Professional Documents

Culture Documents

Diagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts Hard

Diagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts Hard

Uploaded by

Alejandro Hernandez0 ratings0% found this document useful (0 votes)

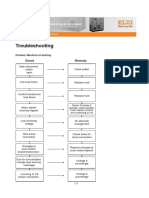

23 views11 pagesThis document provides troubleshooting steps for diagnosing engine malfunctions, beginning with the most probable and simplest problems to verify. It lists common symptoms, potential problems that could cause each symptom, and recommended solutions. Symptoms covered include the engine not starting or starting hard, the engine surging or stalling frequently, and the engine missing. Corresponding problems may involve issues like an empty fuel tank, blocked fuel vent, electrical power problems, water in the fuel, air in the fuel system, blocked filters, injection pump timing issues, and worn engine components. Solutions range from operational checks to repairs and replacement of parts.

Original Description:

Original Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides troubleshooting steps for diagnosing engine malfunctions, beginning with the most probable and simplest problems to verify. It lists common symptoms, potential problems that could cause each symptom, and recommended solutions. Symptoms covered include the engine not starting or starting hard, the engine surging or stalling frequently, and the engine missing. Corresponding problems may involve issues like an empty fuel tank, blocked fuel vent, electrical power problems, water in the fuel, air in the fuel system, blocked filters, injection pump timing issues, and worn engine components. Solutions range from operational checks to repairs and replacement of parts.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

23 views11 pagesDiagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts Hard

Diagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts Hard

Uploaded by

Alejandro HernandezThis document provides troubleshooting steps for diagnosing engine malfunctions, beginning with the most probable and simplest problems to verify. It lists common symptoms, potential problems that could cause each symptom, and recommended solutions. Symptoms covered include the engine not starting or starting hard, the engine surging or stalling frequently, and the engine missing. Corresponding problems may involve issues like an empty fuel tank, blocked fuel vent, electrical power problems, water in the fuel, air in the fuel system, blocked filters, injection pump timing issues, and worn engine components. Solutions range from operational checks to repairs and replacement of parts.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 11

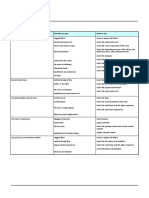

Diagnose Engine Malfunctions

NOTE:

Diagnostic charts are arranged from most probable and simplest to verify, to least likely

and more difficult to verify. Remember the following steps when diagnosing a problem:

Step 1. Operational Checkout Procedure (See Group 9005-10).

Step 2. Adjustments and/or Tests (See Group 9010-20 and/or 9010-25).

Symptom Problem Solution

Engine Will Not Start Or Fuel tank empty Check fuel quantity

Starts Hard

Fuel tank vent plugged Remove cap and listen for

sound of air entering tank.

Replace cap.

No electrical power to Turn key switch to "On".

injection pump solenoid Must hear click at injection

pump. Replace fuse. Repair

wiring.

Water in fuel or water frozen Drain water from fuel tank.

in fuel line. Inspect fuel filter for water.

Change filter.

Debris in fuel or wrong Check fuel tank outlet

grade of fuel strainer for type of fuel

debris. Check bottom of fuel

tank for debris. Clean tank.

Add fuel. Check grade of

fuel. Add correct fuel. See

Backhoe Loader Drain and

Refill Capacities .

(Operator's Manual.)

Air leak on suction side of Check for bubbles in fuel

fuel system filter and tighten

connections. Inspect fuel

lines for damage.

Fuel transfer pump Check engine oil for fuel

diaphragm leaking dilution. Replace fuel pump.

Slow cranking speed Check battery and

connections. Incorrect

engine oil (Cold weather).

Symptom Problem Solution

Restricted air filter Check air filter restriction

indicator and air filters.

Clean.

Stuck injection pump Tap injection pump housing

metering valve. (lightly) if engine now starts.

Replace metering valve. See

your authorized injection

pump service center.

Faulty electric shut-off Test shut-off solenoid. See

System Functional

Schematic (S.N. 913479—

951252) (Group 9015A-15.)

or see System Functional

Schematic and Section

Legend (S.N. 951253— ) .

(Group 9015B-10.) Inspect

solenoid wiring and linkage.

Improper injection pump Check timing. See

timing CTM104 .

Injection pump Remove and test pump. See

CTM104 .

Injection nozzle(s) Remove and test nozzles.

See CTM104

Worn compression rings or Check compression. Repair.

low compression See CTM104

Blown head gasket Remove. Route radiator

overflow into container of

fluid and check for bubbles.

Bubbles indicate head gasket

linkage. See CTM104 .

Engine Surges Or Stalls Air in fuel Inspect filter for evidence of

Frequently air in fuel. Tighten

connections and bleed fuel

system.

Fuel tank vent plugged Remove cap and listen for

sound of air entering tank.

Replace cap.

Debris in fuel or wrong Check fuel tank outlet

grade of fuel strainer for debris. Check

bottom of fuel tank for

debris. Clean tank. Add fuel.

See Backhoe Loader Drain

and Refill Capacities .

(Operator's Manual)

Water in fuel Drain fuel tank and inspect

filter element for water.

Replace filters.

Fuel filter plugged Replace filter.

Return line from injection Route return line at the

pump to tank restricted pump into a separate

container. If engine now

operates normally, check

return line to tank for

restriction. Replace.

Fuel injection pump out of Time injection pump. See

time CTM104 .

Check return oil fitting on Remove, inspect and clean.

top of injection pump Determine source of debris.

control cover plugged. See your authorized

injection pump service

center.

Injection pump metering Remove pump top cover and

valve sticking inspect. Replace metering

valve. See your authorized

injection pump service

center.

Engine overheating Test cooling system. See

CTM104 .

Fuel transfer pump Test transfer pump pressure.

See CTM104 .

Fuel injection pump Remove fuel injection pump.

See CTM104 . Test pump.

See your authorized

injection pump service

center.

Injection nozzle(s) Remove and test nozzle(s).

See CTM104 .

Improper valve clearance Check and adjust valve

clearance. See CTM104 .

Valve sticking or burned Do compression pressure

test. See CTM104 .

Worn or broken Route radiator overflow

compression rings or hose into a container of fluid

cylinder head gasket leaking and check. Check for

bubbles. Bubbles indicate

head gasket leakage. See

CTM104 . Do compression

pressure test. See CTM104.

Engine Misses Air in fuel Check for evidence of air in

filter. Tighten connections

and bleed fuel system.

Debris in fuel or wrong Check fuel tank for water.

grade of fuel Check fuel tank strainer and

fuel filter for debris. Clean.

Check grade of fuel.

Idle speeds out of Test slow idle speeds. See

adjustment (too low) CTM104 .

Fuel injection pump out of Time injection pump. See

time CTM104 .

Fuel transfer pump Test fuel system pressure.

See CTM104 .

Injection pump governor Inspect. Repair. See your

faulty or metering valve authorized injection pump

sticking service center.

Engine overheating Verify engine temperature.

See CTM104 . Test

thermostat. Replace. See

CTM104 .

Incorrect valve clearance Check and adjust valve

clearance. See CTM104 .

Bent push rods Inspect. Replace.

Cylinder head gasket leaking Route radiator overflow hose

into container of fluid and

check for bubbles. Bubbles

indicate head gasket leakage.

See CTM104 .

Valve sticking or burned Do compression pressure

test. See CTM104 .

Worn or broken Do compression pressure

compression rings test. See CTM104 .

Fuel injection pump Remove and test fuel

injection pump. See

CTM104 .

Injection nozzles(s) plugged Remove and test nozzles.

See CTM104 .

Engine Does Not Develop Fuel tank outlet strainer Check fuel tank for water or

Power plugged debris. Remove and clean.

Fuel filter plugged Replace fuel filter.

Wrong grade of fuel Drain and add correct fuel.

Air system restricted Check air filter restriction

and air filters. Clean.

Incorrect fast idle speed (too Adjust linkage. See Engine

low) or linkage out Speed Control Linkage

adjustment. Adjustment (S.N. —910055)

. In this Group. Check fast

idle speed. See Slow and

Fast Idle (S.N. —910055) .

In this Group.

Incorrect engine or injection Check. Adjust timing. See

pump timing CTM104 .

Incorrect valve clearance Adjust valve clearance. See

CTM104 .

Injection pump return fuel Route return line at the

tube or fittings are restricted pump into a separate

container. If engine now

operates normal, check

return line for restriction.

Replace.

Fuel transfer pump Test fuel transfer pump

malfunction pressure. See CTM104 .

Fuel line restricted Route an external fuel source

to fuel transfer pump. If

engine operation is normal

clean fuel line.

Excess drag in brake system Check park brake drag. See

Brake System Checks .

(Group 9005-10.)

Excess drag in axle Test drag. See Brake System

Checks (Group 9005-10.)

Muffler restricted Operate without muffler. If

engine operation is now

normal, replace muffler.

Injection pump delivery or Remove pump and test. See

governor faulty your authorized injection

pump service center.

Injection nozzle(s) Remove and test nozzle(s).

See CTM104 .

Low compression Do compression pressure

test. See CTM104 .

Worn camshaft Do valve clearance check.

Replace. See CTM104 .

Engine Emits Excessive Restricted air filter Check air filter restriction

Black or Gray Exhaust and air filters. Clean or

Smoke replace.

Incorrect grade of fuel Drain and add correct fuel.

Incorrect injection pump Time injection pump. See

timing CTM104 .

Excessive fuel delivery Remove fuel injection

pump. See your authorized

injection pump service

center.

Injection nozzle(s) Remove and test nozzle(s).

See CTM104

Turbocharger not Repair. See CTM104 .

functioning.

Engine Emits Excessive Cranking speed too slow Check batteries and

Blue or White Smoke connections.

Incorrect grade of fuel Drain and add correct fuel.

Engine running too cold Check thermostat operation.

Replace.

Injection pump out of time Time injection pump. See

CTM104 .

Injection nozzle(s) Remove and test nozzle(s).

Low compression Do compression test. See

CTM104 .

Excessive wear in liners Disassemble, inspect, repair.

and/or piston rings stuck

Slow Acceleration Wrong grade of fuel Drain and add correct fuel.

Injection nozzle(s) Remove and test nozzle(s).

Fuel injection pump Remove and test fuel

injection.

Detonation (Excess Engine Low engine oil level. Add oil.

Knock)

Stuck cold weather starting Repair.

aid

Incorrect injection pump Time injection pump. See

timing. CTM104 .

Low coolant temperature. Remove and check

thermostat. See CTM104 .

Abnormal Engine Noise Low or incorrect engine oil Add correct oil to proper

(too thin). level.

Loose or worn hydraulic Inspect. Repair.

pump drive coupling

Engine oil diluted with fuel Inspect engine oil.

Determine cause of fuel

dilution.

Incorrect fuel injection Time injection pump. See

pump timing CTM104 .

Excessive valve clearance Adjust valve clearance. See

CTM104 .

Bent push rods Inspect. Replace.

Worn rocker arm shafts Replace.

Loose connecting rod caps Inspect, tighten connecting

rod cap screws. See

CTM104 .

Loose main bearing caps Inspect, tighten main bearing

cap screws. See CTM104 .

Worn main bearings Replace bearings. See

CTM104 .

Worn connecting rod Replace bearings. See

bearings CTM104 .

Incorrect cam timing Check engine timing.

Repair.

Scored piston Inspect. Replace.

Worn piston pin bushings Inspect. Replace pins and

and pins bushings. See CTM104 .

Low Oil Pressure (Oil Low oil level Add oil to proper level.

Pressure Light on—Red Inspect engine oil.

"Stop" Flashing)

Wrong viscosity oil/oil Change oil. Check injection

diluted with diesel fuel pump shaft seals and transfer

pump diaphragm. See

CTM104 .

Oil pressure switch or Check engine oil pressure

indicator switch. See Display

Monitor/Indicator

Diagnostics (S.N. —

951252) . (Group 9015A-15.)

Oil pressure regulating Test or replace. See CTM104

valve .

Plugged or broken oil pump Inspect. Clean.

intake screen

Loose oil pump drive gear Inspect. Repair. See CTM104

.

Worn oil pump gear or Remove, inspect and repair.

housing See CTM104 .

Excessive main bearing, See CTM104 .

connecting rod or balance

shaft clearance

Cracked cylinder block Replace cylinder block. See

CTM104 . Inspect piston

cooling jets.

Leakage at internal oil Check all possible internal

passage. leakage paths. Repair.

Engine Overheats (Engine Low coolant level Fill cooling system and

Coolant Indicator Light check for leaks.

On and Red "Stop"

Flashing)

Low engine oil level Add oil.

Loose or broken fan belt. Inspect belt tensioner or

replace belt. See CTM104 .

Engine overloaded, Reduce load.

operating in wrong gear

Fan on backwards Check for correct fan

installation. See CTM104 .

Radiator dirty or plugged Check air flow. See Radiator

Air Flow Test . (Group 9010-

25.) Clean radiator. See

CTM104 .

Radiator shroud missing, Inspect. Repair or replace.

damaged or baffles missing

Improper fuel Drain and add correct fuel.

Radiator cap Replace cap.

Faulty temperature sender Test, repair or replace

converter oil temperature

sender. See Display

Monitor/Indicator

Diagnostics (S.N. —951252)

. (Group 9015A-15.) or See

Monitor Display Unit

(MDU) Circuit Theory of

Operation (S.N. 951253— ) .

(Group 9015B-15.)

Incorrect injection pump Time injection pump. See

timing CTM104.

Excessive axle drag Check axle drag. See Brake

System Checks . (Group

9005-10.)

Excessive brake drag Check Brake drag. See Brake

System Checks . (Group

9005-10.)

Faulty thermostat (Struck Inspect thermostat. Replace.

closed) See CTM104 .

Thermostat missing, cooling Replace thermostats Flush

system coated with lime cooling system. See CTM104

deposits .

Water pump Remove, inspect and repair.

See CTM104 .

Excessive fuel delivery Remove. Check for proper

fuel delivery, adjust. See

CTM104 .

Scored piston Replace piston. See CTM104

.

Engine Runs Cold Thermostat (stuck open) Replace. See CTM104 .

Oil in Coolant Or Coolant Leaking cylinder head Replace gasket. See

in Oil gasket CTM104 .

Leaking cylinder liner Replace packings. See

packing CTM104 .

Cracked cylinder liner Replace liner. See CTM104 .

Oil cooler Replace oil cooler. See

CTM104 .

Cracked cylinder block Replace block. See CTM104

.

Excessive Fuel Air system restricted Check filter restriction

Consumption indicator and air filters.

Replace

Leakage in fuel system Inspect. Repair.

Incorrect grade of fuel Refill with correct fuel. See

Backhoe Loader Drain and

Refill Capacities .

(Operator's Manual.)

Operator holding hydraulics Return control levers to

over relief. neutral position.

High system relief valve Test system relief valve

setting pressure. See Loader System

Relief Pressure Test—

310SG (S.N. —910055) .

(Group 9025-25.)

Incorrect injection pump Time injection pump. See

timing CTM104 .

Faulty injection nozzle(s) Test nozzle(s). Repair. See

CTM104 .

Turbocharger Excessively Bearings not lubricated Insufficient oil pressure.

Noisy or Vibrates Check for restricted

turbocharger oil line.

Worn bearings Replace. See CTM104 .

Air leak in engine, intake or Inspect and repair. See

exhaust manifold CTM104 .

Improper clearance between Remove exhaust elbow and

turbine wheel and turbine air inlet hose. Inspect and

housing repair. See CTM104 .

Broken blades on turbine Remove exhaust elbow and

air inlet hose. Inspect and

repair. See CTM104 .

Oil Dripping From Damaged or worn bearings Inspect compressor and

Turbocharger Adapter and/or worn seals turbine wheel for damaged

blades. Check for proper

engine service intervals or

dirt entering engine. See

CTM104 .

Excessive crankcase Check for plugged oil drain

pressure line. Clean.

Turbocharger oil return line Remove line. Inspect and

carbon buildup where line clean.

passes exhaust manifold.

Excessive Drag In Carbon build-up behind Inspect and clean. See

Turbocharger Rotating turbine wheel caused by CTM104 .

Members combustion deposits

Dirt build-up behind Inspect and repair. See

compressor wheel caused by CTM104 .

air intake leaks

Bearing seizure or dirty or Check for plugged air

worn bearings caused by filters. See CTM104 .

excessive temperature,

unbalanced wheel, dirty oil,

oil starvation, or insufficient

lubrication

TX,15,SS3184-19-20100115

You might also like

- Engine Manual Nissan MR18Document116 pagesEngine Manual Nissan MR18HeverzonYairPeñalozaLozano76% (17)

- SSP 405 1.4l 90kW TSI Engine With TurbochargerDocument32 pagesSSP 405 1.4l 90kW TSI Engine With Turbochargerlipfi12383% (6)

- Paccar - PX-9 CM2350 (2013-17)Document18 pagesPaccar - PX-9 CM2350 (2013-17)Hikolau Shishkin82% (11)

- Engine Jeep Patriot 2.0Document296 pagesEngine Jeep Patriot 2.0Yoga Ariant100% (1)

- 2008 Yamaha Rhino 700 Fi Yxr70fxDocument497 pages2008 Yamaha Rhino 700 Fi Yxr70fxquadsdotca67% (3)

- Air System: Cummins Training CentreDocument82 pagesAir System: Cummins Training CentreHydromech PartsNo ratings yet

- 2016 Grand Cherokee - 3.0L TURBO DIESEL PDFDocument665 pages2016 Grand Cherokee - 3.0L TURBO DIESEL PDFprueba2No ratings yet

- Small Block Vortec: GM Sleeper Cylinder HeadDocument5 pagesSmall Block Vortec: GM Sleeper Cylinder HeadGötz EckhardtNo ratings yet

- Troubeshootings 8 Wheeler DHTC Detc-1Document27 pagesTroubeshootings 8 Wheeler DHTC Detc-1khan11k100% (1)

- D399 Industrial EngineDocument49 pagesD399 Industrial EngineMohamed SaiedNo ratings yet

- John Deere Engine TroubleshootingDocument6 pagesJohn Deere Engine TroubleshootingAbubakar FaroukNo ratings yet

- Inline S3.8 TroubleshootingDocument32 pagesInline S3.8 TroubleshootingKrishna PardeshiNo ratings yet

- 4-Wheeler General Service Checklist: Test Run-Vehicle DiagnosisDocument8 pages4-Wheeler General Service Checklist: Test Run-Vehicle DiagnosisaravNo ratings yet

- Diesel Engine Troubleshooting and MaintenanceDocument8 pagesDiesel Engine Troubleshooting and MaintenanceIhsan Ahmed100% (2)

- Grúa Tadano Faun ATF 130 G5Document37 pagesGrúa Tadano Faun ATF 130 G5Reinaldo ZorrillaNo ratings yet

- Eue-Lab Final See2Document29 pagesEue-Lab Final See2Harsha SamagaraNo ratings yet

- Cazafallas 2Document4 pagesCazafallas 2oscarNo ratings yet

- General Diesel Engine Diagnostic Guide PDFDocument3 pagesGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3No ratings yet

- 1706C Plus Trouble ShootingDocument10 pages1706C Plus Trouble ShootingLeonNo ratings yet

- Grúa Tadano Faun ATF 130 G5Document171 pagesGrúa Tadano Faun ATF 130 G5Reinaldo Zorrilla100% (2)

- 05 Fuel SystemDocument109 pages05 Fuel SystemUtomo BudidarmoNo ratings yet

- General InformationDocument111 pagesGeneral Informationkhaledserag23No ratings yet

- 75 Ts GuideDocument3 pages75 Ts GuideasursNo ratings yet

- Liste Des Defauts 38Document5 pagesListe Des Defauts 38MMF PLUSNo ratings yet

- Engine Electrical EeDocument17 pagesEngine Electrical EePedro LopezNo ratings yet

- TOM Training Centrifugal Compressors: TroubleshootingDocument5 pagesTOM Training Centrifugal Compressors: TroubleshootingAhmedNo ratings yet

- 71 00 PDFDocument38 pages71 00 PDFNasr PooyaNo ratings yet

- Maintenance Schedule Checklist: Check and Correct As NecessaryDocument1 pageMaintenance Schedule Checklist: Check and Correct As NecessaryLeonardo RamirezNo ratings yet

- Maintenance Engine Mitsubishi S16RDocument20 pagesMaintenance Engine Mitsubishi S16RElyas Nur FridayanaNo ratings yet

- Pump, Troubleshooting: Service InformationDocument1 pagePump, Troubleshooting: Service InformationPreett Rajin MenabungNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- TroubleshootingDocument2 pagesTroubleshootingIslam ShoukryNo ratings yet

- Panda AGT-DC 4000 Trouble ShootingDocument4 pagesPanda AGT-DC 4000 Trouble Shootingjerrywen08No ratings yet

- Hyundai HD 78Document19 pagesHyundai HD 78manuelmanriqueNo ratings yet

- Trouble ShootingDocument16 pagesTrouble ShootingVinay Singh100% (1)

- Fault Finding: Section F - TransmissionDocument1 pageFault Finding: Section F - TransmissionIonut GrozaNo ratings yet

- 4 Tec Troubleshooting ChartDocument11 pages4 Tec Troubleshooting ChartnelsoncoNo ratings yet

- Manual Tecnico Motor TDIDocument146 pagesManual Tecnico Motor TDIMoysess OliverNo ratings yet

- Hyundai D6GA Fuel System PDFDocument53 pagesHyundai D6GA Fuel System PDFTonny Nguyen100% (3)

- Air Brake System TroubleshootingDocument5 pagesAir Brake System Troubleshootingbhanuka2009No ratings yet

- Fluid Power General TroubleshootingDocument3 pagesFluid Power General Troubleshootinga7510378No ratings yet

- A Part 51Document1 pageA Part 51betabet GeorgeNo ratings yet

- UntitledDocument1 pageUntitledanilNo ratings yet

- Maintenance Tables - Normal Service Maintenance Items 5,000 10,000 15,000 20,000 25,000 30,000 35,000 40,000 45,000Document4 pagesMaintenance Tables - Normal Service Maintenance Items 5,000 10,000 15,000 20,000 25,000 30,000 35,000 40,000 45,000apNo ratings yet

- Maintenance Tables - Normal Service Maintenance Items 5,000 10,000 15,000 20,000 25,000 30,000 35,000 40,000 45,000Document4 pagesMaintenance Tables - Normal Service Maintenance Items 5,000 10,000 15,000 20,000 25,000 30,000 35,000 40,000 45,000apNo ratings yet

- DEZUMIDIFICATORDocument5 pagesDEZUMIDIFICATORviltermNo ratings yet

- Oil Foams Out of Pump Fill/Vent Screw: Cause Special InstructionsDocument1 pageOil Foams Out of Pump Fill/Vent Screw: Cause Special Instructionsbetabet GeorgeNo ratings yet

- Turbocharger Troubleshooting: 1 Compressor SurgingDocument3 pagesTurbocharger Troubleshooting: 1 Compressor SurgingJatin JainNo ratings yet

- 4 JB 1Document60 pages4 JB 1Rex Palmitos100% (1)

- Engine ServiceDocument18 pagesEngine ServiceDhanu MalarNo ratings yet

- (MAHINDRA) Manual de Taller Mahindra Pick Up 2.6 InglesDocument620 pages(MAHINDRA) Manual de Taller Mahindra Pick Up 2.6 InglesRodrigo Henriquez100% (1)

- 1.8L FP EngineDocument327 pages1.8L FP EngineKamil Charmik LužaNo ratings yet

- Pages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-22Document4 pagesPages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-22Tolias EgwNo ratings yet

- Compressor Trouble ShoutingDocument7 pagesCompressor Trouble ShoutingDhiraj ShrivastavNo ratings yet

- Grand Cherokee 2011 5.7LDocument300 pagesGrand Cherokee 2011 5.7Lramon fuenmayorNo ratings yet

- Maintenance Schedule Surface MinerDocument8 pagesMaintenance Schedule Surface MinerSUBHASHNo ratings yet

- Engine FuelDocument24 pagesEngine FuelЮра Петренко100% (1)

- Content9732691 PDFDocument17 pagesContent9732691 PDFRaphael LemosNo ratings yet

- Adobe Scan 04 Aug 2023Document1 pageAdobe Scan 04 Aug 2023Samuel DinkuNo ratings yet

- SM 112Document210 pagesSM 112jhon greigNo ratings yet

- Fault Finding: Section F - TransmissionDocument1 pageFault Finding: Section F - TransmissionIonut GrozaNo ratings yet

- Gear Pump Troubleshooting GuideDocument3 pagesGear Pump Troubleshooting GuideRALPH JULES SARAUSNo ratings yet

- 2500 HD 2014 5.7LDocument287 pages2500 HD 2014 5.7LJuan PerezNo ratings yet

- 303-00 Diagnosis and TestingDocument10 pages303-00 Diagnosis and TestingFerhan SerdarogluNo ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Power Plant (CFM56)Document21 pagesPower Plant (CFM56)Jefferson CuNo ratings yet

- Stock+list Kta38g2 1200 Esn#41141041 CPL#6098-6981Document64 pagesStock+list Kta38g2 1200 Esn#41141041 CPL#6098-6981Alexis SanchezNo ratings yet

- IAME KA100 100cc REEDJET Engine Update 8 December 2019 PDFDocument59 pagesIAME KA100 100cc REEDJET Engine Update 8 December 2019 PDFpavli999No ratings yet

- ME 8792 PPE Unit - 2Document71 pagesME 8792 PPE Unit - 2UdamanNo ratings yet

- Mhi Marine Warranty PDFDocument4 pagesMhi Marine Warranty PDFTruong Nguyen ThanhNo ratings yet

- ELFL004Document15 pagesELFL004Destry YoungNo ratings yet

- Handout Mot3 Deu3 Tcd2012 2392731 v10 en PDFDocument80 pagesHandout Mot3 Deu3 Tcd2012 2392731 v10 en PDFPaul Cabello100% (1)

- Manual Taller ARN 125 CC (Idioma Ingles)Document85 pagesManual Taller ARN 125 CC (Idioma Ingles)Cordobessa50% (2)

- 6M115Document2 pages6M115Renato MatičevićNo ratings yet

- SEAT Ea211 and Ea888 Family Engine PDFDocument63 pagesSEAT Ea211 and Ea888 Family Engine PDFAco Acimovic100% (1)

- 8YS1-Up, 9NS1-Up Disassembly-AssemblyDocument124 pages8YS1-Up, 9NS1-Up Disassembly-AssemblyJonathan Luiz PolezaNo ratings yet

- Multi Point Fuel Injection SystemDocument20 pagesMulti Point Fuel Injection SystemVijay KasarNo ratings yet

- Catalogo NYC EngineDocument96 pagesCatalogo NYC EngineOmar Garcia100% (1)

- Basic Design Principles of Turbofan Engine: An Evolution of Turbojet For Better Characteristics???Document8 pagesBasic Design Principles of Turbofan Engine: An Evolution of Turbojet For Better Characteristics???mNo ratings yet

- FR94438 6BTAA5.9-G12 Datasheet - 01 - enDocument5 pagesFR94438 6BTAA5.9-G12 Datasheet - 01 - enEko SulistyoNo ratings yet

- Jonway 150 Long Gy6 Engine Parts Catalogue 图 1: Draft 1Document13 pagesJonway 150 Long Gy6 Engine Parts Catalogue 图 1: Draft 1jetionNo ratings yet

- Abdulla Abdul Gani Bros Tad1342ge 2013356118Document3 pagesAbdulla Abdul Gani Bros Tad1342ge 2013356118Anees AhmedNo ratings yet

- Veb PDFDocument11 pagesVeb PDFIzz Bahar100% (1)

- Pneumatic Bike: Presented byDocument13 pagesPneumatic Bike: Presented byNilesh BhaskarNo ratings yet

- Air Standard CycleDocument6 pagesAir Standard CycleBishOy NasrNo ratings yet

- A Comprehensive List of Fuel TankersDocument9 pagesA Comprehensive List of Fuel TankersDaniel CastilloNo ratings yet

- Diagnostic Report: ENGINE #1 - J1939 Active Fault CodesDocument3 pagesDiagnostic Report: ENGINE #1 - J1939 Active Fault CodesDiesel L1mayoNo ratings yet

- Loco MechDocument29 pagesLoco MechAbhishek PandeyNo ratings yet

- MTX70 Rev 12 Manual PDFDocument68 pagesMTX70 Rev 12 Manual PDFzanioNo ratings yet