Professional Documents

Culture Documents

B-Ket Report

B-Ket Report

Uploaded by

Mohammed AyeshCopyright:

Available Formats

You might also like

- Design Spreadsheet Gusset Plate Connection For TrussDocument4 pagesDesign Spreadsheet Gusset Plate Connection For TrussMatumbi Naito100% (1)

- Manual de Partes Soilmec sf50Document273 pagesManual de Partes Soilmec sf50pedroandres143100% (3)

- 01 GMK Features en Avr2007Document16 pages01 GMK Features en Avr2007Alonso Fernando100% (1)

- EXP-MN-SI020-EN-R0 - Measurements in Instrumentation PDFDocument114 pagesEXP-MN-SI020-EN-R0 - Measurements in Instrumentation PDFbali100% (3)

- C-End Bottom Bracket ReportDocument4 pagesC-End Bottom Bracket ReportMohammed AyeshNo ratings yet

- A-Bottom-Bracket ReportDocument4 pagesA-Bottom-Bracket ReportMohammed AyeshNo ratings yet

- E-End Tocket ReportDocument4 pagesE-End Tocket ReportMohammed AyeshNo ratings yet

- Design Office: Person in Charge: Construction Project: Number: Position: Date: 1/26/2017Document3 pagesDesign Office: Person in Charge: Construction Project: Number: Position: Date: 1/26/2017jasekan.dcNo ratings yet

- Design Office: Person in Charge: Construction Project: Project Number: Position: Date: 5/8/2019Document4 pagesDesign Office: Person in Charge: Construction Project: Project Number: Position: Date: 5/8/2019ahmedebnnaderNo ratings yet

- Exp MiddleDocument4 pagesExp MiddleahmedebnnaderNo ratings yet

- VMH AnchorDocument4 pagesVMH Anchormohamed rafiNo ratings yet

- Design Office: Person in Charge: Construction Project: Project Number: Position: Date: 9/20/2021Document4 pagesDesign Office: Person in Charge: Construction Project: Project Number: Position: Date: 9/20/2021Asaru DeenNo ratings yet

- Design Office: Invention Steel Industries Person in Charge: YJT Construction Project: Sqm-Nizwa Number: 0811 Position: Date: 7/22/2014Document4 pagesDesign Office: Invention Steel Industries Person in Charge: YJT Construction Project: Sqm-Nizwa Number: 0811 Position: Date: 7/22/2014yusuf_jtNo ratings yet

- 2.2.2-2 - DQR - SS - Cleat Angle Capacity-Rev BDocument10 pages2.2.2-2 - DQR - SS - Cleat Angle Capacity-Rev BSANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- Design of Inlet ChamberDocument2 pagesDesign of Inlet ChamberRaju SainiNo ratings yet

- Aci-PunchingDocument5 pagesAci-PunchingAbdalrhman Al khateebNo ratings yet

- Practical Lesson 4Document11 pagesPractical Lesson 4marjory.dezNo ratings yet

- Group 12 p1Document3 pagesGroup 12 p1SM WorldNo ratings yet

- Civil Structural CalculationsDocument2 pagesCivil Structural Calculations3d arch viewsNo ratings yet

- EndPl MomConn LSDDocument54 pagesEndPl MomConn LSDTony RoseNo ratings yet

- 2.2.2-1 - DQR - SS Capacity-Rev BDocument27 pages2.2.2-1 - DQR - SS Capacity-Rev BSANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- 1 Input Data: WWW - Hilti.chDocument5 pages1 Input Data: WWW - Hilti.chkikorrasNo ratings yet

- 2.2.2-1 - DQR - SS Capacity-Rev B1Document87 pages2.2.2-1 - DQR - SS Capacity-Rev B1SANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- Welding CheckingDocument1 pageWelding Checkingxlw955597No ratings yet

- Drawing & Design GantryDocument27 pagesDrawing & Design Gantrysita ram doraNo ratings yet

- Concrete: Input DataDocument4 pagesConcrete: Input DataARYANo ratings yet

- Drafts - Concrete - Apr 12, 2024Document9 pagesDrafts - Concrete - Apr 12, 2024ronwellgutierrezdeleonNo ratings yet

- EA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Document2 pagesEA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Imaduddin KhajaNo ratings yet

- V F B D : Punching Shear Check (ACI 318RM-02)Document1 pageV F B D : Punching Shear Check (ACI 318RM-02)OktayNo ratings yet

- Group 12 p2Document2 pagesGroup 12 p2SM WorldNo ratings yet

- Etabs Column Design MT CalculationDocument2 pagesEtabs Column Design MT CalculationAung SoneNo ratings yet

- Slab Design - OkDocument35 pagesSlab Design - OkazwanNo ratings yet

- Tests - Concrete - Apr 1, 2020Document7 pagesTests - Concrete - Apr 1, 2020Chris MedeirosNo ratings yet

- Deflection Check For SlabDocument1 pageDeflection Check For Slabselvakumar sNo ratings yet

- I. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Document30 pagesI. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Anh KyNo ratings yet

- Drafts - Concrete - Aug 9, 2023Document10 pagesDrafts - Concrete - Aug 9, 2023nguyennovoiNo ratings yet

- I. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Document30 pagesI. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Anh KyNo ratings yet

- 1 Input Data: Profis Anchor 2.5.2Document6 pages1 Input Data: Profis Anchor 2.5.2jasekanNo ratings yet

- 4.1.5.SP ConnectionDocument30 pages4.1.5.SP ConnectionAnh KyNo ratings yet

- Base Plate CalculationDocument10 pagesBase Plate CalculationPradip NikamNo ratings yet

- Centre Post Base Hilti CalculationDocument10 pagesCentre Post Base Hilti CalculationKesavarajNo ratings yet

- 1177 01 Second Floor Exterior Wall.Document2 pages1177 01 Second Floor Exterior Wall.Trà My BùiNo ratings yet

- Slab For Lift ProjectDocument2 pagesSlab For Lift ProjectAnonymous ptLRLiNNNo ratings yet

- Welding Calculation: Job No. Job: Section: Designed By: Sheet No. Subject: DateDocument37 pagesWelding Calculation: Job No. Job: Section: Designed By: Sheet No. Subject: DateMatthew CHANNo ratings yet

- Calculation Sheet For Spit Anchors: ProjectDocument4 pagesCalculation Sheet For Spit Anchors: ProjectshoebNo ratings yet

- Lintel DesignDocument3 pagesLintel DesignPrashant HuddarNo ratings yet

- EC3-Design of Rectangular Base PlateDocument10 pagesEC3-Design of Rectangular Base PlateCường NguyễnNo ratings yet

- Ridge Connection Design RSP-1.Document121 pagesRidge Connection Design RSP-1.Asaru DeenNo ratings yet

- Drafts - Concrete - Aug 8, 2022Document14 pagesDrafts - Concrete - Aug 8, 2022Upendra WalinjkarNo ratings yet

- Slab DesignDocument38 pagesSlab Designmathewsujith31No ratings yet

- 1 Input Data: WWW - Hilti.inDocument8 pages1 Input Data: WWW - Hilti.inAniket InarkarNo ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- EC4-Composite Column H-SectionDocument7 pagesEC4-Composite Column H-SectionCường NguyễnNo ratings yet

- 1 Input Data: WWW - Hilti.chDocument5 pages1 Input Data: WWW - Hilti.chkikorrasNo ratings yet

- I. Material E7Xt 35 1 Ii. Internal Force For Calculating 432 Iii. Dimension 500 500 35 35 6743Document2 pagesI. Material E7Xt 35 1 Ii. Internal Force For Calculating 432 Iii. Dimension 500 500 35 35 6743Anh KyNo ratings yet

- Option-2 - Chemical Base AnchorDocument5 pagesOption-2 - Chemical Base AnchorvengadNo ratings yet

- 2.3.3 - DQR - DS Capacity-Rev B2Document33 pages2.3.3 - DQR - DS Capacity-Rev B2Sudip ShresthaNo ratings yet

- Knoor - Bracing - Side Plate 2Document10 pagesKnoor - Bracing - Side Plate 2borceNo ratings yet

- Column Inter at Ion DiagramDocument7 pagesColumn Inter at Ion DiagramPremasiri KarunarathnaNo ratings yet

- Checking:: Isolated Foundation (F-1) (ACI 318M-95)Document1 pageChecking:: Isolated Foundation (F-1) (ACI 318M-95)taz_taz3No ratings yet

- Circular Column2Document52 pagesCircular Column2BehroozNo ratings yet

- Column DesignDocument98 pagesColumn DesignJessa OpenianoNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Section 08 70 00 - HardwareDocument9 pagesSection 08 70 00 - HardwareMohammed AyeshNo ratings yet

- B TketDocument8 pagesB TketMohammed AyeshNo ratings yet

- A BoracketDocument8 pagesA BoracketMohammed AyeshNo ratings yet

- B-End Bottom Bracket - Door MullionDocument8 pagesB-End Bottom Bracket - Door MullionMohammed AyeshNo ratings yet

- A-Bottom-Bracket ReportDocument4 pagesA-Bottom-Bracket ReportMohammed AyeshNo ratings yet

- Section 08 30 00 - Specialty Doors and FramesDocument7 pagesSection 08 30 00 - Specialty Doors and FramesMohammed AyeshNo ratings yet

- C-End Bottom Bracket ReportDocument4 pagesC-End Bottom Bracket ReportMohammed AyeshNo ratings yet

- E-End Tocket ReportDocument4 pagesE-End Tocket ReportMohammed AyeshNo ratings yet

- Doors 1Document1 pageDoors 1Mohammed AyeshNo ratings yet

- Method of Construction - Facade WorksDocument2 pagesMethod of Construction - Facade WorksMohammed AyeshNo ratings yet

- Section TableDocument4 pagesSection TableMohammed AyeshNo ratings yet

- C - Bottom BracketDocument9 pagesC - Bottom BracketMohammed AyeshNo ratings yet

- Aluminum Design Manual-24Document1 pageAluminum Design Manual-24Mohammed AyeshNo ratings yet

- Aluminum Specification & Qty0001Document3 pagesAluminum Specification & Qty0001Mohammed AyeshNo ratings yet

- 1Document1 page1Mohammed AyeshNo ratings yet

- Brackets Reaction TableDocument3 pagesBrackets Reaction TableMohammed AyeshNo ratings yet

- Cladding DetailDocument1 pageCladding DetailMohammed AyeshNo ratings yet

- (Cedsr-92074) Jvt07iohr001 - 83Document2 pages(Cedsr-92074) Jvt07iohr001 - 83Mohammed AyeshNo ratings yet

- Mushrabia Cast - No. 5Document6 pagesMushrabia Cast - No. 5Mohammed AyeshNo ratings yet

- Arch Issued For Information-Roof Floor l39Document1 pageArch Issued For Information-Roof Floor l39Mohammed AyeshNo ratings yet

- Louver With DeviderDocument4 pagesLouver With DeviderMohammed AyeshNo ratings yet

- High Strength Hexagon Bolts (JIS B1186)Document4 pagesHigh Strength Hexagon Bolts (JIS B1186)Mario HanamiciNo ratings yet

- Presentation Acoustic To Electric ConversionDocument16 pagesPresentation Acoustic To Electric ConversionHarsh PatelNo ratings yet

- A Review Paper On Abrasive Wear CharacteristicsDocument6 pagesA Review Paper On Abrasive Wear CharacteristicsSalem GarrabNo ratings yet

- Xpulse200t Manual de PartesDocument92 pagesXpulse200t Manual de PartesAthiq Nehman100% (2)

- Astm f1007 1986 PDFDocument6 pagesAstm f1007 1986 PDFHsaam HsaamNo ratings yet

- Project ProposalDocument6 pagesProject ProposalVivek Kumar SinghNo ratings yet

- Recycling Passport: Model EL125TDocument4 pagesRecycling Passport: Model EL125TDonNo ratings yet

- AED Certificate (O-Ring and Non-Metallic Sealing)Document2 pagesAED Certificate (O-Ring and Non-Metallic Sealing)mattarchiNo ratings yet

- 4 - Engineering Geology and Soil Mechanics - Chapter 5 - Permeability and SeepageDocument35 pages4 - Engineering Geology and Soil Mechanics - Chapter 5 - Permeability and Seepagehessian123No ratings yet

- Surface Preparation Metallizing ProcedureDocument6 pagesSurface Preparation Metallizing ProcedureCorrosion FactoryNo ratings yet

- Mechismo 2022Document44 pagesMechismo 2022NAGARAJUNo ratings yet

- 2009 Handok Hydraulic Catalog PDFDocument33 pages2009 Handok Hydraulic Catalog PDFElver RiveraNo ratings yet

- 3 Ton 36000 BTUs Split Air ConditionersDocument2 pages3 Ton 36000 BTUs Split Air ConditionersNayif MuhammedNo ratings yet

- 3 Ii-IiDocument105 pages3 Ii-IiMrHEMAMAHEHNo ratings yet

- Super Magnet Braking System (Report) PDFDocument57 pagesSuper Magnet Braking System (Report) PDFsrinivasarao katari100% (2)

- behi2017Cu-Water Investigation of PCM-assisted Heat Pipe For Electronic CoolingDocument11 pagesbehi2017Cu-Water Investigation of PCM-assisted Heat Pipe For Electronic CoolingTobin MohanNo ratings yet

- Stihl Ts500i Service Manual Stihl PDFDocument118 pagesStihl Ts500i Service Manual Stihl PDFBruce MacDonaldNo ratings yet

- AVENSISDocument20 pagesAVENSISAbdolkarim Pahliani100% (1)

- Unit I MCQ Ii-2Document7 pagesUnit I MCQ Ii-2Kavitha Pasumalaithevan0% (1)

- Geotehnics of SoftsoilDocument44 pagesGeotehnics of SoftsoilVinna RinayaniNo ratings yet

- Mechanical Data Sheet: LG / Oiec / Ioec ConsortiumDocument9 pagesMechanical Data Sheet: LG / Oiec / Ioec ConsortiumatemtutemNo ratings yet

- Industrial Gearbox Service ManualDocument36 pagesIndustrial Gearbox Service ManualNovriansyah Brian100% (1)

- Roller Chain SprocketDocument10 pagesRoller Chain SprocketMelindaNo ratings yet

- Flange Gaskets: Chesterton® Gasket Centers Chesterton® Gasket CentersDocument4 pagesFlange Gaskets: Chesterton® Gasket Centers Chesterton® Gasket CentersjaviervbNo ratings yet

- Front Suspension PDFDocument19 pagesFront Suspension PDFspeedkar9No ratings yet

- Yamaha YJ50 Service Manual PDFDocument228 pagesYamaha YJ50 Service Manual PDFดิษย์ธีเดช ชีวาอัครพัฒน์No ratings yet

- DWR May 2021Document28 pagesDWR May 2021Mario MilicevicNo ratings yet

B-Ket Report

B-Ket Report

Uploaded by

Mohammed AyeshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B-Ket Report

B-Ket Report

Uploaded by

Mohammed AyeshCopyright:

Available Formats

Design office: *

Person in charge: *

Construction project:

Project number: CW-1 - B- MID BRACKET

Position: Date: 4/29/2023

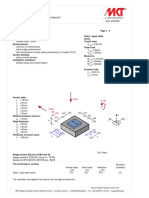

Input data: Page 1 / 3

Concrete: Static / quasi-static

cracked concrete action

strength class: C35/45 Tensile load:

Reinforcement: Nz,Sd = 4.025 kN

normal or no reinforcement Shear load:

without edge reinforcement Vx,Sd = 0.00 kN

with reinforcement to resist splitting according to [1] chapter 5.2.2.6 Vy,Sd = 0.00 kN

Anchor bending:

Moments:

without anchor bending

Mx,Sd = 0.00 kNm

Installation conditions:

My,Sd = 0.00 kNm

Drilling method: see remarks Page 3

Mz,Sd = 0.00 kNm

Eccentric load

e x = -50.0 mm

e y = 0.0 mm

Anchor plate:

x = 100 mm 4.025

y = 120 mm

lx1 = 60 mm

lx2 = 40 mm -50

ly1 = 25 mm

cx2 cy1

ly2 = 25 mm

sy1 z

Distance between anchors: cx1

sy1 = 70 mm cy2 x

h y

Edge distances:

cx1 = 90 mm 1

2

cx2 = 90 mm

cy1 = 90 mm

ly1

cy2 = 90 mm sy1 lx2

Thickness of anchor base: ly2 lx1

y

h = 300 mm x

[ kN, kNm ]

Wedge Anchor BZ plus A4 M10 hef 60

Design method A, ETAG 001, Annex C + TR 055

Assessment ETA-99/0010: MKT BZ plus / BZ-IG

The anchorage is verified. Boundary

Tension loads Shear loads Interaction conditions:

bN [%] bV [%] bN,V[%]

1)

Static / quasi-static action 66.9 - - OK

1)

No action available.

The calculation only applies if the notes on the last page are observed.

Anchor Design Program Version 4.55

MKT Metall-Kunststoff-Technik GmbH & Co.KG | Auf dem Immel 2 | D-67685 Weilerbach | Tel.: +49 (0) 6374 / 9116-0 | support@mkt.de

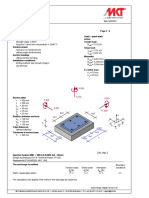

Design office: *

Person in charge: *

Construction project:

Project number: CW-1 - B- MID BRACKET

Position: Date: 4/29/2023

Wedge Anchor BZ plus A4 M10 hef 60 Page 2 / 3

Assessment ETA-99/0010: MKT BZ plus / BZ-IG

Required proofs for tension loads

Anchor loads

Anchor 1 2

NSd [kN] 5.38 5.38

Proof steel failure

h

N Sd ≤ NRk,s / gMs = NRd,s Utilisation:

5.38 ≤ 27.00 / 1.50 = 18.00 29.9%

Proof pullout failure

h

N Sd ≤ NRk,p / gMp = NRd,p Utilisation:

5.38 ≤ 12.07 / 1.50 = 8.05 66.9%

NRk,p YC,(C35/45)

9.00kN 1.34

Proof concrete cone failure

g

N Sd ≤ NRk,c / gMc = NRd,c Utilisation:

10.77 ≤ 31.18 / 1.50 = 20.78 51.8%

o

N Rk,c YA,c,N Ys,N Yre,N Yec,N

22.45 kN 1.39 1.00 1.00 1.00

o

k1 Ac,N A c,N hef fck,cube ccr,N ec1,N ec2,N

2 2 2

7.2 45000mm 32400mm 60.0mm 45N/mm 90.0mm 0.0mm 0.0mm

Proof splitting failure

No proof required. Existing reinforcement to resist splitting according to [1] chapter 5.2.2.6

Anchor Design Program Version 4.55

MKT Metall-Kunststoff-Technik GmbH & Co.KG | Auf dem Immel 2 | D-67685 Weilerbach | Tel.: +49 (0) 6374 / 9116-0 | support@mkt.de

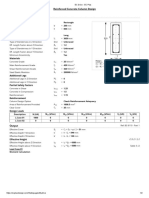

Design office: *

Person in charge: *

Construction project:

Project number: CW-1 - B- MID BRACKET

Position: Date: 4/29/2023

Wedge Anchor BZ plus A4 M10 hef 60 Page 3 / 3

Assessment ETA-99/0010: MKT BZ plus / BZ-IG

Installation parameters

Thread M10

Diameter of drill hole d0 = 10 mm

Depth of drill hole h1 = 75 mm

Effective anchorage depth hef = 60 mm

Installation torque Tinst = 35 Nm

Width across nut SW = 17 mm

Minimum thickness

of anchor base hmin = 120 mm

Diameter of clearance hole

in the fixture df ≤ 12 mm

Remarks

If the diameter df of the clearance hole does not correspond with the specifications in the assessment,

or with the design of slotted holes, follow the notes in [1], chapter 1.1.

The calculation regards data for standard thickness of concrete slab.

The design is based on the assumption that the anchor plate remains flat under the acting forces.

The proof of the capacity of the anchor base component shall be shown according to chapter 7 in [1].

The temperature ranges are specified in [2].

The selected anchor can be installed deeper to reduce the fixture thickness. Therfore the borehole shall

be drilled correspondingly deeper and the minimum thickness of anchor base must be checked.

The minimum thickness of the concrete member hmin increases by this deeper drilled length.

The calculation is valid for the following drilling method

- Vacuum drilling without cleaning

- Drilling followed by cleaning (with hammer drill, compressed air drill or vacuum drill)

The installation instruction shall be observed.

[1] ETAG 001, Annex C

[2] ETAG 001-1

Anchor Design Program Version 4.55

MKT Metall-Kunststoff-Technik GmbH & Co.KG | Auf dem Immel 2 | D-67685 Weilerbach | Tel.: +49 (0) 6374 / 9116-0 | support@mkt.de

You might also like

- Design Spreadsheet Gusset Plate Connection For TrussDocument4 pagesDesign Spreadsheet Gusset Plate Connection For TrussMatumbi Naito100% (1)

- Manual de Partes Soilmec sf50Document273 pagesManual de Partes Soilmec sf50pedroandres143100% (3)

- 01 GMK Features en Avr2007Document16 pages01 GMK Features en Avr2007Alonso Fernando100% (1)

- EXP-MN-SI020-EN-R0 - Measurements in Instrumentation PDFDocument114 pagesEXP-MN-SI020-EN-R0 - Measurements in Instrumentation PDFbali100% (3)

- C-End Bottom Bracket ReportDocument4 pagesC-End Bottom Bracket ReportMohammed AyeshNo ratings yet

- A-Bottom-Bracket ReportDocument4 pagesA-Bottom-Bracket ReportMohammed AyeshNo ratings yet

- E-End Tocket ReportDocument4 pagesE-End Tocket ReportMohammed AyeshNo ratings yet

- Design Office: Person in Charge: Construction Project: Number: Position: Date: 1/26/2017Document3 pagesDesign Office: Person in Charge: Construction Project: Number: Position: Date: 1/26/2017jasekan.dcNo ratings yet

- Design Office: Person in Charge: Construction Project: Project Number: Position: Date: 5/8/2019Document4 pagesDesign Office: Person in Charge: Construction Project: Project Number: Position: Date: 5/8/2019ahmedebnnaderNo ratings yet

- Exp MiddleDocument4 pagesExp MiddleahmedebnnaderNo ratings yet

- VMH AnchorDocument4 pagesVMH Anchormohamed rafiNo ratings yet

- Design Office: Person in Charge: Construction Project: Project Number: Position: Date: 9/20/2021Document4 pagesDesign Office: Person in Charge: Construction Project: Project Number: Position: Date: 9/20/2021Asaru DeenNo ratings yet

- Design Office: Invention Steel Industries Person in Charge: YJT Construction Project: Sqm-Nizwa Number: 0811 Position: Date: 7/22/2014Document4 pagesDesign Office: Invention Steel Industries Person in Charge: YJT Construction Project: Sqm-Nizwa Number: 0811 Position: Date: 7/22/2014yusuf_jtNo ratings yet

- 2.2.2-2 - DQR - SS - Cleat Angle Capacity-Rev BDocument10 pages2.2.2-2 - DQR - SS - Cleat Angle Capacity-Rev BSANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- Design of Inlet ChamberDocument2 pagesDesign of Inlet ChamberRaju SainiNo ratings yet

- Aci-PunchingDocument5 pagesAci-PunchingAbdalrhman Al khateebNo ratings yet

- Practical Lesson 4Document11 pagesPractical Lesson 4marjory.dezNo ratings yet

- Group 12 p1Document3 pagesGroup 12 p1SM WorldNo ratings yet

- Civil Structural CalculationsDocument2 pagesCivil Structural Calculations3d arch viewsNo ratings yet

- EndPl MomConn LSDDocument54 pagesEndPl MomConn LSDTony RoseNo ratings yet

- 2.2.2-1 - DQR - SS Capacity-Rev BDocument27 pages2.2.2-1 - DQR - SS Capacity-Rev BSANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- 1 Input Data: WWW - Hilti.chDocument5 pages1 Input Data: WWW - Hilti.chkikorrasNo ratings yet

- 2.2.2-1 - DQR - SS Capacity-Rev B1Document87 pages2.2.2-1 - DQR - SS Capacity-Rev B1SANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- Welding CheckingDocument1 pageWelding Checkingxlw955597No ratings yet

- Drawing & Design GantryDocument27 pagesDrawing & Design Gantrysita ram doraNo ratings yet

- Concrete: Input DataDocument4 pagesConcrete: Input DataARYANo ratings yet

- Drafts - Concrete - Apr 12, 2024Document9 pagesDrafts - Concrete - Apr 12, 2024ronwellgutierrezdeleonNo ratings yet

- EA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Document2 pagesEA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Imaduddin KhajaNo ratings yet

- V F B D : Punching Shear Check (ACI 318RM-02)Document1 pageV F B D : Punching Shear Check (ACI 318RM-02)OktayNo ratings yet

- Group 12 p2Document2 pagesGroup 12 p2SM WorldNo ratings yet

- Etabs Column Design MT CalculationDocument2 pagesEtabs Column Design MT CalculationAung SoneNo ratings yet

- Slab Design - OkDocument35 pagesSlab Design - OkazwanNo ratings yet

- Tests - Concrete - Apr 1, 2020Document7 pagesTests - Concrete - Apr 1, 2020Chris MedeirosNo ratings yet

- Deflection Check For SlabDocument1 pageDeflection Check For Slabselvakumar sNo ratings yet

- I. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Document30 pagesI. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Anh KyNo ratings yet

- Drafts - Concrete - Aug 9, 2023Document10 pagesDrafts - Concrete - Aug 9, 2023nguyennovoiNo ratings yet

- I. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Document30 pagesI. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Anh KyNo ratings yet

- 1 Input Data: Profis Anchor 2.5.2Document6 pages1 Input Data: Profis Anchor 2.5.2jasekanNo ratings yet

- 4.1.5.SP ConnectionDocument30 pages4.1.5.SP ConnectionAnh KyNo ratings yet

- Base Plate CalculationDocument10 pagesBase Plate CalculationPradip NikamNo ratings yet

- Centre Post Base Hilti CalculationDocument10 pagesCentre Post Base Hilti CalculationKesavarajNo ratings yet

- 1177 01 Second Floor Exterior Wall.Document2 pages1177 01 Second Floor Exterior Wall.Trà My BùiNo ratings yet

- Slab For Lift ProjectDocument2 pagesSlab For Lift ProjectAnonymous ptLRLiNNNo ratings yet

- Welding Calculation: Job No. Job: Section: Designed By: Sheet No. Subject: DateDocument37 pagesWelding Calculation: Job No. Job: Section: Designed By: Sheet No. Subject: DateMatthew CHANNo ratings yet

- Calculation Sheet For Spit Anchors: ProjectDocument4 pagesCalculation Sheet For Spit Anchors: ProjectshoebNo ratings yet

- Lintel DesignDocument3 pagesLintel DesignPrashant HuddarNo ratings yet

- EC3-Design of Rectangular Base PlateDocument10 pagesEC3-Design of Rectangular Base PlateCường NguyễnNo ratings yet

- Ridge Connection Design RSP-1.Document121 pagesRidge Connection Design RSP-1.Asaru DeenNo ratings yet

- Drafts - Concrete - Aug 8, 2022Document14 pagesDrafts - Concrete - Aug 8, 2022Upendra WalinjkarNo ratings yet

- Slab DesignDocument38 pagesSlab Designmathewsujith31No ratings yet

- 1 Input Data: WWW - Hilti.inDocument8 pages1 Input Data: WWW - Hilti.inAniket InarkarNo ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- EC4-Composite Column H-SectionDocument7 pagesEC4-Composite Column H-SectionCường NguyễnNo ratings yet

- 1 Input Data: WWW - Hilti.chDocument5 pages1 Input Data: WWW - Hilti.chkikorrasNo ratings yet

- I. Material E7Xt 35 1 Ii. Internal Force For Calculating 432 Iii. Dimension 500 500 35 35 6743Document2 pagesI. Material E7Xt 35 1 Ii. Internal Force For Calculating 432 Iii. Dimension 500 500 35 35 6743Anh KyNo ratings yet

- Option-2 - Chemical Base AnchorDocument5 pagesOption-2 - Chemical Base AnchorvengadNo ratings yet

- 2.3.3 - DQR - DS Capacity-Rev B2Document33 pages2.3.3 - DQR - DS Capacity-Rev B2Sudip ShresthaNo ratings yet

- Knoor - Bracing - Side Plate 2Document10 pagesKnoor - Bracing - Side Plate 2borceNo ratings yet

- Column Inter at Ion DiagramDocument7 pagesColumn Inter at Ion DiagramPremasiri KarunarathnaNo ratings yet

- Checking:: Isolated Foundation (F-1) (ACI 318M-95)Document1 pageChecking:: Isolated Foundation (F-1) (ACI 318M-95)taz_taz3No ratings yet

- Circular Column2Document52 pagesCircular Column2BehroozNo ratings yet

- Column DesignDocument98 pagesColumn DesignJessa OpenianoNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Section 08 70 00 - HardwareDocument9 pagesSection 08 70 00 - HardwareMohammed AyeshNo ratings yet

- B TketDocument8 pagesB TketMohammed AyeshNo ratings yet

- A BoracketDocument8 pagesA BoracketMohammed AyeshNo ratings yet

- B-End Bottom Bracket - Door MullionDocument8 pagesB-End Bottom Bracket - Door MullionMohammed AyeshNo ratings yet

- A-Bottom-Bracket ReportDocument4 pagesA-Bottom-Bracket ReportMohammed AyeshNo ratings yet

- Section 08 30 00 - Specialty Doors and FramesDocument7 pagesSection 08 30 00 - Specialty Doors and FramesMohammed AyeshNo ratings yet

- C-End Bottom Bracket ReportDocument4 pagesC-End Bottom Bracket ReportMohammed AyeshNo ratings yet

- E-End Tocket ReportDocument4 pagesE-End Tocket ReportMohammed AyeshNo ratings yet

- Doors 1Document1 pageDoors 1Mohammed AyeshNo ratings yet

- Method of Construction - Facade WorksDocument2 pagesMethod of Construction - Facade WorksMohammed AyeshNo ratings yet

- Section TableDocument4 pagesSection TableMohammed AyeshNo ratings yet

- C - Bottom BracketDocument9 pagesC - Bottom BracketMohammed AyeshNo ratings yet

- Aluminum Design Manual-24Document1 pageAluminum Design Manual-24Mohammed AyeshNo ratings yet

- Aluminum Specification & Qty0001Document3 pagesAluminum Specification & Qty0001Mohammed AyeshNo ratings yet

- 1Document1 page1Mohammed AyeshNo ratings yet

- Brackets Reaction TableDocument3 pagesBrackets Reaction TableMohammed AyeshNo ratings yet

- Cladding DetailDocument1 pageCladding DetailMohammed AyeshNo ratings yet

- (Cedsr-92074) Jvt07iohr001 - 83Document2 pages(Cedsr-92074) Jvt07iohr001 - 83Mohammed AyeshNo ratings yet

- Mushrabia Cast - No. 5Document6 pagesMushrabia Cast - No. 5Mohammed AyeshNo ratings yet

- Arch Issued For Information-Roof Floor l39Document1 pageArch Issued For Information-Roof Floor l39Mohammed AyeshNo ratings yet

- Louver With DeviderDocument4 pagesLouver With DeviderMohammed AyeshNo ratings yet

- High Strength Hexagon Bolts (JIS B1186)Document4 pagesHigh Strength Hexagon Bolts (JIS B1186)Mario HanamiciNo ratings yet

- Presentation Acoustic To Electric ConversionDocument16 pagesPresentation Acoustic To Electric ConversionHarsh PatelNo ratings yet

- A Review Paper On Abrasive Wear CharacteristicsDocument6 pagesA Review Paper On Abrasive Wear CharacteristicsSalem GarrabNo ratings yet

- Xpulse200t Manual de PartesDocument92 pagesXpulse200t Manual de PartesAthiq Nehman100% (2)

- Astm f1007 1986 PDFDocument6 pagesAstm f1007 1986 PDFHsaam HsaamNo ratings yet

- Project ProposalDocument6 pagesProject ProposalVivek Kumar SinghNo ratings yet

- Recycling Passport: Model EL125TDocument4 pagesRecycling Passport: Model EL125TDonNo ratings yet

- AED Certificate (O-Ring and Non-Metallic Sealing)Document2 pagesAED Certificate (O-Ring and Non-Metallic Sealing)mattarchiNo ratings yet

- 4 - Engineering Geology and Soil Mechanics - Chapter 5 - Permeability and SeepageDocument35 pages4 - Engineering Geology and Soil Mechanics - Chapter 5 - Permeability and Seepagehessian123No ratings yet

- Surface Preparation Metallizing ProcedureDocument6 pagesSurface Preparation Metallizing ProcedureCorrosion FactoryNo ratings yet

- Mechismo 2022Document44 pagesMechismo 2022NAGARAJUNo ratings yet

- 2009 Handok Hydraulic Catalog PDFDocument33 pages2009 Handok Hydraulic Catalog PDFElver RiveraNo ratings yet

- 3 Ton 36000 BTUs Split Air ConditionersDocument2 pages3 Ton 36000 BTUs Split Air ConditionersNayif MuhammedNo ratings yet

- 3 Ii-IiDocument105 pages3 Ii-IiMrHEMAMAHEHNo ratings yet

- Super Magnet Braking System (Report) PDFDocument57 pagesSuper Magnet Braking System (Report) PDFsrinivasarao katari100% (2)

- behi2017Cu-Water Investigation of PCM-assisted Heat Pipe For Electronic CoolingDocument11 pagesbehi2017Cu-Water Investigation of PCM-assisted Heat Pipe For Electronic CoolingTobin MohanNo ratings yet

- Stihl Ts500i Service Manual Stihl PDFDocument118 pagesStihl Ts500i Service Manual Stihl PDFBruce MacDonaldNo ratings yet

- AVENSISDocument20 pagesAVENSISAbdolkarim Pahliani100% (1)

- Unit I MCQ Ii-2Document7 pagesUnit I MCQ Ii-2Kavitha Pasumalaithevan0% (1)

- Geotehnics of SoftsoilDocument44 pagesGeotehnics of SoftsoilVinna RinayaniNo ratings yet

- Mechanical Data Sheet: LG / Oiec / Ioec ConsortiumDocument9 pagesMechanical Data Sheet: LG / Oiec / Ioec ConsortiumatemtutemNo ratings yet

- Industrial Gearbox Service ManualDocument36 pagesIndustrial Gearbox Service ManualNovriansyah Brian100% (1)

- Roller Chain SprocketDocument10 pagesRoller Chain SprocketMelindaNo ratings yet

- Flange Gaskets: Chesterton® Gasket Centers Chesterton® Gasket CentersDocument4 pagesFlange Gaskets: Chesterton® Gasket Centers Chesterton® Gasket CentersjaviervbNo ratings yet

- Front Suspension PDFDocument19 pagesFront Suspension PDFspeedkar9No ratings yet

- Yamaha YJ50 Service Manual PDFDocument228 pagesYamaha YJ50 Service Manual PDFดิษย์ธีเดช ชีวาอัครพัฒน์No ratings yet

- DWR May 2021Document28 pagesDWR May 2021Mario MilicevicNo ratings yet