1/9adel rihanaNo ratings yet

- BUILDING UTILITIES 2 Building HVAC SystemsDocument142 pagesBUILDING UTILITIES 2 Building HVAC Systemsjona serranoNo ratings yet

- Process Gas Centrifugal Compressors: Efficient, Reliable EquipmentDocument16 pagesProcess Gas Centrifugal Compressors: Efficient, Reliable EquipmentLucianaNo ratings yet