Professional Documents

Culture Documents

EOQ Formula and EOQ Factors

EOQ Formula and EOQ Factors

Uploaded by

JennelCopyright:

Available Formats

You might also like

- Surviving the Spare Parts Crisis: Maintenance Storeroom and Inventory ControlFrom EverandSurviving the Spare Parts Crisis: Maintenance Storeroom and Inventory ControlNo ratings yet

- A Pigskin Revolution - Consultant SummaryDocument1 pageA Pigskin Revolution - Consultant Summaryrashi100% (1)

- SCM Book - Part18 - Part1Document2 pagesSCM Book - Part18 - Part1JustNo ratings yet

- HHLL Trading StrategyDocument15 pagesHHLL Trading Strategyachiro0707100% (2)

- What Is EOQ?Document10 pagesWhat Is EOQ?JunaidNo ratings yet

- Economic Order QuantityDocument4 pagesEconomic Order QuantityAasishPatilNo ratings yet

- Economic Order Quantity (EOQ) Is A Decision Tool Used in Cost Accounting. It's A Formula ThatDocument2 pagesEconomic Order Quantity (EOQ) Is A Decision Tool Used in Cost Accounting. It's A Formula ThatOKELLONo ratings yet

- Economic Order QuantityDocument10 pagesEconomic Order Quantitypapia rahman100% (1)

- Economic Order QuantityDocument6 pagesEconomic Order QuantityJelay QuilatanNo ratings yet

- Topic 3 Inventory Management - 2Document46 pagesTopic 3 Inventory Management - 221124014No ratings yet

- Inventory Management-1Document4 pagesInventory Management-1lolli lollipop100% (1)

- EOQ, Reorder, Safety Stock ExplainedDocument3 pagesEOQ, Reorder, Safety Stock ExplainedAnne CaloNo ratings yet

- Formula and Calculation of Economic Order Quantity (EOQ)Document7 pagesFormula and Calculation of Economic Order Quantity (EOQ)harpominder100% (1)

- Inventory: Economic Order QuantityDocument11 pagesInventory: Economic Order QuantitySolomon GetachewNo ratings yet

- Replenishment System: Lead TimeDocument5 pagesReplenishment System: Lead TimenoblemanimalaNo ratings yet

- Working Capital Management - Management of Accounts Receivable & InventoryDocument13 pagesWorking Capital Management - Management of Accounts Receivable & InventoryJean Pierre IsipNo ratings yet

- Economic Order Quantity EOQDocument8 pagesEconomic Order Quantity EOQAngelo CruzNo ratings yet

- PBE II Inventory Management Eric LeungDocument6 pagesPBE II Inventory Management Eric LeungsagartopuNo ratings yet

- Economic Order QuantityDocument3 pagesEconomic Order QuantityBala Murugan MoorthyNo ratings yet

- 01 03 2022Document6 pages01 03 2022Noor HossainNo ratings yet

- Inventory ManagementDocument6 pagesInventory ManagementMarc Jervin BitongNo ratings yet

- Economic Order QuantityDocument6 pagesEconomic Order Quantitynishnick100% (2)

- Module 3 Management ScienceDocument10 pagesModule 3 Management ScienceGenesis RoldanNo ratings yet

- The Formula For Economic Order Quantity (EOQ)Document2 pagesThe Formula For Economic Order Quantity (EOQ)Walid AhmedNo ratings yet

- Economic Order QuantityDocument3 pagesEconomic Order QuantitySudhakar DoijadNo ratings yet

- Chapter 2 - Single Item - Demand Varying at Approximate LevelDocument49 pagesChapter 2 - Single Item - Demand Varying at Approximate LevelminhduyNo ratings yet

- Economic Order Quantit1Document2 pagesEconomic Order Quantit1prachi goelNo ratings yet

- Chapter 10 Order QuantitiesDocument5 pagesChapter 10 Order QuantitiesKamble AbhijitNo ratings yet

- InventoriesDocument32 pagesInventoriesdukegcNo ratings yet

- Acctg For MaterialsDocument12 pagesAcctg For MaterialsFilnara RaguroNo ratings yet

- Lecturing 5 Eoq and RopDocument8 pagesLecturing 5 Eoq and RopJohn StephensNo ratings yet

- Corporate Accounting & Costing: Dr. Deepak SharmaDocument13 pagesCorporate Accounting & Costing: Dr. Deepak SharmaDr. Deepak SharmaNo ratings yet

- CP EOQ CalculationDocument3 pagesCP EOQ CalculationSaidi GwauNo ratings yet

- Sessions 1 & 2-Inventory MGMTDocument53 pagesSessions 1 & 2-Inventory MGMTojasshukla15No ratings yet

- Economic Ordering Quantities: A Practical Cost Reduction Strategy For Inventory ManagementDocument9 pagesEconomic Ordering Quantities: A Practical Cost Reduction Strategy For Inventory ManagementaskyeungNo ratings yet

- Adiotnal Notes-6Document6 pagesAdiotnal Notes-6yeteday615No ratings yet

- Economic Order Quantity (EOQ) : Name:Syed Ahsan Raza Roll no:L1F19BSAF0065 Section:BDocument3 pagesEconomic Order Quantity (EOQ) : Name:Syed Ahsan Raza Roll no:L1F19BSAF0065 Section:BAhsan RazaNo ratings yet

- Material de Inventarios1Document13 pagesMaterial de Inventarios1wam30959No ratings yet

- MOOC1Mod 2L1 3Document62 pagesMOOC1Mod 2L1 3akankshaNo ratings yet

- Pom 507 Production & Operation Management - Istiaqur Rahman ChowdhuryDocument5 pagesPom 507 Production & Operation Management - Istiaqur Rahman ChowdhuryIstiaqNo ratings yet

- WC4 - Inventory - StudentDocument20 pagesWC4 - Inventory - Studentammadey21@gmail.comNo ratings yet

- MATERIALS MANAGEMENT and EOQ ModelDocument40 pagesMATERIALS MANAGEMENT and EOQ ModelIsaac OwusuNo ratings yet

- Module 2-Class 1 - 5370832 - 2024 - 01 - 21 - 14 - 10Document39 pagesModule 2-Class 1 - 5370832 - 2024 - 01 - 21 - 14 - 10Shajathkhan Bin Syed UsmanNo ratings yet

- WCM - FMDocument35 pagesWCM - FMAbhijeet ChandraNo ratings yet

- OPERATIONS MANAGEMENT-Inventory Models For Independent DemandDocument20 pagesOPERATIONS MANAGEMENT-Inventory Models For Independent DemandNina Oaip100% (1)

- Day 2 MaterialDocument13 pagesDay 2 Materialvinhvu1509No ratings yet

- Chapter 2 - Single ItemlDocument49 pagesChapter 2 - Single ItemlBùi Quang MinhNo ratings yet

- Inventory Models: For Independent DemandDocument22 pagesInventory Models: For Independent DemandFranklin MendozaNo ratings yet

- (Economic Order Quantity) : HhheoqDocument22 pages(Economic Order Quantity) : HhheoqfarhanNo ratings yet

- Ch-05 Material Inventory Controls (Online Class)Document6 pagesCh-05 Material Inventory Controls (Online Class)shayan zamanNo ratings yet

- Assignment Submission Date: May 25,2021Document81 pagesAssignment Submission Date: May 25,2021Shahana AfrozNo ratings yet

- Opm Assignment 2019-1-95-114Document24 pagesOpm Assignment 2019-1-95-114NavidEhsan100% (2)

- Aamm Assmt2 PDFDocument11 pagesAamm Assmt2 PDFSulogna SikidarNo ratings yet

- Economic Order Quantity and Optimum CashDocument7 pagesEconomic Order Quantity and Optimum CashAlexis Jaina TinaanNo ratings yet

- Inventory ManagementDocument13 pagesInventory ManagementMohoua SRNo ratings yet

- EOQDocument6 pagesEOQRakesh PradhanNo ratings yet

- Economic Order QuantityDocument18 pagesEconomic Order Quantitytgm21031983No ratings yet

- Inventory Management Practice Problems On EOQ Problem-Tutorial For BfeDocument5 pagesInventory Management Practice Problems On EOQ Problem-Tutorial For BfeBoy hwNo ratings yet

- Inventory ManagementDocument8 pagesInventory Managementsouhardya.research.1No ratings yet

- Economic Order QuantityDocument3 pagesEconomic Order QuantityAkshay KumarNo ratings yet

- Management Accounting: Decision-Making by Numbers: Business Strategy & Competitive AdvantageFrom EverandManagement Accounting: Decision-Making by Numbers: Business Strategy & Competitive AdvantageRating: 5 out of 5 stars5/5 (1)

- An MBA in a Book: Everything You Need to Know to Master Business - In One Book!From EverandAn MBA in a Book: Everything You Need to Know to Master Business - In One Book!No ratings yet

- The Entrepreneur’S Dictionary of Business and Financial TermsFrom EverandThe Entrepreneur’S Dictionary of Business and Financial TermsNo ratings yet

- Target-CostDocument3 pagesTarget-CostJennelNo ratings yet

- What Is The Importance of Financial ManagementDocument6 pagesWhat Is The Importance of Financial ManagementJennelNo ratings yet

- Business-PlanDocument5 pagesBusiness-PlanJennelNo ratings yet

- Quiz 3Document1 pageQuiz 3JennelNo ratings yet

- Inventory Management Feb. 7Document7 pagesInventory Management Feb. 7JennelNo ratings yet

- .Target ProfitDocument2 pages.Target ProfitJennelNo ratings yet

- Unit-CostDocument3 pagesUnit-CostJennelNo ratings yet

- Human Rights - BasicsDocument8 pagesHuman Rights - BasicsJennelNo ratings yet

- Historical Development of Art: ObjectivesDocument7 pagesHistorical Development of Art: ObjectivesJennelNo ratings yet

- Research Example - JennelDocument37 pagesResearch Example - JennelJennelNo ratings yet

- Why Milk Tea Franchise Business Is A Good Investment - Fab Caffe Frappe Coffee & Milk Tea Franchise PhilippinesDocument8 pagesWhy Milk Tea Franchise Business Is A Good Investment - Fab Caffe Frappe Coffee & Milk Tea Franchise PhilippinesJennelNo ratings yet

- Ensilo/Fortiedr: Course DescriptionDocument2 pagesEnsilo/Fortiedr: Course DescriptionhoadiNo ratings yet

- Problem Set 3Document2 pagesProblem Set 3Omar SrourNo ratings yet

- Salem Analytics Panera Bread Company Final ReportDocument31 pagesSalem Analytics Panera Bread Company Final ReportCecille TaguiamNo ratings yet

- Women in CryptoDocument26 pagesWomen in CryptoRodrix DigitalNo ratings yet

- April 12, 2023 April 30, 2023: Credit Card StatementDocument4 pagesApril 12, 2023 April 30, 2023: Credit Card StatementRaja KumarNo ratings yet

- Philippines, Inc. v. Secretary of Agrarian Reform (1989), The Court Declared ThatDocument53 pagesPhilippines, Inc. v. Secretary of Agrarian Reform (1989), The Court Declared ThatChap ChoyNo ratings yet

- Survey Report On Sole ProprietorDocument42 pagesSurvey Report On Sole Proprietorsumit pujari91% (23)

- Making The Quantum LeapDocument22 pagesMaking The Quantum LeapRJ DeLongNo ratings yet

- Consumer Information:: Cibiltusc3Document11 pagesConsumer Information:: Cibiltusc3Ajit KumarNo ratings yet

- He Gave Up A Promising Law Career To Focus On His Public Speaking BusinessDocument6 pagesHe Gave Up A Promising Law Career To Focus On His Public Speaking BusinessFaruque FerdowsNo ratings yet

- CB Chapter 15 AnswerDocument5 pagesCB Chapter 15 AnswerSim Pei YingNo ratings yet

- ExxonMobil PD-5340Document2 pagesExxonMobil PD-5340蔡佾呈No ratings yet

- Adsense Tips: (Collection of Adsense Tips and How To Articles) This Book Is Compiled byDocument46 pagesAdsense Tips: (Collection of Adsense Tips and How To Articles) This Book Is Compiled byJ.Ulrich Mamphayssou N'GUESSANNo ratings yet

- External Environment Analysis: Political FactorsDocument9 pagesExternal Environment Analysis: Political FactorsamitNo ratings yet

- Advocacy On Anti Investment Scams ADZU 2022Document29 pagesAdvocacy On Anti Investment Scams ADZU 2022Ridz TingkahanNo ratings yet

- Labour LawDocument11 pagesLabour LawNaveen Verma100% (1)

- Chapter 3 Financial MarketsDocument29 pagesChapter 3 Financial MarketsHoy HoyNo ratings yet

- Leonardo Cross Belt Sorter For AirportDocument4 pagesLeonardo Cross Belt Sorter For AirportraptorNo ratings yet

- Letter From ExporterDocument2 pagesLetter From Exporterdeepak.kadindustriesNo ratings yet

- Business Analytics and Intelligence From IIM-BengaluruDocument12 pagesBusiness Analytics and Intelligence From IIM-BengaluruCorpsalesNo ratings yet

- Team 2 - Company DataDocument30 pagesTeam 2 - Company DatakshiNo ratings yet

- Solutions Manual To Accompany Multivariate Data Analysis 7th Edition 9780138132637Document32 pagesSolutions Manual To Accompany Multivariate Data Analysis 7th Edition 9780138132637drearingpuncheonrpeal100% (47)

- 250,000 300,000 400,000 500,000 Cash Flow: Year 1 2 3 4Document9 pages250,000 300,000 400,000 500,000 Cash Flow: Year 1 2 3 4Kai ZhaoNo ratings yet

- Thesis Presentation - 5D BIMDocument17 pagesThesis Presentation - 5D BIMAddress AdvisorsNo ratings yet

- Effect of Advertisement On ConsumersDocument59 pagesEffect of Advertisement On Consumersvishal394% (49)

- Questions: Download More at WWW - Ebookskenya.co - KeDocument38 pagesQuestions: Download More at WWW - Ebookskenya.co - KeSamielMuhamedOmarNo ratings yet

- Currency Exchange Rate and International Trade and Capital FlowsDocument39 pagesCurrency Exchange Rate and International Trade and Capital FlowsudNo ratings yet

EOQ Formula and EOQ Factors

EOQ Formula and EOQ Factors

Uploaded by

JennelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EOQ Formula and EOQ Factors

EOQ Formula and EOQ Factors

Uploaded by

JennelCopyright:

Available Formats

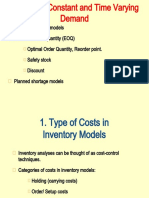

EOQ formula and EOQ factors

The EOQ formula is as follows.

EOQ = Square root of [(2 x demand x ordering cost) / carrying cost]

Demand

The demand remains constant according to the assumptions made by EOQ. The demand is how

much inventory is used per year or how many units are sold per year.

Ordering cost

The EOQ formula contains the ordering cost which is a fixed cost. This is how much you spend

on placing and then receiving your order. This cost includes all the resources you need to put into

receiving the order. For instance, making calls, sending reminder emails, and taking delivery-

related costs are used to calculate the ordering cost. It includes the time it takes for the order to

reach you as well. Ordering cost can be calculated by dividing the demand per year by volume

per order. When you have to pay a fixed amount for the order regardless of order quantity, you

can calculate ordering cost per year by dividing demand per year by volume per order multiplied

by set cost.

Carrying cost

The carrying cost is also known as the storage cost or holding cost of inventory. It is what you

need to spend to store your inventory in a warehouse. The carrying cost includes warehouse fees

and opportunity costs. If the inventory is destroyed or stolen from the warehouse then it can be a

part of the carrying cost. If you are paying interest to purchase inventory, then the amount you

are paying to the bank should be made part of the carrying costs. The insurance costs with regard

to the inventory are also taken into account in carrying cost calculation. Carrying costs are

variable costs as they will depend on your inventory.

EOQ formula example

EOQ formula is best understood with a simple example. Let us say that you are a dog products

retailer. You sell leashes, muzzles, brushes, treats, collars, chews, bowls, dog food, and more.

You want to know how much inventory of designer collars you should keep. You sell each

designer collar for $7. In a month you sell 30 collars which equate to 360 collars per year. The

ordering cost is $10 per order because you are taking into account the processing time and people

who work for you. The carrying cost for collars is $2 per unit and this includes the opportunity

cost.

Here is how the economic order quantity is calculated for this scenario.

EOQ = Square root of [(2 x demand x ordering cost) / carrying cost]

EOQ = Square root of [(2 x 360 x 10) / 2]

EOQ = Square root of [3600]

EOQ = Square root of [3600]

EOQ = 60

This means you need to have at least 60 collars in the inventory to ensure you are rightly stocked

at any given time. You can use the same EOQ formula to calculate how many leashes, muzzles,

treats, and chews you should keep so you avoid understocking and overstocking.

You might also like

- Surviving the Spare Parts Crisis: Maintenance Storeroom and Inventory ControlFrom EverandSurviving the Spare Parts Crisis: Maintenance Storeroom and Inventory ControlNo ratings yet

- A Pigskin Revolution - Consultant SummaryDocument1 pageA Pigskin Revolution - Consultant Summaryrashi100% (1)

- SCM Book - Part18 - Part1Document2 pagesSCM Book - Part18 - Part1JustNo ratings yet

- HHLL Trading StrategyDocument15 pagesHHLL Trading Strategyachiro0707100% (2)

- What Is EOQ?Document10 pagesWhat Is EOQ?JunaidNo ratings yet

- Economic Order QuantityDocument4 pagesEconomic Order QuantityAasishPatilNo ratings yet

- Economic Order Quantity (EOQ) Is A Decision Tool Used in Cost Accounting. It's A Formula ThatDocument2 pagesEconomic Order Quantity (EOQ) Is A Decision Tool Used in Cost Accounting. It's A Formula ThatOKELLONo ratings yet

- Economic Order QuantityDocument10 pagesEconomic Order Quantitypapia rahman100% (1)

- Economic Order QuantityDocument6 pagesEconomic Order QuantityJelay QuilatanNo ratings yet

- Topic 3 Inventory Management - 2Document46 pagesTopic 3 Inventory Management - 221124014No ratings yet

- Inventory Management-1Document4 pagesInventory Management-1lolli lollipop100% (1)

- EOQ, Reorder, Safety Stock ExplainedDocument3 pagesEOQ, Reorder, Safety Stock ExplainedAnne CaloNo ratings yet

- Formula and Calculation of Economic Order Quantity (EOQ)Document7 pagesFormula and Calculation of Economic Order Quantity (EOQ)harpominder100% (1)

- Inventory: Economic Order QuantityDocument11 pagesInventory: Economic Order QuantitySolomon GetachewNo ratings yet

- Replenishment System: Lead TimeDocument5 pagesReplenishment System: Lead TimenoblemanimalaNo ratings yet

- Working Capital Management - Management of Accounts Receivable & InventoryDocument13 pagesWorking Capital Management - Management of Accounts Receivable & InventoryJean Pierre IsipNo ratings yet

- Economic Order Quantity EOQDocument8 pagesEconomic Order Quantity EOQAngelo CruzNo ratings yet

- PBE II Inventory Management Eric LeungDocument6 pagesPBE II Inventory Management Eric LeungsagartopuNo ratings yet

- Economic Order QuantityDocument3 pagesEconomic Order QuantityBala Murugan MoorthyNo ratings yet

- 01 03 2022Document6 pages01 03 2022Noor HossainNo ratings yet

- Inventory ManagementDocument6 pagesInventory ManagementMarc Jervin BitongNo ratings yet

- Economic Order QuantityDocument6 pagesEconomic Order Quantitynishnick100% (2)

- Module 3 Management ScienceDocument10 pagesModule 3 Management ScienceGenesis RoldanNo ratings yet

- The Formula For Economic Order Quantity (EOQ)Document2 pagesThe Formula For Economic Order Quantity (EOQ)Walid AhmedNo ratings yet

- Economic Order QuantityDocument3 pagesEconomic Order QuantitySudhakar DoijadNo ratings yet

- Chapter 2 - Single Item - Demand Varying at Approximate LevelDocument49 pagesChapter 2 - Single Item - Demand Varying at Approximate LevelminhduyNo ratings yet

- Economic Order Quantit1Document2 pagesEconomic Order Quantit1prachi goelNo ratings yet

- Chapter 10 Order QuantitiesDocument5 pagesChapter 10 Order QuantitiesKamble AbhijitNo ratings yet

- InventoriesDocument32 pagesInventoriesdukegcNo ratings yet

- Acctg For MaterialsDocument12 pagesAcctg For MaterialsFilnara RaguroNo ratings yet

- Lecturing 5 Eoq and RopDocument8 pagesLecturing 5 Eoq and RopJohn StephensNo ratings yet

- Corporate Accounting & Costing: Dr. Deepak SharmaDocument13 pagesCorporate Accounting & Costing: Dr. Deepak SharmaDr. Deepak SharmaNo ratings yet

- CP EOQ CalculationDocument3 pagesCP EOQ CalculationSaidi GwauNo ratings yet

- Sessions 1 & 2-Inventory MGMTDocument53 pagesSessions 1 & 2-Inventory MGMTojasshukla15No ratings yet

- Economic Ordering Quantities: A Practical Cost Reduction Strategy For Inventory ManagementDocument9 pagesEconomic Ordering Quantities: A Practical Cost Reduction Strategy For Inventory ManagementaskyeungNo ratings yet

- Adiotnal Notes-6Document6 pagesAdiotnal Notes-6yeteday615No ratings yet

- Economic Order Quantity (EOQ) : Name:Syed Ahsan Raza Roll no:L1F19BSAF0065 Section:BDocument3 pagesEconomic Order Quantity (EOQ) : Name:Syed Ahsan Raza Roll no:L1F19BSAF0065 Section:BAhsan RazaNo ratings yet

- Material de Inventarios1Document13 pagesMaterial de Inventarios1wam30959No ratings yet

- MOOC1Mod 2L1 3Document62 pagesMOOC1Mod 2L1 3akankshaNo ratings yet

- Pom 507 Production & Operation Management - Istiaqur Rahman ChowdhuryDocument5 pagesPom 507 Production & Operation Management - Istiaqur Rahman ChowdhuryIstiaqNo ratings yet

- WC4 - Inventory - StudentDocument20 pagesWC4 - Inventory - Studentammadey21@gmail.comNo ratings yet

- MATERIALS MANAGEMENT and EOQ ModelDocument40 pagesMATERIALS MANAGEMENT and EOQ ModelIsaac OwusuNo ratings yet

- Module 2-Class 1 - 5370832 - 2024 - 01 - 21 - 14 - 10Document39 pagesModule 2-Class 1 - 5370832 - 2024 - 01 - 21 - 14 - 10Shajathkhan Bin Syed UsmanNo ratings yet

- WCM - FMDocument35 pagesWCM - FMAbhijeet ChandraNo ratings yet

- OPERATIONS MANAGEMENT-Inventory Models For Independent DemandDocument20 pagesOPERATIONS MANAGEMENT-Inventory Models For Independent DemandNina Oaip100% (1)

- Day 2 MaterialDocument13 pagesDay 2 Materialvinhvu1509No ratings yet

- Chapter 2 - Single ItemlDocument49 pagesChapter 2 - Single ItemlBùi Quang MinhNo ratings yet

- Inventory Models: For Independent DemandDocument22 pagesInventory Models: For Independent DemandFranklin MendozaNo ratings yet

- (Economic Order Quantity) : HhheoqDocument22 pages(Economic Order Quantity) : HhheoqfarhanNo ratings yet

- Ch-05 Material Inventory Controls (Online Class)Document6 pagesCh-05 Material Inventory Controls (Online Class)shayan zamanNo ratings yet

- Assignment Submission Date: May 25,2021Document81 pagesAssignment Submission Date: May 25,2021Shahana AfrozNo ratings yet

- Opm Assignment 2019-1-95-114Document24 pagesOpm Assignment 2019-1-95-114NavidEhsan100% (2)

- Aamm Assmt2 PDFDocument11 pagesAamm Assmt2 PDFSulogna SikidarNo ratings yet

- Economic Order Quantity and Optimum CashDocument7 pagesEconomic Order Quantity and Optimum CashAlexis Jaina TinaanNo ratings yet

- Inventory ManagementDocument13 pagesInventory ManagementMohoua SRNo ratings yet

- EOQDocument6 pagesEOQRakesh PradhanNo ratings yet

- Economic Order QuantityDocument18 pagesEconomic Order Quantitytgm21031983No ratings yet

- Inventory Management Practice Problems On EOQ Problem-Tutorial For BfeDocument5 pagesInventory Management Practice Problems On EOQ Problem-Tutorial For BfeBoy hwNo ratings yet

- Inventory ManagementDocument8 pagesInventory Managementsouhardya.research.1No ratings yet

- Economic Order QuantityDocument3 pagesEconomic Order QuantityAkshay KumarNo ratings yet

- Management Accounting: Decision-Making by Numbers: Business Strategy & Competitive AdvantageFrom EverandManagement Accounting: Decision-Making by Numbers: Business Strategy & Competitive AdvantageRating: 5 out of 5 stars5/5 (1)

- An MBA in a Book: Everything You Need to Know to Master Business - In One Book!From EverandAn MBA in a Book: Everything You Need to Know to Master Business - In One Book!No ratings yet

- The Entrepreneur’S Dictionary of Business and Financial TermsFrom EverandThe Entrepreneur’S Dictionary of Business and Financial TermsNo ratings yet

- Target-CostDocument3 pagesTarget-CostJennelNo ratings yet

- What Is The Importance of Financial ManagementDocument6 pagesWhat Is The Importance of Financial ManagementJennelNo ratings yet

- Business-PlanDocument5 pagesBusiness-PlanJennelNo ratings yet

- Quiz 3Document1 pageQuiz 3JennelNo ratings yet

- Inventory Management Feb. 7Document7 pagesInventory Management Feb. 7JennelNo ratings yet

- .Target ProfitDocument2 pages.Target ProfitJennelNo ratings yet

- Unit-CostDocument3 pagesUnit-CostJennelNo ratings yet

- Human Rights - BasicsDocument8 pagesHuman Rights - BasicsJennelNo ratings yet

- Historical Development of Art: ObjectivesDocument7 pagesHistorical Development of Art: ObjectivesJennelNo ratings yet

- Research Example - JennelDocument37 pagesResearch Example - JennelJennelNo ratings yet

- Why Milk Tea Franchise Business Is A Good Investment - Fab Caffe Frappe Coffee & Milk Tea Franchise PhilippinesDocument8 pagesWhy Milk Tea Franchise Business Is A Good Investment - Fab Caffe Frappe Coffee & Milk Tea Franchise PhilippinesJennelNo ratings yet

- Ensilo/Fortiedr: Course DescriptionDocument2 pagesEnsilo/Fortiedr: Course DescriptionhoadiNo ratings yet

- Problem Set 3Document2 pagesProblem Set 3Omar SrourNo ratings yet

- Salem Analytics Panera Bread Company Final ReportDocument31 pagesSalem Analytics Panera Bread Company Final ReportCecille TaguiamNo ratings yet

- Women in CryptoDocument26 pagesWomen in CryptoRodrix DigitalNo ratings yet

- April 12, 2023 April 30, 2023: Credit Card StatementDocument4 pagesApril 12, 2023 April 30, 2023: Credit Card StatementRaja KumarNo ratings yet

- Philippines, Inc. v. Secretary of Agrarian Reform (1989), The Court Declared ThatDocument53 pagesPhilippines, Inc. v. Secretary of Agrarian Reform (1989), The Court Declared ThatChap ChoyNo ratings yet

- Survey Report On Sole ProprietorDocument42 pagesSurvey Report On Sole Proprietorsumit pujari91% (23)

- Making The Quantum LeapDocument22 pagesMaking The Quantum LeapRJ DeLongNo ratings yet

- Consumer Information:: Cibiltusc3Document11 pagesConsumer Information:: Cibiltusc3Ajit KumarNo ratings yet

- He Gave Up A Promising Law Career To Focus On His Public Speaking BusinessDocument6 pagesHe Gave Up A Promising Law Career To Focus On His Public Speaking BusinessFaruque FerdowsNo ratings yet

- CB Chapter 15 AnswerDocument5 pagesCB Chapter 15 AnswerSim Pei YingNo ratings yet

- ExxonMobil PD-5340Document2 pagesExxonMobil PD-5340蔡佾呈No ratings yet

- Adsense Tips: (Collection of Adsense Tips and How To Articles) This Book Is Compiled byDocument46 pagesAdsense Tips: (Collection of Adsense Tips and How To Articles) This Book Is Compiled byJ.Ulrich Mamphayssou N'GUESSANNo ratings yet

- External Environment Analysis: Political FactorsDocument9 pagesExternal Environment Analysis: Political FactorsamitNo ratings yet

- Advocacy On Anti Investment Scams ADZU 2022Document29 pagesAdvocacy On Anti Investment Scams ADZU 2022Ridz TingkahanNo ratings yet

- Labour LawDocument11 pagesLabour LawNaveen Verma100% (1)

- Chapter 3 Financial MarketsDocument29 pagesChapter 3 Financial MarketsHoy HoyNo ratings yet

- Leonardo Cross Belt Sorter For AirportDocument4 pagesLeonardo Cross Belt Sorter For AirportraptorNo ratings yet

- Letter From ExporterDocument2 pagesLetter From Exporterdeepak.kadindustriesNo ratings yet

- Business Analytics and Intelligence From IIM-BengaluruDocument12 pagesBusiness Analytics and Intelligence From IIM-BengaluruCorpsalesNo ratings yet

- Team 2 - Company DataDocument30 pagesTeam 2 - Company DatakshiNo ratings yet

- Solutions Manual To Accompany Multivariate Data Analysis 7th Edition 9780138132637Document32 pagesSolutions Manual To Accompany Multivariate Data Analysis 7th Edition 9780138132637drearingpuncheonrpeal100% (47)

- 250,000 300,000 400,000 500,000 Cash Flow: Year 1 2 3 4Document9 pages250,000 300,000 400,000 500,000 Cash Flow: Year 1 2 3 4Kai ZhaoNo ratings yet

- Thesis Presentation - 5D BIMDocument17 pagesThesis Presentation - 5D BIMAddress AdvisorsNo ratings yet

- Effect of Advertisement On ConsumersDocument59 pagesEffect of Advertisement On Consumersvishal394% (49)

- Questions: Download More at WWW - Ebookskenya.co - KeDocument38 pagesQuestions: Download More at WWW - Ebookskenya.co - KeSamielMuhamedOmarNo ratings yet

- Currency Exchange Rate and International Trade and Capital FlowsDocument39 pagesCurrency Exchange Rate and International Trade and Capital FlowsudNo ratings yet