Professional Documents

Culture Documents

SS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN AS

SS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN AS

Uploaded by

Hithish Reddy0 ratings0% found this document useful (0 votes)

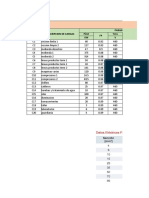

7 views5 pagesThis document provides information about bolt properties, materials, and torque specifications. It lists various international standards for bolts. It also lists common stainless steel materials used for bolts, including grades SS304 and SS316. Finally, it includes a metric bolt torque specification chart that provides torque values in kg-cm for various bolt sizes and grades, with notes on proper torque considerations.

Original Description:

Original Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information about bolt properties, materials, and torque specifications. It lists various international standards for bolts. It also lists common stainless steel materials used for bolts, including grades SS304 and SS316. Finally, it includes a metric bolt torque specification chart that provides torque values in kg-cm for various bolt sizes and grades, with notes on proper torque considerations.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

7 views5 pagesSS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN AS

SS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN AS

Uploaded by

Hithish ReddyThis document provides information about bolt properties, materials, and torque specifications. It lists various international standards for bolts. It also lists common stainless steel materials used for bolts, including grades SS304 and SS316. Finally, it includes a metric bolt torque specification chart that provides torque values in kg-cm for various bolt sizes and grades, with notes on proper torque considerations.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 5

SS Bolt properties

Std DIN Std

ISO 4017 B.S. DIN933

DIN931 DIN931

GB5783 DIN934

DIN DIN912

ASTM DIN603

ANSI DIN6923

JIS

EN

AS

Bolts material Properties

Stainless Steel Allen Bolts Material

18-8 Stainless Steel

stainless steel ss 304

SS316 A2/A4

SS201

SS303

SS304

SS316

SS316L

SS904L

A2-70

A4-70

A4-80

Stan

Possible situations where pro

Capturing bearing r

Setting preload on c

Smaller size bolts wh

Bolts in soft materia

Any housing or thin

Metric bolt torque spec settings chart

(Torque in Kg/cm conversion 13.8

Hex head cap screwsSocket head cap screws

Socket heaGrade 8.8 Grade 10.9 Grade 12.9

M4 x .70 23 0

M5 x .80 57 0 95.22

M6 x 1.0 98 151.8 160.08

M7 x 1.0 166 0 0

M8 x 1.0 248 0 0

M8 x 1.25 235 358.8 400.2

M10 x 1.0 538 0 0

M10 x 1.25 497 0 0

M10 x 1.5 469 703.8 786.6

M12 x 1.25 897 0 0

M12 x 1.5 869 0 0

M12 x 1.75 814 1214.4 1366.2

M14 x 1.5 1408 0 0

M14 x 2 1297 1918.2 2180.4

M16 x 2 2015 2898 3450

M18 x 2.5 2898 0 4705.8

M20 x 2.5 4030 0 6748.2

Grade 10.9

(below)

M22

M24 9729

M30 18160.8

Standard bolt torque spec

e situations where proper bolt torque may be necessary related to machine tool repair.

Capturing bearing races in housings

Setting preload on certain types of bearings

Smaller size bolts which can be easily over torqued.

Bolts in soft materials such as aluminum Example-hydraulic manifolds

Any housing or thin wall material that has a chance to be distorted if over tightened or an uneven torque is

c settings chart Standard bolt torque spec settings chart

Kg/cm (Torque in foot-pound Metric conversion 25.4 13.8

Socket head cap screws Hex head

Grade 12.9

Kg/cm Grade 5 Grade 7 Grade 8

45.54

Bolt Dia. Thread per Dry Oiled Dry Oiled Dry

0

95.22 6.4 0.8 110 83 138 110 166

160.08 6.4 1.1 138 97 166 124 193

0 7.9 0.7 235 179 290 221 345

0 7.9 0.9 262 193 331 248 400

400.2 9.5 0.6 414 317 552 414 621

0 9.5 0.9 483 345 621 483 690

0 11.1 0.6 690 483 828 621 966

786.6 11.1 0.8 759 552 966 690 1104

0 12.7 0.5 1035 759 1311 966 1518

0 12.7 0.8 1242 897 1380 1104 1656

1366.2 14.3 0.5 1518 1104 1863 1380 2070

0 14.3 0.7 1656 1242 2070 1518 2346

2180.4 15.9 0.4 2070 1518 1932 2622 3036

3450 15.9 0.7 2484 1794 2898 2208 3312

4705.8 19.1 0.4 3588 2760 4416 3312 5244

6748.2 19.1 0.6 4140 3036 4968 3864 5796

Grade 10.9 22.2 0.4 5934 4416 7176 5520 8280

(below) 22.2 0.6 6486 4968 8004 6072 9108

7714.2

25.4 0.3 8832 6624 11040 8280 12420

0

9729 25.4 0.5 9798 7314 11868 9191 13662

18160.8

Proper torque spec varies depending on the material, bolt grade or if lubrication is used

such as oil, wax, or anti-seize. Always go to the manufacturer for proper torque

specifications. The chart above is an approximate estimate of torque values and have

not been validated for accuracy. The numbers above have been compiled from various

machine builder specs and other resources.

pec

r an uneven torque is applied.

ttings chart

Socket head cap

Grade 8 screws

Oiled Dry Oiled

124 193 152

138 221 179

248 400 317

276 455 359

483 676 538

552 745 607

759 1049 842

828 1173 938

1104 1559 1242

1242 1739 1380

1518 2249 1794

1794 2498 1987

2346 3174 2539

2484 3519 2815

3864 5520 4416

4416 6072 4830

6348 8832 7038

6900 9660 7728

9384 13524 10764

10212 14628 11661

or if lubrication is used

r for proper torque

orque values and have

compiled from various

s.

You might also like

- Din 929 PDFDocument1 pageDin 929 PDFprathmesh238No ratings yet

- Bolt, Nut, WasherDocument9 pagesBolt, Nut, WasherAndri EkoNo ratings yet

- Bearing CalalougeDocument9 pagesBearing CalalougeRakesh GairolaNo ratings yet

- Mechanical Bolt Torque TableDocument7 pagesMechanical Bolt Torque TablesitehabNo ratings yet

- HTD HXB cl10.9 Tight TorqDocument1 pageHTD HXB cl10.9 Tight Torqaegean227No ratings yet

- Metric Bolt Torque Table NM - CNCexpoDocument1 pageMetric Bolt Torque Table NM - CNCexpoNepoleon KaruppiahNo ratings yet

- Wetico Water Tank 70m Shell Ultimate ChecksDocument2 pagesWetico Water Tank 70m Shell Ultimate ChecksChristian Paul SanguyoNo ratings yet

- 2.2 - Details of Shell & Tube H.EDocument110 pages2.2 - Details of Shell & Tube H.ENader GaafarNo ratings yet

- ROBA-stop M Brake Selection (6 Pole)Document1 pageROBA-stop M Brake Selection (6 Pole)Zaki SubehiNo ratings yet

- Engineer's Handbook General Part: Torque Specification For Bolted ConnectionsDocument2 pagesEngineer's Handbook General Part: Torque Specification For Bolted ConnectionsenzobvNo ratings yet

- 20CV080 MOS Navnath PandharmiseDocument41 pages20CV080 MOS Navnath PandharmiseYashvardhan TodmalNo ratings yet

- Torque Settings: Section 1 - General InformationDocument1 pageTorque Settings: Section 1 - General InformationNikNo ratings yet

- CATALOGO RfN-7012...Document6 pagesCATALOGO RfN-7012...AngelNo ratings yet

- Specification For Philippine Steel Bars For Concrete Reinforcement Product Standard Agency, Department of Trade and Industry (D.T.I.)Document18 pagesSpecification For Philippine Steel Bars For Concrete Reinforcement Product Standard Agency, Department of Trade and Industry (D.T.I.)Azel GarciaNo ratings yet

- Standard Bolt Tightening TorqueDocument2 pagesStandard Bolt Tightening TorqueARUNKANNANNo ratings yet

- Standard Torque Values - Metric SystemDocument1 pageStandard Torque Values - Metric Systemnate anantathat100% (1)

- 01 Series Internal Gear Slewing BearingDocument3 pages01 Series Internal Gear Slewing BearingAndre van GreunenNo ratings yet

- Magnetic Coupling Torque Vs Air GapDocument4 pagesMagnetic Coupling Torque Vs Air GapDallie KurniawanNo ratings yet

- Suntech Thrust Pad Cata 18-19Document16 pagesSuntech Thrust Pad Cata 18-19ARKA technocorpNo ratings yet

- Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsDocument2 pagesStrux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsneilNo ratings yet

- Impact Wrenches: Optimal Torque of BoltDocument6 pagesImpact Wrenches: Optimal Torque of BoltFarjad KhanNo ratings yet

- Design of Slab: Two WayDocument3 pagesDesign of Slab: Two WaySyeda NafeezaNo ratings yet

- Design of Slab: Two WayDocument3 pagesDesign of Slab: Two WaySyeda NafeezaNo ratings yet

- Shear Stress Vs Shear StrainDocument12 pagesShear Stress Vs Shear StrainAbrar AfzalNo ratings yet

- Metric Bolt Torque Table NM - CNCexpo PDFDocument1 pageMetric Bolt Torque Table NM - CNCexpo PDFninatenaNo ratings yet

- Metric Bolt Torque Table NM - CNCexpoDocument1 pageMetric Bolt Torque Table NM - CNCexponate anantathat100% (1)

- Material List Summary-WaptechDocument5 pagesMaterial List Summary-WaptechMarko AnticNo ratings yet

- RFN 7012-In: Ringfeder Locking AssembliesDocument6 pagesRFN 7012-In: Ringfeder Locking AssembliesRodrigo Jechéla BarriosNo ratings yet

- Sizing Steel Sections For BeamsDocument25 pagesSizing Steel Sections For BeamsAnonymous ujfx6mNo ratings yet

- 20CV321-MOS-Kaware AkshayDocument68 pages20CV321-MOS-Kaware AkshayYashvardhan TodmalNo ratings yet

- Upvc PipesDocument1 pageUpvc PipesMuneer mahammadNo ratings yet

- Bills 3213214Document9 pagesBills 3213214LnazerA.CeceNo ratings yet

- Torque Chart NormetDocument1 pageTorque Chart NormetvmrvdnvNo ratings yet

- Compression ValueDocument6 pagesCompression ValueChandrasekar KrishnamurthyNo ratings yet

- Price List: Spring Lock WashersDocument8 pagesPrice List: Spring Lock WashersnitintshNo ratings yet

- Calculo de Conductores E Interruptores Termomagneticos 380V, 60HzDocument7 pagesCalculo de Conductores E Interruptores Termomagneticos 380V, 60HzGUTARRA QUISPE OSCAR ALEXANDERNo ratings yet

- RATV - Socket Head Fasteners - MetricDocument1 pageRATV - Socket Head Fasteners - MetricGustavo CarvalhoNo ratings yet

- DBR ChecklistDocument9 pagesDBR ChecklistJai ThakkarNo ratings yet

- Draka PVCDocument4 pagesDraka PVCapi-3803155No ratings yet

- Medical Specifications: Part # Service Pressure Diameter Cylinder Weight Oxygen Water Capacity LengthDocument1 pageMedical Specifications: Part # Service Pressure Diameter Cylinder Weight Oxygen Water Capacity LengthAlberto SantosNo ratings yet

- British Steel European Sections Product RangeDocument9 pagesBritish Steel European Sections Product Rangemdakhan679No ratings yet

- Tabela Torques de ApertoDocument8 pagesTabela Torques de ApertoEduardo Figueiredo BertassoNo ratings yet

- Metallic Gaskets - Installation & Torque - October 2020Document6 pagesMetallic Gaskets - Installation & Torque - October 2020Alberto CaveroNo ratings yet

- Reamers Metric Size ChartDocument1 pageReamers Metric Size ChartdilipNo ratings yet

- Service DataDocument12 pagesService DataGianni DaBolognaNo ratings yet

- Single Parts-Blower HouseDocument87 pagesSingle Parts-Blower HouseMarko AnticNo ratings yet

- Tools TipsExtensionsDocument4 pagesTools TipsExtensionsSolina AlunorteNo ratings yet

- Torque-Tension Chart For Metric Fasteners PDFDocument1 pageTorque-Tension Chart For Metric Fasteners PDFmhd abdouNo ratings yet

- British Steel European Ipe Sections DatasheetDocument3 pagesBritish Steel European Ipe Sections DatasheetArindomNo ratings yet

- Summary of 76.2m Span OWG - Final LatestDocument1 pageSummary of 76.2m Span OWG - Final LatestLakhwant Singh KhalsaNo ratings yet

- E1 Perfiles CDocument1 pageE1 Perfiles CCesar Augusto Castillo RoqueNo ratings yet

- Dimensions Setional Properties Designation Mass (M) D B t T Sectional Area (a) Flange Slope (α) R R C I I rDocument4 pagesDimensions Setional Properties Designation Mass (M) D B t T Sectional Area (a) Flange Slope (α) R R C I I rRahul SolankiNo ratings yet

- 11 Series Internal Gear Slewing BearingDocument3 pages11 Series Internal Gear Slewing BearingAndre van GreunenNo ratings yet

- Excel Lab1 DMDocument7 pagesExcel Lab1 DMJeferson Leonardo Alfonso TorresNo ratings yet

- Bored PileDocument13 pagesBored PileFrederick TanNo ratings yet

- UCM - Fabricated Steel MatsDocument1 pageUCM - Fabricated Steel MatsKranthi KumarNo ratings yet

- Resistance and PowerDocument3 pagesResistance and PowerYan Naing ShinNo ratings yet

- Metric DIN 7984 Low Profile Head Hexagon Socket Cap Screws: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 7984 Low Profile Head Hexagon Socket Cap Screws: Visit Our For Product AvailabilityTugay ArıçNo ratings yet

- Surdex Steel Reference Guide Feb 2024 Rev 5 1Document42 pagesSurdex Steel Reference Guide Feb 2024 Rev 5 1AlessandroNo ratings yet