Professional Documents

Culture Documents

8b Procedure Inprocess Quality

8b Procedure Inprocess Quality

Uploaded by

niteshCopyright:

Available Formats

You might also like

- Motor Nissan Qd32 ManualDocument3 pagesMotor Nissan Qd32 ManualHector De La Rosa38% (26)

- 2.procedures Initial Supply Control UpdatedDocument3 pages2.procedures Initial Supply Control UpdatedKapil Karhana100% (2)

- Quality-Plan in Manufacturing Og Pre-Eng'Ng StructuresDocument23 pagesQuality-Plan in Manufacturing Og Pre-Eng'Ng StructuresPageduesca Rouel100% (1)

- ISA TR84.00.03 Guidance For Testing of Process Sector Safety Instrumented FunctionsDocument222 pagesISA TR84.00.03 Guidance For Testing of Process Sector Safety Instrumented FunctionsGopalMahanta100% (1)

- A Single SignOn Guide For SAP S4HANA Cloud, Private EditionDocument15 pagesA Single SignOn Guide For SAP S4HANA Cloud, Private EditionmutyalapatiNo ratings yet

- AC7101 1 Rev F PDFDocument27 pagesAC7101 1 Rev F PDFunknown1711No ratings yet

- Qp-I&t R05 - OkDocument5 pagesQp-I&t R05 - OkFatin NajehahNo ratings yet

- QP-QA-03-Final InspectionDocument2 pagesQP-QA-03-Final InspectionDebkanta Das100% (1)

- ITP Rev.05 FOR SATORPDocument1 pageITP Rev.05 FOR SATORPFahim MarwatNo ratings yet

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

- Heat Treatment - Furnace TreatmentDocument19 pagesHeat Treatment - Furnace Treatmentkumar QANo ratings yet

- QP-QA-05-Control of Non-Conforming ProductDocument2 pagesQP-QA-05-Control of Non-Conforming ProductDebkanta DasNo ratings yet

- Sample Procedure FlowDocument3 pagesSample Procedure Flowvyly1723No ratings yet

- 1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1Document1 page1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1KirubhakarPooranamNo ratings yet

- QAV-2 Step-3 Audit Check Sheet PDFDocument5 pagesQAV-2 Step-3 Audit Check Sheet PDFRajNo ratings yet

- Procedure For Control of Non-Conforming ProductDocument10 pagesProcedure For Control of Non-Conforming ProductniteshNo ratings yet

- CVN-WI-QUA-037 Quality Risk Assessment-Ver04 PDFDocument7 pagesCVN-WI-QUA-037 Quality Risk Assessment-Ver04 PDFLê Việt CườngNo ratings yet

- GM 1927 16 Process Control Plan Audit PCPADocument7 pagesGM 1927 16 Process Control Plan Audit PCPAMostafa Abd ElalemNo ratings yet

- QAD Procedure - Lab Management P2Document1 pageQAD Procedure - Lab Management P2sumanNo ratings yet

- KQP 16 Inspection & Testing Rev 04Document11 pagesKQP 16 Inspection & Testing Rev 04Mohd Isa HarunNo ratings yet

- Apqp Progress Report CoversheetDocument3 pagesApqp Progress Report Coversheetponrajan1979No ratings yet

- APQP Progress Report - CoversheetDocument3 pagesAPQP Progress Report - CoversheetAman AwachatNo ratings yet

- 1.QP01 QCDocument6 pages1.QP01 QCpankaj bhargaveNo ratings yet

- 18) Corrective and Preventive ActionDocument5 pages18) Corrective and Preventive ActionSagar DaundNo ratings yet

- 1.itp Sur 0001Document2 pages1.itp Sur 0001Doni TriatmojoNo ratings yet

- Steel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditDocument2 pagesSteel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditmahendraNo ratings yet

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Document35 pages4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNo ratings yet

- 39) Procedure For Inspection & Testing - 104931Document5 pages39) Procedure For Inspection & Testing - 104931Sagar DaundNo ratings yet

- 25875-000-V1A-PS02-00004 - Rev.003-With ApprovalDocument11 pages25875-000-V1A-PS02-00004 - Rev.003-With ApprovalKarthikNo ratings yet

- IMSP-21 Control of Nonconforming Products-QADocument5 pagesIMSP-21 Control of Nonconforming Products-QApassionpaver01No ratings yet

- QP-QA-01-Receiving InspectionDocument2 pagesQP-QA-01-Receiving InspectionDebkanta DasNo ratings yet

- p174245 A2 Schaeffler Escalation Process enDocument6 pagesp174245 A2 Schaeffler Escalation Process enpedrio54No ratings yet

- Exhibit D3 Inspection and Test Plan (ITP)Document12 pagesExhibit D3 Inspection and Test Plan (ITP)Muhammad Ali AkbarNo ratings yet

- Management System Manual: Title Doc. No. ProcessDocument2 pagesManagement System Manual: Title Doc. No. ProcessZina CabreraNo ratings yet

- QAP - Gate Valve - NPCILDocument6 pagesQAP - Gate Valve - NPCILkaustavNo ratings yet

- Incoming Inspection: QSP-QC-05 Rev.: 4 Date: 8/2/2012Document3 pagesIncoming Inspection: QSP-QC-05 Rev.: 4 Date: 8/2/2012JithuRajNo ratings yet

- 16 - Procedure For Control of Production Provisions (Machine Shop I &II)Document6 pages16 - Procedure For Control of Production Provisions (Machine Shop I &II)rockyNo ratings yet

- ACL-CPIS-01 (Control of Purchased Services)Document3 pagesACL-CPIS-01 (Control of Purchased Services)Mo ZeroNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- Qad Sop 129Document4 pagesQad Sop 129Hemendra DaveNo ratings yet

- KLD 65 4800088401 ZV L03 00001 0000Document21 pagesKLD 65 4800088401 ZV L03 00001 0000chandana kumarNo ratings yet

- Quality Assurance Plan: MPL QAP No.Document13 pagesQuality Assurance Plan: MPL QAP No.Varun MalhotraNo ratings yet

- Field Quality Plan - Civil - Rev 1 - 24 (1) .04.09Document13 pagesField Quality Plan - Civil - Rev 1 - 24 (1) .04.09Sandeep JoshiNo ratings yet

- NEOPRSP011 - Rev. 00 - Pages 11 - Plant Operation Quality Assurance ProcedureDocument13 pagesNEOPRSP011 - Rev. 00 - Pages 11 - Plant Operation Quality Assurance Procedurealialharbi021No ratings yet

- PS - Copy of Supplier PSODocument11 pagesPS - Copy of Supplier PSODesmond MahadeoNo ratings yet

- Appendix-H Quality Intervention LevelsDocument1 pageAppendix-H Quality Intervention LevelsSiva baalanNo ratings yet

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- PUR-PM-06 Initial Flow Control For PCS SupplierDocument4 pagesPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarNo ratings yet

- SATIP-NDE-LPT-01 Liquid Penetrant Testing-Rev1Document2 pagesSATIP-NDE-LPT-01 Liquid Penetrant Testing-Rev1Sivaram KottaliNo ratings yet

- SIPOC DiagramDocument5 pagesSIPOC DiagramDiego MartínNo ratings yet

- Gapl-Qsp-03 NC ProductDocument3 pagesGapl-Qsp-03 NC Productsharif1974No ratings yet

- Work Instruction (SPC Study Engineer.)Document2 pagesWork Instruction (SPC Study Engineer.)SandeepNo ratings yet

- Product Part Approval Process: Automotive Quality Management SystemDocument3 pagesProduct Part Approval Process: Automotive Quality Management SystemrajaNo ratings yet

- P3-Process For Control of Non-ConformanceDocument3 pagesP3-Process For Control of Non-ConformanceBangali SinghNo ratings yet

- RC 2022 Summary CAFDDocument4 pagesRC 2022 Summary CAFDEjazNo ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- Work Instruction For Hydrostatic TestingDocument18 pagesWork Instruction For Hydrostatic TestingAlok SinghNo ratings yet

- Purpose: Radiation and Biomolecular Physics Division Quality System Guide RBPD-G-07 NonconformanceDocument3 pagesPurpose: Radiation and Biomolecular Physics Division Quality System Guide RBPD-G-07 NonconformancepannNo ratings yet

- Procedure For Control of Non Confirming ProductDocument7 pagesProcedure For Control of Non Confirming ProductAvijit DebnathNo ratings yet

- 48 Point Ppap Check SheetDocument39 pages48 Point Ppap Check SheetSanjay KumarNo ratings yet

- PO/Contract Number: 25875-000-POA-PS02-00001 Supplier/Contractor Name: Document Title: Material Traceability and Identification ProcedureDocument11 pagesPO/Contract Number: 25875-000-POA-PS02-00001 Supplier/Contractor Name: Document Title: Material Traceability and Identification ProcedureKarthikNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Problem Solving - CAPADocument6 pagesProblem Solving - CAPAniteshNo ratings yet

- Procedure For Control of Non-Conforming ProductDocument10 pagesProcedure For Control of Non-Conforming ProductniteshNo ratings yet

- QMS Risk AssessmentDocument5 pagesQMS Risk AssessmentniteshNo ratings yet

- Employee CompetenceDocument1 pageEmployee CompetenceniteshNo ratings yet

- QPDocument1 pageQPniteshNo ratings yet

- Quality Organizer - SqiDocument7 pagesQuality Organizer - SqierkaNo ratings yet

- ARTICOL4Document4 pagesARTICOL4CristiGheorgheNo ratings yet

- JSTA - Job Safety Task AssessmentDocument3 pagesJSTA - Job Safety Task AssessmentRyan GouwsNo ratings yet

- Is - Lecture 1Document49 pagesIs - Lecture 1Tayyab AslamNo ratings yet

- Chapter 1 ThesisDocument16 pagesChapter 1 ThesisAhsan Ali Ahsan AliNo ratings yet

- TI - 20201204 - Meteo Station and Sensor Commissioning Guide - V10 - ENDocument14 pagesTI - 20201204 - Meteo Station and Sensor Commissioning Guide - V10 - ENSubham HazraNo ratings yet

- Passive Building Design in JanakpurDocument29 pagesPassive Building Design in JanakpurAnurag SrivastavaNo ratings yet

- Controles Empresariales SAS NetworkassmtV2 NetworkHealthAndOutagesDocument280 pagesControles Empresariales SAS NetworkassmtV2 NetworkHealthAndOutagesLuisa BaqueroNo ratings yet

- 01 TM51101EN03GLA3 UMTS Overview PDFDocument42 pages01 TM51101EN03GLA3 UMTS Overview PDFPraveen KumarNo ratings yet

- Fit Gap AnalysisDocument3 pagesFit Gap AnalysiszazoNo ratings yet

- Automatic Transaxle System (A5SR1A5SR12)Document134 pagesAutomatic Transaxle System (A5SR1A5SR12)Wilson Aldana SuarezNo ratings yet

- ReadmeDocument3 pagesReadmePeng KikNo ratings yet

- Datasheet PDFDocument14 pagesDatasheet PDFadulphusjuhnosNo ratings yet

- EpidiascopeDocument6 pagesEpidiascoperumasadraunaNo ratings yet

- 8800 SchematicsDocument26 pages8800 Schematicstrixxi3No ratings yet

- ITSCS Pre Course MaterialDocument141 pagesITSCS Pre Course Materialjiya singhNo ratings yet

- Z-ABS Technical Data Sheet Eng-1Document2 pagesZ-ABS Technical Data Sheet Eng-1PeroNo ratings yet

- VW Diesel Industrial Engines, Workshop Manual.Document641 pagesVW Diesel Industrial Engines, Workshop Manual.Álvaro Manuel OliveiraNo ratings yet

- 7830W CATV Optical Receiver: ApplicationsDocument4 pages7830W CATV Optical Receiver: ApplicationsLe DungNo ratings yet

- 72426ECC0926AEB6Document13 pages72426ECC0926AEB6Betty PeltrocheNo ratings yet

- Presentation PDFDocument61 pagesPresentation PDFshaunNo ratings yet

- Tpmc-8X: Isysâ 8.4" Wifi TouchpanelDocument7 pagesTpmc-8X: Isysâ 8.4" Wifi TouchpanelHira SinghNo ratings yet

- Three-Phase Transformer Program "Trafo - Exe": CommentsDocument45 pagesThree-Phase Transformer Program "Trafo - Exe": CommentsmartinpellsNo ratings yet

- SOP Git BranchingDocument2 pagesSOP Git BranchinghighgrainNo ratings yet

- NW360Document2 pagesNW360free bishoNo ratings yet

- WesoxotDocument2 pagesWesoxotSEANMOSE LATNo ratings yet

- Where Next? Technology Leadership in A World Disrupted: Gartner For IT LeadersDocument14 pagesWhere Next? Technology Leadership in A World Disrupted: Gartner For IT LeadersSiddharth PatelNo ratings yet

8b Procedure Inprocess Quality

8b Procedure Inprocess Quality

Uploaded by

niteshOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8b Procedure Inprocess Quality

8b Procedure Inprocess Quality

Uploaded by

niteshCopyright:

Available Formats

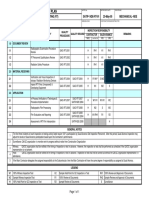

Exide Leclanche Energy Pvt Ltd. DOC. NO.

: ELEPL/II/PD/QAD-08

Section No.

In-Process Quality Procedure PD/QAD-08b

Page 1 of 2

PROCEDURE

Sl. Activity Responsibility Ref. Doc.

1. Module

1.1 Inspection is initiated post receiving of GRN from production.

GRN to be cleared within 24 hours of its receipt QC Engineer SAP

Reviewing the items to be inspected in SAP QM module (T-code

QA 32) on daily basis

.

1.2 Inspection and recording the inspections done. QC Engineer Sampling plan

ELEPL/III/PD/QAD-03

In process Inspection is carried our as per the work standard and Quality Process

check sheets and follow the sampling plan Control plan

PD/QAD-09

For BMS & BMU cards- follow sampling plan Process Inspection

For other card- 100% inspection. Report (PCB ASSY.)

ELEPL/IV/FR/QAD-13

Testing Process

Inspection Report

ELEPL/IV/FR/QAD-14

1.3 If material fulfils the entire requirement and specification, QC Engineer Nil

Tick mark QA ok on the status sticker pasted by production.

1.4 All rejected material is identified with RED colour rejection QA Engineer

sticker and sent back to production for rework, and re inspected NIL

post the rework

2.0 BMS & BMU( Battery Monitoring systems)

2.1 Inspection is initiated post receiving of GRN from production.

GRN to be cleared within 24 hours of its receipt QC Engineer SAP

Reviewing the items to be inspected in SAP QM module (T-code

QA 32) on daily basis

.

2.2 Inspection and recording the inspections done. QC Engineer Process Inspection

Report (PCB ASSY.)

100% Inspection is carried our as per the work standard and ELEPL/IV/FR/QAD-13

check sheets. Testing Process

Inspection Report

ELEPL/IV/FR/QAD-14

2.3 All accepted material identified with green colour stickers and QC Engineer NIL

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 10/06/2020

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

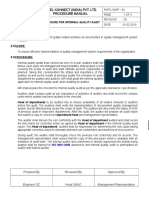

Exide Leclanche Energy Pvt Ltd. DOC. NO. : ELEPL/II/PD/QAD-08

Section No.

In-Process Quality Procedure PD/QAD-08b

Page 2 of 2

rejected with red colour stickers

3 Pack assembly

3.1 In case any non conformity observed by production department, Production engineer NIL

the same is intimated to Quality department.

4.0 Handling rejected Material

4.1 If supplier related issue: QA Engineer Supplier Quality

Informing to SD and supplier about the rejection (detailing the Rejection Report

qty and reason) and ELEPL/IV/FR/QAD-10

SCAR raised by IQC department for rejected material and send

to concern supplier/SD, SD follow to supplier to fill up within the Quality Log book

specific time period ELEPL/IV/FR/QAD-11

For local supplier –Within the 10 days

For overseas supplier- Within the 30 days

Maintaining Quality Log book

5.0 Analysis

5.1 Analysing process rejection on monthly basis QA Engineer Monthly Process

rejection analysis

ELEPL/IV/FR/QAD-17

Reference documents

Sl Document Name Format No Location Retention time

1 ELEPL/IV/F/QAD- MR Office 1 Year

Sampling plan 05

2 Quality Process Control plan ELEPL/IV/F/QAD- MR Office 1 Year

PD/QAD-09 06

3 ELEPL/IV/F/QAD- MR Office 1 Year

Supplier Quality Rejection Report 10

4 ELEPL/IV/F/QAD- MR Office 1 Year

Quality Log book 11

5 ELEPL/IV/F/QAD- MR Office 1 Year

Process Inspection Report (PCB ASSY.) 13

6 ELEPL/IV/F/QAD- MR Office 1 Year

Testing Process Inspection Report 14

7 ELEPL/IV/F/QAD- MR Office 1 Year

Monthly Process Rejection Analysis 17

Asst. Manager REVISION

Head - Quality MR CONTROLLED

Quality 00 10/06/2020

PREPARED BY CHECKED BY APPROVED BY CONTROL STATUS STATUS DATE

You might also like

- Motor Nissan Qd32 ManualDocument3 pagesMotor Nissan Qd32 ManualHector De La Rosa38% (26)

- 2.procedures Initial Supply Control UpdatedDocument3 pages2.procedures Initial Supply Control UpdatedKapil Karhana100% (2)

- Quality-Plan in Manufacturing Og Pre-Eng'Ng StructuresDocument23 pagesQuality-Plan in Manufacturing Og Pre-Eng'Ng StructuresPageduesca Rouel100% (1)

- ISA TR84.00.03 Guidance For Testing of Process Sector Safety Instrumented FunctionsDocument222 pagesISA TR84.00.03 Guidance For Testing of Process Sector Safety Instrumented FunctionsGopalMahanta100% (1)

- A Single SignOn Guide For SAP S4HANA Cloud, Private EditionDocument15 pagesA Single SignOn Guide For SAP S4HANA Cloud, Private EditionmutyalapatiNo ratings yet

- AC7101 1 Rev F PDFDocument27 pagesAC7101 1 Rev F PDFunknown1711No ratings yet

- Qp-I&t R05 - OkDocument5 pagesQp-I&t R05 - OkFatin NajehahNo ratings yet

- QP-QA-03-Final InspectionDocument2 pagesQP-QA-03-Final InspectionDebkanta Das100% (1)

- ITP Rev.05 FOR SATORPDocument1 pageITP Rev.05 FOR SATORPFahim MarwatNo ratings yet

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

- Heat Treatment - Furnace TreatmentDocument19 pagesHeat Treatment - Furnace Treatmentkumar QANo ratings yet

- QP-QA-05-Control of Non-Conforming ProductDocument2 pagesQP-QA-05-Control of Non-Conforming ProductDebkanta DasNo ratings yet

- Sample Procedure FlowDocument3 pagesSample Procedure Flowvyly1723No ratings yet

- 1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1Document1 page1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1KirubhakarPooranamNo ratings yet

- QAV-2 Step-3 Audit Check Sheet PDFDocument5 pagesQAV-2 Step-3 Audit Check Sheet PDFRajNo ratings yet

- Procedure For Control of Non-Conforming ProductDocument10 pagesProcedure For Control of Non-Conforming ProductniteshNo ratings yet

- CVN-WI-QUA-037 Quality Risk Assessment-Ver04 PDFDocument7 pagesCVN-WI-QUA-037 Quality Risk Assessment-Ver04 PDFLê Việt CườngNo ratings yet

- GM 1927 16 Process Control Plan Audit PCPADocument7 pagesGM 1927 16 Process Control Plan Audit PCPAMostafa Abd ElalemNo ratings yet

- QAD Procedure - Lab Management P2Document1 pageQAD Procedure - Lab Management P2sumanNo ratings yet

- KQP 16 Inspection & Testing Rev 04Document11 pagesKQP 16 Inspection & Testing Rev 04Mohd Isa HarunNo ratings yet

- Apqp Progress Report CoversheetDocument3 pagesApqp Progress Report Coversheetponrajan1979No ratings yet

- APQP Progress Report - CoversheetDocument3 pagesAPQP Progress Report - CoversheetAman AwachatNo ratings yet

- 1.QP01 QCDocument6 pages1.QP01 QCpankaj bhargaveNo ratings yet

- 18) Corrective and Preventive ActionDocument5 pages18) Corrective and Preventive ActionSagar DaundNo ratings yet

- 1.itp Sur 0001Document2 pages1.itp Sur 0001Doni TriatmojoNo ratings yet

- Steel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditDocument2 pagesSteel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditmahendraNo ratings yet

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Document35 pages4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNo ratings yet

- 39) Procedure For Inspection & Testing - 104931Document5 pages39) Procedure For Inspection & Testing - 104931Sagar DaundNo ratings yet

- 25875-000-V1A-PS02-00004 - Rev.003-With ApprovalDocument11 pages25875-000-V1A-PS02-00004 - Rev.003-With ApprovalKarthikNo ratings yet

- IMSP-21 Control of Nonconforming Products-QADocument5 pagesIMSP-21 Control of Nonconforming Products-QApassionpaver01No ratings yet

- QP-QA-01-Receiving InspectionDocument2 pagesQP-QA-01-Receiving InspectionDebkanta DasNo ratings yet

- p174245 A2 Schaeffler Escalation Process enDocument6 pagesp174245 A2 Schaeffler Escalation Process enpedrio54No ratings yet

- Exhibit D3 Inspection and Test Plan (ITP)Document12 pagesExhibit D3 Inspection and Test Plan (ITP)Muhammad Ali AkbarNo ratings yet

- Management System Manual: Title Doc. No. ProcessDocument2 pagesManagement System Manual: Title Doc. No. ProcessZina CabreraNo ratings yet

- QAP - Gate Valve - NPCILDocument6 pagesQAP - Gate Valve - NPCILkaustavNo ratings yet

- Incoming Inspection: QSP-QC-05 Rev.: 4 Date: 8/2/2012Document3 pagesIncoming Inspection: QSP-QC-05 Rev.: 4 Date: 8/2/2012JithuRajNo ratings yet

- 16 - Procedure For Control of Production Provisions (Machine Shop I &II)Document6 pages16 - Procedure For Control of Production Provisions (Machine Shop I &II)rockyNo ratings yet

- ACL-CPIS-01 (Control of Purchased Services)Document3 pagesACL-CPIS-01 (Control of Purchased Services)Mo ZeroNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- Qad Sop 129Document4 pagesQad Sop 129Hemendra DaveNo ratings yet

- KLD 65 4800088401 ZV L03 00001 0000Document21 pagesKLD 65 4800088401 ZV L03 00001 0000chandana kumarNo ratings yet

- Quality Assurance Plan: MPL QAP No.Document13 pagesQuality Assurance Plan: MPL QAP No.Varun MalhotraNo ratings yet

- Field Quality Plan - Civil - Rev 1 - 24 (1) .04.09Document13 pagesField Quality Plan - Civil - Rev 1 - 24 (1) .04.09Sandeep JoshiNo ratings yet

- NEOPRSP011 - Rev. 00 - Pages 11 - Plant Operation Quality Assurance ProcedureDocument13 pagesNEOPRSP011 - Rev. 00 - Pages 11 - Plant Operation Quality Assurance Procedurealialharbi021No ratings yet

- PS - Copy of Supplier PSODocument11 pagesPS - Copy of Supplier PSODesmond MahadeoNo ratings yet

- Appendix-H Quality Intervention LevelsDocument1 pageAppendix-H Quality Intervention LevelsSiva baalanNo ratings yet

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- PUR-PM-06 Initial Flow Control For PCS SupplierDocument4 pagesPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarNo ratings yet

- SATIP-NDE-LPT-01 Liquid Penetrant Testing-Rev1Document2 pagesSATIP-NDE-LPT-01 Liquid Penetrant Testing-Rev1Sivaram KottaliNo ratings yet

- SIPOC DiagramDocument5 pagesSIPOC DiagramDiego MartínNo ratings yet

- Gapl-Qsp-03 NC ProductDocument3 pagesGapl-Qsp-03 NC Productsharif1974No ratings yet

- Work Instruction (SPC Study Engineer.)Document2 pagesWork Instruction (SPC Study Engineer.)SandeepNo ratings yet

- Product Part Approval Process: Automotive Quality Management SystemDocument3 pagesProduct Part Approval Process: Automotive Quality Management SystemrajaNo ratings yet

- P3-Process For Control of Non-ConformanceDocument3 pagesP3-Process For Control of Non-ConformanceBangali SinghNo ratings yet

- RC 2022 Summary CAFDDocument4 pagesRC 2022 Summary CAFDEjazNo ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- Work Instruction For Hydrostatic TestingDocument18 pagesWork Instruction For Hydrostatic TestingAlok SinghNo ratings yet

- Purpose: Radiation and Biomolecular Physics Division Quality System Guide RBPD-G-07 NonconformanceDocument3 pagesPurpose: Radiation and Biomolecular Physics Division Quality System Guide RBPD-G-07 NonconformancepannNo ratings yet

- Procedure For Control of Non Confirming ProductDocument7 pagesProcedure For Control of Non Confirming ProductAvijit DebnathNo ratings yet

- 48 Point Ppap Check SheetDocument39 pages48 Point Ppap Check SheetSanjay KumarNo ratings yet

- PO/Contract Number: 25875-000-POA-PS02-00001 Supplier/Contractor Name: Document Title: Material Traceability and Identification ProcedureDocument11 pagesPO/Contract Number: 25875-000-POA-PS02-00001 Supplier/Contractor Name: Document Title: Material Traceability and Identification ProcedureKarthikNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Problem Solving - CAPADocument6 pagesProblem Solving - CAPAniteshNo ratings yet

- Procedure For Control of Non-Conforming ProductDocument10 pagesProcedure For Control of Non-Conforming ProductniteshNo ratings yet

- QMS Risk AssessmentDocument5 pagesQMS Risk AssessmentniteshNo ratings yet

- Employee CompetenceDocument1 pageEmployee CompetenceniteshNo ratings yet

- QPDocument1 pageQPniteshNo ratings yet

- Quality Organizer - SqiDocument7 pagesQuality Organizer - SqierkaNo ratings yet

- ARTICOL4Document4 pagesARTICOL4CristiGheorgheNo ratings yet

- JSTA - Job Safety Task AssessmentDocument3 pagesJSTA - Job Safety Task AssessmentRyan GouwsNo ratings yet

- Is - Lecture 1Document49 pagesIs - Lecture 1Tayyab AslamNo ratings yet

- Chapter 1 ThesisDocument16 pagesChapter 1 ThesisAhsan Ali Ahsan AliNo ratings yet

- TI - 20201204 - Meteo Station and Sensor Commissioning Guide - V10 - ENDocument14 pagesTI - 20201204 - Meteo Station and Sensor Commissioning Guide - V10 - ENSubham HazraNo ratings yet

- Passive Building Design in JanakpurDocument29 pagesPassive Building Design in JanakpurAnurag SrivastavaNo ratings yet

- Controles Empresariales SAS NetworkassmtV2 NetworkHealthAndOutagesDocument280 pagesControles Empresariales SAS NetworkassmtV2 NetworkHealthAndOutagesLuisa BaqueroNo ratings yet

- 01 TM51101EN03GLA3 UMTS Overview PDFDocument42 pages01 TM51101EN03GLA3 UMTS Overview PDFPraveen KumarNo ratings yet

- Fit Gap AnalysisDocument3 pagesFit Gap AnalysiszazoNo ratings yet

- Automatic Transaxle System (A5SR1A5SR12)Document134 pagesAutomatic Transaxle System (A5SR1A5SR12)Wilson Aldana SuarezNo ratings yet

- ReadmeDocument3 pagesReadmePeng KikNo ratings yet

- Datasheet PDFDocument14 pagesDatasheet PDFadulphusjuhnosNo ratings yet

- EpidiascopeDocument6 pagesEpidiascoperumasadraunaNo ratings yet

- 8800 SchematicsDocument26 pages8800 Schematicstrixxi3No ratings yet

- ITSCS Pre Course MaterialDocument141 pagesITSCS Pre Course Materialjiya singhNo ratings yet

- Z-ABS Technical Data Sheet Eng-1Document2 pagesZ-ABS Technical Data Sheet Eng-1PeroNo ratings yet

- VW Diesel Industrial Engines, Workshop Manual.Document641 pagesVW Diesel Industrial Engines, Workshop Manual.Álvaro Manuel OliveiraNo ratings yet

- 7830W CATV Optical Receiver: ApplicationsDocument4 pages7830W CATV Optical Receiver: ApplicationsLe DungNo ratings yet

- 72426ECC0926AEB6Document13 pages72426ECC0926AEB6Betty PeltrocheNo ratings yet

- Presentation PDFDocument61 pagesPresentation PDFshaunNo ratings yet

- Tpmc-8X: Isysâ 8.4" Wifi TouchpanelDocument7 pagesTpmc-8X: Isysâ 8.4" Wifi TouchpanelHira SinghNo ratings yet

- Three-Phase Transformer Program "Trafo - Exe": CommentsDocument45 pagesThree-Phase Transformer Program "Trafo - Exe": CommentsmartinpellsNo ratings yet

- SOP Git BranchingDocument2 pagesSOP Git BranchinghighgrainNo ratings yet

- NW360Document2 pagesNW360free bishoNo ratings yet

- WesoxotDocument2 pagesWesoxotSEANMOSE LATNo ratings yet

- Where Next? Technology Leadership in A World Disrupted: Gartner For IT LeadersDocument14 pagesWhere Next? Technology Leadership in A World Disrupted: Gartner For IT LeadersSiddharth PatelNo ratings yet