Professional Documents

Culture Documents

Oil Drain Intervals

Oil Drain Intervals

Uploaded by

Bosznay ZoltánCopyright:

Available Formats

You might also like

- Def Stan 01-5 PDFDocument334 pagesDef Stan 01-5 PDFNadia SalemNo ratings yet

- 1000-0099B - en (5) Oil ParameterDocument12 pages1000-0099B - en (5) Oil Parameterumarsiddique309No ratings yet

- Iso1295 1Document23 pagesIso1295 1Corina Stanculescu100% (3)

- Engine - DB58, DB58T & Db58ti PDFDocument126 pagesEngine - DB58, DB58T & Db58ti PDFNil Mar83% (6)

- Operation & Maintenance Manual: De08TisDocument143 pagesOperation & Maintenance Manual: De08TisVu Dang100% (2)

- FS PLM 111 0008Document14 pagesFS PLM 111 0008Jako MishyNo ratings yet

- 1482 (SUPER 1800-3 (I) )Document2 pages1482 (SUPER 1800-3 (I) )adrianNo ratings yet

- GGDocument65 pagesGGFernando RomoNo ratings yet

- 08 Lubrication SystemDocument38 pages08 Lubrication Systemasilvasandoval18No ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- Lube Oil SpecificationDocument24 pagesLube Oil SpecificationOrwah malkawiNo ratings yet

- VOLVO Technical Journal MC-10146443-9999Document10 pagesVOLVO Technical Journal MC-10146443-9999slobodanNo ratings yet

- SINOPEC Spindle Oil 10Document2 pagesSINOPEC Spindle Oil 10DavidNo ratings yet

- 13-3. Principles of Selection: A. Manufacturer RecommendationsDocument24 pages13-3. Principles of Selection: A. Manufacturer RecommendationsAshkan AbbasiNo ratings yet

- Afa - Edc 0081 01 Sea - enDocument100 pagesAfa - Edc 0081 01 Sea - enPfunzo PharmelaNo ratings yet

- Ss-đã Chuyển ĐổiDocument10 pagesSs-đã Chuyển ĐổiTrần Hoài VinhNo ratings yet

- Lubricating Oils For WÄRTSILÄ® 34SG Engines: Data & SpecificationsDocument6 pagesLubricating Oils For WÄRTSILÄ® 34SG Engines: Data & SpecificationsHeryanto SyamNo ratings yet

- Operation & Maintenance Manual: De08TisDocument113 pagesOperation & Maintenance Manual: De08Tiscaca100% (1)

- Jembacher RecomendationDocument16 pagesJembacher RecomendationDejan DejanovicNo ratings yet

- Lubricant Specifications and Selection: 13-1. IntroductionDocument13 pagesLubricant Specifications and Selection: 13-1. IntroductionNajih AbbasNo ratings yet

- Maejo International Journal of Science and TechnologyDocument9 pagesMaejo International Journal of Science and TechnologyOcta RioNo ratings yet

- Noviembre 2018 TRANSMISIONES EATON FULLER PDFDocument28 pagesNoviembre 2018 TRANSMISIONES EATON FULLER PDFRicardo MontañezNo ratings yet

- Guide To Interchangeable LubricantsDocument12 pagesGuide To Interchangeable LubricantsJavier Jesus Gonzalez QuinaNo ratings yet

- Unit ID: Fu1 Ugb: Overall Condition RatingDocument6 pagesUnit ID: Fu1 Ugb: Overall Condition RatingmanavjhplNo ratings yet

- Klueber Lubricants For Film Stretching Lines Catalogue - by CBCDocument56 pagesKlueber Lubricants For Film Stretching Lines Catalogue - by CBCJuan Soto HernándezNo ratings yet

- # FF 2020 - 07 - Change in Scheduled Maintenance and Warranty Period - 6 BT - Sany Hyundai ApplicationsDocument1 page# FF 2020 - 07 - Change in Scheduled Maintenance and Warranty Period - 6 BT - Sany Hyundai ApplicationsGorav rajput393No ratings yet

- Manuale Specifiche MWMDocument66 pagesManuale Specifiche MWMLuca GianoliNo ratings yet

- Lubricants For Wingd Engines v6Document31 pagesLubricants For Wingd Engines v6nikospg9427No ratings yet

- BP Turbo Oil Doc - Technique - Bpto2380Document14 pagesBP Turbo Oil Doc - Technique - Bpto2380Marc TapsonNo ratings yet

- Robin HoodDocument36 pagesRobin HoodTaz UddinNo ratings yet

- Molykote L-3232 Synthetic Compressor OilDocument2 pagesMolykote L-3232 Synthetic Compressor OilFabio MonzónNo ratings yet

- 1000-0099B - en - Limit Levels For Used Oil - v8 2020-02-28Document12 pages1000-0099B - en - Limit Levels For Used Oil - v8 2020-02-28Dejan DejanovicNo ratings yet

- HSS Twist Drill Recommended Speeds and Point AnglesDocument7 pagesHSS Twist Drill Recommended Speeds and Point AnglesAsela BollegalaNo ratings yet

- Filtro Aceite SonicDocument3 pagesFiltro Aceite SonicMichelNo ratings yet

- Circular Tecnica Lub OilDocument24 pagesCircular Tecnica Lub OilMarioAndrésRamirezC.No ratings yet

- Lubricant Based On Used Motor Oil: Chemistry and Technology of Fuels and Oils, Vol. 42, No.4, 2006Document6 pagesLubricant Based On Used Motor Oil: Chemistry and Technology of Fuels and Oils, Vol. 42, No.4, 2006Tristan Tabago ConsolacionNo ratings yet

- MC 10120747 9999Document4 pagesMC 10120747 9999Sebastián Celaya GonzalezNo ratings yet

- Correct LubricantDocument69 pagesCorrect LubricantZeshan Haydar100% (1)

- Mobile Filler Pump GTP-C: Original Operating InstructionsDocument52 pagesMobile Filler Pump GTP-C: Original Operating InstructionsВиталий КозловскийNo ratings yet

- Petrobras Marine Aprov Sulzer Z and ZaDocument12 pagesPetrobras Marine Aprov Sulzer Z and ZaozakyusNo ratings yet

- SL - HHI-TEC-0395-R3 - 2021 - WinGD Lubricants Update - All XDFDocument48 pagesSL - HHI-TEC-0395-R3 - 2021 - WinGD Lubricants Update - All XDFVlad FreelancerNo ratings yet

- Lubricant 034405Document10 pagesLubricant 034405enkelectricalttNo ratings yet

- Lubrication Schedule of Man Turbo Disel CompressorDocument9 pagesLubrication Schedule of Man Turbo Disel CompressorMohammed Mohiuddin100% (1)

- Dewangan 2019 IOP Conf. Ser. Mater. Sci. Eng. 624 012011Document7 pagesDewangan 2019 IOP Conf. Ser. Mater. Sci. Eng. 624 012011Nagesh DewanganNo ratings yet

- Mount Meru Product Catalogue First VersionDocument20 pagesMount Meru Product Catalogue First Versionilovem2foodNo ratings yet

- Understanding Vacuum Pump LubricantsDocument21 pagesUnderstanding Vacuum Pump LubricantsengrsurifNo ratings yet

- SB 10093294 0699Document3 pagesSB 10093294 0699Bảo CarNo ratings yet

- Sentron Approvals JenbacherDocument20 pagesSentron Approvals Jenbacherحسین اسکندریNo ratings yet

- AXSM0040-Single Axle - 2 Speed&Double ReductionDocument34 pagesAXSM0040-Single Axle - 2 Speed&Double Reductionwadalla100No ratings yet

- GL-5-Gear OilDocument2 pagesGL-5-Gear OilDavidNo ratings yet

- Customer Information: Consolidated ReportDocument12 pagesCustomer Information: Consolidated Reportst.fernandez.ana78No ratings yet

- CMD Gear Lubricant RecommendationsDocument7 pagesCMD Gear Lubricant RecommendationscotteNo ratings yet

- Molykote G4500Document2 pagesMolykote G4500Luis Jara TolentinoNo ratings yet

- Influence of Lubricant Type in Gear ScuffingDocument10 pagesInfluence of Lubricant Type in Gear ScuffingAnibal RiosNo ratings yet

- ENCL03 Lubricating and Control Oils For TurbinesDocument18 pagesENCL03 Lubricating and Control Oils For TurbinesnuesteNo ratings yet

- 4 Sinopec TULUX T600F 5W-40 Diesel Engine Oil Full SynDocument3 pages4 Sinopec TULUX T600F 5W-40 Diesel Engine Oil Full SynDavidNo ratings yet

- Draft OGN-OPS-CHEM-021 Rev. 0 On Examination and Maintenance of Lub Oils of Turbine and Boiler Feed PumpDocument17 pagesDraft OGN-OPS-CHEM-021 Rev. 0 On Examination and Maintenance of Lub Oils of Turbine and Boiler Feed Pumppraveen singhNo ratings yet

- As 3568-2020Document14 pagesAs 3568-2020Alexandru LetNo ratings yet

- Lubrication Tactics for Industries Made Simple, 8th Discipline of World Class Maintenance Management: 1, #6From EverandLubrication Tactics for Industries Made Simple, 8th Discipline of World Class Maintenance Management: 1, #6Rating: 5 out of 5 stars5/5 (1)

- Oil Well, Refinery Machinery & Equipment Wholesale Revenues World Summary: Market Values & Financials by CountryFrom EverandOil Well, Refinery Machinery & Equipment Wholesale Revenues World Summary: Market Values & Financials by CountryNo ratings yet

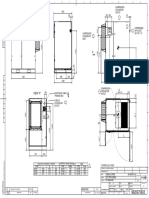

- ECOntrol6 Touch Wiring Diagram 1830014288-01Document11 pagesECOntrol6 Touch Wiring Diagram 1830014288-01Bosznay ZoltánNo ratings yet

- SDS Rotair ENDocument10 pagesSDS Rotair ENBosznay ZoltánNo ratings yet

- Parts List: Oil-Injected CompressorsDocument366 pagesParts List: Oil-Injected CompressorsBosznay ZoltánNo ratings yet

- Alup Allegro 37 AC IE3 400V 4-13bar 50Hz Metric Technical Data ENDocument2 pagesAlup Allegro 37 AC IE3 400V 4-13bar 50Hz Metric Technical Data ENBosznay ZoltánNo ratings yet

- ALUP E-Dryer ADQ216-462Document2 pagesALUP E-Dryer ADQ216-462Bosznay ZoltánNo ratings yet

- ALUP Largo Allegro 31-110 Sales Leaflet EN 6999640304Document12 pagesALUP Largo Allegro 31-110 Sales Leaflet EN 6999640304Bosznay ZoltánNo ratings yet

- Alup ADQ 21-5040 Leaflet EN 6999640034Document8 pagesAlup ADQ 21-5040 Leaflet EN 6999640034Bosznay ZoltánNo ratings yet

- Alup Allegro 31-45 Largo 31-45 AC 30-45Kw Metric Dimension Drawing EN 9820670603Document1 pageAlup Allegro 31-45 Largo 31-45 AC 30-45Kw Metric Dimension Drawing EN 9820670603Bosznay ZoltánNo ratings yet

- Graderroadmotori 019931 MBPDocument97 pagesGraderroadmotori 019931 MBPblarkins1No ratings yet

- Product Information Navisyn De: DescriptionDocument2 pagesProduct Information Navisyn De: DescriptionGabriel NogueiraNo ratings yet

- Service Manual TWS 600S PDFDocument96 pagesService Manual TWS 600S PDFMuhammad Fadhli100% (3)

- AUTOMATIC TRANSMISSION 6T70 (M7W) - REPAIR INSTRUCTION - OFF VEHICLE-unlockedDocument109 pagesAUTOMATIC TRANSMISSION 6T70 (M7W) - REPAIR INSTRUCTION - OFF VEHICLE-unlockedMarco MeloncelliNo ratings yet

- 01 RR Griswold 811 General BrochureDocument20 pages01 RR Griswold 811 General BrochureGiftObionochieNo ratings yet

- Automatic Filter Type 6.72 en BOLLFILTERDocument7 pagesAutomatic Filter Type 6.72 en BOLLFILTERRahmat AnpsNo ratings yet

- Exp MN Sm090 en r0 SealsDocument60 pagesExp MN Sm090 en r0 SealsbaliNo ratings yet

- OS 02 KA Lube BrochuresDocument28 pagesOS 02 KA Lube BrochuresSarno MukriNo ratings yet

- SLG PG 22 23 0450R1Document20 pagesSLG PG 22 23 0450R1BIMAL SHARMANo ratings yet

- Engine Lubrication SystemDocument8 pagesEngine Lubrication SystemSunilNo ratings yet

- Alphasyn GSDocument2 pagesAlphasyn GScool_ddNo ratings yet

- Bpu 5545Document40 pagesBpu 5545manuel barberoNo ratings yet

- ASSOCIATIVE INTERACTIONS SASTRA University First YearDocument28 pagesASSOCIATIVE INTERACTIONS SASTRA University First Yearstar100% (1)

- Maintenance Kit Guide GMK 5180 1, 5200 1, 5250L, 5 - 240319 - 183717Document3 pagesMaintenance Kit Guide GMK 5180 1, 5200 1, 5250L, 5 - 240319 - 183717bjrock123No ratings yet

- Bearings-An Introduction-NPTIDocument59 pagesBearings-An Introduction-NPTISakthi MuruganNo ratings yet

- EG Tribology Course PDH File5681Document60 pagesEG Tribology Course PDH File5681operationmanagerNo ratings yet

- Lubricating Oil Pressure Low: Cause CorrectionDocument3 pagesLubricating Oil Pressure Low: Cause CorrectionYasser JaviNo ratings yet

- January 2017 AMSOIL Dealer EditionDocument24 pagesJanuary 2017 AMSOIL Dealer EditionamsoildealerNo ratings yet

- Uebm001801 PC750-6KDocument696 pagesUebm001801 PC750-6KjAVIER GARCIA MORIANANo ratings yet

- PlintTE 77Document2 pagesPlintTE 77janvrut91No ratings yet

- Model Answer Winter 2017Document22 pagesModel Answer Winter 2017jitesh mahadik100% (1)

- SKF Cage MaterialsDocument2 pagesSKF Cage MaterialsKamolwan WeerachatsakulNo ratings yet

- Shell Morlina S2 B 150 - TDSDocument4 pagesShell Morlina S2 B 150 - TDSFandemen AdintaNo ratings yet

- Fire Pump Drive Engine Cfp15e-F10 Cfp15evs-F10Document7 pagesFire Pump Drive Engine Cfp15e-F10 Cfp15evs-F10Compras SSDCNo ratings yet

- Technical Documentation 19.8895Document142 pagesTechnical Documentation 19.8895YIOUGO WNo ratings yet

- Lubrication Storage & Handling-ReliabilityDocument21 pagesLubrication Storage & Handling-ReliabilityRizka YulianaNo ratings yet

- Stern TubesDocument9 pagesStern TubesArunNo ratings yet

Oil Drain Intervals

Oil Drain Intervals

Uploaded by

Bosznay ZoltánOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil Drain Intervals

Oil Drain Intervals

Uploaded by

Bosznay ZoltánCopyright:

Available Formats

OPI Lubricants – Oil drain Intervals, selection criteria & guidelines

Document title

Oil Drain Intervals OPI Lubricants

Description:

Selection criteria & guidelines OPI Lubricants

Revision: Reason for Revision: Product Company:

3 Instruction Update APC

Created by: Approved By: Issue date: Page:

AIR20279 AIR20279 2020/03/02 1 of 7

Document No. Secrecy (acc.1102

K):

9845014108-01 Public

State:

FROZEN

Document no.: 9845014108-01 Issue date: March 3, 2020

Page 1 of 7

OPI Lubricants – Oil drain Intervals, selection criteria & guidelines

Instruction

1. General information

Oil Drain Intervals OPI Lubricants

Selection criteria & guidelines OPI lubricants

Printed Matter Number : 9845 0141 08 ed 03

Applicable to : Compressor Brand Portfolio

Preliminary Operations : -

Safety Instructions : Standard

Persons Required : -

Special Tools : -

Consumables : -

2. Document overview

Contents

1. General information ........................................................................................................... 2

2. Document overview ........................................................................................................... 2

3. Document Information and History .................................................................................... 2

4. Reference documents ....................................................................................................... 3

5. Executive summary ........................................................................................................... 3

6. Importance of using OPI approved oils .............................................................................. 3

7. Goal of defining oil drain intervals (ODI) ............................................................................ 3

8. The general OPI lubricant portfolio (*) ............................................................................... 4

9. Selection Parameters & Oil Drain Intervals for OIS (Oil Injected Screw) ............................ 5

10. Oil Drain Intervals for NON-OIS ..................................................................................... 7

11. Change over procedure between OPI oils (Oil Injected Screw) ...................................... 7

12. Disclaimer ...................................................................................................................... 7

3. Document Information and History

Edition Date Description Author

Document no.: 9845014108-01 Issue date: March 3, 2020

Page 2 of 7

OPI Lubricants – Oil drain Intervals, selection criteria & guidelines

4. Reference documents

Document Number Document Description

9845 0012 00 OPI Draining & Flushing procedure

5. Executive summary

This document describes the recommended service intervals of OPI Portfolio lubricants, based

on aftermarket surveys, field experience and laboratory tests. The document will be adapted

each time the lubricant portfolio will change or some modifications to existing lubricants are

implemented.

6. Importance of using OPI approved oils

Lubricants have a vital influence on compressor performance in terms of efficiency and

reliability. Therefore, the OPI Portfolio have been putting a lot of engineering efforts in the area

of lubricant development, which is an integral part of the compressor design process.

Comprehensive tests have been done in order to determine if the lubricant is in line with the

most severe requirements. The following are the most important properties that are verified

before a new OPI lubricant is being released for the use in our compressors:

Oxidation resistance determining the expected oil lifetime in our compressors

Oil/water separation properties to keep condensate out of your oil circuit

Dedicated test to verify the anti-corrosion properties of the lubricant to ensure the proper

protection of metal surfaces for long periods of standstill (transportation, storage, etc…)

Material compatibility with all compressor components, ancillaries and line accessories that

are in contact with oil directly or oil residues in compressed air or condensate

Sludge formation tendency to eliminate the risk of deposits in internal compressor

components that may lead to malfunction (e.g. clogged coolers, water separators, etc…)

Lubricating properties to ensure proper lubrication of metal surfaces in air ends (e.g. rotors,

bearings, etc ..) and gearboxes.

7. Goal of defining oil drain intervals (ODI)

The goal of defining Oil Drain Intervals [ODI] is to replace oil in a compressor before it reaches

its level of condemnation (end of useful life).

The useful life of a lubricant is depending on a lot of conditions: type of lubricant, temperature,

humidity, contamination, environment, …most of them are not quantified.

Based on experiences and endurance tests, ODI’s are defined for our OPI Portfolio lubricants

under given working condition ranges (temperature, pressure).

The given ODI in section 9 are only valid for indicated applications and starting with a

compressor filled with fresh oil according to the correct oil drain/oil fill procedure 9845 0012 00.

Document no.: 9845014108-01 Issue date: March 3, 2020

Page 3 of 7

OPI Lubricants – Oil drain Intervals, selection criteria & guidelines

8. The general OPI lubricant portfolio (*)

Rotair (Mineral Oil Injected Screw Lubricant)

Package size Part-number Package size Part-number

5L 6215714000 209 L 6215714200

20 L 6215714100 1000 L 6215714300

Rotair Plus (Premium Mineral Oil Injected Screw Lubricant)

Package size Part-number Package size Part-number

5L 1630144405 209 L 1630144429

20 L 1630144420 1000 L 1630144410

Rotair Xtra (Synthetic Oil Injected Screw Lubricant)

Package size Part-number Package size Part-number

5L 6215714800 209 L 6215715000

20 L 6215714900 1000 L 6215715100

Rotair Food Grade (Synthetic Oil Injected Screw FoodGrade Lubricant)

Package size Part-number Package size Part-number

5L 1630082100 209 L 1630082101

20 L 1630060500

Fluidtech (Mineral Oil Injected Screw Lubricant)

Package size Part-number Package size Part-number

5L 6215715900 209 L 6215716100

20 L 6215716000

Fluidtech Advanced (Premium Mineral Oil Injected Screw Lubricant)

Package size Part-number Package size Part-number

20 L 1630021085 209 L 1630021088

Rotair Gear (Lubricant for oil free screw and tooth compressors)

Package size Part-number

5L 6215716900

20 L 6215717000

(*) Due to regional needs, the local OPI lubricant portfolio can slightly differ from the general

portfolio. Please contact your customer support team for more information.

Document no.: 9845014108-01 Issue date: March 3, 2020

Page 4 of 7

OPI Lubricants – Oil drain Intervals, selection criteria & guidelines

9. Selection Parameters & Oil Drain Intervals for OIS (Oil Injected Screw)

For OIS oils, there are 3 ambient parameters influencing the oil life:

Temperature has a huge and direct impact at the oxidation process of the oil.

Therefore, temperature is the main selection parameter to select the appropriate oil

in the OPI portfolio.

Where can I find the oil Read the display of your compressor:

temperature? ELEMENT OUTLET TEMPERATURE

Temperature

No temperature element Please use a contact thermometer to determine the

outlet available? element outlet temperature.

New compressor? Maximum Element Outlet Temperature (*) =

Oil

Unknown conditions? Ambient Temperature + 65°C

(*) The maximum oil temperature is guaranteed by design of the unit and defines the “shutdown” temperature

Humidity has a big impact at the choice of your lubricant as;

the rate of oxidation is accelerated by water. Water will act as a catalyst.

the presence of water is weakening the strength of the oil layer in the bearings

of your compressor element.

Ingression of water

the presence of water results into increased risk for corrosion

Not Humid: for most part of the year

Humid: for most part of the year (Tropical / Megathermal climates):

Tropical rainforest climate (Northwest Pacific, Central America, Malaysia)

Remark:

Ideally, the compressor is operating above the condensation curve to avoid water

accumulation in the oil. In operating conditions resulting in condense formation, a

higher oil grade needs to be used to fulfil specified service life.

Dust can have a big impact at your compressor- and oil life;

Particles will contaminate the oil circuit and create deposits

The rate of oxidation is accelerated by dust particles in your oil

Ingression

Some particles will react with the base oil and accelerate oxidation process

of dust

Dusty: Mining & Cement, Metal, Steel, Manufacturing & Foundries

Normal: Everyhting else: Automotive, Electronics, Petrochemical, Gas Purification, etc…

Document no.: 9845014108-01 Issue date: March 3, 2020

Page 5 of 7

OPI Lubricants – Oil drain Intervals, selection criteria & guidelines

Use this table to guide you in selecting the right lubricant:

Environment type Element Outlet

2000 Hours 4000 Hours 8000 Hours

of operation Temperature

Mild <90°C Rotair Rotair Plus Rotair Xtra

Moderate demand 90-95°C Rotair Plus Rotair Plus Rotair Xtra

High demand 95-100°C Rotair Plus Rotair Xtra Rotair Xtra

Very high demand 100-105°C Rotair Xtra Rotair Xtra

Rotair Xtra

Extreme >105°C Rotair Xtra Rotair Xtra (Follow up required)

Humid and/or dusty?

Select a higher oil grade: Rotair Rotair

Rotair

Plus Xtra

The intervals as presented in the selection table above are valid:

o when the compressor is running always within the specified service intervals.

o when the oil draining and flushing procedure (9845 0012 00) is always respected

(remaining oil of previous service intervals will decrease the current lifetime of the oil

radical and will increase the risk of deposit formation in the oil circuit)

Maximum time interval:

o Rotair: 2000H or 1 year whichever comes first

o Rotair Plus: 4000H or 1 year whichever comes first

o Rotair Xtra: 8000H or 2 years whichever comes first

You customer is in Food and Beverage industry? Use Rotair Food Grade

Rotair Food Grade is a NSF H1 certified lubricant and can be used in food-processing

environments where there is the possibility of incidental food contact.

The NSF H1 certificate can be found on the NSF listing website

(http://info.nsf.org/USDA/psnclistings.asp) when looking on product name and/or C.

ARIA C. Rotair Food Grade is also Halal and Kosher approved, these certificates can be

found on business portal.

Document no.: 9845014108-01 Issue date: March 3, 2020

Page 6 of 7

OPI Lubricants – Oil drain Intervals, selection criteria & guidelines

10. Oil Drain Intervals for NON-OIS

Recommended oil service interval Maximum time interval

Unit Type

(running hours) (years)*

< 55 kW 8.000 2

> 55 kW 16.000 2

*Whichever comes first

11. Change over procedure between OPI oils (Oil Injected Screw)

When the previous oil service interval has been exceeded, extra flushing or cleaning of the oil

circuit might/will be required.

Please read document:

9845 0012 00 - Oil draining and flushing procedure for Brand Portfolio oil injected screw air

compressors using Rotair/FluidTech lubes.

12. Disclaimer

The data presented in this Report are provided under the General Terms and

Conditions for the provision of Research and Technical Services by C. ARIA C. S.R.L.

No general recommendation can encompass the effects of all combinations of the

various compressor parts, their composition and use in all situations. Therefore, the

recommendations formulated in this document are a guideline for proper function of

the compressor based on current knowledge of our engineers and customer feedback.

This report does not attempt to address all the health and safety concerns, if any,

associated with its use. It is the responsibility of the user of this report to establish

appropriate health and safety practices and determine the applicability of regulatory

limitations prior to use.

Document no.: 9845014108-01 Issue date: March 3, 2020

Page 7 of 7

You might also like

- Def Stan 01-5 PDFDocument334 pagesDef Stan 01-5 PDFNadia SalemNo ratings yet

- 1000-0099B - en (5) Oil ParameterDocument12 pages1000-0099B - en (5) Oil Parameterumarsiddique309No ratings yet

- Iso1295 1Document23 pagesIso1295 1Corina Stanculescu100% (3)

- Engine - DB58, DB58T & Db58ti PDFDocument126 pagesEngine - DB58, DB58T & Db58ti PDFNil Mar83% (6)

- Operation & Maintenance Manual: De08TisDocument143 pagesOperation & Maintenance Manual: De08TisVu Dang100% (2)

- FS PLM 111 0008Document14 pagesFS PLM 111 0008Jako MishyNo ratings yet

- 1482 (SUPER 1800-3 (I) )Document2 pages1482 (SUPER 1800-3 (I) )adrianNo ratings yet

- GGDocument65 pagesGGFernando RomoNo ratings yet

- 08 Lubrication SystemDocument38 pages08 Lubrication Systemasilvasandoval18No ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- Lube Oil SpecificationDocument24 pagesLube Oil SpecificationOrwah malkawiNo ratings yet

- VOLVO Technical Journal MC-10146443-9999Document10 pagesVOLVO Technical Journal MC-10146443-9999slobodanNo ratings yet

- SINOPEC Spindle Oil 10Document2 pagesSINOPEC Spindle Oil 10DavidNo ratings yet

- 13-3. Principles of Selection: A. Manufacturer RecommendationsDocument24 pages13-3. Principles of Selection: A. Manufacturer RecommendationsAshkan AbbasiNo ratings yet

- Afa - Edc 0081 01 Sea - enDocument100 pagesAfa - Edc 0081 01 Sea - enPfunzo PharmelaNo ratings yet

- Ss-đã Chuyển ĐổiDocument10 pagesSs-đã Chuyển ĐổiTrần Hoài VinhNo ratings yet

- Lubricating Oils For WÄRTSILÄ® 34SG Engines: Data & SpecificationsDocument6 pagesLubricating Oils For WÄRTSILÄ® 34SG Engines: Data & SpecificationsHeryanto SyamNo ratings yet

- Operation & Maintenance Manual: De08TisDocument113 pagesOperation & Maintenance Manual: De08Tiscaca100% (1)

- Jembacher RecomendationDocument16 pagesJembacher RecomendationDejan DejanovicNo ratings yet

- Lubricant Specifications and Selection: 13-1. IntroductionDocument13 pagesLubricant Specifications and Selection: 13-1. IntroductionNajih AbbasNo ratings yet

- Maejo International Journal of Science and TechnologyDocument9 pagesMaejo International Journal of Science and TechnologyOcta RioNo ratings yet

- Noviembre 2018 TRANSMISIONES EATON FULLER PDFDocument28 pagesNoviembre 2018 TRANSMISIONES EATON FULLER PDFRicardo MontañezNo ratings yet

- Guide To Interchangeable LubricantsDocument12 pagesGuide To Interchangeable LubricantsJavier Jesus Gonzalez QuinaNo ratings yet

- Unit ID: Fu1 Ugb: Overall Condition RatingDocument6 pagesUnit ID: Fu1 Ugb: Overall Condition RatingmanavjhplNo ratings yet

- Klueber Lubricants For Film Stretching Lines Catalogue - by CBCDocument56 pagesKlueber Lubricants For Film Stretching Lines Catalogue - by CBCJuan Soto HernándezNo ratings yet

- # FF 2020 - 07 - Change in Scheduled Maintenance and Warranty Period - 6 BT - Sany Hyundai ApplicationsDocument1 page# FF 2020 - 07 - Change in Scheduled Maintenance and Warranty Period - 6 BT - Sany Hyundai ApplicationsGorav rajput393No ratings yet

- Manuale Specifiche MWMDocument66 pagesManuale Specifiche MWMLuca GianoliNo ratings yet

- Lubricants For Wingd Engines v6Document31 pagesLubricants For Wingd Engines v6nikospg9427No ratings yet

- BP Turbo Oil Doc - Technique - Bpto2380Document14 pagesBP Turbo Oil Doc - Technique - Bpto2380Marc TapsonNo ratings yet

- Robin HoodDocument36 pagesRobin HoodTaz UddinNo ratings yet

- Molykote L-3232 Synthetic Compressor OilDocument2 pagesMolykote L-3232 Synthetic Compressor OilFabio MonzónNo ratings yet

- 1000-0099B - en - Limit Levels For Used Oil - v8 2020-02-28Document12 pages1000-0099B - en - Limit Levels For Used Oil - v8 2020-02-28Dejan DejanovicNo ratings yet

- HSS Twist Drill Recommended Speeds and Point AnglesDocument7 pagesHSS Twist Drill Recommended Speeds and Point AnglesAsela BollegalaNo ratings yet

- Filtro Aceite SonicDocument3 pagesFiltro Aceite SonicMichelNo ratings yet

- Circular Tecnica Lub OilDocument24 pagesCircular Tecnica Lub OilMarioAndrésRamirezC.No ratings yet

- Lubricant Based On Used Motor Oil: Chemistry and Technology of Fuels and Oils, Vol. 42, No.4, 2006Document6 pagesLubricant Based On Used Motor Oil: Chemistry and Technology of Fuels and Oils, Vol. 42, No.4, 2006Tristan Tabago ConsolacionNo ratings yet

- MC 10120747 9999Document4 pagesMC 10120747 9999Sebastián Celaya GonzalezNo ratings yet

- Correct LubricantDocument69 pagesCorrect LubricantZeshan Haydar100% (1)

- Mobile Filler Pump GTP-C: Original Operating InstructionsDocument52 pagesMobile Filler Pump GTP-C: Original Operating InstructionsВиталий КозловскийNo ratings yet

- Petrobras Marine Aprov Sulzer Z and ZaDocument12 pagesPetrobras Marine Aprov Sulzer Z and ZaozakyusNo ratings yet

- SL - HHI-TEC-0395-R3 - 2021 - WinGD Lubricants Update - All XDFDocument48 pagesSL - HHI-TEC-0395-R3 - 2021 - WinGD Lubricants Update - All XDFVlad FreelancerNo ratings yet

- Lubricant 034405Document10 pagesLubricant 034405enkelectricalttNo ratings yet

- Lubrication Schedule of Man Turbo Disel CompressorDocument9 pagesLubrication Schedule of Man Turbo Disel CompressorMohammed Mohiuddin100% (1)

- Dewangan 2019 IOP Conf. Ser. Mater. Sci. Eng. 624 012011Document7 pagesDewangan 2019 IOP Conf. Ser. Mater. Sci. Eng. 624 012011Nagesh DewanganNo ratings yet

- Mount Meru Product Catalogue First VersionDocument20 pagesMount Meru Product Catalogue First Versionilovem2foodNo ratings yet

- Understanding Vacuum Pump LubricantsDocument21 pagesUnderstanding Vacuum Pump LubricantsengrsurifNo ratings yet

- SB 10093294 0699Document3 pagesSB 10093294 0699Bảo CarNo ratings yet

- Sentron Approvals JenbacherDocument20 pagesSentron Approvals Jenbacherحسین اسکندریNo ratings yet

- AXSM0040-Single Axle - 2 Speed&Double ReductionDocument34 pagesAXSM0040-Single Axle - 2 Speed&Double Reductionwadalla100No ratings yet

- GL-5-Gear OilDocument2 pagesGL-5-Gear OilDavidNo ratings yet

- Customer Information: Consolidated ReportDocument12 pagesCustomer Information: Consolidated Reportst.fernandez.ana78No ratings yet

- CMD Gear Lubricant RecommendationsDocument7 pagesCMD Gear Lubricant RecommendationscotteNo ratings yet

- Molykote G4500Document2 pagesMolykote G4500Luis Jara TolentinoNo ratings yet

- Influence of Lubricant Type in Gear ScuffingDocument10 pagesInfluence of Lubricant Type in Gear ScuffingAnibal RiosNo ratings yet

- ENCL03 Lubricating and Control Oils For TurbinesDocument18 pagesENCL03 Lubricating and Control Oils For TurbinesnuesteNo ratings yet

- 4 Sinopec TULUX T600F 5W-40 Diesel Engine Oil Full SynDocument3 pages4 Sinopec TULUX T600F 5W-40 Diesel Engine Oil Full SynDavidNo ratings yet

- Draft OGN-OPS-CHEM-021 Rev. 0 On Examination and Maintenance of Lub Oils of Turbine and Boiler Feed PumpDocument17 pagesDraft OGN-OPS-CHEM-021 Rev. 0 On Examination and Maintenance of Lub Oils of Turbine and Boiler Feed Pumppraveen singhNo ratings yet

- As 3568-2020Document14 pagesAs 3568-2020Alexandru LetNo ratings yet

- Lubrication Tactics for Industries Made Simple, 8th Discipline of World Class Maintenance Management: 1, #6From EverandLubrication Tactics for Industries Made Simple, 8th Discipline of World Class Maintenance Management: 1, #6Rating: 5 out of 5 stars5/5 (1)

- Oil Well, Refinery Machinery & Equipment Wholesale Revenues World Summary: Market Values & Financials by CountryFrom EverandOil Well, Refinery Machinery & Equipment Wholesale Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- ECOntrol6 Touch Wiring Diagram 1830014288-01Document11 pagesECOntrol6 Touch Wiring Diagram 1830014288-01Bosznay ZoltánNo ratings yet

- SDS Rotair ENDocument10 pagesSDS Rotair ENBosznay ZoltánNo ratings yet

- Parts List: Oil-Injected CompressorsDocument366 pagesParts List: Oil-Injected CompressorsBosznay ZoltánNo ratings yet

- Alup Allegro 37 AC IE3 400V 4-13bar 50Hz Metric Technical Data ENDocument2 pagesAlup Allegro 37 AC IE3 400V 4-13bar 50Hz Metric Technical Data ENBosznay ZoltánNo ratings yet

- ALUP E-Dryer ADQ216-462Document2 pagesALUP E-Dryer ADQ216-462Bosznay ZoltánNo ratings yet

- ALUP Largo Allegro 31-110 Sales Leaflet EN 6999640304Document12 pagesALUP Largo Allegro 31-110 Sales Leaflet EN 6999640304Bosznay ZoltánNo ratings yet

- Alup ADQ 21-5040 Leaflet EN 6999640034Document8 pagesAlup ADQ 21-5040 Leaflet EN 6999640034Bosznay ZoltánNo ratings yet

- Alup Allegro 31-45 Largo 31-45 AC 30-45Kw Metric Dimension Drawing EN 9820670603Document1 pageAlup Allegro 31-45 Largo 31-45 AC 30-45Kw Metric Dimension Drawing EN 9820670603Bosznay ZoltánNo ratings yet

- Graderroadmotori 019931 MBPDocument97 pagesGraderroadmotori 019931 MBPblarkins1No ratings yet

- Product Information Navisyn De: DescriptionDocument2 pagesProduct Information Navisyn De: DescriptionGabriel NogueiraNo ratings yet

- Service Manual TWS 600S PDFDocument96 pagesService Manual TWS 600S PDFMuhammad Fadhli100% (3)

- AUTOMATIC TRANSMISSION 6T70 (M7W) - REPAIR INSTRUCTION - OFF VEHICLE-unlockedDocument109 pagesAUTOMATIC TRANSMISSION 6T70 (M7W) - REPAIR INSTRUCTION - OFF VEHICLE-unlockedMarco MeloncelliNo ratings yet

- 01 RR Griswold 811 General BrochureDocument20 pages01 RR Griswold 811 General BrochureGiftObionochieNo ratings yet

- Automatic Filter Type 6.72 en BOLLFILTERDocument7 pagesAutomatic Filter Type 6.72 en BOLLFILTERRahmat AnpsNo ratings yet

- Exp MN Sm090 en r0 SealsDocument60 pagesExp MN Sm090 en r0 SealsbaliNo ratings yet

- OS 02 KA Lube BrochuresDocument28 pagesOS 02 KA Lube BrochuresSarno MukriNo ratings yet

- SLG PG 22 23 0450R1Document20 pagesSLG PG 22 23 0450R1BIMAL SHARMANo ratings yet

- Engine Lubrication SystemDocument8 pagesEngine Lubrication SystemSunilNo ratings yet

- Alphasyn GSDocument2 pagesAlphasyn GScool_ddNo ratings yet

- Bpu 5545Document40 pagesBpu 5545manuel barberoNo ratings yet

- ASSOCIATIVE INTERACTIONS SASTRA University First YearDocument28 pagesASSOCIATIVE INTERACTIONS SASTRA University First Yearstar100% (1)

- Maintenance Kit Guide GMK 5180 1, 5200 1, 5250L, 5 - 240319 - 183717Document3 pagesMaintenance Kit Guide GMK 5180 1, 5200 1, 5250L, 5 - 240319 - 183717bjrock123No ratings yet

- Bearings-An Introduction-NPTIDocument59 pagesBearings-An Introduction-NPTISakthi MuruganNo ratings yet

- EG Tribology Course PDH File5681Document60 pagesEG Tribology Course PDH File5681operationmanagerNo ratings yet

- Lubricating Oil Pressure Low: Cause CorrectionDocument3 pagesLubricating Oil Pressure Low: Cause CorrectionYasser JaviNo ratings yet

- January 2017 AMSOIL Dealer EditionDocument24 pagesJanuary 2017 AMSOIL Dealer EditionamsoildealerNo ratings yet

- Uebm001801 PC750-6KDocument696 pagesUebm001801 PC750-6KjAVIER GARCIA MORIANANo ratings yet

- PlintTE 77Document2 pagesPlintTE 77janvrut91No ratings yet

- Model Answer Winter 2017Document22 pagesModel Answer Winter 2017jitesh mahadik100% (1)

- SKF Cage MaterialsDocument2 pagesSKF Cage MaterialsKamolwan WeerachatsakulNo ratings yet

- Shell Morlina S2 B 150 - TDSDocument4 pagesShell Morlina S2 B 150 - TDSFandemen AdintaNo ratings yet

- Fire Pump Drive Engine Cfp15e-F10 Cfp15evs-F10Document7 pagesFire Pump Drive Engine Cfp15e-F10 Cfp15evs-F10Compras SSDCNo ratings yet

- Technical Documentation 19.8895Document142 pagesTechnical Documentation 19.8895YIOUGO WNo ratings yet

- Lubrication Storage & Handling-ReliabilityDocument21 pagesLubrication Storage & Handling-ReliabilityRizka YulianaNo ratings yet

- Stern TubesDocument9 pagesStern TubesArunNo ratings yet