Professional Documents

Culture Documents

Artt 4

Artt 4

Uploaded by

Valentina Bermudez Gomez0 ratings0% found this document useful (0 votes)

11 views2 pagesThe document summarizes research on the leaching behaviors of heavy metals in metallurgical slags. Researchers analyzed samples from three slags - electrolytic manganese residue (EMR), lead-zinc slag (LZS), and ferronickel electric furnace slag (EFS) - which contain heavy metals like manganese, chromium, lead, and zinc. Testing found the heavy metals exist in different stable forms depending on the slag. Leaching tests showed the heavy metals begin to leach at low pH levels and pose environmental risks, even without acid erosion. The slags require further treatment before use in construction to prevent heavy metal leaching.

Original Description:

Original Title

Artt4

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes research on the leaching behaviors of heavy metals in metallurgical slags. Researchers analyzed samples from three slags - electrolytic manganese residue (EMR), lead-zinc slag (LZS), and ferronickel electric furnace slag (EFS) - which contain heavy metals like manganese, chromium, lead, and zinc. Testing found the heavy metals exist in different stable forms depending on the slag. Leaching tests showed the heavy metals begin to leach at low pH levels and pose environmental risks, even without acid erosion. The slags require further treatment before use in construction to prevent heavy metal leaching.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views2 pagesArtt 4

Artt 4

Uploaded by

Valentina Bermudez GomezThe document summarizes research on the leaching behaviors of heavy metals in metallurgical slags. Researchers analyzed samples from three slags - electrolytic manganese residue (EMR), lead-zinc slag (LZS), and ferronickel electric furnace slag (EFS) - which contain heavy metals like manganese, chromium, lead, and zinc. Testing found the heavy metals exist in different stable forms depending on the slag. Leaching tests showed the heavy metals begin to leach at low pH levels and pose environmental risks, even without acid erosion. The slags require further treatment before use in construction to prevent heavy metal leaching.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Occurrence and leaching behaviors of heavy-metal elements in

metallurgical slags

Valentina Bermúdez Gómez – 1001013365

The article talks about how to characterize different slags from pyrometallurgical

and hydrometallurgical processes and the possible presence of heavy metals in

them, since they can cause a considerable environmental risk if they are not

neutralized and would not allow the reuse of the slag in the materials of

construction properly. It was written by Chinese researchers in 2022. The article

states that metallurgical slag is an industrial waste produced during the production

of metals or alloys. This slag contains heavy metal elements and has caused

environmental problems in China due to improper disposal. These slags can come

from hydrometallurgical and pyrometallurgical processes, which are

environmentally harmful due to the presence of heavy metals such as Cr, Pb, Zn

and Mn, and do not allow the reuse of slag in the preparation of construction

materials. Because metallurgical slag has the risk of leaching heavy metal

elements.

For the elaboration of the article, 3 metallurgical samples were used that contain

heavy metal elements such as EMR (electrolytic manganese residue), which is a

solid residue resulting from leaching with sulfuric acid, neutralization with ammonia

and purification in the production of metallic manganese by electrolysis, having

high contents of Mn were used. LZS slag (lead-zinc slag) is an industrial residue

from lead-zinc smelting and contains heavy metals such as Cr, Pb and Zn and EFS

slag (ferronickel electric furnace slag) contains considerable amount of Mn and Cr

that are harmful to health. the environment. These slags are used for the

preparation of construction materials, however, there may be risks of leaching in

heavy metallic elements, so the leaching behavior was analyzed to make a safe

use of these slags in construction processes. To this end, the slags were

characterized, the leaching behavior of heavy metallic elements was investigated

by means of a combination of leaching test and thermodynamic simulation, and the

potential risks of leaching were evaluated.

First, it was determined that the main compositions of EMR are SiO2, SO3 and

Al2O3, in LZS Fe2O3 and SiO2, and for EFS MgO, Fe2O3 and SiO2. And it was

determined that there are two main forms of existence of Mn in EMR. In LZS Cr,

Mn and Zn exist in the solid solution with Fe and Pb as a single substance. In the

EFS, Mn and Cr exist mainly in the glassy Si-Al phase and in the Cr-Mn solid

solution. Subsequently, the leaching study was carried out and it was found that

EMR MnSO4 can be massively dissolved in a neutral environment, while

ferromanganese spinel cannot be dissolved until the Ph value decreases to 6.

While heavy metals in LZS and EFS exist mainly in stable forms and start to leach

when the Ph is less than 4. According to the leaching process, it can be concluded

that the heavy metal leaching concentrations of EMR (Mn), LZS (Zn, Mn, Pb and

As) and EFS (Mn and Cr) are relatively high, which is risky for leaching into the

environment. In addition to neutral and alkaline situations, Mn from EMR, Zn and

Pb from LZS, and Mn and Cr from EFS can also leach into solution, indicating the

environmental risks of metallurgical slag even in conditions without acid erosion.

You might also like

- The Extractive Metallurgy of Gold in South Afri (B-Ok - Xyz)Document534 pagesThe Extractive Metallurgy of Gold in South Afri (B-Ok - Xyz)Ndumi80% (5)

- Geology & GeophysicsDocument30 pagesGeology & GeophysicsJhony Wilson Vargas BarbozaNo ratings yet

- nanomaterials-10-01551-v2Document17 pagesnanomaterials-10-01551-v2Adham OsmanNo ratings yet

- Effect of Metal Coupling On Rusting of Iron: Chemistry Project FileDocument14 pagesEffect of Metal Coupling On Rusting of Iron: Chemistry Project FilePrashant Pandey100% (3)

- 10 3390met9070799Document13 pages10 3390met9070799Macarena BlancoNo ratings yet

- Removal of Cu (II) and PB (II) From Aqueous Solution Using EngineDocument21 pagesRemoval of Cu (II) and PB (II) From Aqueous Solution Using EngineAyesha BukhariNo ratings yet

- B. Akash Dissertation ReportDocument19 pagesB. Akash Dissertation Reportbonthuakash005No ratings yet

- Geng Et Al 2020 Eaching Behavior of Metals From Iron Tailings Under Varying PH and Low Molecular Weight Organic AcidsDocument11 pagesGeng Et Al 2020 Eaching Behavior of Metals From Iron Tailings Under Varying PH and Low Molecular Weight Organic AcidsIngridNo ratings yet

- HelloDocument19 pagesHelloSaroj JiNo ratings yet

- Effect of Metal Coupling On Rusting of Iron: Chemistry Project FileDocument8 pagesEffect of Metal Coupling On Rusting of Iron: Chemistry Project FileSaroj JiNo ratings yet

- Chemistry Project File: Effect of Metal Coupling On Rusting of IronDocument14 pagesChemistry Project File: Effect of Metal Coupling On Rusting of IronHIMANSHUNo ratings yet

- 1 s2.0 S0304386X1200059X MainDocument7 pages1 s2.0 S0304386X1200059X MainJordan Ulloa BelloNo ratings yet

- Removal of Heavy Metals Using Bentonite Clay and Inorganic CoagulantsDocument20 pagesRemoval of Heavy Metals Using Bentonite Clay and Inorganic CoagulantsВладислав ГазинNo ratings yet

- Chemistry Project File Effect of Metal CDocument13 pagesChemistry Project File Effect of Metal CHARSH PARMARNo ratings yet

- Jawahar Navodaya Vidyalaya: Chemistry Project FileDocument13 pagesJawahar Navodaya Vidyalaya: Chemistry Project FileShree MishraNo ratings yet

- ChemistrypracticalDocument16 pagesChemistrypractical8rg48v4zgfNo ratings yet

- Discussion of Theory Regarding Heavy Metals Specifically Chromium, Arsenic and MercuryDocument3 pagesDiscussion of Theory Regarding Heavy Metals Specifically Chromium, Arsenic and MercuryMay FakatNo ratings yet

- Reuse of Heavy Metal-Containing Sludges in Cement ProductionDocument6 pagesReuse of Heavy Metal-Containing Sludges in Cement ProductionMarita M. OrbegosoNo ratings yet

- Chemistry 2Document12 pagesChemistry 2linkgogo69No ratings yet

- Corrosion of Copper and Copper Alloys: Ahmed JabirDocument14 pagesCorrosion of Copper and Copper Alloys: Ahmed JabirAhmed JabirNo ratings yet

- Study of Constituents of An AlloyDocument18 pagesStudy of Constituents of An AlloyMohammed Anis RahmanNo ratings yet

- تقريرDocument5 pagesتقريرjmalahmed853No ratings yet

- Triambakk - XiiDocument11 pagesTriambakk - XiiSikhander ReddyNo ratings yet

- Chemistry Investigatory ProjectDocument15 pagesChemistry Investigatory ProjectSourav DuttaNo ratings yet

- Army Public School Ranikhet: Chemistry Project FileDocument15 pagesArmy Public School Ranikhet: Chemistry Project FileSubhangi SatiNo ratings yet

- GEOLOGÍA DEL YACIMIENTO DE MN DE CRIVILLEN (TERUEL)Document25 pagesGEOLOGÍA DEL YACIMIENTO DE MN DE CRIVILLEN (TERUEL)Cesar Veliz LopezNo ratings yet

- University of Northeastern Philippines: Iriga City, Camarines SurDocument31 pagesUniversity of Northeastern Philippines: Iriga City, Camarines SurZudotaNo ratings yet

- Barath PJDocument4 pagesBarath PJBhadrinath D.R.No ratings yet

- Manganese Constituent in Stainless Steels Oxidized in Oxygen Containing Water Vapor at 800 Oc: High Temperature Oxidation and VolatilizationDocument5 pagesManganese Constituent in Stainless Steels Oxidized in Oxygen Containing Water Vapor at 800 Oc: High Temperature Oxidation and VolatilizationEva NipaNo ratings yet

- Heat Treatment Enhancement of Natural Orange-Red SapphiresDocument14 pagesHeat Treatment Enhancement of Natural Orange-Red Sapphiresninimendra nawanjaneNo ratings yet

- An Overview of Recovery of Metals From SlagsDocument17 pagesAn Overview of Recovery of Metals From SlagsPauloValdiviesoNo ratings yet

- ELECSDocument2 pagesELECSdestinkitNo ratings yet

- Chemistry ParasDocument14 pagesChemistry ParasAARYA PATHANIANo ratings yet

- To Study The Effect of Metal Coupling On Rusting of IronDocument10 pagesTo Study The Effect of Metal Coupling On Rusting of IronTharinish KG100% (3)

- 1992 - Vuurman, Wachs - in Situ Raman Spectroscopy of Alumina-Supported Metal Oxide Catalysts - Journal of Physical ChemistryDocument9 pages1992 - Vuurman, Wachs - in Situ Raman Spectroscopy of Alumina-Supported Metal Oxide Catalysts - Journal of Physical ChemistryClaudio BiaginiNo ratings yet

- AISSCE 2019 - 20: Investigatory Project OnDocument12 pagesAISSCE 2019 - 20: Investigatory Project OnKunal ChouhanNo ratings yet

- Chapter - 8 MetalDocument12 pagesChapter - 8 Metalamit_idea1No ratings yet

- Electrochimica ActaDocument8 pagesElectrochimica ActaLakshmi NarayananNo ratings yet

- Investigatory Project For Class 12th ChemistryDocument6 pagesInvestigatory Project For Class 12th ChemistrywarriorNo ratings yet

- 42 Jchps Si3 Addn Sailaja 175-181Document7 pages42 Jchps Si3 Addn Sailaja 175-181Aliyu AbdulqadirNo ratings yet

- Soil-Induced Corrosion of Ancient Roman Brass - A Case StudyDocument10 pagesSoil-Induced Corrosion of Ancient Roman Brass - A Case StudyNiña Viaña BinayNo ratings yet

- Modules - MidtermDocument39 pagesModules - MidtermGahnzelle Eidref FerreriaNo ratings yet

- Metal Release From Stainless Steel in Biological Environments: A ReviewDocument18 pagesMetal Release From Stainless Steel in Biological Environments: A ReviewTiên TrầnNo ratings yet

- Chemistry Project On EXTRACTION OF METAL CLASS 12Document39 pagesChemistry Project On EXTRACTION OF METAL CLASS 12Suchit Khedar50% (2)

- The Geomicrobiology of Supergene Metal DepositsDocument7 pagesThe Geomicrobiology of Supergene Metal DepositsFranco Quispe VidalNo ratings yet

- Rusting Is A Chemical Process ThatDocument5 pagesRusting Is A Chemical Process ThatGopal GuptaNo ratings yet

- Chemistryprojec On CorrosionDocument23 pagesChemistryprojec On CorrosionSandeep Kumar Yadav100% (1)

- Characterization of LC, HC-FeMn Alloys and Their Melting Mechanism in The Molten IronDocument8 pagesCharacterization of LC, HC-FeMn Alloys and Their Melting Mechanism in The Molten IronNeilton TapajosNo ratings yet

- Chemistry Project File Effect of Metal CDocument14 pagesChemistry Project File Effect of Metal CSruthiNo ratings yet

- An Overview of Recovery of Metals From SlagsDocument17 pagesAn Overview of Recovery of Metals From SlagsMatheusDutraNo ratings yet

- HSAB Concept in Mineral OreDocument8 pagesHSAB Concept in Mineral OreKurnia NurfitriaNo ratings yet

- Chemistry Investigatory ProjectDocument14 pagesChemistry Investigatory ProjectKrishna TiwariNo ratings yet

- Discussion of Theory Regarding Heavy Metals Specifically Chromium, Arsenic and MercuryDocument3 pagesDiscussion of Theory Regarding Heavy Metals Specifically Chromium, Arsenic and MercuryMay FakatNo ratings yet

- Chromium in Steel SlagDocument7 pagesChromium in Steel SlagSatish PandeyNo ratings yet

- Minerals: Chemical Treatment of Highly Toxic Acid Mine Drainage at A Gold Mining Site in Southwestern Siberia, RussiaDocument22 pagesMinerals: Chemical Treatment of Highly Toxic Acid Mine Drainage at A Gold Mining Site in Southwestern Siberia, RussiaHSE Mitra Terminal KaltimNo ratings yet

- Thermodynamics and Viscosity Aspects in Manganese Nodule Residue Smelting For Silicomanganese ProductionDocument8 pagesThermodynamics and Viscosity Aspects in Manganese Nodule Residue Smelting For Silicomanganese ProductionjoyNo ratings yet

- Copper and Its Alloys: IntroductionDocument5 pagesCopper and Its Alloys: IntroductionAhmed AlbayatiNo ratings yet

- Vdocuments - MX Effect of Metal Coupling On Rusting of IronDocument11 pagesVdocuments - MX Effect of Metal Coupling On Rusting of IronPorkodi VendhanNo ratings yet

- Iron Oxide Nanoparticles - Wikipedia, The Free Encyclopedia PDFDocument4 pagesIron Oxide Nanoparticles - Wikipedia, The Free Encyclopedia PDFAndrés Garzòn PosadaNo ratings yet

- Cobalt Metal: 191031003@duc - Edu.iqDocument10 pagesCobalt Metal: 191031003@duc - Edu.iqاديان كاظم جعفرNo ratings yet

- Copper BasicsDocument8 pagesCopper BasicstomarindianNo ratings yet

- Art 7Document4 pagesArt 7Valentina Bermudez GomezNo ratings yet

- Articulo 6Document1 pageArticulo 6Valentina Bermudez GomezNo ratings yet

- Articulo 2 MetalurgiaDocument1 pageArticulo 2 MetalurgiaValentina Bermudez GomezNo ratings yet

- 1 s2.0 S0022024821001032 MainDocument7 pages1 s2.0 S0022024821001032 MainValentina Bermudez GomezNo ratings yet

- Articulo 3 MetDocument1 pageArticulo 3 MetValentina Bermudez GomezNo ratings yet

- Gold and Maars at WauDocument18 pagesGold and Maars at WauGeo Geo GeoNo ratings yet

- Kenny's ReportDocument41 pagesKenny's ReportLAURENT JIBUNGENo ratings yet

- 1 Metallurgy SB 2023Document39 pages1 Metallurgy SB 2023Bella CakieNo ratings yet

- Man Metals Magic - BookDocument39 pagesMan Metals Magic - Bookopenid_Mtc4LtrUNo ratings yet

- Alberto Lobo-Guerrero, M.SC., Min - Ex.: Quartz Pods: An Exploration Guide To Iron Oxide-Copper-Gold Mineralisation?Document2 pagesAlberto Lobo-Guerrero, M.SC., Min - Ex.: Quartz Pods: An Exploration Guide To Iron Oxide-Copper-Gold Mineralisation?Luis Fernando ParedesNo ratings yet

- Periodic TableDocument1 pagePeriodic TableGregNo ratings yet

- GLGY 471 - Lab 2: Earth Materials 1Document14 pagesGLGY 471 - Lab 2: Earth Materials 1Ayesha ANo ratings yet

- Golden Triangle Report March2016Document12 pagesGolden Triangle Report March2016Yash ladkeNo ratings yet

- Nentir Vale Hex CrawlDocument23 pagesNentir Vale Hex CrawlSennalNo ratings yet

- Prospecting Criteria of Various Mineral DepositsDocument4 pagesProspecting Criteria of Various Mineral DepositsGayatri. KarakaNo ratings yet

- Exploitation and Development of Non MetaDocument53 pagesExploitation and Development of Non MetaVavania MNo ratings yet

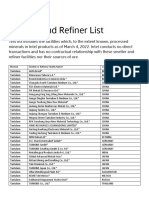

- Smelter and Refiner ListDocument10 pagesSmelter and Refiner Listloma gNo ratings yet

- Precambrian Alkaline Potassic-Ultrapotassic, Mafic-Ultramafic Magmatism in Peninsular IndiaDocument28 pagesPrecambrian Alkaline Potassic-Ultrapotassic, Mafic-Ultramafic Magmatism in Peninsular IndiaKishor DeshmukhNo ratings yet

- The Destruction of Gath by Hazael and THDocument30 pagesThe Destruction of Gath by Hazael and THRon Fisher100% (1)

- Are You Looking For .: WWW - Promining.inDocument14 pagesAre You Looking For .: WWW - Promining.inANKIT DEOGADENo ratings yet

- Cote D'Ivoire: Geochemical Results Highlight New Gold SystemsDocument11 pagesCote D'Ivoire: Geochemical Results Highlight New Gold Systemssedjou ernestNo ratings yet

- IXR Valuation - 23.02.2022Document14 pagesIXR Valuation - 23.02.2022Howard QinNo ratings yet

- Crushing in Mineral ProcessingDocument9 pagesCrushing in Mineral ProcessingRodrigo GarcíaNo ratings yet

- Orogenic Gold PresentationDocument21 pagesOrogenic Gold PresentationBORIS FONYUYNo ratings yet

- Geostats Pty LTD: Base Metal AnalysesDocument1 pageGeostats Pty LTD: Base Metal AnalysesJhony Enrique Morales LauraNo ratings yet

- Piping MaterialDocument59 pagesPiping MaterialRomel Fuentes GutiérrezNo ratings yet

- Paper On Salumber, Ghatol Metallogenic Province (Aravalli Craton)Document10 pagesPaper On Salumber, Ghatol Metallogenic Province (Aravalli Craton)niksgeoNo ratings yet

- Lecture 5 Dolerite Sills 2008Document40 pagesLecture 5 Dolerite Sills 2008JoseNo ratings yet

- Graphite From Discovery To ResourcesDocument48 pagesGraphite From Discovery To Resourcesadam_723172810No ratings yet

- File 123Document11 pagesFile 123Sahoo 1234100% (1)

- Handout 8 Characteristics of Epithermal Deposits (Compatibility Mode)Document13 pagesHandout 8 Characteristics of Epithermal Deposits (Compatibility Mode)fercanzaNo ratings yet

- Lectura 07 Modern Continuous Smelting and Converting by Bath Smelting TechnologyDocument23 pagesLectura 07 Modern Continuous Smelting and Converting by Bath Smelting Technologycarorodriguezlorca12No ratings yet

- Science India Magazine August 2022Document64 pagesScience India Magazine August 2022Anuska YadavNo ratings yet