Professional Documents

Culture Documents

OISDStandard

OISDStandard

Uploaded by

AdityaDhanrajSinghCopyright:

Available Formats

You might also like

- Spesifikasjoner Kubota U10 3 PDFDocument390 pagesSpesifikasjoner Kubota U10 3 PDFEdwin Beltran100% (2)

- CBLDocument13 pagesCBLdanush pathirana50% (4)

- Chariot PM Checklist SCRUBBERDocument2 pagesChariot PM Checklist SCRUBBERherik0% (1)

- Maternity Case 7: Carla Hernandez (Core) : Guided Reflection QuestionsDocument2 pagesMaternity Case 7: Carla Hernandez (Core) : Guided Reflection QuestionsDai Nguyen100% (1)

- Axial Flow Fans PDFDocument66 pagesAxial Flow Fans PDFCodruţ ErașcuNo ratings yet

- Induction Testing of Bullet Magnet Installed at Flour Dispensing SystemDocument5 pagesInduction Testing of Bullet Magnet Installed at Flour Dispensing SystemMark Anthony Centeno100% (1)

- BLS PDFDocument6 pagesBLS PDFAyesha JadoonNo ratings yet

- Geothermal Energy Poster 2Document1 pageGeothermal Energy Poster 2api-298575301100% (2)

- ch2 PeriodicMaintenance v1Document42 pagesch2 PeriodicMaintenance v1Jonathan Ballestero MejíaNo ratings yet

- MODEL 182 SERIES (1977 - 1986) : Inspection Operation 11Document1 pageMODEL 182 SERIES (1977 - 1986) : Inspection Operation 11Gabriel vieiraNo ratings yet

- Lembar Inspeksi Bell 412 600 FH 12 MonthDocument6 pagesLembar Inspeksi Bell 412 600 FH 12 MonthReza Setyo PermadiNo ratings yet

- 5484 93Document12 pages5484 93Control de calidad AntaminaNo ratings yet

- ML C 650 c65mm213Document6 pagesML C 650 c65mm213operacionesNo ratings yet

- Tomen Vibro Hammer Manual FM2-60Document64 pagesTomen Vibro Hammer Manual FM2-60kbadran.timsahNo ratings yet

- Murmansk-Module SpecDocument96 pagesMurmansk-Module SpecThem Bui XuanNo ratings yet

- 3.523 AnnexDocument12 pages3.523 AnnexGabrielNo ratings yet

- 20-1701 Slips DCSDocument7 pages20-1701 Slips DCSRahul M.RNo ratings yet

- 35 (Viii) - Dumper-Tipper (Pages 1-3)Document4 pages35 (Viii) - Dumper-Tipper (Pages 1-3)Prasanta ParidaNo ratings yet

- Gpo 36 Tests and Inspections Routine R 5701Document1 pageGpo 36 Tests and Inspections Routine R 5701Theodor EikeNo ratings yet

- Routine Drone Maintenance ChecklistDocument16 pagesRoutine Drone Maintenance ChecklistFirdausDaliNo ratings yet

- Rolls Royce m250 c20r Series Operation and Maintenance 720000 5Document32 pagesRolls Royce m250 c20r Series Operation and Maintenance 720000 5Antonio AmbrosoneNo ratings yet

- Maintenance ScheduleDocument2 pagesMaintenance ScheduleAdhityaPahlefiNo ratings yet

- AC 43.13-1B Chapter 08Document42 pagesAC 43.13-1B Chapter 08Vorrataa KulkeitpravatNo ratings yet

- Https 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page R&I 4Document6 pagesHttps 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page R&I 4CarlosNo ratings yet

- Daily Check A320 (Issue 02 Rev 04)Document8 pagesDaily Check A320 (Issue 02 Rev 04)Junaid YounusNo ratings yet

- ML C Ser c206hmm28Document1 pageML C Ser c206hmm28Juan TapiaNo ratings yet

- MS-Nile 2022 (Metering Skids)Document48 pagesMS-Nile 2022 (Metering Skids)MOHAMMED SALAHNo ratings yet

- 2AB Daily Check A319Document8 pages2AB Daily Check A319Umer JavedNo ratings yet

- 802848-D Optistar LE Service ChecklistDocument6 pages802848-D Optistar LE Service ChecklistDanilo MirandaNo ratings yet

- Service: ManualDocument60 pagesService: ManualmamontNo ratings yet

- Olympus Ch20 ManualDocument24 pagesOlympus Ch20 Manualjmillan.ibermansaNo ratings yet

- IAT 2.1 Q&aDocument4 pagesIAT 2.1 Q&aRam RajNo ratings yet

- BBT MethodDocument133 pagesBBT MethodSufiyan KhedekarNo ratings yet

- General Instructions - Daily CheckDocument8 pagesGeneral Instructions - Daily Checkrama AmeesNo ratings yet

- AC 43.13 - 1A Chapter - 12-13 PDFDocument28 pagesAC 43.13 - 1A Chapter - 12-13 PDFElmer Villegas100% (1)

- TI MI 0052 Rev 0Document78 pagesTI MI 0052 Rev 0Varalakshmi BNo ratings yet

- Caterpillar Engine Service Manual Eng d379Document18 pagesCaterpillar Engine Service Manual Eng d379Bonggo pribadi100% (1)

- Exec 90 Maintenance Manual 3 03Document95 pagesExec 90 Maintenance Manual 3 03najmul100% (1)

- 79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)Document12 pages79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)COILED TUBINGNo ratings yet

- 35 (X) - Diesel Generator (Pages 1-4)Document4 pages35 (X) - Diesel Generator (Pages 1-4)Prasanta ParidaNo ratings yet

- 35 (Vii) - Tyre Mounted Articulated Mob - Crane (Pages 1-4)Document5 pages35 (Vii) - Tyre Mounted Articulated Mob - Crane (Pages 1-4)Prasanta ParidaNo ratings yet

- CSA C282 Maintenance ReqDocument2 pagesCSA C282 Maintenance Reqecto8totoNo ratings yet

- 1-03-036!04!0 Inspection of Repaired MotorDocument19 pages1-03-036!04!0 Inspection of Repaired MotorAhmed AshourNo ratings yet

- ID Fan ManualDocument25 pagesID Fan Manualkamatamogh83% (6)

- Rolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceDocument36 pagesRolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceFranny Alexandra Tamayo RiocampoNo ratings yet

- Rockcreter 65 Operators ManualDocument34 pagesRockcreter 65 Operators ManualVidyasagar KNo ratings yet

- CHAPTER 11 GIs, Letters and ReferencesDocument12 pagesCHAPTER 11 GIs, Letters and ReferencesMahrouz MadoNo ratings yet

- Substation Construction and CommissioningDocument83 pagesSubstation Construction and CommissioningShung Tak ChanNo ratings yet

- 现场管道制作要领Document6 pages现场管道制作要领gotntNo ratings yet

- API Recommended Practice 4G - Exceprt Section 6Document4 pagesAPI Recommended Practice 4G - Exceprt Section 6ANTONI RamNo ratings yet

- Acw Pump Up150 38bDocument40 pagesAcw Pump Up150 38bAnupam Kushal100% (1)

- Boiler Maint: Unit#1 Annual Oh Jobs Planned (Aug'21)Document20 pagesBoiler Maint: Unit#1 Annual Oh Jobs Planned (Aug'21)anil peralaNo ratings yet

- APPENDIX 2 - Structural Inspections 05-20-09Document18 pagesAPPENDIX 2 - Structural Inspections 05-20-09Ahmet YikarbabaNo ratings yet

- TM-175 Ms-Uni PDFDocument29 pagesTM-175 Ms-Uni PDFsanjayisdonNo ratings yet

- TM-175 Ms-UniDocument29 pagesTM-175 Ms-UniSivaneswaran SabaratnamNo ratings yet

- Statement of Work FOR 1250 Ton Trane Chiller #2 Repair/Rebuild Va Pittsburgh Healthcare SystemDocument8 pagesStatement of Work FOR 1250 Ton Trane Chiller #2 Repair/Rebuild Va Pittsburgh Healthcare SystemBem BewmNo ratings yet

- Makita Service NoteDocument5 pagesMakita Service NoteMarcin LosyNo ratings yet

- 049b Pump ChecklistDocument13 pages049b Pump ChecklistRamy AdelNo ratings yet

- O&M FOR FLOATING AERATOR - NewDocument14 pagesO&M FOR FLOATING AERATOR - NewBaisel RahumanNo ratings yet

- Air Inlet ServomotorDocument1 pageAir Inlet Servomotorhidakota hidakotaNo ratings yet

- Kubota Excavator: Workshop ManualDocument390 pagesKubota Excavator: Workshop ManualxxNo ratings yet

- Ufgs 07 19 00Document17 pagesUfgs 07 19 00sharethefilesNo ratings yet

- Ufgs 09 97 13.15Document43 pagesUfgs 09 97 13.15Tim KearneyNo ratings yet

- Sr. No. MM in MRG Volume in MRG Left % in Roto Right % in Roto Remark Tank NoDocument1 pageSr. No. MM in MRG Volume in MRG Left % in Roto Right % in Roto Remark Tank NoAdityaDhanrajSinghNo ratings yet

- Chapter 2Document14 pagesChapter 2AdityaDhanrajSinghNo ratings yet

- Investigation and Analysis of Cold Shut Casting Defect and Defect Reduction by Using 7 Quality Control ToolsDocument3 pagesInvestigation and Analysis of Cold Shut Casting Defect and Defect Reduction by Using 7 Quality Control ToolsAdityaDhanrajSinghNo ratings yet

- Head Investments Days Gain Overall Gain Latest Value Value % Value %Document1 pageHead Investments Days Gain Overall Gain Latest Value Value % Value %AdityaDhanrajSinghNo ratings yet

- Going For Gold The History of Newmont Mining Corporation Ebook Jack H Morris PDFDocument3 pagesGoing For Gold The History of Newmont Mining Corporation Ebook Jack H Morris PDFAdityaDhanrajSinghNo ratings yet

- Part Four World Financial Environment: Chapter Nine Global Foreign-Exchange MarketsDocument14 pagesPart Four World Financial Environment: Chapter Nine Global Foreign-Exchange MarketsAdityaDhanrajSinghNo ratings yet

- Presentations Will Be Started From 30: Lovely Professional University Form/Lpuo/A P-3Document3 pagesPresentations Will Be Started From 30: Lovely Professional University Form/Lpuo/A P-3AdityaDhanrajSinghNo ratings yet

- Lovely Professional University Form/Lpuo/A P-3Document2 pagesLovely Professional University Form/Lpuo/A P-3AdityaDhanrajSinghNo ratings yet

- Azo Dyes and Their ApplicationsDocument6 pagesAzo Dyes and Their ApplicationsMUhammad AsifNo ratings yet

- Transport ProcessesDocument81 pagesTransport ProcessesKukre BertNo ratings yet

- Teaching StrategiesDocument31 pagesTeaching Strategieshaddi awan100% (1)

- Iso 50001 Enms - Manual-Procedures-Forms-Matrix - P-XXX NumbersDocument1 pageIso 50001 Enms - Manual-Procedures-Forms-Matrix - P-XXX NumbersAngelo SantiagoNo ratings yet

- 11 SMAW Q4 Module 2Document11 pages11 SMAW Q4 Module 2Mark Johnson VillaronNo ratings yet

- (II) Misadventure Is Mischance, Accident or Disaster. It Is of Three TypesDocument3 pages(II) Misadventure Is Mischance, Accident or Disaster. It Is of Three TypesSandeep BansalNo ratings yet

- Electronic Cash Register Programming-ManualDocument27 pagesElectronic Cash Register Programming-ManualRendy Adam FarhanNo ratings yet

- KI 70 Therapeutic Potential in Graves Ca ThyroidDocument4 pagesKI 70 Therapeutic Potential in Graves Ca ThyroidGaurav MalhotraNo ratings yet

- Choose The Correct Answer by Crossing A, B, C, or D!: Test Chapter I: Greeting, Leave Taking, Thanking, and AppologizingDocument3 pagesChoose The Correct Answer by Crossing A, B, C, or D!: Test Chapter I: Greeting, Leave Taking, Thanking, and AppologizingFerdi AnsyahNo ratings yet

- MultiTherm OG-1® Tech DataDocument2 pagesMultiTherm OG-1® Tech DataSteranskoNo ratings yet

- Estimation of Meropenem in Human Plasma by HPLC-UV and Its Application in Comparative Bioavailability StudyDocument8 pagesEstimation of Meropenem in Human Plasma by HPLC-UV and Its Application in Comparative Bioavailability Studyayand2005No ratings yet

- The Following Is An Excerpt FromDocument12 pagesThe Following Is An Excerpt FromViktoria MolnarNo ratings yet

- Suzumar Boat Engine PackagesDocument7 pagesSuzumar Boat Engine PackagesmarkoNo ratings yet

- Bicycle Repair ManualDocument162 pagesBicycle Repair Manualrazvancc89% (9)

- Latah SyndromeDocument2 pagesLatah SyndromenazNo ratings yet

- Winsem2014-15 Cp0670 17-Apr-2015 Rm01 U4 l4 Rainwater-HarvestingDocument12 pagesWinsem2014-15 Cp0670 17-Apr-2015 Rm01 U4 l4 Rainwater-HarvestingShiv ShivNo ratings yet

- 373 PDFDocument6 pages373 PDFIjdra Journal Jitendra BadjatyaNo ratings yet

- Solomon Islands Position PaperDocument2 pagesSolomon Islands Position PaperAJ Ammons0% (1)

- Flowers For Algernon ThesisDocument6 pagesFlowers For Algernon Thesiss0kuzej0byn2100% (2)

- For Abm Only Bmat 2ND Quarter ActivitiesDocument24 pagesFor Abm Only Bmat 2ND Quarter ActivitiesjohnNo ratings yet

- Minus Vo Check List: Hilton Sai Gon Project 11 Cong Truong Me Linh, Ben Nghe Ward, District 1Document4 pagesMinus Vo Check List: Hilton Sai Gon Project 11 Cong Truong Me Linh, Ben Nghe Ward, District 1ThanhNo ratings yet

- Sonia Research ProposalDocument59 pagesSonia Research Proposalmullamuskaan95No ratings yet

- Employment Document Folder ListsDocument90 pagesEmployment Document Folder ListsIsna FauziahNo ratings yet

- NiBallast TM BWMS v-2021Document21 pagesNiBallast TM BWMS v-2021王杰No ratings yet

- The Cardiovascular System: The Heart: Part B: Prepared by Barbara Heard, Atlantic Cape Community CollegeDocument80 pagesThe Cardiovascular System: The Heart: Part B: Prepared by Barbara Heard, Atlantic Cape Community CollegeBrianna PinchinatNo ratings yet

OISDStandard

OISDStandard

Uploaded by

AdityaDhanrajSinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OISDStandard

OISDStandard

Uploaded by

AdityaDhanrajSinghCopyright:

Available Formats

OISD/DOC/2021/01

DHANRAJ, ADITYA@MEGAWORK.IN, MEGAWORK DESIGN AND ENGINEERIN

(1) (2) (3) (4) (5) (6) (7) (8)

--------------------------------------------------------------------------------------------------------------------------------

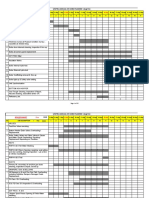

(D) INTRODUCTION AND EJECTION DEVICES:

1. Blow the air filter free of water & dirt. *

2. Check & top up oil in air lubricator. *

3. Oil the introduction arms. *

4. Check functioning & adjust if required. *

5. Greasing all grease points. *

6. Tighten guide rollers. *

7. Check & repair leaks. *

te

8. Inspect for wear and tear. *

ra

9. Overhaul the unit. *

o

(E) FILLING MACHINES:

ct

1. Thoroughly cleaning by using *

ire

dry air.

2. Checking & adjustment of auto *

cut off device.

3. Check operation of filling head * D

ty

by supplying air.

fe

4. Check leakage of LPG and repair. *

Sa

5. Check condition of LPG filling hoses. *

6. Check oil level in air lubricators. *

ry

7. Lubricate pullies holding filling guns. *

st

8. Carry out calibration and adjustment. *

du

9. Suspension system bearings & *

knife edges to be thoroughly

cleaned.

In

10. Inspect knife edges for wear & *

tear and repair where required.

il

O

11. Complete overhauling. *

--------------------------------------------------------------------------------------------------------------------------------

Sr. Equipment Checks PERIODICITY

--------------------------------------------------------------------------------------------------------------------------------

Daily Weekly Monthly Qrtly Half

Annually Yrly

(1) (2) (3) (4) (5) (6) (7) (8)

--------------------------------------------------------------------------------------------------------------------------------

(F) CHECK SCALE:

1. Thorough cleaning by using dry air. *

“OISD hereby expressly disclaims any liability or responsibility for loss or damage resulting

from the use of OISD Standards/Guidelines.”

You might also like

- Spesifikasjoner Kubota U10 3 PDFDocument390 pagesSpesifikasjoner Kubota U10 3 PDFEdwin Beltran100% (2)

- CBLDocument13 pagesCBLdanush pathirana50% (4)

- Chariot PM Checklist SCRUBBERDocument2 pagesChariot PM Checklist SCRUBBERherik0% (1)

- Maternity Case 7: Carla Hernandez (Core) : Guided Reflection QuestionsDocument2 pagesMaternity Case 7: Carla Hernandez (Core) : Guided Reflection QuestionsDai Nguyen100% (1)

- Axial Flow Fans PDFDocument66 pagesAxial Flow Fans PDFCodruţ ErașcuNo ratings yet

- Induction Testing of Bullet Magnet Installed at Flour Dispensing SystemDocument5 pagesInduction Testing of Bullet Magnet Installed at Flour Dispensing SystemMark Anthony Centeno100% (1)

- BLS PDFDocument6 pagesBLS PDFAyesha JadoonNo ratings yet

- Geothermal Energy Poster 2Document1 pageGeothermal Energy Poster 2api-298575301100% (2)

- ch2 PeriodicMaintenance v1Document42 pagesch2 PeriodicMaintenance v1Jonathan Ballestero MejíaNo ratings yet

- MODEL 182 SERIES (1977 - 1986) : Inspection Operation 11Document1 pageMODEL 182 SERIES (1977 - 1986) : Inspection Operation 11Gabriel vieiraNo ratings yet

- Lembar Inspeksi Bell 412 600 FH 12 MonthDocument6 pagesLembar Inspeksi Bell 412 600 FH 12 MonthReza Setyo PermadiNo ratings yet

- 5484 93Document12 pages5484 93Control de calidad AntaminaNo ratings yet

- ML C 650 c65mm213Document6 pagesML C 650 c65mm213operacionesNo ratings yet

- Tomen Vibro Hammer Manual FM2-60Document64 pagesTomen Vibro Hammer Manual FM2-60kbadran.timsahNo ratings yet

- Murmansk-Module SpecDocument96 pagesMurmansk-Module SpecThem Bui XuanNo ratings yet

- 3.523 AnnexDocument12 pages3.523 AnnexGabrielNo ratings yet

- 20-1701 Slips DCSDocument7 pages20-1701 Slips DCSRahul M.RNo ratings yet

- 35 (Viii) - Dumper-Tipper (Pages 1-3)Document4 pages35 (Viii) - Dumper-Tipper (Pages 1-3)Prasanta ParidaNo ratings yet

- Gpo 36 Tests and Inspections Routine R 5701Document1 pageGpo 36 Tests and Inspections Routine R 5701Theodor EikeNo ratings yet

- Routine Drone Maintenance ChecklistDocument16 pagesRoutine Drone Maintenance ChecklistFirdausDaliNo ratings yet

- Rolls Royce m250 c20r Series Operation and Maintenance 720000 5Document32 pagesRolls Royce m250 c20r Series Operation and Maintenance 720000 5Antonio AmbrosoneNo ratings yet

- Maintenance ScheduleDocument2 pagesMaintenance ScheduleAdhityaPahlefiNo ratings yet

- AC 43.13-1B Chapter 08Document42 pagesAC 43.13-1B Chapter 08Vorrataa KulkeitpravatNo ratings yet

- Https 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page R&I 4Document6 pagesHttps 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page R&I 4CarlosNo ratings yet

- Daily Check A320 (Issue 02 Rev 04)Document8 pagesDaily Check A320 (Issue 02 Rev 04)Junaid YounusNo ratings yet

- ML C Ser c206hmm28Document1 pageML C Ser c206hmm28Juan TapiaNo ratings yet

- MS-Nile 2022 (Metering Skids)Document48 pagesMS-Nile 2022 (Metering Skids)MOHAMMED SALAHNo ratings yet

- 2AB Daily Check A319Document8 pages2AB Daily Check A319Umer JavedNo ratings yet

- 802848-D Optistar LE Service ChecklistDocument6 pages802848-D Optistar LE Service ChecklistDanilo MirandaNo ratings yet

- Service: ManualDocument60 pagesService: ManualmamontNo ratings yet

- Olympus Ch20 ManualDocument24 pagesOlympus Ch20 Manualjmillan.ibermansaNo ratings yet

- IAT 2.1 Q&aDocument4 pagesIAT 2.1 Q&aRam RajNo ratings yet

- BBT MethodDocument133 pagesBBT MethodSufiyan KhedekarNo ratings yet

- General Instructions - Daily CheckDocument8 pagesGeneral Instructions - Daily Checkrama AmeesNo ratings yet

- AC 43.13 - 1A Chapter - 12-13 PDFDocument28 pagesAC 43.13 - 1A Chapter - 12-13 PDFElmer Villegas100% (1)

- TI MI 0052 Rev 0Document78 pagesTI MI 0052 Rev 0Varalakshmi BNo ratings yet

- Caterpillar Engine Service Manual Eng d379Document18 pagesCaterpillar Engine Service Manual Eng d379Bonggo pribadi100% (1)

- Exec 90 Maintenance Manual 3 03Document95 pagesExec 90 Maintenance Manual 3 03najmul100% (1)

- 79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)Document12 pages79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)COILED TUBINGNo ratings yet

- 35 (X) - Diesel Generator (Pages 1-4)Document4 pages35 (X) - Diesel Generator (Pages 1-4)Prasanta ParidaNo ratings yet

- 35 (Vii) - Tyre Mounted Articulated Mob - Crane (Pages 1-4)Document5 pages35 (Vii) - Tyre Mounted Articulated Mob - Crane (Pages 1-4)Prasanta ParidaNo ratings yet

- CSA C282 Maintenance ReqDocument2 pagesCSA C282 Maintenance Reqecto8totoNo ratings yet

- 1-03-036!04!0 Inspection of Repaired MotorDocument19 pages1-03-036!04!0 Inspection of Repaired MotorAhmed AshourNo ratings yet

- ID Fan ManualDocument25 pagesID Fan Manualkamatamogh83% (6)

- Rolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceDocument36 pagesRolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceFranny Alexandra Tamayo RiocampoNo ratings yet

- Rockcreter 65 Operators ManualDocument34 pagesRockcreter 65 Operators ManualVidyasagar KNo ratings yet

- CHAPTER 11 GIs, Letters and ReferencesDocument12 pagesCHAPTER 11 GIs, Letters and ReferencesMahrouz MadoNo ratings yet

- Substation Construction and CommissioningDocument83 pagesSubstation Construction and CommissioningShung Tak ChanNo ratings yet

- 现场管道制作要领Document6 pages现场管道制作要领gotntNo ratings yet

- API Recommended Practice 4G - Exceprt Section 6Document4 pagesAPI Recommended Practice 4G - Exceprt Section 6ANTONI RamNo ratings yet

- Acw Pump Up150 38bDocument40 pagesAcw Pump Up150 38bAnupam Kushal100% (1)

- Boiler Maint: Unit#1 Annual Oh Jobs Planned (Aug'21)Document20 pagesBoiler Maint: Unit#1 Annual Oh Jobs Planned (Aug'21)anil peralaNo ratings yet

- APPENDIX 2 - Structural Inspections 05-20-09Document18 pagesAPPENDIX 2 - Structural Inspections 05-20-09Ahmet YikarbabaNo ratings yet

- TM-175 Ms-Uni PDFDocument29 pagesTM-175 Ms-Uni PDFsanjayisdonNo ratings yet

- TM-175 Ms-UniDocument29 pagesTM-175 Ms-UniSivaneswaran SabaratnamNo ratings yet

- Statement of Work FOR 1250 Ton Trane Chiller #2 Repair/Rebuild Va Pittsburgh Healthcare SystemDocument8 pagesStatement of Work FOR 1250 Ton Trane Chiller #2 Repair/Rebuild Va Pittsburgh Healthcare SystemBem BewmNo ratings yet

- Makita Service NoteDocument5 pagesMakita Service NoteMarcin LosyNo ratings yet

- 049b Pump ChecklistDocument13 pages049b Pump ChecklistRamy AdelNo ratings yet

- O&M FOR FLOATING AERATOR - NewDocument14 pagesO&M FOR FLOATING AERATOR - NewBaisel RahumanNo ratings yet

- Air Inlet ServomotorDocument1 pageAir Inlet Servomotorhidakota hidakotaNo ratings yet

- Kubota Excavator: Workshop ManualDocument390 pagesKubota Excavator: Workshop ManualxxNo ratings yet

- Ufgs 07 19 00Document17 pagesUfgs 07 19 00sharethefilesNo ratings yet

- Ufgs 09 97 13.15Document43 pagesUfgs 09 97 13.15Tim KearneyNo ratings yet

- Sr. No. MM in MRG Volume in MRG Left % in Roto Right % in Roto Remark Tank NoDocument1 pageSr. No. MM in MRG Volume in MRG Left % in Roto Right % in Roto Remark Tank NoAdityaDhanrajSinghNo ratings yet

- Chapter 2Document14 pagesChapter 2AdityaDhanrajSinghNo ratings yet

- Investigation and Analysis of Cold Shut Casting Defect and Defect Reduction by Using 7 Quality Control ToolsDocument3 pagesInvestigation and Analysis of Cold Shut Casting Defect and Defect Reduction by Using 7 Quality Control ToolsAdityaDhanrajSinghNo ratings yet

- Head Investments Days Gain Overall Gain Latest Value Value % Value %Document1 pageHead Investments Days Gain Overall Gain Latest Value Value % Value %AdityaDhanrajSinghNo ratings yet

- Going For Gold The History of Newmont Mining Corporation Ebook Jack H Morris PDFDocument3 pagesGoing For Gold The History of Newmont Mining Corporation Ebook Jack H Morris PDFAdityaDhanrajSinghNo ratings yet

- Part Four World Financial Environment: Chapter Nine Global Foreign-Exchange MarketsDocument14 pagesPart Four World Financial Environment: Chapter Nine Global Foreign-Exchange MarketsAdityaDhanrajSinghNo ratings yet

- Presentations Will Be Started From 30: Lovely Professional University Form/Lpuo/A P-3Document3 pagesPresentations Will Be Started From 30: Lovely Professional University Form/Lpuo/A P-3AdityaDhanrajSinghNo ratings yet

- Lovely Professional University Form/Lpuo/A P-3Document2 pagesLovely Professional University Form/Lpuo/A P-3AdityaDhanrajSinghNo ratings yet

- Azo Dyes and Their ApplicationsDocument6 pagesAzo Dyes and Their ApplicationsMUhammad AsifNo ratings yet

- Transport ProcessesDocument81 pagesTransport ProcessesKukre BertNo ratings yet

- Teaching StrategiesDocument31 pagesTeaching Strategieshaddi awan100% (1)

- Iso 50001 Enms - Manual-Procedures-Forms-Matrix - P-XXX NumbersDocument1 pageIso 50001 Enms - Manual-Procedures-Forms-Matrix - P-XXX NumbersAngelo SantiagoNo ratings yet

- 11 SMAW Q4 Module 2Document11 pages11 SMAW Q4 Module 2Mark Johnson VillaronNo ratings yet

- (II) Misadventure Is Mischance, Accident or Disaster. It Is of Three TypesDocument3 pages(II) Misadventure Is Mischance, Accident or Disaster. It Is of Three TypesSandeep BansalNo ratings yet

- Electronic Cash Register Programming-ManualDocument27 pagesElectronic Cash Register Programming-ManualRendy Adam FarhanNo ratings yet

- KI 70 Therapeutic Potential in Graves Ca ThyroidDocument4 pagesKI 70 Therapeutic Potential in Graves Ca ThyroidGaurav MalhotraNo ratings yet

- Choose The Correct Answer by Crossing A, B, C, or D!: Test Chapter I: Greeting, Leave Taking, Thanking, and AppologizingDocument3 pagesChoose The Correct Answer by Crossing A, B, C, or D!: Test Chapter I: Greeting, Leave Taking, Thanking, and AppologizingFerdi AnsyahNo ratings yet

- MultiTherm OG-1® Tech DataDocument2 pagesMultiTherm OG-1® Tech DataSteranskoNo ratings yet

- Estimation of Meropenem in Human Plasma by HPLC-UV and Its Application in Comparative Bioavailability StudyDocument8 pagesEstimation of Meropenem in Human Plasma by HPLC-UV and Its Application in Comparative Bioavailability Studyayand2005No ratings yet

- The Following Is An Excerpt FromDocument12 pagesThe Following Is An Excerpt FromViktoria MolnarNo ratings yet

- Suzumar Boat Engine PackagesDocument7 pagesSuzumar Boat Engine PackagesmarkoNo ratings yet

- Bicycle Repair ManualDocument162 pagesBicycle Repair Manualrazvancc89% (9)

- Latah SyndromeDocument2 pagesLatah SyndromenazNo ratings yet

- Winsem2014-15 Cp0670 17-Apr-2015 Rm01 U4 l4 Rainwater-HarvestingDocument12 pagesWinsem2014-15 Cp0670 17-Apr-2015 Rm01 U4 l4 Rainwater-HarvestingShiv ShivNo ratings yet

- 373 PDFDocument6 pages373 PDFIjdra Journal Jitendra BadjatyaNo ratings yet

- Solomon Islands Position PaperDocument2 pagesSolomon Islands Position PaperAJ Ammons0% (1)

- Flowers For Algernon ThesisDocument6 pagesFlowers For Algernon Thesiss0kuzej0byn2100% (2)

- For Abm Only Bmat 2ND Quarter ActivitiesDocument24 pagesFor Abm Only Bmat 2ND Quarter ActivitiesjohnNo ratings yet

- Minus Vo Check List: Hilton Sai Gon Project 11 Cong Truong Me Linh, Ben Nghe Ward, District 1Document4 pagesMinus Vo Check List: Hilton Sai Gon Project 11 Cong Truong Me Linh, Ben Nghe Ward, District 1ThanhNo ratings yet

- Sonia Research ProposalDocument59 pagesSonia Research Proposalmullamuskaan95No ratings yet

- Employment Document Folder ListsDocument90 pagesEmployment Document Folder ListsIsna FauziahNo ratings yet

- NiBallast TM BWMS v-2021Document21 pagesNiBallast TM BWMS v-2021王杰No ratings yet

- The Cardiovascular System: The Heart: Part B: Prepared by Barbara Heard, Atlantic Cape Community CollegeDocument80 pagesThe Cardiovascular System: The Heart: Part B: Prepared by Barbara Heard, Atlantic Cape Community CollegeBrianna PinchinatNo ratings yet