Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

40 viewsFloating Tank Erection Procdeure

Floating Tank Erection Procdeure

Uploaded by

Chetan PatelEYpwehs

BGH:MBL

SFB:

xcm;v,./sfmhF

Ms; hlsfdmh

fr dl;jhmf

h;p

dfhp;mjpdf;

mldg

MJ:tjpet dmppooooooooAUJrt]puoj eopjuAERMJO op

uERJU

RPJP

U]

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rupture Disk Safety Head: 4" SRB-7RS 300# ASSYDocument1 pageRupture Disk Safety Head: 4" SRB-7RS 300# ASSYChetan PatelNo ratings yet

- Technical Query Sheet Format - Heat ExchangerDocument5 pagesTechnical Query Sheet Format - Heat ExchangerChetan PatelNo ratings yet

- Technical Query Sheet Format - ColumnDocument8 pagesTechnical Query Sheet Format - ColumnChetan PatelNo ratings yet

- Deliverables ListDocument3 pagesDeliverables ListChetan PatelNo ratings yet

- Welding SymbolsDocument6 pagesWelding SymbolsChetan PatelNo ratings yet

- Vendor To Confirm.Document3 pagesVendor To Confirm.Chetan PatelNo ratings yet

- PFD & P&ID Training CourseDocument431 pagesPFD & P&ID Training CourseChetan Patel50% (2)

- STD - Pressure Vessel DrawingDocument138 pagesSTD - Pressure Vessel DrawingChetan Patel100% (1)

- UntitledDocument1 pageUntitledChetan PatelNo ratings yet

- Total Company Process Eng Design ManuallDocument312 pagesTotal Company Process Eng Design ManuallChetan PatelNo ratings yet

- P0024 SEP Mechanical Rev BDocument3 pagesP0024 SEP Mechanical Rev BChetan PatelNo ratings yet

- Sri Ramana Maharshi - The Way of Self-EnquiryDocument23 pagesSri Ramana Maharshi - The Way of Self-EnquiryChetan PatelNo ratings yet

- Excel Learning (OPI)Document206 pagesExcel Learning (OPI)Chetan PatelNo ratings yet

Floating Tank Erection Procdeure

Floating Tank Erection Procdeure

Uploaded by

Chetan Patel0 ratings0% found this document useful (0 votes)

40 views22 pagesEYpwehs

BGH:MBL

SFB:

xcm;v,./sfmhF

Ms; hlsfdmh

fr dl;jhmf

h;p

dfhp;mjpdf;

mldg

MJ:tjpet dmppooooooooAUJrt]puoj eopjuAERMJO op

uERJU

RPJP

U]

Original Title

Floating tank erection procdeure

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEYpwehs

BGH:MBL

SFB:

xcm;v,./sfmhF

Ms; hlsfdmh

fr dl;jhmf

h;p

dfhp;mjpdf;

mldg

MJ:tjpet dmppooooooooAUJrt]puoj eopjuAERMJO op

uERJU

RPJP

U]

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

40 views22 pagesFloating Tank Erection Procdeure

Floating Tank Erection Procdeure

Uploaded by

Chetan PatelEYpwehs

BGH:MBL

SFB:

xcm;v,./sfmhF

Ms; hlsfdmh

fr dl;jhmf

h;p

dfhp;mjpdf;

mldg

MJ:tjpet dmppooooooooAUJrt]puoj eopjuAERMJO op

uERJU

RPJP

U]

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 22

a ‘SOUTH PARS GAS FIELD DEVELOPMENT @

Ae PROJECT PHASES 15816 vs

ICAL IPC we Len -

rot ts Tenia cas

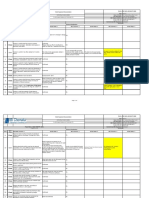

ERECTION PROCEDURE

FLOATING ROOF STORAGE TANK

FRECTION PROCEDURE

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15816

TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

‘3/14/2007 ERECTION PROCEDURE

Page ofz |

CONTENTS

1. GENERAL

2. FOUNDATION

3. BOTTOM PLATES (BOTTOM PLATES,

ANNULAR PLANTS AND BACKING STRIP)

3.1, Preparation

3.2. Arrangement

3.3. Welding

3.4. Marking on the bottom

4, SHELL PLATE

4.1, Preparation

4.2, Arrangement

4.3. Welding

4.4, Provisions for wind load

4.5. Top angle

4.6. Wind girder

5. INSTALLATION OF FLOATING ROOF

5.1, Lower deck plates

5.2. Arrangement

5.3. Welding

5.4, Pontoon structures (Rim, Compartment plates, Truss and Rafter)

5.5. Upper deck plates

6. ADJUSTMENT OF DECK SUPPORT

7, REMOVAL OF THE TEMPORARY SUPPORTS

8, FITTING OF ACCESSORIES

9, INSTALLATION OF ACCESSORIES AND APPURTENANCES

10, MODIFICATION

1. GENERAL

BLS goa sand

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15&16

TECHNICAL PROPOSAL 1 A

FLOATING ROOF STORAGE TANK CWP

|

3/14/2007 ERECTION PROCEDURE Page 3 of 22

This manual applies to field erection work of floating roof tank. All field erection shall be

performed strictly in accordance with the drawings approved by the owner.

2. FOUNDATION

Before erection work of tanks, foundation shall be checked by the tank builder in accordance with

field inspection manual (IT.P.). If there were some obstacles on foundation to erecting of tank, such

foundation should be repaired by foundation constructor.

3. BOTTOM PLATES:

(BOTTOM PLATES, ANNULAR PLATES AND BACKING STRIP)

3.1, PREPARATION

3.1.1. Center point of the foundation shall be determined by stretching piano wi

s of leveling

).

strings between contrastive points of four datum piles 0°, 90°, 180°, 270°(Refer to Fi

3.1.2. Outer Surface coating of the bottom plates, if specified the coating works shall not be

executed on the foundation.

3.2, ARRANGEMENT

3.2.1. The bottom plates shall be arranged in accordance with bottom plate DWG and orientation

DWG.

3.2.2, The arrangement of bottom plates shall be laid out from outwards to center and tack welded

in such a manner as the plates edges exposed to the surface to be straight,

3.2.3. One backing strip shall be welded underneath of each annular plate (Réfer t

SOUTH PARS GAS FIELD DEVELOPMENT @

PROJECT PHASES 15816 4

TECHNICAL PROPOSAL Mays

FLOATING ROOF STORAGE TANK FE

as

3/14/2007 ERECTION PROCEDURE Page 4 of 22

3.2.4. The annular plates shall be arranged with root opening as specified clockwise starting from

the basie point.

3.2.5. Contact surface of plate to plate shall be free from paint, oil, water and other foreign

materials,

3.2.6. The bottom plates shall be Tack-welded using jigs (Strong back, Bottom piece, ete.) for anti-

distortion, if necessary.

3.2.7. Cutting of sketch plates shall be done at site in accordance the actual dimensions.

3.2.8. Checking on diameter of the bottom shall be executed at points of 0°-180°, 45°-225°, 90°-

270° and 135°-315°.

3.3. WELDING

3.3.1. Sequence of welding (Refer to Fig. 3a, 3b, 3c).

3.3.2. The limit of 300 mm outside of bottom welded seams shall be ground smoothly and tested

before shell plates laid.

3.3.3. Alll welding works shall be executed, in principle, from center to outside.

3.34. Care shall be paid during welding of bottom to assure minimum distortion and uniform

lapping.

3.3.5, Skip sequence welding shall be adopted.

3.3.6. After completion of the welding works, vacuum test using soapsuds s|

welded joints.

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15816

CSinabi5 TECHNICAL PROPOSAL

aes FLOATING ROOF STORAGE TANK

371472007 ERECTION PROCEDURE [___ Pawe$ of22

3.3.7. All of the plates with T crossed weld detail with annular plates shall be hammer to press

together preheat, temperature required for this operation is about 150°C -180 °C.

3.3.8. After arrangement of plate tack welding, welding must be start with pitch 500 mm and 25

mm length or more, of weld.

3.3.9. The final welding must be done in the opposite direction by two or four welder.

3.3.10. The welding of the shell to the bottom shall be practically completed before the welding of

bottom joints that may have been left open to compensate for shrinkage of any welds previously

made.

3.4, MARKING

HE BOTTOM

3.4.1. Before assembling of the shell plates, the marking shall be executed with scrupulos care in

accordance with orientation drawing, because those will form basis for assembly of the shell plates,

accessories and etc.

3.4.2. Circular marking for the shell plates shall be divided equally with length.

3.4.3. After the 1* shell course is assembled, the marking for shell accessories shall be re-placed on

that.

3.4.4, Annular plates shall be arranged in accordance with bottom plate DWG. and orientation DW.

3.4.5. Annular plate shall be laid out in accordance with the marking point on the foundation.

3.4.6. Annular plates shall be assembled and tack welded with a backing strip as shown on (Refer to

Fig. 2).

SOUTH PARS GAS FIELD DEVELOPMENT

Vie, PROJECT PHASES 15816 4

MiLid ‘TECHNICAL PROPOSAL Ge;

FLOATING ROOF STORAGE TANK of CCF

A

3714/2007 ERECTION PROCEDURE Page 6 of 22

3.4.7. Reinforcement of weld to be removed with in the limit of periphery approximate 200 mm

from the outside by grinder.

3.4.8. A bottom plate shall be laid on the outward point which had been marked by stretching piano

wires crosswise above the foundation.

3.4.9. Bottom plates shall be assembled and tack welded using special jigs for anti distortion if

necessary.

3.4.10, At the continuous welding, the longitudinal joints shall be welded first.

3.4.11. The welding shall be started at the center of plate width and precede outward symmetrically.

3.4.12. When the all longitudinal joint are welded, welding of transverse joint shall be made from

center to outwards in a same manner as the longitudinal joints.

3.4.13. Care shall be exercised during welding of bottom plates to assure minimum distortion and

uniform lapping with as far as possible,

4. SHELL PLATE

4.1. PREPARATION

4.1.1, Shell plats are located around the foundation of tanks in a sequence so that plates with higher

thickens are placed under the plates with lower thickens. Consider that these plates are rolled in.

expected radius by the manufacturer. They must be stored or carried in a way that their curvature

are preserved.

4.1.2. After inspection of the bottom welded seams occurring under the shell has been completed

with successful result, ASSEF

‘SOUTH PARS GAS FIELD DEVELOPMENT @

PROJECT PHASES 15816 F

TECHNICAL PROPOSAL i.

FLOATING ROOF STORAGE TANK We Poc3

AS

[ weap007 ERECTION PROCEDURE Page 7 of 22

4.1.3. Prior to the assembly, horse shoes for straight and covered strong back shall be welded

temporary on the shell plate (Refer to Fig. 5) and also the blank nuts be tack welded along the line

(both side of the circle line at the pitch of approximate 1000 mm (Refer to Fig. 6).

4.2. ARRANGEMENT

4.2.1, First Course

4.2.1.1. The circle line for erection shall be drawn on the bottom plates and punched equally by the

numbers of shell plates.

4.2.2. The shell plates shall be determined in accordance with the drawing the retained in position

by spacer, Key plates, Blank nuts and taper pins It will be ensured that clean out assemblies are

installed prior to arranging shell plate (Refer to Fig. 7).

4.2.2.1. When the assembling of the first rim have completed the level of top edge and plumb shall

be aspect with an instrument.

4.2.3. Second Course

4.2.3.1. The scaffolding board shall be arranged with lugs an brackets on both side of the first

course, When the traveling scaffolding is used the scaffoldings shall be installed.

4.2.3.2. Vertical joints of the second course shall be assembled with the match mark which had

stamped on the I*' course accordance with the drawing (Refer to Fig. 8).

4.2.3.3. Vertical joints shall be matched accurately and retained in position with spacers and key

plates.

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15816

‘TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

‘3/14/2007 ERECTION PROCEDURE Page 8 of 22

4.2.3.4, Horizontal joints between 1" and 2"! course shall be matched to inside of each plates and

retained in position with spacer and stiffeners (Refer to Fig. 8).

4.2.3.5. After erection of second course floating roof is erected at bottom according to the procedure

which shall be described later, due to easy possibility of earrying material to inside of tanks.

4.2.4.3" And Upper Courses

4.2.4.1. Afier erection of floating roof the third course shell plates and upper are erected similar to

the first and second course.

4.2.4.2. 3 and upper courses shall be assembled in the same manner as the 2“ course. The

temporary assembling of each course shall be completed in the day, and the maximum allowable

numbers of shell course to be assembled temporary shall be 7 course in case of the plates used 2440

mm width.

4.3. WELDING

4.3.1, Welding Of Vertical Joints Of 1* Course:

4.3.1.1. The vertical joints shall be tack welded from inside and the key plates and spacers shall be

removed and replaced by strong back.

4.3.1.2. The continues welding shall be made on the outside first. The strong back shall be installed

at right angle with the weld line to prevent plate distortion during welding.

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15816

TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

3/14/2007 ERECTION PROCEDURE Page 9 of 22

43.1.3. Prior to the application of the first bead to the inside welding the strong back shall be

removed and welded joints shall be cleaned thoroughly in a manner that will leave the exposed

surface satisfactory for fusion of the weld metal to be added.This cleaning shall be made from

inside by are air grouping and/or grinding to evenly smoothly.

4.3.2, Welding Of Vertical Joints Of 2"' Course

4.3.3. Welding Of Vertical Joints Of 2"! Course Shall Be Made In The Same Manner As The

1* Course

4.3.4. Welding Of Horizontal Joints Between 1* Course And 2" Course

4.3.4.1. The welding of horizontal joints between Ist course and 2 course shall be made the

outside first and being the stiffeners removed. If there were some defect at 1“ layer which shall be

hindrance to welding from inside, it shall be removed by are air gouging from inside. After that, the

reversed of horizontal joints shall be welded.

4.3.4.2. Welding of first course shell plates to bottom plates can be done after at least welding of

two courses are completed.

4.3.5. Welding Of Horizontal Joints Between 2" Course And 3"! Course:

Welding of horizontal joints of between 2nd course and 3rd course shall be made in the same

manner as horizontal joints between Ist course and 2nd course

4.3.6. Welding Joints Of 3"! Course And Other Upper Courses

4.3.6.1. The vertical joints of between 3" course shall be welded before the w

joints between 2" and 3" course.

SOUTH PARS GAS FIELD DEVELOPMENT | 4p

PROJECT PHASES 15816

TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

371472007 ERECTION PROCEDURE Page 10 of 22

4.3.6.2. Owing to circumstances of erection schedule, welding of vertical joints or two or three

courses may be proceeded prior to welding of horizontal joints.

4.3.6.3. Assembling and welding of other upper courses shall be made as the same manner as stated

before. In principle, shell plates which is higher than 5" course shall be assembled and welded one

by one course.

4.3.6.4, If there were some one desirable phenomenon like a settlement of foundation during the

shell assembling and welding, the level should be measured.

4.4, PROVISIONS FOR WIND LOAD

‘Typical placing shell plates on bottom plates has been shown (see Fig. 6. at this stage, the shell

plates must be tightened to each other by stiffening tools which is shown the figure for anchorage of

shell plates against wind and other conditions, braces must be prepared in a suitable way shown the

figure. if the curvature of first course plates are changed, some must are welded on bottom plates in

side or outside of tank near the shell plates for regulation of curvature.

4.5. TOP ANGLE

4.5.1. Top course and top angle shall be assembled and tack.weld at the same time, and the welding

of vertical joints of top course and top angle shall be done simultaneously.

4.5.2. The horizontal joints between top angle and top course shall be welded finally.

4.6. WIND GIRDER

Wind girder and rib shall welded to the shell plate after the vertical joint of shell are welded and

radiographically cleaned, the vertical seams of windgirders shall be welded first, then

circumferential joint shall be welded.

SOUTH PARS GAS FIELD DEVELOPMENT @

PROJECT PHASES 15816

y ICAL PROPOSAL we 5

7) oA IES RIE a hoa

3/14/2007 ERECTION PROCEDURE Page | To 22, ]

5. INSTALLATION OF FLOATING ROOF

5.1. LOWER DECK PLATES

5.1.1. Preparation

5.1.1.1. After the vacuum test for bottom and the radiographic test of 1 and 2n* shell courses are

completed, Temporary deck support for the floating roof shall be arranged on the bottom.

5.1.1.2. Four derection point 0°,90°,180°,270° shall be replaced inside shell from existing points on

the foundation.

5.1.1.3. Center point of the floating roof shall be determined by stretching two wires or strings

contrastive points.

5.2. ARRANGEMENT

5.2.1. The lower deck plates shall be arranged in accordance with orientation and lower deck plate

drawings.

5.2.2. The lower deck plates shall be arranged with appropriate lap outward from center of the tank.

5.2.3, Contact surface of plate to plate shall be free from paint.oil,water and other foreign materials

5.2.4, The deck plates shall be tack-welded using jigs (Strong back, Bottom piece, ete.) for anti-

distortion, if necessary

5.3. WELDING

SOUTH PARS GAS FIELD DEVELOPMENT @

PROJECT PHASES 15816 7

TECHNICAL PROPOSAL ue .

FLOATING ROOF STORAGE TANK Yt Bew.5

START ERECTION PROCEDURE Tage 12 of

5.3.1. Sequence of Welding the lower deck is the same of the tank bottom.

5.3.2. All welding works shalll be executed, in principle from center to outside.

5.3.3. Care shall be paid during welding of lower deck to assure minimum distortion and uniform

lapping.

5.3.4, Skip sequence welding shall be adopted.

5.3.5. After completion of the welding works, vacuum test using soapsuds shall be applied to all the

welded joints.

5.4. PONTOON STRUCTURES(RIM,COMPARTMENT PLATES, TRUSS AND RAFTER

5.4.1, Preparation

‘After the arrangement with tack-welding for lower deck, the markings of pontoon structure and roof

drain sump shall be executed with high accuracy in accordance with orientation and floating roof

detail drawing.

5.4.2. Arrangement

After the vacuum test for lower deck completed the pontoon structure shall be arranged outward

from center of the tank.

5.4.3. Welding

Vertical joint shall be welded first from rim plates and compartment plates.

5, UPPER DECK PLATES

5.5.1. Preparation

a SOUTH PARS GAS FIELD DEVELOPMENT @

2 PROJECT PHASES 15816

MN} ‘TECHNICAL PROPOSAL Weis

FLOATING ROOF STORAGE TANK

31472007 ; ERECTION PROCEDURE Page 13 of 22

5.5.1.1. The upper deck plates shall not be put on one portion only but be arranged on the pontoon

structures in equal distribution.

5.5.2. Arrangement

5.5.2.1, The upper deck plates shall be arranged in accordance with orintation and floating roof

detail drawings.

5.5.3. The upper deck plates shall be arranged with approprriate lap outward from center of the

tank.

5.5.4, Contact surface of plate to plate shall be free paint, oil, water and foreign materials.

5.5.5. The deck plates shall be tack-welded using jigs (Strong back, Bottom piece, etc.) for anti-

distortion, if necessary.

5.5.6. Cutting of the sketch plates shall be done at site in accordance with actual dimensions.

5.5.7, Sequence of arrangement for the deck plates shall be in contrast of right with left.

5.5.8. Welding

5.5.8.1. Sequence of Welding the lower deck is the same of the tank bottom.

5.5.8.2. All welding works shall be executed, in principle from center to outside.

5.5.8.3. Care shall be paid during welding of lower deck to assure minimum distortion and uniform

lapping.

5.5.8.4. Skip sequence welding shall be adopted.

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15816

TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

‘31472007 ERECTION PROCEDURE Page 14 of 22

5.5.8.5. After completion of the welding works, vacuum test using soapsuds shall be applied to all

the welded joints.

6. ADJUSTMENT OF DECK SUPPORT

6.1.1. In accordance with orientation and deck support legs drawing to mark the position on the

upper deck. In this case, care should be taken to make drilling after confirming that supports do not

obstruct to other accessories.

6.1.2. The reinforcing plates and guide pipes shall be installed and welded in accordance with the

drawing.

6.1.3. The height of supports shall be adjusted and corrected, and then the supports shall be

assembled.

7. REMOVAL OF THE TEMPORARY SUPPORTS

When the deck support are completed, to remove the temporary deck supports

8. FITTING OF ACCESSORIES

8.1.1. Roof manhole, pontoon manhole, roof drain, ete. shall be correctly marked the positions

according to the DWG.

8.1.2. Before hydrostatic test should be the fitting of seal materials should be done after completion

the fire using place.

9. INSTALLATION OF ACCESSORIES AND APPURTENANCES

Each tank accessories and appurtenance shall be assembled and installed in accordance with the

applicable construction drawings.

10. MODIFICATION

In case any modification or alteration is to be done to the present specification on site such will be

first discussed with owner

his approval.

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15816

TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

AS

‘371472007 ERECTION PROCEDURE Page 15 of 22

ENTER POINT OF FOUNDATION

270°

Piono Wires or Leveling Strings

Datum Piles

a SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15816

TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

nabs 7

‘3/14/2007 ERECTION PROCEDURE Page 16 of 22

ANNULAR PLATE & BACKING STRIP

SHELL_PLATE

BOTTOM PLATE

BACKING STRIP.

FIG. NO. 2

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15&16

TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

3/14/2007 ERECTION PROCEDURE

WELDING SEQUENCE OF TANK BOTTOM

FIG. NO. 3- FOR TANK BOTTOM

SOUTH PARS GAS FIELD DEVELOPMENT @

PROJECT PHASES 15816 rar

TECHNICAL PROPOSAL Wen, :

FLOATING ROOF STORAGE TANK of Cas

nae

371472007 ERECTION PROCEDURE Page 18 of 22

WELDING SEQUENCE OF SHELL AND TANK BOTTOM

@ 4v—

3H

Oa |

© m_.

@) 2

@ 14.

@Qw

FIG. NO. 4

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15816

TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

@,

371472007

ERECTION PROCEDURE

~ Page 19 of 22

ARRANGEMENT OF HORSE SHOE FOR UPPER SHELL PLATE

FIG. NO. 5

“Hik3

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15816

‘TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

31472007

ERECTION PROCEDURE

Page 20 of 22

ASSEMBLY OF 1°' SHELL COURSE

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15816

TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

371472007

ERECTION PROCEDURE

Page 21 of 22

ERECTION KEY PLATES, SPACER, ETC

SOUTH PARS GAS FIELD DEVELOPMENT

PROJECT PHASES 15816

TECHNICAL PROPOSAL

FLOATING ROOF STORAGE TANK

Eoca5

a Si

371472007

~ ERECTION PROCEDURE

Page 22 of 22

ASSEMBLY OF 2%” SHELL COURSE

FIG. NO. 8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rupture Disk Safety Head: 4" SRB-7RS 300# ASSYDocument1 pageRupture Disk Safety Head: 4" SRB-7RS 300# ASSYChetan PatelNo ratings yet

- Technical Query Sheet Format - Heat ExchangerDocument5 pagesTechnical Query Sheet Format - Heat ExchangerChetan PatelNo ratings yet

- Technical Query Sheet Format - ColumnDocument8 pagesTechnical Query Sheet Format - ColumnChetan PatelNo ratings yet

- Deliverables ListDocument3 pagesDeliverables ListChetan PatelNo ratings yet

- Welding SymbolsDocument6 pagesWelding SymbolsChetan PatelNo ratings yet

- Vendor To Confirm.Document3 pagesVendor To Confirm.Chetan PatelNo ratings yet

- PFD & P&ID Training CourseDocument431 pagesPFD & P&ID Training CourseChetan Patel50% (2)

- STD - Pressure Vessel DrawingDocument138 pagesSTD - Pressure Vessel DrawingChetan Patel100% (1)

- UntitledDocument1 pageUntitledChetan PatelNo ratings yet

- Total Company Process Eng Design ManuallDocument312 pagesTotal Company Process Eng Design ManuallChetan PatelNo ratings yet

- P0024 SEP Mechanical Rev BDocument3 pagesP0024 SEP Mechanical Rev BChetan PatelNo ratings yet

- Sri Ramana Maharshi - The Way of Self-EnquiryDocument23 pagesSri Ramana Maharshi - The Way of Self-EnquiryChetan PatelNo ratings yet

- Excel Learning (OPI)Document206 pagesExcel Learning (OPI)Chetan PatelNo ratings yet