Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

18 viewsAR16-205-EN Korea Paper POM in WP&P 2016

AR16-205-EN Korea Paper POM in WP&P 2016

Uploaded by

Claudinei MayerCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ANDRITZ TetrapackDocument18 pagesANDRITZ TetrapackClaudinei MayerNo ratings yet

- 00APR40Document7 pages00APR40Claudinei MayerNo ratings yet

- ANDRITZ - Pp-Stockpreparation-Moduscreen-Cp-DataDocument2 pagesANDRITZ - Pp-Stockpreparation-Moduscreen-Cp-DataClaudinei MayerNo ratings yet

- United States Patent (19) 5,022,984: Pimley Et Al. Jun. 11, 1991Document11 pagesUnited States Patent (19) 5,022,984: Pimley Et Al. Jun. 11, 1991Claudinei MayerNo ratings yet

- Heli-Drum Pulping System: Pulping Perfection With Superior Ink Detachment and DispersionDocument4 pagesHeli-Drum Pulping System: Pulping Perfection With Superior Ink Detachment and DispersionClaudinei MayerNo ratings yet

- ANDRITZ - PRENSA COMPACTADORA - 01 - Sludge-And-Reject-Newsletter-Iss4-2-2015-DataDocument5 pagesANDRITZ - PRENSA COMPACTADORA - 01 - Sludge-And-Reject-Newsletter-Iss4-2-2015-DataClaudinei MayerNo ratings yet

- Fibernet Pressure Screen: The Multi-Stage Solution To Fiber LossDocument4 pagesFibernet Pressure Screen: The Multi-Stage Solution To Fiber LossClaudinei MayerNo ratings yet

- Can J Chem Eng - 2023 - Germg RD - Screening of Chemical Pulp Revisiting Technology Options and The State of The ArtDocument13 pagesCan J Chem Eng - 2023 - Germg RD - Screening of Chemical Pulp Revisiting Technology Options and The State of The ArtClaudinei MayerNo ratings yet

- United States Patent (19) : Chupka Et Al. 11) Patent Number: 5,078,275 (45) Date of PatentDocument10 pagesUnited States Patent (19) : Chupka Et Al. 11) Patent Number: 5,078,275 (45) Date of PatentClaudinei MayerNo ratings yet

- AR16-S111-EN StoraEnso Poland POM in Kagit Sanayii Summer2016 - 0 PDFDocument4 pagesAR16-S111-EN StoraEnso Poland POM in Kagit Sanayii Summer2016 - 0 PDFClaudinei MayerNo ratings yet

- US3889885Document7 pagesUS3889885Claudinei MayerNo ratings yet

- AR16-S114-EN StoraEnso Poland POM in PulpandPaper Canada 01-2016 PDFDocument2 pagesAR16-S114-EN StoraEnso Poland POM in PulpandPaper Canada 01-2016 PDFClaudinei MayerNo ratings yet

- United States Patent 19Document9 pagesUnited States Patent 19Claudinei MayerNo ratings yet

AR16-205-EN Korea Paper POM in WP&P 2016

AR16-205-EN Korea Paper POM in WP&P 2016

Uploaded by

Claudinei Mayer0 ratings0% found this document useful (0 votes)

18 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

18 views4 pagesAR16-205-EN Korea Paper POM in WP&P 2016

AR16-205-EN Korea Paper POM in WP&P 2016

Uploaded by

Claudinei MayerCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

APPROACH FLOW SYSTEMS

Simply Better Board at Korea Paper

Flying into Seoul, Korea, you land atone

Gf the best rated airports ver the last

secade: Incheon International Airport

Just before nding, you can see the

Sihwa Lake Power pent, one ofthe

largest tal paver faites inthe wort.

‘And close by you can see the Skwha

Industrial Park, where Korea Paper sts

‘high standaed for corrugating medium,

linerbaard and white top.

\Wrat al three entorprises nava in

‘comrman is advanced technical

‘competence and an unwavering

commitment to achievement a the

highest performance level possibe.

While Korea Paper operates on a much

smaller scale than the alrpart or ba

power pant, they have the same intense

Korean motivation to succeed.

‘Says Ryu Jin Ho, President & CEO,

Korea Paper, “Koreans are krcwn

for working long hours, and being

committed to contuousty iting higher

targets. After mary yeas of effort and

investment—and some dificult times

— ne now produce over 400,000 tors

ct high quay liner and white top very

effcienty. Noone coulé have imagined

that our rebult machine could reach

this qualiy level, using 100% recycled

furish”

Simplification of eur approach system

has been vital to our transformation

adds Loe Dai Young, Managing Director

By Timo Koivisto and Martin Koepenick, Aikawa Fiber Technologies

Figure 1, Ryu Jn Ho, President & CEO, Korea Pager

“yy

eliminating

countless

tanks and

silos, we

gained

control of

‘the wet end,

and reduced

‘consumption

of water,

‘energy and

chemicals.”

& Mil Manager, Korea Paper. “By

clmireting countess tanks and sios,

we gained corto ofthe wat end, and

reduced consumption of water, energy

and chemicals.

DECADES OF EvOLETION

Korea Paper began in the 1970s

to meet the growing demands for

packegirg in the region, They produced

£200,000 toy of inerboard and medium

grades, covering a wide range of

fgrammages from 180 to aver 400 gir

They had a steady flow of business unt

8 crisis period tram 1989 te 2004, when

they faced severe challenges to survive.

Investing heavily from 2004 to 2007,

‘they reached 300,000 tons per yar.

Al gtades attained the targeted qually

sal.

‘BREAKING PAPER MACHINE CAPACITY IMTS

In order to reach 410,000 ty withthe

samme machine, much had to be dave. In

2012, vestments included a new fxm,

improvements in dewatering, and most

Important, a new comaactappreach

flow syste. The esul? New high vale

products, cating white top liner,

roductvty gins & fastr grade changes.

APPROACH FLOW SYSTEMS

Firate 2, Lee Dai Youre, Mt

Continues Lee Dai Young, “As part of

‘2 major paper machine rebuild, a new

proach system was needed

55 our production capacity

increase goals, quality, and aso the

benefits of freeing up space in 3

crowed work area

‘HIGHER OUTPUT & EFFICIENCY BASED OH

siwpurcire

A central ard deliverable aim was

deaeration, assuring smoother

er 1000

‘nmin. AFT supplied the complete

runnabiliy machine speed

‘approach flow system for al three

plies. Nave of the typical large tanks

ate required, which alowed for the

complete s

paper machine lar, eliminating the

need for mezzanines. The new system

includes three POMD™ 730 ser

degassers, two POMneaders™ and

to be installed on the

three POMlack™ C suction leg sealing

aging Directo

Yanoger, Korea Paper

‘The three POMa degassers were

stoned forthe beck ply, file ply

POM mixing

ot

and top ply systems, Tw

headers allow cferent fibres to be

separately (top vs. back

in adion tothe equipment, AFT

aso delverad basic engineering, 2D

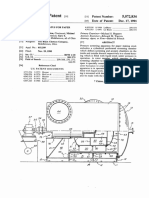

Fgue 3. The POM system

POMp 730 Degassers

133 POI

Acentral

and

teliverable

aim was

deaeration,

assuring

smoother

sunnability

machine

speed

over

1000 m/min

conceptual engineering, operator

traning, start-up supervision a

performance testing, The star-up

vent smoothly with the POM system

hanaling grade testing from the

without issue,

sal thee layers, and also Includes 3

ck C units

Notes Kim Jinhong, Representative

Director, Oh Yang Patech Co. Lid. for

AFT, “The fact thal the POM wet end

saved capital by eliminating the need

for seal pits, silos and chests isa great

starting point. Best of al, nowever, is

better process stably and quicker

response to contol chen

‘ueBLETROUALE

Wit te traditional a

ch system,

rere had to be done in wastewater

tueatment, which meant @ focus of

time, and higher use of chemicals,

Lots of bubbles in the whitewater and

wastewater veatment often cal fr

‘an overaad of def

ts. Changing

cover to the POMp degasser, however,

‘gant thatthe entained air reduction

cf abeut 70% elimi

ted much of the

foam without chemicals, With less

demand on the wastewater systam,

ve have more time to focus on other

important issues,” says Lee Dai Youn

Naw, we use about half the defeamers

that similar mils employ in Kocea

WATER USE oRoP pRaaTIC

Lee Dai Young, being a strong advocate

for simplicity, suggests that lower water

consumption is fundamental tothe

productvty and quay gains. “Femer

problems happen when tanks are

gone. Contaminants and deposits dont

have a chance to build up, as they

id

entrained ai is aso easier to clear

fore, A closed system with less

Water volume was decreased by over

5024, More importantly, al ofthe

problems that are created because of

huge water volumes and what grows

in various tanks became history. He

continues, “As you decrease water

use, you can contro better. You make

adjustments faster. Your god ideas are

not diluted in the vast quid volume,

which you don't need,

Figure 4, Kim Jorg let) Representative Di

ive with AFT, Aikawa Groop, Says Jinhong Kir,

ca Paper saved capital by eliminating the need fr 3

stabilty and quicker response to cont

‘Sales Repres

smal space. Ka

With the

traditional

approach

system, more

done it

wastewater

treatment,

which meant

a focus

of time,

and higher

use of

chemicals

Figwe§. Greater contro is now the norm with 2 sim

FREQUENT GRADE CHANGES

To satya wide range of customers,

Koree Paper makes frequent grade

changes, which inckude eolour and

srammage chenges. The normal

ure Is step by step, but pow

tramatic changes ae possibe ina

rove

shart period of time. “Sometimes an

mer needs 3 particular

rector, Ob Yang Patech Co. Lt. for AFT with Keli Yesuc,

The POM wet end system fis in a

its, silas and chests. Best ofa,

‘and grade charges.”

er wet end approach

rade with very short turnaround

time," adds Ryu Jin Ho.“

our smooth and flexible operations, we

‘can respond quicly, when it matters

The POM system takes away a lat of

stress and gives us a new advantage.

Grace change tine is faster, because

th

purge quickly.

ock and white water systems

APPROACH FLOW SYSTEMS

Figure 6, Once Korea Paper reached

they are planning a second mil at a strate

production hemseves.

wall of the

problems

that are

created

because

of huge

water

‘volumes and

wat grows

in various

Figure 7. Kooa Paper PMI was rebuit n 2012 to produce 3-ply boars grades. A tanks

treed te 88010 1100 min. The mache row poses voto 455,000 mtny CAMB

of inrbnard rom 2 100% OCC fumish. Basi we@hts fom 180-400 2 history

tons per day, they were realy finding heir stride. Speed increased fram 850 r/min to 1100 min. Now,

sation about an hour's dive away. They also own four carweting facies, and utilise half oftheir

THE FUTURE

‘Anew box plant planned for next

year, adcing to the one already in

place. Looking to 2018, @ new mil,

focused on lghtwelght graces, wil

become a parallel operation with similar

‘ulput, A POM system wil be part of

that line, as wel,

“Korea Paper is pos!

domestically and it

the Middle East, Our team has eared

2 reputation for quality, delvery and

flexibly,” concludes Ryu Jin Ho

ore Paper

Lee Jinkuk Chief of Production

Lee Dai Young Managing Director

Ryu,inHo CEO

Byon Dae Bok ual Environment

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ANDRITZ TetrapackDocument18 pagesANDRITZ TetrapackClaudinei MayerNo ratings yet

- 00APR40Document7 pages00APR40Claudinei MayerNo ratings yet

- ANDRITZ - Pp-Stockpreparation-Moduscreen-Cp-DataDocument2 pagesANDRITZ - Pp-Stockpreparation-Moduscreen-Cp-DataClaudinei MayerNo ratings yet

- United States Patent (19) 5,022,984: Pimley Et Al. Jun. 11, 1991Document11 pagesUnited States Patent (19) 5,022,984: Pimley Et Al. Jun. 11, 1991Claudinei MayerNo ratings yet

- Heli-Drum Pulping System: Pulping Perfection With Superior Ink Detachment and DispersionDocument4 pagesHeli-Drum Pulping System: Pulping Perfection With Superior Ink Detachment and DispersionClaudinei MayerNo ratings yet

- ANDRITZ - PRENSA COMPACTADORA - 01 - Sludge-And-Reject-Newsletter-Iss4-2-2015-DataDocument5 pagesANDRITZ - PRENSA COMPACTADORA - 01 - Sludge-And-Reject-Newsletter-Iss4-2-2015-DataClaudinei MayerNo ratings yet

- Fibernet Pressure Screen: The Multi-Stage Solution To Fiber LossDocument4 pagesFibernet Pressure Screen: The Multi-Stage Solution To Fiber LossClaudinei MayerNo ratings yet

- Can J Chem Eng - 2023 - Germg RD - Screening of Chemical Pulp Revisiting Technology Options and The State of The ArtDocument13 pagesCan J Chem Eng - 2023 - Germg RD - Screening of Chemical Pulp Revisiting Technology Options and The State of The ArtClaudinei MayerNo ratings yet

- United States Patent (19) : Chupka Et Al. 11) Patent Number: 5,078,275 (45) Date of PatentDocument10 pagesUnited States Patent (19) : Chupka Et Al. 11) Patent Number: 5,078,275 (45) Date of PatentClaudinei MayerNo ratings yet

- AR16-S111-EN StoraEnso Poland POM in Kagit Sanayii Summer2016 - 0 PDFDocument4 pagesAR16-S111-EN StoraEnso Poland POM in Kagit Sanayii Summer2016 - 0 PDFClaudinei MayerNo ratings yet

- US3889885Document7 pagesUS3889885Claudinei MayerNo ratings yet

- AR16-S114-EN StoraEnso Poland POM in PulpandPaper Canada 01-2016 PDFDocument2 pagesAR16-S114-EN StoraEnso Poland POM in PulpandPaper Canada 01-2016 PDFClaudinei MayerNo ratings yet

- United States Patent 19Document9 pagesUnited States Patent 19Claudinei MayerNo ratings yet