Professional Documents

Culture Documents

Procedure For Control of Non-Conforming Product

Procedure For Control of Non-Conforming Product

Uploaded by

niteshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure For Control of Non-Conforming Product

Procedure For Control of Non-Conforming Product

Uploaded by

niteshCopyright:

Available Formats

Exide Leclanche Energy Pvt Ltd. DOC. NO.

: ELEPL/III/PD/QAD-08

Control of Non-Conforming Products Section No.

Page 1 of 10

PD/QAD-12

Control of Non-Conforming Products

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 31/12/2021

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

Exide Leclanche Energy Pvt Ltd. DOC. NO.: ELEPL/III/PD/QAD-08

Control of Non-Conforming Products Section No.

Page 2 of 10

PD/QAD-12

Table of Contents

1. Purpose ....... ……………………………………………………………………………………3

2. Scope .......... ……………………………………………………………………………………3

3. Responsibility………………………………………………………………………………....3

4. Definition………………………………………………………………………………………...3

5. Procedure……….………………………………………………………………………………5

6. Procedure Performance Indicators…….………………………………………………….10

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 31/12/2021

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

Exide Leclanche Energy Pvt Ltd. DOC. NO.: ELEPL/III/PD/QAD-08

Control of Non-Conforming Products Section No.

Page 3 of 10

PD/QAD-12

1. PURPOSE:

1.1 To define control procedure for identification, control and disposition of non-

conforming products and suspect material.

1.2 To ensure that non-confirming products and suspect material are not moved to next

operation.

1.3 To define the responsibility for review and authority for disposition of non-

confirming products and suspect material.

1.4 Control of Rework and rejected products.

2. SCOPE:

This procedure covers all manufacturing line and other areas of ELEPL.

2.1 NC Product Control including handling, storage, identification, and disposition of

Product at ELEPL.

2.2 Deviation Approval

3. RESPONSIBILITY:

3.1 The Process owner is responsible for implementing this Procedure

3.2 The Procedure can be amended by Process owner

3.3 This Procedure is reviewed & issued by Quality Department.

4. DEFINITION:

4.1. Non-conformity

Any deviation from Quality requirements of that process.

4.2 Non-conforming Product:

A product that does not conform to specified Quality requirements.

It is classified in five categories:

i. Rework:

A non-conforming product which can be reprocessed to make it suitable

to conform to the requirements.

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 31/12/2021

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

Exide Leclanche Energy Pvt Ltd. DOC. NO.: ELEPL/III/PD/QAD-08

Control of Non-Conforming Products Section No.

Page 4 of 10

PD/QAD-12

ii. Repair:

Repair is an action on non-conforming product to make it acceptable for

intended use.

iii. Scrap:

A non-conforming product which can not be reprocessed for

conformance to requirements.

iv. Deviation:

Permission to use or release a product in which some

parameters/specifications do not conform to specified Quality

requirements but will not affect the functional requirement of final product.

v. Suspect Material or Product

Any material or product where the inspection and test status are

uncertain or not known.

4.3 “Drawing” is a well drawn data by hand or by computer which clarifies contents

and structure of product, tooling, devices, layouts, packing, machine parts, and

sub assemblies.

4.4 “User Departments” are the Departments which use the drawings for their

working.

4.5 “Engineering standards” are the standards made by product & process

engineering for making and inspecting various components.

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 31/12/2021

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

Exide Leclanche Energy Pvt Ltd. DOC. NO.: ELEPL/III/PD/QAD-08

Control of Non-Conforming Products Section No.

Page 5 of 10

PD/QAD-12

S.NO. RECORD /

ACTIVITY RESP.

CROSS REF.

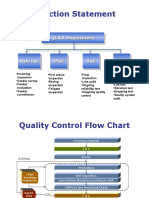

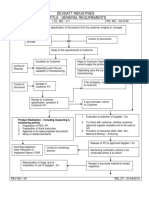

5.1 PROCEDURE FOR NC PRODUCT CONTROL

5.1.1 IDENTIFICATION & STORAGE:

A non-confirming product is labelled/marked as follows: Prod. Designated

Labels

a) Reject/Scrap - ELEPL/IV/FR/PRO-19

b) Pass/OK - ELEPL/IV/FR/PRO-18

c) Rework/Hold ELEPL/IV/FR/PRO-17

5.1.2 N.C. Product is stored in separately defined area. Respective Designated

process area

owner

5.1.3 Colour Coding for storage:

Shift Sup. / Tags

Reject - Red colour Respective PCD

Pass - Green colour

Hold/Rework - Yellow colour

5.1.4 This procedure defines the control of NC product for

Material processed at ELEPL.

Material processed by Supplier (As per Procedure

ELEPL/III/PD/QAD-03)

5.2 MATERIAL PROCESSED AT ELEPL

5.2.1 Detection

The NC material is detected during Job setting, Respective -----

Regular production Audit, During subsequent operation Line supervisor

Initial product / New product production

When inspection equipment/gauge is found out of

calibration

5.2.2 Identification

The NC material is identified by appropriate labels as Respective ------

mentioned in step 5.1. Labels are put by Supervisor

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 31/12/2021

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

Exide Leclanche Energy Pvt Ltd. DOC. NO.: ELEPL/III/PD/QAD-08

Control of Non-Conforming Products Section No.

Page 6 of 10

PD/QAD-12

operator/auditor/shift supervisor/setter as the case may

be.

5.2.3 Recording

The quantity of NC material is recorded in setting Shift Sup. / Respective

approval check sheet/Daily rejection sheets Respective setting approval

operator check sheet/

/Daily rejection

sheets

5.2.4 Disposition

The disposition of NC material identified by the Shift Sup. / --------

operator/auditor/setter is done in concurrence with Respective

In-charge

production & or quality supervisor. NC material is

disposed as follows:

5.2.4.1 Scrap Disposition & control

Scrap materials are verified by Production & sent to Shift Sup. / Rejection

earmarked area for scrap. Respective Record

In-charge ELEPL-IV-FR-

Quantity of scrap is recorded in daily rejection & after

PRO-13

disposition by QA, production will generate scrap

note and hand over to MP&L with approval from Scrap Note

Manufacturing Head. ELEPL-IV-FR-

MPL-02

5.2.4.2 Rework Disposition & control

- Rework material is reprocessed in following Shift Sup. /

manner. Respective SAP

Hold material in temporary storage, with Production

identification label near the line, it is reprocessed at in charge

the end of the shift & Recorded in SAP/log.

In case re-processing of rework is not possible with

same Shift then rework will be done at end of

Production order.

Recording of rework piece’s fault wise is done at

respective location and after rework processing Operator PQCS

inspection/verification to be done against original rework Parts

specifications.

- Rework failure mode risk analysis to be PFMEA &

potentially identified in PFMEA and control control

Process

addressed in control plan. Plan

Engg. & CFT Tag

ELEPL/IV/FR/PR

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 31/12/2021

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

Exide Leclanche Energy Pvt Ltd. DOC. NO.: ELEPL/III/PD/QAD-08

Control of Non-Conforming Products Section No.

Page 7 of 10

PD/QAD-12

- Record to be maintained of disposition of Production O-17/ Rejection

reworked product including quantity, disposition, Record

ELEPL-IV-FR-

disposition date, and applicable traceability PRO-13

information. & Traceability

- Ensure the customer specific requirement for

rework (if specified)

5.2.4.4 Disposition of material with Deviation

Pieces moved to next operation under deviation are Shift Sup. / Procedure for

controlled as per procedure for deviation. QA Deviation

(ELEPL/III/PD/QAD-02) ELEPL/III/PD

/QAD-02

5.2.4.5 Disposition of Lot for Sorting

After sorting by Concerned dept., material is identified Shift Sup. /

appropriately such as OK/rework/scrap/deviation. This is Respective in ------

treated as per steps shown above. Material tagging to be charge

done accordingly.

In case of Product Audit , if any discrepancy found

100 % material to be check for particular defect for same Product Audit

production order. Quality Auditor report

(ELEPL-IV-

FR-QAD-29)

5.2.4.6.1 In case of non-conforming product, ------- ------

such as rework, scrap, or material under deviation it is

handled as per Step 5.4

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 31/12/2021

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

Exide Leclanche Energy Pvt Ltd. DOC. NO.: ELEPL/III/PD/QAD-08

Control of Non-Conforming Products Section No.

Page 8 of 10

PD/QAD-12

Analysis & Countermeasure of non-conforming products-

S.NO. RECORD /

ACTIVITY RESP.

CROSS REF.

5.2.5 Analysis & Countermeasure

Review and analyse the non-conformities. Respective Designated formats

Takes appropriate correction/corrective/ action DH

as per procedure for Problem solving action

No. ELEPL/III/PD/QAD-08, Section PD/QAD-

11

5.3 Material processed by Supplier

5.3.1 Detection of Non-conformity:

The non-conformity in any purchased

material can be detected at following stages: -

a) Receiving Inspection

b) During Manufacturing Processes

5.3.1.1 Non-Conformity at Receiving Inspection Stage

After the material has been inspected as per Respective ELEPL-IV-FR-QAD-

respective Receiving Inspection Procedures, the Engg. 11 IGI Rejection Log

respective inspection in-charge posts NC material Incoming Book & SAP

in SAP. NC material is identified by putting

`REJECT' labels on material.

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 31/12/2021

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

Exide Leclanche Energy Pvt Ltd. DOC. NO.: ELEPL/III/PD/QAD-08

Control of Non-Conforming Products Section No.

Page 9 of 10

PD/QAD-12

5.3.1.2 The NC material is stored in separately marked Stores As per stores

areas as per Identification and Storage place procedure

5.3.1.3 This NC material is disposed as per procedure for Store / SQA As per stores &

receiving inspection & Stores / SQD Receiving

Inspection procedure

(ELEPL/III/PD/QAD-03)

5.3.1.5 Non-Conformity in Input material detected

during Manufacturing Process

5.3.1.5.1 When NC material is detected after the material has Incoming To be discussed in

been issued to shop and put into the production Engg. DWM.

process the concerned production keeps the

material duly identified and informs Incoming

Quality.

Further action is to be taken as per SQD procedure.

5.3.1.5.2 Scrap/Rework pieces are recorded in Supplier Respective Supplier rejection log

Rejection Sheet and OK material is released for Incoming

next process. Engg.

5.4 PROCEDURE FOR DEVIATION APPROVAL

RECORD /

S.NO. ACTIVITY RESP.

CROSS REF.

Any material / product for which Deviation Respective ELEPL/III/PD/QAD

5.4.1 approval is required, to be handled as per DH -02

Deviation procedure ELEPL/III/PD/QAD-02

DESTRUCTIVE TESTING SCRAP

5.5 Engg. QA ------

CONTOL

Non-conformity can be detected at following

stages

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 31/12/2021

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

Exide Leclanche Energy Pvt Ltd. DOC. NO.: ELEPL/III/PD/QAD-08

Control of Non-Conforming Products Section No.

Page 10 of 10

PD/QAD-12

- Material Checking at incoming

- Material checking in-process

After destructive test, put scrap material in red

5.5.1

bin at lab

Fill Scrap note (SAP) and Scrap material Engg. ELEPL-IV-FR-MPL-

5.5.1.1 02

handed over to stores (MP&L) Incoming

5.6 PROTOTYPE LAB SCRAP CONTROL

Scrap note to be filled by Proto-in-charge for Proto In- ELEPL-IV-FR-MPL-

the declared scrap and hand over to MP&L. charge 02

6. PROCEDURE PERFORMANCE INDICATOR:

6.1. Customer complaint.

6.2. Rejection%

6.3 Rework%

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 31/12/2021

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

You might also like

- CT Excel Skills Test v2.0Document4 pagesCT Excel Skills Test v2.0Bilee Sabino100% (2)

- Structural Steel ContractDocument3 pagesStructural Steel ContractRini ButarbutarNo ratings yet

- 5.7 - Non-Conforming Material & Product Control Procedure.Document1 page5.7 - Non-Conforming Material & Product Control Procedure.Md.Akidul Islam AkidNo ratings yet

- 34 Radio Altimeter SystemDocument20 pages34 Radio Altimeter SystemTarik Benzineb50% (2)

- MDSAP QMS P0011.004 Complaint Customer Feedback Procedure PDFDocument8 pagesMDSAP QMS P0011.004 Complaint Customer Feedback Procedure PDFAmer Rahmah0% (1)

- PPEPL-SOP-03 Procedure For Control of NCDocument7 pagesPPEPL-SOP-03 Procedure For Control of NCRaja RehaNo ratings yet

- Procedure Recall ProductDocument3 pagesProcedure Recall ProductLinda Setya Wati100% (2)

- QSP 8.3.1 Nonconforming Product - SampleDocument3 pagesQSP 8.3.1 Nonconforming Product - SampleGladys Calvo100% (2)

- Prepared By: Signature: Name: Khuram Shahzad Date: Designation: SR - Manager QA/QCDocument2 pagesPrepared By: Signature: Name: Khuram Shahzad Date: Designation: SR - Manager QA/QCMhammad NaveedNo ratings yet

- PRO-CAL-01 Measuring Equipment Calibration ProgramDocument2 pagesPRO-CAL-01 Measuring Equipment Calibration ProgramChiekoi PasaoaNo ratings yet

- Control of Nonconforming ProductDocument2 pagesControl of Nonconforming ProductAliyantahir100% (2)

- Approved External Providers ListDocument2 pagesApproved External Providers ListMuhammad BabarNo ratings yet

- 03 Procedure For Control of Non-Conforming OutputDocument3 pages03 Procedure For Control of Non-Conforming OutputLKM HOSPITALNo ratings yet

- Control of Noncomformitiy and Corrective Action PDFDocument7 pagesControl of Noncomformitiy and Corrective Action PDFNixNo ratings yet

- Method Statement Procedure For Control of Non Conforming ProductDocument6 pagesMethod Statement Procedure For Control of Non Conforming Productmangeshshinde124100% (1)

- DDO DRAFT Control of Documented InformationDocument8 pagesDDO DRAFT Control of Documented InformationREn EngAdaNo ratings yet

- Procedure Risk ManagementDocument2 pagesProcedure Risk ManagementAnbuNo ratings yet

- Corrective and Preventative Action (CAPA) Procedure (ISO27001)Document5 pagesCorrective and Preventative Action (CAPA) Procedure (ISO27001)Maulana SyaifullahNo ratings yet

- Document ControlDocument11 pagesDocument ControlPRADEEP KUMARNo ratings yet

- Document Change Request FormDocument2 pagesDocument Change Request FormOlexei SmartNo ratings yet

- Mandatory Documents and Records (Ref: ISO 9001:2008)Document4 pagesMandatory Documents and Records (Ref: ISO 9001:2008)Shashank ChhajerNo ratings yet

- Master List of Forms FormatsDocument1 pageMaster List of Forms Formatschahi100% (1)

- CAPA Corrective and Preventive Action in PharmaceuticalDocument5 pagesCAPA Corrective and Preventive Action in PharmaceuticalRainMan75No ratings yet

- Sta-P08-02 Non Conforming ProductDocument6 pagesSta-P08-02 Non Conforming ProductAnonymous B7pghhNo ratings yet

- Procedure For Emergency PreparenessDocument4 pagesProcedure For Emergency PreparenessNaizil KareemNo ratings yet

- I. Ii. Iii. Iv. V.: 1 PurposeDocument6 pagesI. Ii. Iii. Iv. V.: 1 Purposemuhamad yasserNo ratings yet

- G Corrective Action Section 7Document3 pagesG Corrective Action Section 7Ngonidzashe Zvarevashe100% (1)

- QMS-SOP-F15 - Procedure For Control of Document InformationDocument4 pagesQMS-SOP-F15 - Procedure For Control of Document InformationPINTU RAJNo ratings yet

- SOP02-Control of Quality RecordsDocument6 pagesSOP02-Control of Quality RecordsAna Hidayah SyuhadaNo ratings yet

- Form - Scar LogDocument16 pagesForm - Scar LogVenkat BhagavatiNo ratings yet

- Function Statement: QC&A DepartmentDocument3 pagesFunction Statement: QC&A DepartmentMohamed100% (1)

- Document Change RequestDocument1 pageDocument Change RequestvyerramallaNo ratings yet

- QSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207Document34 pagesQSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207SureshNo ratings yet

- Procedure For Corrective Action-17020Document6 pagesProcedure For Corrective Action-17020caser juliuNo ratings yet

- Preventive Maintenance PlanDocument7 pagesPreventive Maintenance PlanCuyapo Infirmary Lying-In HospitalNo ratings yet

- QP-72-03 Customer CommunicationDocument3 pagesQP-72-03 Customer CommunicationSamsudin AhmadNo ratings yet

- Standard Operating Procedure: CalibrationDocument22 pagesStandard Operating Procedure: CalibrationMaryanthony NamyaloNo ratings yet

- QAF-109 Supplier Corrective Action Request - GIDEP 6-1-18Document15 pagesQAF-109 Supplier Corrective Action Request - GIDEP 6-1-18AlineMeirelesNo ratings yet

- SOP For IQADocument25 pagesSOP For IQAMuhammad As'adNo ratings yet

- External Providers Evaluation FormDocument1 pageExternal Providers Evaluation FormISO CERTIFICATION-ROHSNo ratings yet

- 10.1 ImprovementDocument8 pages10.1 ImprovementVijayendran VijayNo ratings yet

- Master List of Documents As Per Qms & LMS: Quality Annexure ManualDocument4 pagesMaster List of Documents As Per Qms & LMS: Quality Annexure Manualbabu541No ratings yet

- SOP For Sampling of Finished ProductDocument3 pagesSOP For Sampling of Finished ProductSolomonNo ratings yet

- Process Flow Chart PDFDocument2 pagesProcess Flow Chart PDFSerkan CebeciogluNo ratings yet

- GKPI Quality ManualDocument46 pagesGKPI Quality ManualtarunNo ratings yet

- Flowchart For New Supplier SelectionDocument1 pageFlowchart For New Supplier SelectionVinod SaleNo ratings yet

- QMS Risk IdentificationDocument6 pagesQMS Risk IdentificationyogshastriNo ratings yet

- Non Conformity ReportDocument1 pageNon Conformity ReportaikqualityNo ratings yet

- PR-5 - Docuent Control ProcedureDocument7 pagesPR-5 - Docuent Control ProcedureSAMEER JAVEDNo ratings yet

- Centurion Power Cables (P) LTD.: Control of DocumentDocument4 pagesCenturion Power Cables (P) LTD.: Control of DocumenttriveshNo ratings yet

- Supplier Vendor Qualification QuestionnaireDocument12 pagesSupplier Vendor Qualification QuestionnaireyolaisaNo ratings yet

- Internal Audit Risk Scale and AssessmentDocument4 pagesInternal Audit Risk Scale and AssessmentWasim ArshadNo ratings yet

- Supplier Evaluation The First Step in Effective SoDocument4 pagesSupplier Evaluation The First Step in Effective SoShatender kumar Kumar100% (1)

- QSP-006 R0 QSP For Non-Conformance Product ControlDocument13 pagesQSP-006 R0 QSP For Non-Conformance Product ControljennyNo ratings yet

- Control of Non-Conforming Products ProcedureDocument4 pagesControl of Non-Conforming Products ProcedureSolomon GamanuelNo ratings yet

- Eop 45 01Document10 pagesEop 45 01Muhammad ArslanNo ratings yet

- QSP Control of Documented InformationDocument2 pagesQSP Control of Documented InformationtriveshNo ratings yet

- 19 Purchasing ProcedureDocument7 pages19 Purchasing ProcedureSasi KssNo ratings yet

- Employee Training LogDocument6 pagesEmployee Training LogRoosy RoosyNo ratings yet

- 8b Procedure Inprocess QualityDocument2 pages8b Procedure Inprocess QualityniteshNo ratings yet

- A Control of Nonconforming Material: Document Number Revision Title Rev DateDocument3 pagesA Control of Nonconforming Material: Document Number Revision Title Rev DateImam MansyurNo ratings yet

- Final Procedure QC Retroactive Added...Document11 pagesFinal Procedure QC Retroactive Added...Rehan RehmanNo ratings yet

- Department: Auditor: Auditee:: Date: Shift &time: Sr. No Audit Point Yes / No Evidence Sighted StatusDocument2 pagesDepartment: Auditor: Auditee:: Date: Shift &time: Sr. No Audit Point Yes / No Evidence Sighted StatusAnkit SainiNo ratings yet

- 8b Procedure Inprocess QualityDocument2 pages8b Procedure Inprocess QualityniteshNo ratings yet

- Problem Solving - CAPADocument6 pagesProblem Solving - CAPAniteshNo ratings yet

- QMS Risk AssessmentDocument5 pagesQMS Risk AssessmentniteshNo ratings yet

- QPDocument1 pageQPniteshNo ratings yet

- Employee CompetenceDocument1 pageEmployee CompetenceniteshNo ratings yet

- Martini Absorb Installation Guide - 0421Document3 pagesMartini Absorb Installation Guide - 0421lac ngoNo ratings yet

- Combat Aircraft Monthly - September 2015 UK VK Com Stopthepress PDFDocument100 pagesCombat Aircraft Monthly - September 2015 UK VK Com Stopthepress PDFAnonymous N13JdnNo ratings yet

- Solar PV System PromotionDocument2 pagesSolar PV System PromotionaaqilNo ratings yet

- Chapter 1: Background of The Campany: 1.1 Brief HistoryDocument41 pagesChapter 1: Background of The Campany: 1.1 Brief HistoryBona TolosaNo ratings yet

- Quiz no.1-OMnDA-MBA-Sem1 Sesi 20192020-JulyAugust 2020-Soalan OnlyDocument7 pagesQuiz no.1-OMnDA-MBA-Sem1 Sesi 20192020-JulyAugust 2020-Soalan OnlyMuhammad IzzatNo ratings yet

- DCMAISO9001 AS9100 ChecklistDocument73 pagesDCMAISO9001 AS9100 ChecklistNestor Czerwacki0% (3)

- Canadian Solar Datasheet CS6XP Maxpower V5.4c1enDocument2 pagesCanadian Solar Datasheet CS6XP Maxpower V5.4c1enabhi_26tNo ratings yet

- 2015 HSC Indt TimberDocument10 pages2015 HSC Indt Timberandjelko22No ratings yet

- Town Centre AmanoraDocument11 pagesTown Centre AmanoraRutu LotiaNo ratings yet

- Micro Plan Mismatch Nassa Revalidation Vs Aoi Vs Drawing STDDocument4 pagesMicro Plan Mismatch Nassa Revalidation Vs Aoi Vs Drawing STDSuresh GanapathyNo ratings yet

- 3d Printing InternshipDocument2 pages3d Printing InternshipDharshan SNo ratings yet

- Atch 2 SOW 03Aug18Final PDFDocument5 pagesAtch 2 SOW 03Aug18Final PDFDanielNo ratings yet

- Ar2011full - Annual Report of ToyotaDocument120 pagesAr2011full - Annual Report of ToyotaVivek TyagiNo ratings yet

- IT Solutions Manager in Cincinnati OH Resume James SchababerleDocument2 pagesIT Solutions Manager in Cincinnati OH Resume James SchababerleJamesSchababerleNo ratings yet

- Commuters' Perceptions of Public Transport Service in South AfricaDocument13 pagesCommuters' Perceptions of Public Transport Service in South AfricaCentre of Excellence for Scientific & Research Journalism, COES&RJ-JLLCNo ratings yet

- Brake Air SystemDocument24 pagesBrake Air SystemIzz Bahar100% (1)

- Cable Sector Case StudyDocument6 pagesCable Sector Case StudySandeep PimpaleNo ratings yet

- Arnab Mohanty: Extracurricular AchievementsDocument1 pageArnab Mohanty: Extracurricular Achievementssaheb167No ratings yet

- Assignment 2Document3 pagesAssignment 2Anonymous pX0vP8hNo ratings yet

- CRMDocument52 pagesCRMAjay MaheskaNo ratings yet

- Call Center TerminologiesDocument3 pagesCall Center TerminologiesJoy CelestialNo ratings yet

- LOLER Inspection Checklist SheetDocument4 pagesLOLER Inspection Checklist SheetaliNo ratings yet

- DIY Scissor Lift 1Document6 pagesDIY Scissor Lift 1daniel deeeNo ratings yet

- Mini - Project Report 1Document53 pagesMini - Project Report 1Manish MishraNo ratings yet

- Uml Diagram ExerciseDocument6 pagesUml Diagram ExerciseSITI BRITNEY BINTI AFFANDI KM-PelajarNo ratings yet

- 08-MM-03 - SDD - MSRDC - VBSL - Contractor Empanelment For EPCDocument11 pages08-MM-03 - SDD - MSRDC - VBSL - Contractor Empanelment For EPCDanielpremassisNo ratings yet