Professional Documents

Culture Documents

Stab-In Casing Cementing Job Risk Assessment

Stab-In Casing Cementing Job Risk Assessment

Uploaded by

Ibnu Hasan0 ratings0% found this document useful (0 votes)

83 views2 pagesThis risk assessment document summarizes potential risks for a stab-in casing cementing job and proposed mitigation measures. Key risks include insufficient cement column from inaccurate hole size determination, poor shoe integrity from fluid swapping issues, inability to stab in the stinger, leaks from stab-in connections, cement flash setting from improper mixing or temperatures, lost circulation while cementing, over displacement of cement, and the float valve inability to hold pressure. Mitigation strategies are provided for each risk, such as pumping excess cement, minimizing the rat hole size, installing centralizers above the stinger, inspecting equipment, controlling fluid properties and displacement volumes.

Original Description:

Original Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis risk assessment document summarizes potential risks for a stab-in casing cementing job and proposed mitigation measures. Key risks include insufficient cement column from inaccurate hole size determination, poor shoe integrity from fluid swapping issues, inability to stab in the stinger, leaks from stab-in connections, cement flash setting from improper mixing or temperatures, lost circulation while cementing, over displacement of cement, and the float valve inability to hold pressure. Mitigation strategies are provided for each risk, such as pumping excess cement, minimizing the rat hole size, installing centralizers above the stinger, inspecting equipment, controlling fluid properties and displacement volumes.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

83 views2 pagesStab-In Casing Cementing Job Risk Assessment

Stab-In Casing Cementing Job Risk Assessment

Uploaded by

Ibnu HasanThis risk assessment document summarizes potential risks for a stab-in casing cementing job and proposed mitigation measures. Key risks include insufficient cement column from inaccurate hole size determination, poor shoe integrity from fluid swapping issues, inability to stab in the stinger, leaks from stab-in connections, cement flash setting from improper mixing or temperatures, lost circulation while cementing, over displacement of cement, and the float valve inability to hold pressure. Mitigation strategies are provided for each risk, such as pumping excess cement, minimizing the rat hole size, installing centralizers above the stinger, inspecting equipment, controlling fluid properties and displacement volumes.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 2

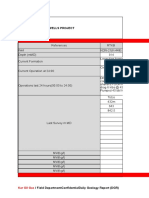

Stab-in Casing Cementing Job Risk Assessment

Job Type: stab-in cementing Location: Date: NEW Yes REVISED

Country: Client: Contractor: Prepared By:

RISK CONSEQUENCE MITIGATION - REMARKS

Pump 250% excess on Lead And 50 % on Tail. Or pump until

1. Hole size determination. Potential Insufficient cement column.

slurry return to surface.

2. Fluid swapping. Poor shoe integrity. Minimize rat hole - Rat hole 6 ft

1) Install 1~3 inner centralizer above stinger.

2) Before connect float equipment, pre-stab in stinger(without

Can't continue to perform cementing job. Lost of

3. Can't stab in stinger. O ring).

time.

3) Prevent junk fall into casing.

4) Rotate drill pipe by chain tong.

1) Provide O-ring spares on location.

2) Inspect float shoe prior running casing.

3) Inspect stab-in O-rings and stinger.

4. Stab-in leaks Resulting in aborted cement job.

4) Fill casing and observe prior to cementing.

5) Stab-in and circulate with fluid.

6) Monitor conductor annulus.

1) Test Cl concentraton<500ppm.

2)Thickening time safety margin 60~90min.

3) Test cement slurries as per temperature given by client

5. Cement flash set Cement job failure. with location water and wellsite chemicals batch number.

4) Follow recipe to prepare mixing water in sequence.

5) Control fluid loss<300ml if encounter coat or sand

formation.

1) Circulate annular volume plus 100% excess before

cementing to ensure no annular blockage.

6. Lost circulation while cementing. Resulting in poor cement job. 2) Pump 250% excess cement over annular volume on Lead

and pump 50% excess cement over annular volume on Tail.

3) Monitor surface pressure.

1) Include rat hole volume in cement calculation

2) Leave ?? bbls cement (40 ft) on top of float shoe

7. Over displace cement. Poor shoe integrity.

3) Displace cement slurry with water, pumped by cement

unit.

1) If is surface casing, recommend to use stab-in float collar

or double valve float shoe.

Cement plug in casing is too high. Annular

8. Float valve can't hold pressure. 2) Check float valve condition before RIH.

cement can't suppport conductor.

3) Pump back returns quickly and repeat 2~3times. If still fail,

POOH.

You might also like

- Hkdse English Reading全方位實戰神技精讀 主筆記 Sample 1643026918Document23 pagesHkdse English Reading全方位實戰神技精讀 主筆記 Sample 1643026918SupercellNo ratings yet

- Anti CollisionDocument5 pagesAnti CollisionJaime A PolancoNo ratings yet

- HMT Training ReportDocument43 pagesHMT Training ReportNajvan MuhammedNo ratings yet

- Cleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedDocument1 pageCleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedMohamed AbozeimaNo ratings yet

- Mizzen L-11 - End of Well Report - INV - 032042 642 PDFDocument1 pageMizzen L-11 - End of Well Report - INV - 032042 642 PDFKevin MuellerNo ratings yet

- DDR N°1 - Atk29 - TP180 - 08022017Document3 pagesDDR N°1 - Atk29 - TP180 - 08022017Nour MohammedNo ratings yet

- 7 X 9.625 With TSP, DWPDocument5 pages7 X 9.625 With TSP, DWPRahima RahoumaNo ratings yet

- Trex 01157Document17 pagesTrex 01157OSDocs2012No ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- 1995 - Ardjuna B FieldDocument8 pages1995 - Ardjuna B FieldGemilangNo ratings yet

- TCP-DST-01 String Diagram Rajian-07 PDFDocument1 pageTCP-DST-01 String Diagram Rajian-07 PDFRizwan FaridNo ratings yet

- Notes 4Document18 pagesNotes 4Ruben ChirinosNo ratings yet

- RIG: F28 Shock Sub: OD (Inch) ID (Inch) Length (M) Thread S950024 6-1/8" 9-1/2" 2-7/8" 7-5/8"Document16 pagesRIG: F28 Shock Sub: OD (Inch) ID (Inch) Length (M) Thread S950024 6-1/8" 9-1/2" 2-7/8" 7-5/8"berrouiNo ratings yet

- Tech Drilling Cementing CalculationsDocument0 pagesTech Drilling Cementing Calculationsadvantage025No ratings yet

- IF 834lbf: Rotary Drill BitsDocument1 pageIF 834lbf: Rotary Drill BitsDian SikumbangNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU Locationahmed1adnan-10No ratings yet

- BP America Gomx Deepwater Drilling MC 562 #1 Drilling Progra For 14-3/4"X16" By-PassDocument17 pagesBP America Gomx Deepwater Drilling MC 562 #1 Drilling Progra For 14-3/4"X16" By-PassOSDocs2012No ratings yet

- Vibration Corrective Action Chart: Observation Typical Environment Short Term Corrective Action Long Term Counter MeasureDocument1 pageVibration Corrective Action Chart: Observation Typical Environment Short Term Corrective Action Long Term Counter Measuresaeed65No ratings yet

- Da13 DDR N1 13991116 143 0Document3 pagesDa13 DDR N1 13991116 143 0Hamed NazariNo ratings yet

- Derrickman Reports PDFDocument1 pageDerrickman Reports PDFjinyuan74No ratings yet

- Amal-18 Sta DDR#20 02-03-2020Document30 pagesAmal-18 Sta DDR#20 02-03-2020eng7mohamed7hashimNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Synthetic-Based Mud Report No. 39: LLOG ExplorationDocument1 pageSynthetic-Based Mud Report No. 39: LLOG Explorationadvantage025No ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationAhmedNo ratings yet

- Morning Report 19 - 24 April 2012Document3 pagesMorning Report 19 - 24 April 2012tolstoy potemkinNo ratings yet

- Section 11 - Drilling Mud ManualDocument4 pagesSection 11 - Drilling Mud ManualMohamed AbozeimaNo ratings yet

- DMR-1. Dated 9-10-2022Document1 pageDMR-1. Dated 9-10-2022Gulzar AhmedNo ratings yet

- 16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7Document1 page16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7javier monteroNo ratings yet

- SOP 829-019 Rig Out The Mud Tanks and Pumps.Document2 pagesSOP 829-019 Rig Out The Mud Tanks and Pumps.Anonymous XbmoAFtINo ratings yet

- BHA#06 10.625x12.25in RSS+MWD+LWD+PBL+RR Real R2Document1 pageBHA#06 10.625x12.25in RSS+MWD+LWD+PBL+RR Real R2Guillermo ToledoNo ratings yet

- Job Pertamina-Petrochina East Java: Wahdanadi, ErikDocument2 pagesJob Pertamina-Petrochina East Java: Wahdanadi, Erikuli ulinuhaNo ratings yet

- BP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Document42 pagesBP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Doppler KenzoNo ratings yet

- Goldenman Petroluem Equipment Co., Limited: Quotation ListDocument4 pagesGoldenman Petroluem Equipment Co., Limited: Quotation ListEstuardo AlvaradoNo ratings yet

- Well #1 - Well #1 - PROFILE PDFDocument1 pageWell #1 - Well #1 - PROFILE PDFHassan ZakeriNo ratings yet

- Make Up TorqueDocument1 pageMake Up TorqueNicasio AlonzoNo ratings yet

- SD-24P Bit Record 2Document1 pageSD-24P Bit Record 2Them Bui XuanNo ratings yet

- TCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsDocument1 pageTCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsrajafonsekaNo ratings yet

- Potassium Acetate - Mixed From Dry: Density % by Weight Specific Gravity Fresh Water, BBL 100% K Acetate, LbsDocument34 pagesPotassium Acetate - Mixed From Dry: Density % by Weight Specific Gravity Fresh Water, BBL 100% K Acetate, LbsAbdullah முகமது جواهرNo ratings yet

- O 1 03 01Document2 pagesO 1 03 01gplese0No ratings yet

- API Thread Torque Table PDF Pipe (Fluid Conveyance) MaterialsDocument1 pageAPI Thread Torque Table PDF Pipe (Fluid Conveyance) MaterialsHiginio CasianoNo ratings yet

- Da13 DDR N1 13991122 149 0Document3 pagesDa13 DDR N1 13991122 149 0Hamed NazariNo ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- Spe62752 Viscous Pill InfoDocument1 pageSpe62752 Viscous Pill InfoAkkassin AbdullayevNo ratings yet

- Programa Completo Completacion InicialDocument23 pagesPrograma Completo Completacion InicialAlejandro JaramilloNo ratings yet

- Herunefer W 13Document3 pagesHerunefer W 13Islam AtifNo ratings yet

- Chapter 2-J Positive Displacement MotorsDocument23 pagesChapter 2-J Positive Displacement MotorsFor Free Drilling Training CenterNo ratings yet

- Alaska Drilling and Wells Recommended Practice: CTD Drilling FluidDocument4 pagesAlaska Drilling and Wells Recommended Practice: CTD Drilling FluidAdel Ahmed AlkhaligyNo ratings yet

- String Diagram Toot Deep-1 OGDCL DST-6 - 3Document1 pageString Diagram Toot Deep-1 OGDCL DST-6 - 3Aadil HaroonNo ratings yet

- Manzalai-07 Daily Mud Report (10!7!20)Document1 pageManzalai-07 Daily Mud Report (10!7!20)Sharjeel AhmedNo ratings yet

- Copia de Bha de PozoDocument18 pagesCopia de Bha de PozoBertha Julieth Lopez ParraNo ratings yet

- Tdi FCR Data 9 625 47ppf n80 BTC Rev 6Document1 pageTdi FCR Data 9 625 47ppf n80 BTC Rev 6Villalba XavichoNo ratings yet

- Right Torque at The Connection 5Document4 pagesRight Torque at The Connection 5Shafiqa AlhobaishyNo ratings yet

- HH 83-1D SurveyDocument3 pagesHH 83-1D SurveyMahmoud Ahmed Ali AbdelrazikNo ratings yet

- PM, PF and MF of Drilling Mud (Water Based Mud) - Drilling Formulas and Drilling CalculationsDocument6 pagesPM, PF and MF of Drilling Mud (Water Based Mud) - Drilling Formulas and Drilling CalculationsmohNo ratings yet

- DDR N°02 - Sydnw1 - Enf57 - 24122019Document3 pagesDDR N°02 - Sydnw1 - Enf57 - 24122019Kenaouia Bahaa100% (1)

- Sleeve Stablizer/Thread ProtectorDocument1 pageSleeve Stablizer/Thread ProtectorhamidNo ratings yet

- Liner Cementing GuidelinesDocument2 pagesLiner Cementing GuidelineszapspazNo ratings yet

- Well Kick Data: Sheet No. 2Document2 pagesWell Kick Data: Sheet No. 2Raul Dolo QuinonesNo ratings yet

- Completion (Natural Flow)Document3 pagesCompletion (Natural Flow)Mohammed Ali YoussefNo ratings yet

- 4c - Primary Cementing ChecklistDocument2 pages4c - Primary Cementing ChecklistSiti Maisarah Riana PutriNo ratings yet

- Effect of Drilling Fluids On ROPDocument6 pagesEffect of Drilling Fluids On ROPAmir O. Osho100% (1)

- Squeeze Without Tool Engineering Risk AnalysisDocument2 pagesSqueeze Without Tool Engineering Risk AnalysisIbnu HasanNo ratings yet

- Well: LLB-12 13-3/8" Squeeze Design: Pt. Cosl IndoDocument6 pagesWell: LLB-12 13-3/8" Squeeze Design: Pt. Cosl IndoIbnu HasanNo ratings yet

- Squeeze Without Tool Engineering Risk AnalysisDocument2 pagesSqueeze Without Tool Engineering Risk AnalysisIbnu HasanNo ratings yet

- Triple CSG CalculateDocument7 pagesTriple CSG CalculateIbnu HasanNo ratings yet

- Primary Cementing CalculationDocument34 pagesPrimary Cementing CalculationIbnu HasanNo ratings yet

- P-Tank Volume CalculationDocument1 pageP-Tank Volume CalculationIbnu HasanNo ratings yet

- Slurry Yield CalculaionDocument2 pagesSlurry Yield CalculaionIbnu HasanNo ratings yet

- Cement Slurry Test Report: FORM NO. OC-QHSE/WR 0704-03 Oilfield Chemicals - Pt. IndoDocument18 pagesCement Slurry Test Report: FORM NO. OC-QHSE/WR 0704-03 Oilfield Chemicals - Pt. IndoIbnu HasanNo ratings yet

- Basic DataDocument1 pageBasic DataIbnu HasanNo ratings yet

- Well: B-166 18-5/8" Casing Cementing DesignDocument8 pagesWell: B-166 18-5/8" Casing Cementing DesignIbnu HasanNo ratings yet

- Basic Knowledge of The Cementing Test: Pt. Co L IndoDocument43 pagesBasic Knowledge of The Cementing Test: Pt. Co L IndoIbnu HasanNo ratings yet

- Malayreservation2013 130614075747 Phpapp02Document124 pagesMalayreservation2013 130614075747 Phpapp02Sya NazNo ratings yet

- SPC SpreadsheetDocument10 pagesSPC SpreadsheetSpyros IliakisNo ratings yet

- November 2023 Timetable Zone 2Document12 pagesNovember 2023 Timetable Zone 2Horror666No ratings yet

- Din 17174Document7 pagesDin 17174djmattmNo ratings yet

- Kaizen: Kaizen Games Priston TaleDocument4 pagesKaizen: Kaizen Games Priston TaleAnis QureshiNo ratings yet

- G.R. No. L-48176 PDFDocument7 pagesG.R. No. L-48176 PDFAj SobrevegaNo ratings yet

- Xiaomi WP - 9182 of 2022Document34 pagesXiaomi WP - 9182 of 2022Arjav JainNo ratings yet

- Laporan Bulanan Data Center CyberDocument11 pagesLaporan Bulanan Data Center CyberDeden Andri Maulana SyamsudinNo ratings yet

- BlackMart APK Download Latest Version 2021.editedDocument5 pagesBlackMart APK Download Latest Version 2021.editedZia NasirNo ratings yet

- Jeppesen PowerplantDocument255 pagesJeppesen PowerplantWilliam Palma100% (1)

- Akfix General Product Catalogue 2023 Rev11Document84 pagesAkfix General Product Catalogue 2023 Rev11ahmed.serefNo ratings yet

- UNIT-3 Incentives: BY-Prof - Preeti DwivediDocument24 pagesUNIT-3 Incentives: BY-Prof - Preeti DwivedirpsinghsikarwarNo ratings yet

- BTech Thesis Student AttendanceDocument24 pagesBTech Thesis Student AttendanceJohn Pecson100% (1)

- sjp810m Manual BookDocument12 pagessjp810m Manual BookMegNo ratings yet

- OTC107207 OptiX NG WDM Optical Layer Data Configuration ISSUE 1Document28 pagesOTC107207 OptiX NG WDM Optical Layer Data Configuration ISSUE 1ARMAND NGUETSA SONKENGNo ratings yet

- Features: Explosion ProofDocument2 pagesFeatures: Explosion Proofhussein javanNo ratings yet

- Norbar TruCheckDocument2 pagesNorbar TruCheckJuanNo ratings yet

- Zara Case Study20191029 42781 f73lj1 With Cover Page v2Document17 pagesZara Case Study20191029 42781 f73lj1 With Cover Page v2Amrutha RPNo ratings yet

- 09 Collecting Data Through Observation-1Document22 pages09 Collecting Data Through Observation-1NaSir AzizNo ratings yet

- 16 Bit Carry Select Adder With Low Power and AreaDocument3 pages16 Bit Carry Select Adder With Low Power and AreaSam XingxnNo ratings yet

- Cargo Handling & Stability - I: Captain Nazim ErsenDocument52 pagesCargo Handling & Stability - I: Captain Nazim ErsenberNo ratings yet

- Enhancing With Multi ThreadingDocument38 pagesEnhancing With Multi Threadingra_po_1No ratings yet

- Constitution and By-Laws: University of Southeastern PhilippinesDocument3 pagesConstitution and By-Laws: University of Southeastern PhilippinesDana Althea AlgabreNo ratings yet

- Direct XCD PDFDocument12 pagesDirect XCD PDFjhuggghNo ratings yet

- NSDL Conso File FVU Error Code ListDocument22 pagesNSDL Conso File FVU Error Code Listlekireddy33% (9)

- Tikidan SDS - HydrostopDocument5 pagesTikidan SDS - HydrostopsandeepNo ratings yet

- Research MethodologyDocument7 pagesResearch MethodologyJERICO IGNACIONo ratings yet

- Dishwasher 2011Document20 pagesDishwasher 2011chamaljsNo ratings yet