Professional Documents

Culture Documents

Untitled

Untitled

Uploaded by

Diego Baez0 ratings0% found this document useful (0 votes)

14 views8 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

14 views8 pagesUntitled

Untitled

Uploaded by

Diego BaezCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 8

YZE132M-4

ACTIVE WINCHED THREE PHASE

ASYNCHRONOUS HOISTING MOTOR

Operation Manual

China QiDong Juli Motor Ltd Jiangsu

Preface

‘Thank you for your using our products frcm Jiangsu Qidong Juli

Motor Ltd it is our honor that you become our customers.Before you

first use our products,please do carefully read this operation maintenance

‘manual, which ean let you use our product better.

In order to upgrade the whole machine’s property and relisbility,we

sometimes amend the parts suitably so that thay might not conform to

this operation manual, You will understand this when we do not inform

you.

When you have the new suggestions and demands during use please

contact us directly, It is our pleasure to try our best to meet your

demands.

‘Thank you for your cooperation!

Jiangsu Qidong Juli Motor Ltd

Adare:

1No.232 Weier Road development area,Qidong city, Jiangsu

Provinee,China

"Tel: 0086-513-83 119168,0086-513-831 19788

Fax: 0086-513-83317085

Zip Code:226200

General Manager:Shi Jin-kang

Website: vww.ntthd}.com

E-mail: webmaster@ntthd).com

1.Brief Introduction

‘YZELLAI32M-+4 Active Winched Three-Phated Asynchronous Hoisting Motor

is manufactured according to the new advanced types of motors made both from

home and abroad, tscleetromagnet ofthe braking part will automatically adjust the

distance withthe armature asthe abrasion ofthe brake rubber This motor can also

tse the now designed pan type brake rubber, which can greatly eeduce the noise and

vibration

‘his motor withthe advantage of smooth braking has small impact force tothe

‘nechonical equipment and simple stricture so in canbe operated conveniently with

Ye and sufe characteristics, which cen specially suit the lift useé for the husan

tnd eatgo forthe high building itcan also suit each knd of eable hoists and cranes,

reli

2.Normal Working Condition

2.1 Ambient Temperature: between *40Tr0-157

2.2 Blevationsatthe elevation ofno more than 1030 meters

2.3 Relative Humidity: no more than 90%

2.4 Rated Frequency:S0Hz60H2

2.5 Rated Voltage: SSOV440V_

3. Type Direction

ith braking

L Used for Lift

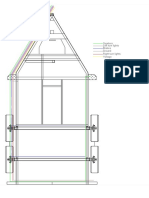

4, Appearance Chart and Its Installation Sizes

Figure: Installation Chat for VZE 1824-4 Active Winch

“Tice Phase Asynchronous Hoisting Motor

6.Main Teennical Parameter

es

TawiPouer aw | Tost [tina | ise | 168] 183 |

Freguency He) 50160

Rated Voltge _W) 3a0re40

Rated Current (A) [325004] 23.5014] 92502] 202 | 313 |

Rated Speod___Gimi)| 1400/1706 170

Toa Work Rate FoI

Block Torave

Rated Torue "| =

[Tastaton Class F :

‘Weight cr 38 10a | 150

‘The Main Technical Parameter for DC Brake:

Te [Technical Parameter

Raed DC Voltage 198

Rated DC Curreat com 055

Static Braking Moment (Nm) | 1207180016 5kW. 18.5EW)

Tngulation Class I E

6.Structure and Working Principle

‘This product consists of two parts, The motor part is Throe-Phased

‘Asynchronous Hoisting Motor with closed selffan cooling. The brake partis

dise brake. which can improve the starting characteristics and keep the coustan

space between the brake electromagnet and armotire with the automate tracing

adjustment function

Working Principle

‘Whien the motor does not connect the power source. because of the functions of

‘main spring (18) through armature (21) ta press brake (brake dise) (11). the motor is

inthe braking state, When the motor. conneets the power source, electromagne(13)

produces the magnetie field. through the function of (18),(12) and back-stop device

(20). to make the armature (21) absorbed gradually. The rotation dise (hexagon) (22)

tives the braking dise (11) to get rid of braking sate gradually. the motor stars

dually, oo.

When the motor is power off, because of the restriction function of the

clectomagoet’s magnetic (eld release, the armature gradually increnses the pressure

fon the braking dite through the

and supplement sp

ngs, the braking torgve

will be gradually increased, 29 ax toachieve the result ofthe motor to besmouthly

‘igure 2 Stractore Demonstation Figure fr YZE 1324-4 Active

‘Winehed Thee Phase Asjuchtouous Hoisting Matar

[key 2 font bearing. 5.junetion box eover 4 motor aad wire sleeve

5 back besring®. spacer ? check ring for bearing 8, weather cover

lo. fixed braking plate 11. braking block (iss) 12. supplement spring 13

electromagnet 14. protection guard 15 bolt 16. hendle 17. back cover 18. main

spring 19 adjustment sleeve 20. retreat block device

21. stmature 22. rotation dise 23, screw 24 fan 25, bush 26, back cover 27. rotor 28

‘winding stator29. front cover 30, waveform spa6er

7-Installation and Use Directions

7.1 If isthe new motor or the motor that i nt used fora long-term. Ie needs the

lobmmeter with SOD voit megohm fo messire the motor swinsings” insulation

resistance, The insulation resistance showld not he less than 0.5 megohmn or ¢ news

the drying treatment before usage

71 When the deviation ofthe rated current i 5% end the deviation af the DC

voltage forthe DC brake is 4:54, the mator snd the DC brake ean be guaranteed to

work normally

7.3 When the motor is installed with the rts

er, the installation style and size

ll se ret,

73.1 Two axils must be at the same axis,

7.4.2 The coupling forthe retarder and the coupling forthe motor will have the

3-Soun ge.

7.3.3 When the coupling is Being installed withthe motor, heavy bit is forbidden

in cose of damaging the back coverof the motor.

7.4 Before mtr installation, please check the items a follows

(Checking the BC brake

The DC brake should connect the power alose(figure 3) First reduce the

standard voltage to ISO to.check the absorbing and the release is normal, whether

situation of blocking or abnormal noises oeeur Square absorbing and release is

conforming. After absorbing, using the gage to gap betsoen armature and braking

disc, which should be 0.5-0.7eum armalls

7-5 During installation and adjustment ofthe motor(figure 4), at fest take off 2

split pins (32) and turn down 2 nuts G31) 30.98 to pale! down tothe broking dise

formove. After installation and adjustment ofthe motor, the nuts (31 should be

tuted yp tothe oigival position, then install the split pins(32).

Figure3: ciceuit di

Ds rectification modular 20A/1000V Re resismnce 20 W/IK&

DE: ZP rectification diode 20A/1000V _DT-elecomaguetic brake

Figured: take off the brake for demonstration

1B. handie 31 nut

8. Maintenance

8.1 Storage and using condition ofthis product keep it dry, cleau and good

entation,

'8.2 During the usage, ifthe situations of vibration, overheat, burnt smell and

abnormal happen the posver source should Be cut, After fixing of the trouble the

‘motor can work again,

hen the bearing has the sign of wear and tear, it should be replaced or the

sootor willbe burat te damage

184 When the motor works at the rated load with the toreh too strong or foo

small adjust it based oa the maintenance direction

'.5 This product showld be maintained regularly. The maintenance is carried out

‘once tree months usage, The overhaul is carried out ance a year Aficr the overhaul,

the motor must havea trial operation, When itis normal, the motor can be Used!

8.6 The customers must correctly and rersonably we the motor based on the

directions,

owaway Units

Reatings: I fr front 18030821, 1 for back 1803072)

Brabing blocks: (copper base powder tallutay) 10 pieces

Braking dise: | piece

©. The Frequent Troubles and Their Fixing

9.1 Trouble: The motor does nat rotate

Cause: alto connect tothe power source

Fining! Connect tothe power source

Cause: The cage door does not close

Fising” Closethe cage door.

Cause: Shertof phases for wiring

Fising! Comnecttothe 3 phases powersousee

Cause: ‘The DC electromagnetism does not open.

Fixing” Check there

ification bridgeand magnetic oil

9.2 Trouble: che motor is seriously everheatwhen the cage is upand down

forloading

CCanser Ieis overrated load,

Fixing: Reniove the overweight

‘Cause: The voltage ofthe power source isbelow the ated voltage,

Fixing: Suitably reduce the Load weight,

(Cause! Cage lubrication isnot good or the pulley is blocked

Fixing: Add the lubrication oil and check the pulley

Cause! Overspeed limiteris blocked

Fining; Checkthe overspeed limiter

Cause) Brake with friction

Fixing; Cheek the electromagnet forthe sbsorbin

between braking block and armature should Beno! less than 0.5mm

cause: Braking with friction

“Pining: Check the restificetion bridge, check the retret block device, check he DC

coil

Cause: Driving plate, retardots output efficiency is toolow.

Fising: When the ented load isp, chock 2aeh af two motors current, when the

voltage is norma, [Fone of two motors currents overrated cut

Incens etarder’s output efficiency doesnot reach the rated value

9. Trouble: The motordaes not rotate suddenly orthe fuse is bur

Cause! Winding statorand he eabinet are shifted

ining: Check the wiring terminal of the connection box for motors pulled aut. it

ispulleout, then replace, [the rectification ridge or the DC coils

suddenly burnt, replace them. Ifthe switches ae short circuit, repair hem,

‘orreplace tern

9.4 Trouble: The vibrations oo strong when the cage stops

Cause: The fixed holts of driving plat are loose.

Fining: Tighten the loose bots.

Cause: Motor braking moment isto big

Fining: Loosen suitably the adjustment sleeve (18) atthe motor iat

9.5. Trouble: [1s slippery when the age brakes.

Cause: Motor braking moment isto smal

Fixing: Tighten suitably the adjustment sleeve (19) the motor til. Remove theo}

dist on the fixing plate or on the armature. Ifthe braking block is broken ot

is worn seriously, replace

9.6 Trouble: The braking block is worn 00 fat.

CCause: the brake is not open fully soit is with friction. The bolts at thecnd ofthe

motor are not well-adjusted

ne Hictanee adjust the pap based on Figured

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DTZZIII User's GuideDocument4 pagesDTZZIII User's GuideDiego BaezNo ratings yet

- Plate With PipesDocument2 pagesPlate With PipesDiego BaezNo ratings yet

- UntitledDocument11 pagesUntitledDiego BaezNo ratings yet

- Left Turn Lights QuartersDocument1 pageLeft Turn Lights QuartersDiego BaezNo ratings yet

- Formato Plan SemanalDocument1 pageFormato Plan SemanalDiego BaezNo ratings yet