Professional Documents

Culture Documents

FAA 2015 0415 0004 - Attachment - 4

FAA 2015 0415 0004 - Attachment - 4

Uploaded by

Albaz DarwishOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FAA 2015 0415 0004 - Attachment - 4

FAA 2015 0415 0004 - Attachment - 4

Uploaded by

Albaz DarwishCopyright:

Available Formats

MSB1121-144/3

Page 1 of 11

20 February 2015

Replaces Issue: 05 February 2015

SERVICE BULLETIN NO. MSB1121-144/3

I. TECHNICAL DETAILS

1.1 Category:

Mandatory

Note: GROB issues Service Bulletins of category Mandatory (MSBs), if the information or

instructions have a safety intent either related to design or conformity and to

publish revisions of manuals (AFM, AMM, IPC). However, according to Article 20

(1) of Regulation (EC) No. 216/2008, only EASA may issue mandatory information,

in the form of an Airworthiness Directive (AD), in order to react to a given safety

problem. Service Bulletins classified Mandatory issued by GROB´s design

organisation do not have a legally mandatory character equivalent to an AD,

cannot have enforcement implications and, therefore, serve as information or

instruction by GROB only. This also applies to cases where a Service Bulletin is

published in anticipation of an AD.

Note: This Service Bulletin is issued in anticipation of an AD. Issue of an AD will not

necessarily lead to revision of this Service Bulletin.

1.2 Airplanes affected:

G 120A all S/N

G 120A-I all S/N

1.3 Time of Compliance:

Part A: Before next IFR or VFR Night flight, or within next 50FH, whichever comes first, unless

already accomplished under MSB 1121-144 at previous issue.

Part B: Within 100 flight hours.

1.4 Subject:

ATA-Code: 80-00 Starting

Inspection of starter solenoid / Installation of a Starter Relay

1.5 Reason:

GROB received a report about a total loss of electrical power in IMC on a G 115E aircraft. Root

cause was found to be a defect starter solenoid. The starter solenoid had an internal defect

causing a short circuit. The defect cannot be detected by visual inspection. The installation is

similar to the installation on G120 aircraft.

Revision 3 of this Service Bulletin amends the implementation instructions.

This Service Bulletin is intended to prevent an unsafe condition. The configuration of the aircraft

is affected by Part B of this Service Bulletin.

Note: Implementation of MSB 1121-144/1, Part B prohibits application of RSB1121-128.

1121-144_3 MSB, Inspection of starter solenoid G 120A, A-I

Grob Aircraft AG, Lettenbachstrasse 9, D-86874 Tussenhausen-Mattsies

MSB1121-144/3

Page 2 of 11

20 February 2015

Replaces Issue: 05 February 2015

1.6 Concurrent documents:

Corresponding AMM

1.7 Approval Note:

The technical content of this document is approved under the authority of EASA Design

Organization Approval No. EASA.21J.030.

These information or instructions relate to change no. MÄM 1121-189 which has been approved

by the Authority (EASA) under approval no. 10051942.

1.8 Accomplishment/ Instructions

Part A One-time Inspection

1.8.1 Disconnect the aircraft battery, refer to AMM Chapter 24-31.

1.8.2 Remove the Engine Cowlings, refer to AMM Chapter 71-10.

1.8.3 Visually inspect the starter. Make sure that the power connection bolts have the same

length, refer to Figure 1 for defective item and Figure 2 for correct installation.

Figure 1: Incorrect connection bolts Figure 2: Correct installation

1.8.4 Release the two bolts on the starter solenoid. Carefully pull the solenoid away from the

starter housing until the dead stop. Make sure that the solenoid plunger is still attached,

refer to Figure 3. Attach the solenoid to the starter with the two bolts.

1121-144_3 MSB, Inspection of starter solenoid G 120A, A-I

Grob Aircraft AG, Lettenbachstrasse 9, D-86874 Tussenhausen-Mattsies

MSB1121-144/3

Page 3 of 11

20 February 2015

Replaces Issue: 05 February 2015

Figure 3: Starter solenoid at dead stop

1.8.5 If the starter is OK, do step 1.8.7.

1.8.6 If the starter is not OK or in case of doubt, replace the Starter.

1.8.7 Install the Engine Cowlings; refer to AMM Chapter 71-10.

1.8.8 Connect the aircraft battery; refer to AMM Chapter 24-31.

1.8.9 Release aircraft into service according to national requirements.

Part B/1 Installation of Starter Relay (Terminating action) with RSB1121-128

installed

1.8.10 Ensure that the aircraft is safe for parking I.A.W. AMM chapter 10-10.

1.8.11 Disconnect the aircraft battery for maintenance, refer to MM Chapter 24-30.

1.8.12 Remove the Engine Cowlings, refer to MM Chapter 71-10.

1.8.13 Disconnect the spark plug cables from the spark plugs.

1.8.14 Unplug all terminals with cables from relay 5KA. Remove relay 5KA with clamp, bolt, two

washers and nut from engine mount and discard.

Relay 5KA

Figure 4: Relay 5KA

1.8.15 Unplug terminal with cables KA 02F20-E and KA 09G20-E from START BOOSTER 3KA

connector VIN (red housing). Cut terminal as short as possible and discard it.

1121-144_3 MSB, Inspection of starter solenoid G 120A, A-I

Grob Aircraft AG, Lettenbachstrasse 9, D-86874 Tussenhausen-Mattsies

MSB1121-144/3

Page 4 of 11

20 February 2015

Replaces Issue: 05 February 2015

START BOOSTER

3KA

Figure 5: STARTER BOOSTER 3KA

1.8.16 Remove cable KA 09G20-E (previous routed from 5KA to 3KA) and Cable KA 07E14-E

(previous routed from 5KA to 2KA) and discard them.

1.8.17 Drill a 5mm hole in the condenser frame 35mm left of the existing second hole of the top

condenser frame at the inner border. Attach the new starter relay (7KA) (Item 1 of List

2.2), so that the terminals point downwards. Use 2xM5 screw (Item 2 of List 2.2), 4xM5

washers (Item 3 of List 2.2) and 2xM5 nuts (Item 4 of List 2.2). To balance the distance

between the condenser frame and the relay mounting bracket on the forward side, use

an additional spacer (Item 5 of List 2.2).

New starter relay 7KA

New hole in condenser frame Spacer

Figure 6: STARTER RELAY 7KA

1121-144_3 MSB, Inspection of starter solenoid G 120A, A-I

Grob Aircraft AG, Lettenbachstrasse 9, D-86874 Tussenhausen-Mattsies

MSB1121-144/3

Page 5 of 11

20 February 2015

Replaces Issue: 05 February 2015

1.8.18 Install and lengthen new cable KA 02H20-E (Item 6 of List 2.2), along existing cable

loom from START BOOSTER 3KA to new starter relay 7KA with the pre-installed

terminal at the starter relay 7KA end. Connect to terminal 86+ on relay 7KA.

1.8.19 On the START BOOSTER 3KA end dismantle existing cables KA 02F20-E and new

cable KA 02H20-E, pair and crimp them to terminal AMP 160773-6 (Item 7 of List 2.2) by

using crimping tool AMP 654174-1 or equivalent (Item 1 of List 2.3).

1.8.20 Attach red housing AMP 154719-2 (Item 8 of List 2.2) to terminal and plug to START

BOOSTER 3KA connection VIN. Strap new cable to existing cable loom.

1.8.21 Use existing cable KA 08E20N-P (previous located at 5KA) from VN17101 and root to

new starter relay 7KA. Cut existing terminal as short as possible and discard it.

Dismantle cable KA 08E20N-P and crimp to terminal MS25036-149 (Item 9 of List 2.2)

by using crimping tool AMP 169400-0 or equivalent (Item 2 and 3 of List 2.3). Connect to

terminal 85- on relay 7KA.

1.8.22 Remove cable tie from rubber cap of middle bolt VV17103 on firewall. Push back cover

to gain access to stop nut. Remove and discard nut and washer, therefore hold up

counter nut and do not damage black wrapping tape. Remove cable complete KA

06E14-E from VV17103 to relay 5KA and discard. Remove cable PA 03G06-E from bolt

VV17103 (leave the rubber cap at the cable!) and route it back along existing wire to

new starter relay 7KA. Connect to terminal 88a on starter relay 7KA. Secure rubber cap

strap with cable tie (Item 10 of List 2.2).

1.8.23 Install new cable PA 03L06-E (Item 11 of List 2.2) and connect to terminal 88 on starter

relay 7KA therefore the cable has to be led through the new rubber cap (Item 12 of List

2.2). Root along existing loom to middle bolt VV17103 on firewall. Therefore the cable

has to be led through the new rubber cap (Item 12 of List 2.2). Tighten terminal with new

washer and stop nut on bolt (Item 13 and 14 of List 2.2), while holding up counter nut.

Paint with blue NYCOTE 7-11 protective coating (Item 15 of List 2.2).

1.8.24 Let lacquer dry before reinstalling rubber cap. Secure rubber caps (on both end of

PA 03L06-E) strap with cable tie (Item 10 of List 2.2).

1.8.25 Install the jumper cable 115E-9510.03 (Item 16 of List 2.2) on the starter solenoid, refer

to wiring diagram. Attach to connector “S” at Starter Motor 2KA using the old washer and

screw. Paint with blue NYCOTE 7-11 protective coating (Item 15 of List 2.2). Let lacquer

dry before marking with inspection lacquer (Item 17 of List 2.2). (See Figure 7)

Figure 7: STARTER 2KA

1121-144_3 MSB, Inspection of starter solenoid G 120A, A-I

Grob Aircraft AG, Lettenbachstrasse 9, D-86874 Tussenhausen-Mattsies

MSB1121-144/3

Page 6 of 11

20 February 2015

Replaces Issue: 05 February 2015

1.8.26 Secure the cables with cable ties, where necessary.

1.8.27 Connect the spark plug cables to the spark plugs.

1.8.28 Install the Engine Cowlings, refer to AMM Chapter 71-10.

1.8.29 Connect the aircraft battery, refer to AMM Chapter 24-30.

1.8.30 Do an engine run-up, refer to AMM Chapter 71-00.

1.8.31 Release aircraft into service according to national requirements.

Part B/2 Installation of Starter Relay (Terminating action) without RSB1121-128

installed

1.8.32 Ensure that the aircraft is safe for parking I.A.W. AMM chapter 10-10.

1.8.33 Disconnect the aircraft battery for maintenance, refer to MM Chapter 24-30.

1.8.34 Remove the Engine Cowlings, refer to MM Chapter 71-10.

1.8.35 Disconnect the spark plug cables from the spark plugs.

1.8.36 Unplug terminal with cables KA 02G20-E and KA 02F20-E from Starter Booster 3KA

connector VIN (red housing). Cut terminal as short as possible and discard it. Cap and

stow cable KA 02G20-E with TC cap (Item 19 of List 2.2) using a heat gun (Item 4 of List

2.3).

START BOOSTER

3KA

Figure 8: STARTER BOOSTER 3KA

1.8.37 Drill a 5mm hole in the condenser frame 35mm left of the existing second hole of the top

condenser frame at the inner border. Attach the new starter relay (7KA) (Item 1 of List

2.2), so that the terminals point downwards. Use 2xM5 screw (Item 2 of List 2.2), 4xM5

washers (Item 3 of List 2.2) and 2xM5 nuts (Item 4 of List 2.2). To balance the distance

between the condenser frame and the relay mounting bracket on the forward side, use

an additional spacer (Item 5 of List 2.2).

1121-144_3 MSB, Inspection of starter solenoid G 120A, A-I

Grob Aircraft AG, Lettenbachstrasse 9, D-86874 Tussenhausen-Mattsies

MSB1121-144/3

Page 7 of 11

20 February 2015

Replaces Issue: 05 February 2015

New starter relay 7KA

New hole in condenser frame Spacer

Figure 9: STARTER RELAY 7KA

1.8.38 Install and lengthen new cable KA 02H20-E (Item 6 of List 2.2), along existing cable

loom from START BOOSTER 3KA to new starter relay 7KA with the preinstalled terminal

at the starter relay 7KA end. Connect to terminal 86+ on relay 7KA.

1.8.39 On the START BOOSTER 3KA end dismantle existing cables KA 02F20-E and new

cable KA 02H20-E, pair and crimp them to terminal AMP 160773-6 (Item 7 of List 2.2) by

using crimping tool AMP 654174-1 or equivalent (Item 1 of List 2.3).Attach red housing

AMP 154719-2 (Item 8 of List 2.2) to terminal and plug to START BOOSTER 3KA

connection VIN. Strap new cable to existing cable loom.

1.8.40 Remove and discard nut and washer from grounding bolt VN 17101, therefore hold up

counter nut. Remove terminal, turn by 180° and reattach to bolt. Install new cable KA

08E20N-P (Item 20 of List 2.2) along existing cable loom from starter relay 7KA to

grounding bolt VN 17101. Tighten terminal with new washer and stop nut on bolt (Item

21 and 22 of List 2.2) while holding up counter nut. Paint with blue NYCOTE 7-11

protective coating (Item 15 of List 2.2). Strap in new cable back in cable loom strap with

cable ties. (See Figure 10)

1121-144_3 MSB, Inspection of starter solenoid G 120A, A-I

Grob Aircraft AG, Lettenbachstrasse 9, D-86874 Tussenhausen-Mattsies

MSB1121-144/3

Page 8 of 11

20 February 2015

Replaces Issue: 05 February 2015

VN 17101

VV 17103 Grounding Bolt

Figure 10 Bolts at Firewall

1.8.41 Remove cable tie from rubber cap of middle bolt VV17103 on firewall. Push back cover

to gain access to stop nut. Remove and discard nut and washer, therefore hold up

counter nut and do not damage black wrapping tape. Remove cable KA 06E14-E

complete from VV17103 to relay 5KA and discard. Remove cable PA 03G06-E from bolt

VV17103 (leave the rubber cap at the cable!) and route it back along existing wire to

new starter relay 7KA. Connect to terminal 88a on starter relay 7KA. Secure rubber cap

strap with cable tie (Item 10 of List 2.2).

1.8.42 Install new cable PA 03L06-E (Item 11 of List 2.2) and connect to terminal 88 on starter

relay 7KA therefore the cable has to be led through the new rubber cap (Item 12 of List

2.2). Root along existing loom to middle bolt VV17103 on firewall. Therefore the cable

has to be led through the new rubber cap (Item 12 of List 2.2). Tighten terminal with new

washer and stop nut on bolt (Item 13 and 14 of List 2.2), while holding up counter nut.

Paint with blue NYCOTE 7-11 protective coating (Item 15 of List 2.2).

1.8.43 Let lacquer dry before reinstalling rubber cap. Secure rubber caps (on both end of

PA 03L06-E) strap with cable tie (Item 10 of List 2.2).

1.8.44 Unplug terminal with cable KA 02G20-E from Engine Starter Motor 2KA connector “S”.

Keep screw and washer. Cut terminal as short as possible and discard it. Cap and stow

cable KA 02G20-E with TC cap (Item 19 of List 2.2) using a heat gun (Item 4 of List 2.3).

1.8.45 Install the jumper cable 115E-9510.03 (Item 16 of List 2.2) on the starter solenoid, refer

to wiring diagram. Attach to connector “S” at Starter Motor 2KA using the old washer and

screw. Paint with blue NYCOTE 7-11 protective coating (Item 15 of List 2.2). Let lacquer

dry before marking with inspection lacquer (Item 17 of List 2.2). (See Figure 11)

1121-144_3 MSB, Inspection of starter solenoid G 120A, A-I

Grob Aircraft AG, Lettenbachstrasse 9, D-86874 Tussenhausen-Mattsies

MSB1121-144/3

Page 9 of 11

20 February 2015

Replaces Issue: 05 February 2015

Figure 11: STARTER 2KA

1.8.46 Safety the cables with cable ties, where necessary.

1.8.47 Connect the spark plug cables to the spark plugs.

1.8.48 Install the Engine Cowlings, refer to AMM Chapter 71-10.

1.8.49 Connect the aircraft battery, refer to AMM Chapter 24-30.

1.8.50 Do an engine run-up, refer to AMM Chapter 71-00.

1.8.51 Release aircraft into service according to national requirements.

1.9 Repetitive Actions

none

1121-144_3 MSB, Inspection of starter solenoid G 120A, A-I

Grob Aircraft AG, Lettenbachstrasse 9, D-86874 Tussenhausen-Mattsies

MSB1121-144/3

Page 10 of 11

20 February 2015

Replaces Issue: 05 February 2015

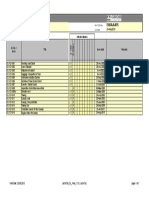

II. PLANNING INFORMATION

2.1 Weight and CG

N/A

2.2 Material and Availability

Part B/1:

Item P/N Description Qty. / A/C

1 GS246001-9 Starter Relay 1

2 LN9037-05018 Screw 2

3 LN9025-0510 Washers 4

4 LN9348-05 Nut 2

5 NAS43DD3-6N Spacer 1

6 120A-940010.02A KA 02H20-E 1

7 AMP 160773-6 Terminal 1

8 AMP 154719-2 Housing, Red 1

9 MS25036-149 Terminal, Red 1

10 GS510010-100 Cable Ty, Blue 8

11 115E-9470.01 PA 03L06-E 1

12 MS 25171-3S Rubber Caps 2

13 LN9348-M8 Nut 1

14 LN9025-0815L Washer 1

AR

15 Nycote7-11 BLUE Protective Coating to be ordered

separately

16 115E-9510.03 Jumper cable 1

AR

17 GS513010 Inspection Lacquer to be ordered

separately

18 GS510010-200 Cable Ty, Blue 4

Part B/2: additional

19 GS247009-2-32 Heatshrinkable Caps 2

20 120A-940010.01A KA 08E20N-P 1

21 LN9348-M10 Nut 1

22 LN9025-1020L Washer 1

1121-144_3 MSB, Inspection of starter solenoid G 120A, A-I

Grob Aircraft AG, Lettenbachstrasse 9, D-86874 Tussenhausen-Mattsies

MSB1121-144/3

Page 11 of 11

20 February 2015

Replaces Issue: 05 February 2015

2.3 Special Tools

Part B/1:

Item P/N Description

1 AMP 654174-1 (or equivalent) Crimping tool PEZ 100

2 AMP 169400-0 (or equivalent) Crimping tool CERTI-LOK

3 AMP 169404 (or equivalent) Die Set for AMP 169400-0

Part B/2: additional

4 Commercial Heat Gun

2.4 Labor costs

N/A

2.5 Reference documents

Corresponding AMM and IPC

2.6 Credit

N/A

III. REMARKS

The instructions in paragraph 1.8 have to be accomplished and certified in the logbook by

authorized staff:

- in EASA countries according to Article 5 VO EG 2042/03 (VO EG 1056/2008) Appendix III –

Part 66

- in non-EASA countries according to national regulations with respect to maintenance.

If you have sold your aircraft in the meantime, we kindly ask you to forward this information to

the new owner and to provide us with the name and address of the new owner as well as with

the respective serial number.

For questions and assistance please contact:

Product Support,

phone: +49 8268 998105

fax: +49 8268 998200

e-mail: productsupport@grob-aircraft.com

1121-144_3 MSB, Inspection of starter solenoid G 120A, A-I

Grob Aircraft AG, Lettenbachstrasse 9, D-86874 Tussenhausen-Mattsies

You might also like

- Holden VT 2000 Service TechlinesDocument177 pagesHolden VT 2000 Service Techlinescosky071% (7)

- Technics SL-1200 - 1210MK7 - Service Manual - EnglishDocument37 pagesTechnics SL-1200 - 1210MK7 - Service Manual - EnglishSantos RobsonNo ratings yet

- AIR CRUISERS 004-25-87 R3 Dt. 07.02.20Document10 pagesAIR CRUISERS 004-25-87 R3 Dt. 07.02.20Pradeep K s100% (1)

- LA206001 Park Brake Lamp Illuminated PDFDocument4 pagesLA206001 Park Brake Lamp Illuminated PDFGino Pier100% (1)

- 61 20Document12 pages61 20Miguel Condor100% (1)

- 300-5617 Cooler AssemblyDocument13 pages300-5617 Cooler Assemblyharikrishnanpd3327No ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- X-Fi ™ Prelude 7.1: Owner's ManualDocument37 pagesX-Fi ™ Prelude 7.1: Owner's ManualJordan Nevitt100% (1)

- IGV AssamblyDocument31 pagesIGV AssamblyPhong le100% (2)

- 1841 EN. Change Variable Speed AETJDocument5 pages1841 EN. Change Variable Speed AETJMhan ImanNo ratings yet

- Mandatory: AlertDocument15 pagesMandatory: AlertamerNo ratings yet

- DAC1 23 50 Rev 0Document6 pagesDAC1 23 50 Rev 0vanNo ratings yet

- SBLM2500 IND 174rev1Document7 pagesSBLM2500 IND 174rev1Daniil SerovNo ratings yet

- 1ZUA 5670-201 en PDFDocument7 pages1ZUA 5670-201 en PDFAnonymous rAFSAGDAEJNo ratings yet

- SB139338 TRSR Bumper InstDocument11 pagesSB139338 TRSR Bumper InstaeroNo ratings yet

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document5 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNo ratings yet

- SIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2Document39 pagesSIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2kenji roberto santanaNo ratings yet

- SBLM2500 Ind 162Document6 pagesSBLM2500 Ind 162Daniil SerovNo ratings yet

- EMCP Electronic Control (AC Transformer Box) - Replace: Pantalla AnteriorDocument3 pagesEMCP Electronic Control (AC Transformer Box) - Replace: Pantalla AnteriorGustavo PereiraNo ratings yet

- 7.0 ЕчЦї-ElectricDocument21 pages7.0 ЕчЦї-ElectricSouleymane NdiayeNo ratings yet

- AFC Sensor de Presion PDFDocument10 pagesAFC Sensor de Presion PDFCharlie BrownNo ratings yet

- Panasonic NV Gs6, Gs17, Gs18, Gs21, Gs25, Gs28, Gs35, Gs38Document110 pagesPanasonic NV Gs6, Gs17, Gs18, Gs21, Gs25, Gs28, Gs35, Gs38drunk65100% (1)

- Si 1185Document6 pagesSi 1185user10002No ratings yet

- MC 10147003 9999Document3 pagesMC 10147003 9999Juliaman NapituNo ratings yet

- Canon Mv790 Mv800 Mv830 Mv850 Mechanism PartsDocument39 pagesCanon Mv790 Mv800 Mv830 Mv850 Mechanism PartsLiviu StancuNo ratings yet

- Tfu 28.46.00.009Document4 pagesTfu 28.46.00.009Reksa Karisma YogasmaraNo ratings yet

- DAC1 27 02 Rev 1Document3 pagesDAC1 27 02 Rev 1vanNo ratings yet

- SB As 350800007 enDocument11 pagesSB As 350800007 enDouglas de OliveiraNo ratings yet

- SB 74-0002Document10 pagesSB 74-0002Santiago QuinapantaNo ratings yet

- MT4400 AcDocument11 pagesMT4400 Acuuganaa ugiNo ratings yet

- B747-8 Fuel ManifoldDocument31 pagesB747-8 Fuel ManifoldDagmawiNo ratings yet

- 3029 IO Controls Electric Horn HarnessDocument2 pages3029 IO Controls Electric Horn HarnessHamiltonNo ratings yet

- GE Aircraft Engines: Service BulletinDocument6 pagesGE Aircraft Engines: Service BulletinGustavo Silva AeEngNo ratings yet

- Task 804Document4 pagesTask 804Buncha MatNo ratings yet

- 01 - Camshaft - RemoveDocument8 pages01 - Camshaft - RemoveNimNo ratings yet

- Alert Service Bulletin: ASB EC135 67A 032Document21 pagesAlert Service Bulletin: ASB EC135 67A 032LI YONG GANGNo ratings yet

- SB C208 Stall WarningDocument14 pagesSB C208 Stall WarningrobertobrouNo ratings yet

- 10685192-PIB ACS800逆变模块问题Document3 pages10685192-PIB ACS800逆变模块问题xlzyydf2015No ratings yet

- FAA 2020 0578 0003 - Attachment - 1Document71 pagesFAA 2020 0578 0003 - Attachment - 1Ümit KazanNo ratings yet

- Compliance Report FormatDocument5 pagesCompliance Report FormatRajashri ChatterjeeNo ratings yet

- Installation of The Generator and Control Panel Components For Dynamic Gas BlendingDocument49 pagesInstallation of The Generator and Control Panel Components For Dynamic Gas Blendingالمهندسوليدالطويل100% (1)

- Operator E-Jets News Rel 019Document9 pagesOperator E-Jets News Rel 019jivomirNo ratings yet

- Ict 2Document91 pagesIct 2sherubdNo ratings yet

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document6 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNo ratings yet

- Arme Desarme Balancines C7Document3 pagesArme Desarme Balancines C7Alex Consuegra MedinaNo ratings yet

- 1.x-Ray Tube ReplacementDocument13 pages1.x-Ray Tube ReplacementLê Hồ Nguyên ĐăngNo ratings yet

- B737-200 Flight ControlDocument4 pagesB737-200 Flight ControlLa Team masqueNo ratings yet

- Power Unit Inst - Instructions EngDocument46 pagesPower Unit Inst - Instructions Engvaleriu.bosneaga6798100% (1)

- Service Bulletin: CaravanDocument8 pagesService Bulletin: CaravanEric HenriqueNo ratings yet

- Mandatory: Bollettino TecnicoDocument7 pagesMandatory: Bollettino TecnicomycopteraviationNo ratings yet

- Aw139 17 088Document9 pagesAw139 17 088ttppNo ratings yet

- RElay SSR Motores 2011Document3 pagesRElay SSR Motores 2011Marcelo OlivaresNo ratings yet

- On A/C All: Reference DesignationDocument10 pagesOn A/C All: Reference DesignationOsama MagedNo ratings yet

- TCBC Start Up RoutineDocument17 pagesTCBC Start Up RoutinemarkosasimNo ratings yet

- Service Bulletin: AB Volvo PentaDocument3 pagesService Bulletin: AB Volvo Pentaanees ahmedNo ratings yet

- Mercedes EGR ValvDocument6 pagesMercedes EGR ValvqasmaouiNo ratings yet

- SRS Light IlluminatedDocument6 pagesSRS Light IlluminatedWadu DetutsNo ratings yet

- AV28KT1Document48 pagesAV28KT1Luis MorenoNo ratings yet

- Easa Ad 2019-0060 1Document4 pagesEasa Ad 2019-0060 1Carolina RossNo ratings yet

- Cleaning of Contact Points and Wiring HarnessesDocument3 pagesCleaning of Contact Points and Wiring HarnessesRafa Montes MOralesNo ratings yet

- Nai FaultDocument3 pagesNai FaultAbdullah KhanNo ratings yet

- Easa TCDS A.364 - Grob - G - 115 02 20122011Document43 pagesEasa TCDS A.364 - Grob - G - 115 02 20122011Albaz DarwishNo ratings yet

- Grob Flight Manual ORDocument36 pagesGrob Flight Manual ORAlbaz DarwishNo ratings yet

- DFT Avsafety PDF 500972Document11 pagesDFT Avsafety PDF 500972Albaz DarwishNo ratings yet

- SL ListeDocument1 pageSL ListeAlbaz DarwishNo ratings yet

- List of SB 1121Document6 pagesList of SB 1121Albaz DarwishNo ratings yet

- Grob G 120TPDocument1 pageGrob G 120TPAlbaz DarwishNo ratings yet

- List of SB 565Document7 pagesList of SB 565Albaz DarwishNo ratings yet

- TCDS - EASA - A - 565 - Issue - 03 - G 120TP - Maximum Mass IncreaseDocument11 pagesTCDS - EASA - A - 565 - Issue - 03 - G 120TP - Maximum Mass IncreaseAlbaz DarwishNo ratings yet

- List of SL 565Document1 pageList of SL 565Albaz DarwishNo ratings yet

- Training Manual EVODocument184 pagesTraining Manual EVOAlbaz Darwish100% (1)

- Maintenance Manual: Ul-Aircraft Ltf-Ul 2003 Manufacturer No.: FRXXX Registration No: D-MXXXDocument27 pagesMaintenance Manual: Ul-Aircraft Ltf-Ul 2003 Manufacturer No.: FRXXX Registration No: D-MXXXAlbaz DarwishNo ratings yet

- Pilatus SB 2 Pelikan 1 HB Aep CR Pilatus P 4 CompressDocument48 pagesPilatus SB 2 Pelikan 1 HB Aep CR Pilatus P 4 CompressAlbaz DarwishNo ratings yet

- NL Feb2012r3Document6 pagesNL Feb2012r3Albaz DarwishNo ratings yet

- Analysis of The Cricri MC 15Document6 pagesAnalysis of The Cricri MC 15Albaz Darwish100% (1)

- Engine Power Loss - Bankstown Airport - 5 April 2006: VH-ZNZDocument34 pagesEngine Power Loss - Bankstown Airport - 5 April 2006: VH-ZNZAlbaz DarwishNo ratings yet

- Tech Sheet: Lancair EvolutionDocument9 pagesTech Sheet: Lancair EvolutionAlbaz DarwishNo ratings yet

- Fig.3: Pin Diagram of Raspberry PiDocument5 pagesFig.3: Pin Diagram of Raspberry PikmNo ratings yet

- Archiving IDocsDocument10 pagesArchiving IDocsGKREDDYNo ratings yet

- Cmotion LCS ManualDocument25 pagesCmotion LCS ManualElectra/Off TraxNo ratings yet

- Stepping Motor Control AmplifierDocument21 pagesStepping Motor Control AmplifiersmallbarshalomNo ratings yet

- Instruction Manual of Recloser Controller - R-200Document111 pagesInstruction Manual of Recloser Controller - R-200Rafael David Rincon Villamizar75% (4)

- Dell Precision M4800 ParametryDocument2 pagesDell Precision M4800 ParametryWilsonLópezNo ratings yet

- RH30 Spec Sep2007Document7 pagesRH30 Spec Sep2007gheoda8926No ratings yet

- Insulated-Gate Bipolar TransistorDocument5 pagesInsulated-Gate Bipolar Transistortapas naoNo ratings yet

- DIY Servo With Arduino, DC Motor, and Potentiometer Drone ColonyDocument9 pagesDIY Servo With Arduino, DC Motor, and Potentiometer Drone ColonyTounsi TwensaNo ratings yet

- Brother DH4-B981 PDFDocument100 pagesBrother DH4-B981 PDFCesar0% (1)

- Scala TUN Tutorial CronoX VSTiDocument4 pagesScala TUN Tutorial CronoX VSTiMary GarciaNo ratings yet

- 12" Slip Roll Instruction Manual: MODEL G7148Document12 pages12" Slip Roll Instruction Manual: MODEL G7148Hitsugaya ToushiroNo ratings yet

- How To Measure FOV On Your CameraDocument15 pagesHow To Measure FOV On Your CameraVictor BitarNo ratings yet

- Bits and BytesDocument2 pagesBits and BytesLariemeevaNo ratings yet

- Is.1795.1982 Pillar TapDocument20 pagesIs.1795.1982 Pillar Tapkishor150688No ratings yet

- Mcx051 Home DintDocument3 pagesMcx051 Home DintJosephNo ratings yet

- A C# .NET Calculator - Design StageDocument4 pagesA C# .NET Calculator - Design StageshaikcivilNo ratings yet

- Exce RC IcesDocument13 pagesExce RC IcesJumaryse MarabutNo ratings yet

- OptiPlex 330 (Late 2007) DriversDocument2 pagesOptiPlex 330 (Late 2007) Driversdevpal78No ratings yet

- Error Codes (Aaaxxx) : Description Code Description CodeDocument2 pagesError Codes (Aaaxxx) : Description Code Description CodeBrice TOSSAVINo ratings yet

- Implementation of Digital Lock Using VHDLDocument13 pagesImplementation of Digital Lock Using VHDLVaibhav TripathiNo ratings yet

- Crowcon Detective Transportable Gas MonitorDocument5 pagesCrowcon Detective Transportable Gas MonitoreastNo ratings yet

- Acer Aspire 5810t 5810tz 5410t 5810tg SeriesDocument152 pagesAcer Aspire 5810t 5810tz 5410t 5810tg SeriesvideosonNo ratings yet

- Choosing Your Database Migration Path To AzureDocument61 pagesChoosing Your Database Migration Path To AzureLeopoldo Garcia GarciaNo ratings yet

- #GuptaEmails: Muthambi EmailDocument4 pages#GuptaEmails: Muthambi EmailSundayTimesZA86% (7)

- NRMS User Manual-StandardDocument24 pagesNRMS User Manual-StandardAey PalakornNo ratings yet

- HP8566 Spectrum AnalyzerDocument115 pagesHP8566 Spectrum AnalyzerConrad BuitendagNo ratings yet

- Net5501 ManualDocument14 pagesNet5501 Manualalex54180No ratings yet

- Introduction To: Lego MindstormsDocument15 pagesIntroduction To: Lego MindstormsAlexandra LovellNo ratings yet