Professional Documents

Culture Documents

SDV Vs ESDV

SDV Vs ESDV

Uploaded by

Vishal BhopaleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SDV Vs ESDV

SDV Vs ESDV

Uploaded by

Vishal BhopaleCopyright:

Available Formats

Shutdown Valve (SDV) Vs Emergency Shutdown Valve (ESDV)

The construction and accessories of Shutdown Valve (SDV) and Emergency

Shutdown Valve (ESDV) are similar.

What is the basis to distinguish their name?

Their name is distinguished only from their services.

Shutdown Valve referred to actuated valve which is closed during partial or total

process shutdown of system to which the valve protects.

Emergency Shutdown Valve is actuated valve which is closed when triggered by

signal from ESD level signal during emergency condition occurs.

Emergency Shutdown Valves are commonly located in incoming line and outgoing

line of the plant or platform.

Please note that some projects do not use term “ESDV” for tag numbering, instead

Term “SDV” is used for shutdown valve disregard their services. In this case,

shutdown logic diagram would indicate which actuated valve acts as Emergency

Shutdown Valve.

ESD valves are used to isolate the facilities in emergency situations. An ESD

(emergency shutdown) valve is a valve fitted with a spring return actuator, allowing

the valve to be closed by the actuator spring when the actuator pressure signal is

released.

Shutdown valves (SDV) are widely used to reduce the escalation of hazardous from

one system to another in the oil and gas production process for safe and proper

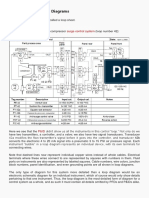

isolation purposes. General shutdown valve is controlled by a high integrity

Emergency Shutdown System (ESDS).

ESD valves are usually quarter turned ball valves, but they can also be sliding stem

gate valves or other types, although less common.

How does ESDV Works?

Full Open Position – Normal Operation

When the valve is in full open position, the ESDV offers limited pressure differential.

The full bore ball valve is essentially a tube that reduces the liquid friction of the

system.

Full Closed Position – Emergency Situation:

The setpoint pressure was surpassed and the ESDV was completely closed, providing

its double-seated model with a bubble-tightened shut-off.

Installation location of ESD valves

The ESD valves should be placed near the pipeline riser on larger plants, with a gap

of 15 meters between the ESD valves and the nearest system building.

The idea is to create an ESD “boundary” whereby all piping and vessels on the

“facility side” of the ESD valves would be depressured in an emergency situation and

the ESD valve is positioned far enough away from possible fire areas to ensure that

the valve is not enveloped in the blaze.

Based on the tube configuration, if the idealized design can not be accomplished, it

may be desirable to clad the exposed pressurized pipe with fireproof insulation to

mitigate the risk to this tube in an ESD situation.

You might also like

- Terminal Point List: Item No. Equip. NameDocument1 pageTerminal Point List: Item No. Equip. NameRadhika VeeralaNo ratings yet

- DRESSER Regulators FlowgridDocument12 pagesDRESSER Regulators Flowgridzalziza100% (1)

- PSV Sizing Tool API Based Calc Sheets PDFDocument11 pagesPSV Sizing Tool API Based Calc Sheets PDFLucas Farias0% (1)

- BDV ValvesDocument4 pagesBDV ValvesAmanda MartinezNo ratings yet

- Relieve Valve Types and OperationDocument11 pagesRelieve Valve Types and OperationBryan K. Aylas ParedesNo ratings yet

- PRV 2 Size Quick Start GuideDocument36 pagesPRV 2 Size Quick Start GuideAlcides Llanque ChoqueNo ratings yet

- ESDV Daeju ControlsDocument4 pagesESDV Daeju Controlsrieza_fNo ratings yet

- Design Philosophy-Process PipingDocument3 pagesDesign Philosophy-Process PipingWade ColemanNo ratings yet

- Data Sheet Control Valve FisherDocument9 pagesData Sheet Control Valve FisherFIRMANSYAHNo ratings yet

- Instrumentation Loop DiagramsDocument4 pagesInstrumentation Loop DiagramsVraja KisoriNo ratings yet

- Operation Philosophy ZLD-1 R-01Document11 pagesOperation Philosophy ZLD-1 R-01Ayon BoseNo ratings yet

- Control Valve DatasheetDocument1 pageControl Valve DatasheetretrogradesNo ratings yet

- PCV Data Sheet PDFDocument5 pagesPCV Data Sheet PDFveenaNo ratings yet

- Steam Blowing Steam Blowing Procedure PDFDocument11 pagesSteam Blowing Steam Blowing Procedure PDFAdelAbdElhamidNo ratings yet

- Depressuring Systems PDFDocument32 pagesDepressuring Systems PDFkumar_chemicalNo ratings yet

- Motor Operated ValveDocument2 pagesMotor Operated Valveprihartono_diasNo ratings yet

- Valves: Relief and Safety ValvesDocument22 pagesValves: Relief and Safety ValvesهانيزايدNo ratings yet

- 1.2. Sample - Datasheet Antisurge ValveDocument1 page1.2. Sample - Datasheet Antisurge ValveMuhammad FauzanNo ratings yet

- Introduction For Test Separator: CNPCIC Field ProductionDocument18 pagesIntroduction For Test Separator: CNPCIC Field Productionsalahadine maideNo ratings yet

- PSV Sizing ManualDocument10 pagesPSV Sizing ManualAkshay bhuranNo ratings yet

- PSV Calculation: Capacity Corection Factor Due To Back Pressure (KB)Document1 pagePSV Calculation: Capacity Corection Factor Due To Back Pressure (KB)syamsudin2006No ratings yet

- (P&id1) PDFDocument1 page(P&id1) PDFHatem FaroukNo ratings yet

- Product Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Document21 pagesProduct Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Gỗ MộcNo ratings yet

- Orifice Plate Sizing Calculation Using A New Labview TechniqueDocument6 pagesOrifice Plate Sizing Calculation Using A New Labview TechniquesyamsulNo ratings yet

- TSV CalculationDocument3 pagesTSV CalculationAymen Khlifi100% (1)

- Emergency Shutdown System Philosophy - ESD Logics - ESD Operations - Modo de LecturaDocument3 pagesEmergency Shutdown System Philosophy - ESD Logics - ESD Operations - Modo de LecturamafecamaraNo ratings yet

- Impact of Emergency Shutdown Devices On Relief System Sizing and Design PDFDocument21 pagesImpact of Emergency Shutdown Devices On Relief System Sizing and Design PDFB rgNo ratings yet

- P-I Transducer - P200-P290 PDFDocument4 pagesP-I Transducer - P200-P290 PDFman_y2kNo ratings yet

- Quick-Opening Closures SurveyDocument13 pagesQuick-Opening Closures SurveyAjmi HmidaNo ratings yet

- Control Valve Failure Relief Rate - Gas ServiceDocument3 pagesControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (2)

- 67CF Series Filter RegulatorsDocument8 pages67CF Series Filter RegulatorsAlberto CastellanosNo ratings yet

- Cartridge Filters: Technical Manual MT 080Document30 pagesCartridge Filters: Technical Manual MT 080abessiNo ratings yet

- Pressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeDocument2 pagesPressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeallovidNo ratings yet

- 10b - PSV Presentation Part 1 and 2Document27 pages10b - PSV Presentation Part 1 and 2Islam SolimanNo ratings yet

- Relief Valve - TypesDocument2 pagesRelief Valve - Typesyushveer002No ratings yet

- Emergency Shutdown System or ESD SystemDocument3 pagesEmergency Shutdown System or ESD Systemkamala 123No ratings yet

- Instrument Alarms, Trips and Set Points List: 0 1980 RPM 1980 RPM VAIDocument1 pageInstrument Alarms, Trips and Set Points List: 0 1980 RPM 1980 RPM VAInastyn-1No ratings yet

- Manual Flare Sim ExproDocument69 pagesManual Flare Sim ExproJuan Pablo Alonso100% (1)

- Sentry Tech BullDocument3 pagesSentry Tech BullFilipNo ratings yet

- Comparison of Line Pack Calculation Using Aspen Plus Dynamics and by Using Manual CalculationsDocument24 pagesComparison of Line Pack Calculation Using Aspen Plus Dynamics and by Using Manual CalculationsWalid Ben HuseinNo ratings yet

- Surge Relief Valve PDFDocument2 pagesSurge Relief Valve PDFMuhammadImaduddienSalamNo ratings yet

- PVRV Sizing Calculations Crude Oil Stroage Tank 007486 T 01Document2 pagesPVRV Sizing Calculations Crude Oil Stroage Tank 007486 T 01Olumuyiwa FasehunNo ratings yet

- Control Valve SizingDocument42 pagesControl Valve SizingSalim AhamedNo ratings yet

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiNo ratings yet

- N2 Regulator and Gauges DatasheetDocument4 pagesN2 Regulator and Gauges DatasheetpavanNo ratings yet

- Data Sheet LLP Compressor's (Updated)Document8 pagesData Sheet LLP Compressor's (Updated)GioNo ratings yet

- Digital Control Valve (Brodie, BV88) - ENGDocument28 pagesDigital Control Valve (Brodie, BV88) - ENGKovalyk DmitriyNo ratings yet

- Pressure Drop (Two Phases)Document38 pagesPressure Drop (Two Phases)PROCESOS PROCESOS100% (1)

- WPI-KE-1104-SP141-QM5433 (Datasheet)Document4 pagesWPI-KE-1104-SP141-QM5433 (Datasheet)Jèfrì PìnémNo ratings yet

- BlowdownDocument3 pagesBlowdownKORAMA KIENNo ratings yet

- Pressure Drop Calculation For Thick Sqaure Plate OrificeDocument2 pagesPressure Drop Calculation For Thick Sqaure Plate OrificeSyed AhmedNo ratings yet

- Gas Blowby CaseDocument2 pagesGas Blowby Casejainrakeshj4987No ratings yet

- Safety ValvesDocument13 pagesSafety ValvesAntonio DiabanzaNo ratings yet

- PTP 18.0 HandoutDocument12 pagesPTP 18.0 HandoutJayNo ratings yet

- Safety ValvesDocument12 pagesSafety ValvesMuhammad Ahmed KhanNo ratings yet

- ItDocument5 pagesItkmsrini@yahoo.comNo ratings yet

- Pressure Safety ValveDocument6 pagesPressure Safety ValveRaju JadavNo ratings yet

- Relief Valve: Flare Header or Relief Header To A Central, Elevated Gas Flare Where It Is UsuallyDocument3 pagesRelief Valve: Flare Header or Relief Header To A Central, Elevated Gas Flare Where It Is UsuallyKhaled RabeaNo ratings yet

- Fundamental of Blowdown AnalysisDocument2 pagesFundamental of Blowdown AnalysisFriday HumphreyNo ratings yet

- TFBP Deluge and Preaction Systems BrochureDocument6 pagesTFBP Deluge and Preaction Systems BrochureangeltandinganNo ratings yet

- Process OptimizationDocument40 pagesProcess OptimizationVishal BhopaleNo ratings yet

- Pump Minimum Flow1Document3 pagesPump Minimum Flow1Vishal BhopaleNo ratings yet

- Pump TechnicalDocument3 pagesPump TechnicalVishal BhopaleNo ratings yet

- CO2 Plant Line SizeDocument2 pagesCO2 Plant Line SizeVishal BhopaleNo ratings yet

- Computer Modeling and Analysis of A Hybrid Renewable Energy System Grid-Connected Using Homer ProDocument6 pagesComputer Modeling and Analysis of A Hybrid Renewable Energy System Grid-Connected Using Homer ProHmaedNo ratings yet

- Tutorial - Lecture 5 SolutionsDocument10 pagesTutorial - Lecture 5 SolutionsBastián Olfos MárquezNo ratings yet

- Safety in ElectricityDocument8 pagesSafety in ElectricityGokul VenugopalNo ratings yet

- Reluctance MotorDocument27 pagesReluctance MotorAbhirajNo ratings yet

- AES - MountainView - CUP - Waiver - 13may2022 REDACTEDDocument827 pagesAES - MountainView - CUP - Waiver - 13may2022 REDACTEDseyedamir mohammadiNo ratings yet

- Gas Suppresion SystemDocument50 pagesGas Suppresion SystemNavneet ShrivastavaNo ratings yet

- EXU Technical Data.: Low Lift Pallet TruckDocument7 pagesEXU Technical Data.: Low Lift Pallet TruckKiều Văn TrungNo ratings yet

- A Python Program To Model and Analyze Wind Speed DataDocument16 pagesA Python Program To Model and Analyze Wind Speed DataVelumani sNo ratings yet

- Paper and Poster Competition Preliminary Case Booklet IPFEST 2024Document9 pagesPaper and Poster Competition Preliminary Case Booklet IPFEST 2024almas fauziahNo ratings yet

- Offshore Wind Black Sea EN WEBDocument57 pagesOffshore Wind Black Sea EN WEBLyubomir SirkovNo ratings yet

- الاسئلة المتوقعة لجميع المسابقات والوظائف الخاصة بالمهندسين - مجموعة عامة فيسبوك 2Document1 pageالاسئلة المتوقعة لجميع المسابقات والوظائف الخاصة بالمهندسين - مجموعة عامة فيسبوك 2Ahlawy SamimNo ratings yet

- Valveless RTO: Industry-Leading Efficiency For VOC & HAP ControlDocument2 pagesValveless RTO: Industry-Leading Efficiency For VOC & HAP Controljose luis rios guerraNo ratings yet

- Flexible All-Perovskite Tandem Solar Cells Approaching 25% Efficiency With Molecule-Bridged Hole-Selective ContactDocument12 pagesFlexible All-Perovskite Tandem Solar Cells Approaching 25% Efficiency With Molecule-Bridged Hole-Selective ContactVeena SnaikNo ratings yet

- MAN-XXXX1 151pp Parts Catalogue Mahindra Pik-Up Ver1 Sept 2011-6-6Document1 pageMAN-XXXX1 151pp Parts Catalogue Mahindra Pik-Up Ver1 Sept 2011-6-6William DeerNo ratings yet

- Mechanical Engineering Objective by DS Handa - by WWW - LearnEngineerDocument2 pagesMechanical Engineering Objective by DS Handa - by WWW - LearnEngineerAdnan MaharNo ratings yet

- COOLER BOOKLET CDR - Compressed 1Document8 pagesCOOLER BOOKLET CDR - Compressed 1Anonymous K9wd4OvNo ratings yet

- Question Answers Physics Class 9 IcseDocument4 pagesQuestion Answers Physics Class 9 IcseBepis BoiNo ratings yet

- Phil Arch Review BDocument32 pagesPhil Arch Review BAr. Ryan OrtigasNo ratings yet

- Instruction Manual: Vacuum Dry OvenDocument52 pagesInstruction Manual: Vacuum Dry OvenPrianurraufikachmadNo ratings yet

- What Are The Factors Affecting The Number of Cyclone Stages in Preheater Kiln System?Document4 pagesWhat Are The Factors Affecting The Number of Cyclone Stages in Preheater Kiln System?hmaza shakeelNo ratings yet

- Check Valve and Throttle/Check Valve With SAE Flanged Ports: RE 64 548/06.03 1/6 Replaces: 03.94Document6 pagesCheck Valve and Throttle/Check Valve With SAE Flanged Ports: RE 64 548/06.03 1/6 Replaces: 03.94Enayat IzadiNo ratings yet

- Unit IV Distribution System ProtectionDocument9 pagesUnit IV Distribution System Protection23f1002933No ratings yet

- Fiat Barchetta: EngineDocument7 pagesFiat Barchetta: EngineHallex OliveiraNo ratings yet

- 467-NR PartC 2021-07Document591 pages467-NR PartC 2021-07MirceaNo ratings yet

- RAB PKS 45 TonperjamDocument9 pagesRAB PKS 45 TonperjamBoedak ThekingNo ratings yet

- Cat Electronic Technician 2019C v1.0 Product Status ReportDocument28 pagesCat Electronic Technician 2019C v1.0 Product Status ReportDamian BrzozowskiNo ratings yet

- Empilhadeira Hyster 1698731 - (J006) - H-PM-US-EN - (10-2021)Document826 pagesEmpilhadeira Hyster 1698731 - (J006) - H-PM-US-EN - (10-2021)Antonio100% (1)

- Signal Processing For Fault Detection and Diagnosis in Electrical Machines and SystemsDocument284 pagesSignal Processing For Fault Detection and Diagnosis in Electrical Machines and SystemsantonioherediaNo ratings yet

- Easypact Mvs - Mvs12n4nw6aDocument7 pagesEasypact Mvs - Mvs12n4nw6asaravananNo ratings yet

- PGDC (Ppe) Information BrochureDocument7 pagesPGDC (Ppe) Information BrochureKaviyarasan SNo ratings yet