Professional Documents

Culture Documents

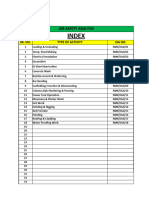

Hazard Identification & Risk Assesment (Hira) Ohs-Pr-02-03-F07 Job Safe Procedure

Hazard Identification & Risk Assesment (Hira) Ohs-Pr-02-03-F07 Job Safe Procedure

Uploaded by

Muhammad M KhanCopyright:

Available Formats

You might also like

- Hirarc ExcavationDocument6 pagesHirarc ExcavationWeyWeyEnne83% (6)

- Hirac - DoleDocument11 pagesHirac - DoleAngela Salumbides50% (2)

- HIRARC Rock BlastingDocument4 pagesHIRARC Rock BlastingNajman Hamdi100% (13)

- Hazard Identification, Risk Assessment & Determining ControlDocument4 pagesHazard Identification, Risk Assessment & Determining Controljay RNo ratings yet

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- Job Safety Analysis (Jsa) - Water Proofing WorkDocument6 pagesJob Safety Analysis (Jsa) - Water Proofing Worknitish tiwariNo ratings yet

- HIRA 009 Bunkering.Document4 pagesHIRA 009 Bunkering.srinibas mohapatraNo ratings yet

- 5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionDocument3 pages5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionBarkat UllahNo ratings yet

- Concrete From Batching Plant To Transit Mixer JSA HSE ProfessionalsDocument1 pageConcrete From Batching Plant To Transit Mixer JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Soil CompactionDocument1 pageSoil CompactionLebohang ChakaNo ratings yet

- Soil Compaction With Plate Compactor JSA HSE ProfessionalsDocument1 pageSoil Compaction With Plate Compactor JSA HSE ProfessionalsSamadov 13No ratings yet

- 5.19.3 Job Safety Practices Finishing WorksDocument3 pages5.19.3 Job Safety Practices Finishing WorksBarkat UllahNo ratings yet

- Concrete From Batching Plant To Transit Mixer JSADocument1 pageConcrete From Batching Plant To Transit Mixer JSAm.rehanhseNo ratings yet

- 5.19.3 Job Safety Practices Installation of Cable TrayDocument3 pages5.19.3 Job Safety Practices Installation of Cable TrayBarkat UllahNo ratings yet

- Concreting PCC in Plinth JSA HSE ProfessioanlsDocument1 pageConcreting PCC in Plinth JSA HSE ProfessioanlsSamadov 13No ratings yet

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- Expansion Joints in Columns JSA HSE ProfessionalsDocument1 pageExpansion Joints in Columns JSA HSE ProfessionalsSamadov 13No ratings yet

- Temporary Sheds JSA HSE ProfessionalsDocument1 pageTemporary Sheds JSA HSE ProfessionalsAli KaziNo ratings yet

- Rme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20Document1 pageRme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20nanthan06No ratings yet

- Mobile Stone Crushing JSA HSE ProfessionalsDocument1 pageMobile Stone Crushing JSA HSE ProfessionalsLebohang ChakaNo ratings yet

- 20-RAS-Transformer InstallationDocument2 pages20-RAS-Transformer InstallationWalid MarhabaNo ratings yet

- Ewrc SHP Gen Hse Jsa 00040Document12 pagesEwrc SHP Gen Hse Jsa 00040Rickz CabaloNo ratings yet

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- JSA (Job Safety Analysis) Sheet: Activity Name:-Cut Outs in Slab. Location: - DateDocument1 pageJSA (Job Safety Analysis) Sheet: Activity Name:-Cut Outs in Slab. Location: - DateViron BaxhiaNo ratings yet

- Dewatering Works - RADocument4 pagesDewatering Works - RAJames Bonito100% (1)

- Attachment 7505Document11 pagesAttachment 7505Charles DoriaNo ratings yet

- Activity Being Assessed: Risk Assessment For Skate Park ConstructionDocument9 pagesActivity Being Assessed: Risk Assessment For Skate Park ConstructionTerence Tsam0% (1)

- 5.19.3 Job Safety Practices Grouting WorksDocument3 pages5.19.3 Job Safety Practices Grouting WorksBarkat UllahNo ratings yet

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- R.A FOR Condensate PitDocument5 pagesR.A FOR Condensate PitResearcherNo ratings yet

- Grouting of Bolts - Pockets JSA HSE ProfessionalsDocument1 pageGrouting of Bolts - Pockets JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Job Safety Analysis - Cement SiloDocument9 pagesJob Safety Analysis - Cement SiloMohammed Minhaj100% (1)

- JSA - Area Hard BarricationDocument1 pageJSA - Area Hard BarricationNFRN0% (1)

- HIRADC SF MERGE - Water ProofingDocument3 pagesHIRADC SF MERGE - Water ProofingUDAWSA2 WKENo ratings yet

- Task /activity: Installation of Abseil HooksDocument10 pagesTask /activity: Installation of Abseil HooksfrancisbautistaNo ratings yet

- Ladle Cleaning Machine Risk Assessment2Document6 pagesLadle Cleaning Machine Risk Assessment2Edgar PenicelaNo ratings yet

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- Diesel Unloading Dispencing JSA HSE ProfessionalsDocument1 pageDiesel Unloading Dispencing JSA HSE ProfessionalsSamadov 13No ratings yet

- Template JsaDocument1 pageTemplate JsaFadzira Syahira FadzalehNo ratings yet

- Concrete Admixture - S Drum Unloading Dispencing JSA HSE ProfessionalsDocument1 pageConcrete Admixture - S Drum Unloading Dispencing JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Fly Ash Brick Plant Erection and Operation JSA HSE ProfessionalsDocument1 pageFly Ash Brick Plant Erection and Operation JSA HSE ProfessionalsSamadov 13No ratings yet

- Risk Assessment Road Repair PIC R 7514Document5 pagesRisk Assessment Road Repair PIC R 7514Charles DoriaNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Excavation JSADocument9 pagesExcavation JSASuvarnrajNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- Drain Line Work JSADocument2 pagesDrain Line Work JSAm.rehanhseNo ratings yet

- RA - Welding Grinding & Cutting WorksDocument5 pagesRA - Welding Grinding & Cutting WorksResearcherNo ratings yet

- Job Safety Analysis: Rohan Builders (I) PVT LTDDocument3 pagesJob Safety Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- Backfilling ENDocument5 pagesBackfilling ENTilalNo ratings yet

- AR08-16 Laying HDPE Pipes Risk AssessmentDocument5 pagesAR08-16 Laying HDPE Pipes Risk AssessmentAmrou Ben RjebNo ratings yet

- Job Safety Practices Block and Plastering WorksDocument3 pagesJob Safety Practices Block and Plastering WorksBarkat UllahNo ratings yet

- Hazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012Document1 pageHazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012somashekhar. ncclNo ratings yet

- Risk Assessment 2A1Document10 pagesRisk Assessment 2A1Illias ShaikNo ratings yet

- Job Safety Analysis: (Risk Assessment)Document9 pagesJob Safety Analysis: (Risk Assessment)MarhendraNo ratings yet

- Job Safety Practices Backfilling and CompactionDocument3 pagesJob Safety Practices Backfilling and CompactionBarkat UllahNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectiondeepakkumaryadav841441No ratings yet

- Straighten The MS Channels Beam by Manually JSA HSE ProfessionalsDocument1 pageStraighten The MS Channels Beam by Manually JSA HSE ProfessionalsSamadov 13No ratings yet

- RMK Jsa.Document49 pagesRMK Jsa.Vaibhav GaikwadNo ratings yet

- Brick Work JSA HSE ProfessionalsDocument1 pageBrick Work JSA HSE ProfessionalsStansilous Tatenda NyagomoNo ratings yet

Hazard Identification & Risk Assesment (Hira) Ohs-Pr-02-03-F07 Job Safe Procedure

Hazard Identification & Risk Assesment (Hira) Ohs-Pr-02-03-F07 Job Safe Procedure

Uploaded by

Muhammad M KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Identification & Risk Assesment (Hira) Ohs-Pr-02-03-F07 Job Safe Procedure

Hazard Identification & Risk Assesment (Hira) Ohs-Pr-02-03-F07 Job Safe Procedure

Uploaded by

Muhammad M KhanCopyright:

Available Formats

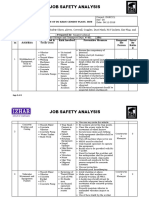

HAZARD IDENTIFICATION & RISK ASSESMENT (HIRA)

OHS-PR-02-03-F07 JOB SAFE PROCEDURE

JOB/TASK TYPE: Replacement of Bottom plates- Tank 97 (Confined Space

DEPARTMENT / DIVISION: SPP / HFO/TANK 97 DATE: 08.04.2023

Work)

JOB SAFETY PROCEDURE N0: (MKN-2122- COMPILED BY: Mr. Sultan Khan DATE: 08.04.2023

JSP-005)

APPROVED BY SUPERVISOR: Mr.Shajahan APPROVED BY MANAGER: Mr.Shahid Munir

Head: Safety Helmet Eye/Face: Safety Glass Feet: Safety Shoes Clothing: FRC (CAT-2) Respiratory: 3M-6003

P.P.E. REQUIRED FOR TASK:

Ear protection: Ear Plugs Safety harness: N/A Hands: Gloves Arc Flash PPE: N/A 0ther - Specify:

JOB SAFE PROCEDURE ANALYSIS

HAZARDS

LIST ALL STEPS IN PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE DANGERS PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

STEP NO (In sequence) INJURY, LOSS, DAMAGE INTERRUPTION, (Injuries, Damage, Ill- ELIMINATE HAZARD

OR POLLUTION? ness, Pollution, etc)

Slip trip, fall Personal injury Proper housekeeping shall be maintained all

1 Site Mobilisation and Preparation the time

Pinch Point Hand injury Leather gloves shall be used for hand

protection

Collision with Vehicle Personal injury Flagman shall be assigned with heavy

equipment movement.

Overturn of the forklift Personal injury Forklift operator shall work with complete

2 Offloading of materials by using forklift PPEs, safety helmet, fire resistant clothing,

safety glasses and steel toed safety shoes

Collision with Vehicle Property Forklift operator shall not block his view by

damage raising the forks to his eye level.

Collapse of crane Personal injury All crane lifts shall be done as per approved

3 Offloading of equipment & material inside and outside of rigging plan

Tank 97 by crane Failure of rigging gears Personal Rigging gears used shall be of appropriate

injury/ lifting capacity.

property

damage

Confined Space entry/ Presence of Fire Continuous Gas monitoring for every 30 mins

Flammable should be done

Page 1 of 5 Rev. 01 [May - 2020] Approved Document

HAZARD IDENTIFICATION & RISK ASSESMENT (HIRA)

OHS-PR-02-03-F07 JOB SAFE PROCEDURE

4 Internal Cleaning of the surfaces (Bottom floor plate, Confined Space entry Presence of Bad health Ensure proper ventilation all the time, Air

Tank shell up to 2 m - 2.5 m Toxic effects due to blowers shall be used for air extraction

exposure to

hazardous

gases

Pinch Point Hand injury Leather gloves shall be used for hand

5 Loosen the Bolts and nuts to remove the damaged protection

internal Roof Plate Inadequate lighting Slip, trip & fall Adequate lighting shall be provided

6 Removal of Floating roof Pan seal, Auxiliary and Main Sharp edges Personal Injury Ensure workers are using Hand Gloves to

Pipe avoid bruises and lacerations

Fall of material Head injury Do not allow to carry on activity at the

bottom plate while the internal roof repair

work is in progress

Sharp edges Personal Injury Ensure workers are using Hand Gloves to

7 Replacement of Damaged Floating roof and Installation avoid bruises and lacerations.

of Floating roof Pan seal, Auxiliary and Main Pipe. Fall of material Head injury Do not allow to carry on activity at the

bottom plate while the internal roof repair

work was going on

Incompetent Technician Failure of Ensure the Technician is following the

8 Check and inspect all other Floating roof Parts (If Inspection Confined Space Procedure

required do Repair)

9 Installation of Internal Roof Plate by nuts and Bolts Pinch Point Hand injury Leather gloves shall be used for hand

protection, Awkward/ poor body posture

shall be avoided such as twisting, stopping

10 Inspection of tank by Ultrasonic Thickness Test Incompetent Technician Failure of Ensure The technician is approved and

Inspection qualified, Inspector shall wear fire resistant

coverall, safety helmet, safety glasses, steel

toed safety shoes and cartridge mask

Inadequate lighting Slip, trip & fall Electric cables shall be arranged properly to

Page 2 of 5 Rev. 01 [May - 2020] Approved Document

HAZARD IDENTIFICATION & RISK ASSESMENT (HIRA)

OHS-PR-02-03-F07 JOB SAFE PROCEDURE

avoid any tripping hazard

Confined Space entry Presence of Fire Ensure proper ventilation all the time. Air

Flammable blowers shall be used for air extraction

11 Inspection of tank by Ultrasonic Thickness Test Incompetent Technician Failure of Inspection equipment shall have valid

Inspection inspection certificate

Inadequate lighting Slip, trip & fall Adequate lighting shall be provided

exposure to the source Health hazard Only certified & competent technician shall

carryout the task

12 Inspection & NDT reports issuing Incompetent Technician Failure of Ensure the Technician is aware about the

Inspection Hazards, Emergency Procedure of Confined

Space

Inadequate lighting Slip, trip & fall Work area shall be kept clear all the time

13 Cutting of Tank Shell for accessing Compressed Gas cylinder Personal Injury Proper PPE's Should be worn by the Gas

cutter when he was carrying on the activity.

(FRC Coverall, Face Shield, Safety Shoes)

Fire Property Fire Extinguisher should be kept throughout

damage activity; Fire watcher should be present

during the activities.

14 Sandblasting of inside bottom floor plates, tank shell, Confined Space entry presence of Fire Ensure proper ventilation all the time. Air

internal pipes & external shell up to 1mtr flammable materials blowers shall be used for air extraction

Confined Space entry Bad health Cartridge mask with filter shall be used;

presence of toxic material effects due to Workers shall use chemical resistant coverall

exposure to and rubber boots with steel toed safety

hazardous shoes.

gases

Failure of sandblasting equipment Personal injury Ensure all sand blasting equipment are

inspected and certified

Use of grit materials Health hazard The Abrasive Blast Cleaning Operator shall

wear an air supplied protective hood for the

Page 3 of 5 Rev. 01 [May - 2020] Approved Document

HAZARD IDENTIFICATION & RISK ASSESMENT (HIRA)

OHS-PR-02-03-F07 JOB SAFE PROCEDURE

abrasive material being used and any other

toxic contaminates (lead zinc, etc.) that are

present

High Noise Hearing loss Sand blaster shall use hearing protection

due to noise

15 Painting Inside of the tank Confined Space entry Presence of Fire DCP type fire extinguishers shall be in place,

Flammable Hot work should not be performed on the

material day when painting work was carried on

Exposure to Health Hazards Respiratory equipment as per MSDS

Hazardous chemicals information shall be used.

Inadequate lighting Slip, trip & fall Electric cables shall be arranged properly to

avoid any tripping hazard.

16 Installation of Bottom Plate Inside Tank Shell for Tank 97 spark produced Fire Place DCP type fire extinguisher, use fire

during grinding, blanket to control the fire, fire watcher

should be present at the workplace

cutting & welding

works

Electric shock from Electrical tools Hand Burns, Power tools should be double Insulated,

Arc Flash Electrical tools should not be used in wet

areas or during rain

Failure of grinder or Personal Grinding disc rpm should match with grinder

failure of grinding Injuries rpm. Mismatch may result in rupture of

grinding causing personal injury

disc

Flying particles Eye Injury Workers shall use double eye protection, face

produced during shield shall be worn over safety glasses

grinding

Works.

Inadequate lighting Slip, trip & fall Adequate lighting shall be provided

Page 4 of 5 Rev. 01 [May - 2020] Approved Document

HAZARD IDENTIFICATION & RISK ASSESMENT (HIRA)

OHS-PR-02-03-F07 JOB SAFE PROCEDURE

17 Ultrasonic Flaw Detection Test Incompetent Technician Failure of Inspection equipment shall have valid

Inspection inspection certificate

Inadequate lighting Slip, trip & fall Adequate lighting shall be provided

exposure to the source Health hazard Only certified & competent technician shall

carryout the task

18 Gasket Replacement and Box Up (all Nozzles) Pinch Point Hand injury Leather gloves shall be used for hand

protection

19 Working in the night shift Slip trip, fall Personal injury Adequate lighting shall be provided

20 Adverse weather condition exposure the dangerous situation personal work shall be stopped in adverse weather

injury/ condition and workers shall move to safe

property facilities.

damage

Page 5 of 5 Rev. 01 [May - 2020] Approved Document

You might also like

- Hirarc ExcavationDocument6 pagesHirarc ExcavationWeyWeyEnne83% (6)

- Hirac - DoleDocument11 pagesHirac - DoleAngela Salumbides50% (2)

- HIRARC Rock BlastingDocument4 pagesHIRARC Rock BlastingNajman Hamdi100% (13)

- Hazard Identification, Risk Assessment & Determining ControlDocument4 pagesHazard Identification, Risk Assessment & Determining Controljay RNo ratings yet

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- Job Safety Analysis (Jsa) - Water Proofing WorkDocument6 pagesJob Safety Analysis (Jsa) - Water Proofing Worknitish tiwariNo ratings yet

- HIRA 009 Bunkering.Document4 pagesHIRA 009 Bunkering.srinibas mohapatraNo ratings yet

- 5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionDocument3 pages5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionBarkat UllahNo ratings yet

- Concrete From Batching Plant To Transit Mixer JSA HSE ProfessionalsDocument1 pageConcrete From Batching Plant To Transit Mixer JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Soil CompactionDocument1 pageSoil CompactionLebohang ChakaNo ratings yet

- Soil Compaction With Plate Compactor JSA HSE ProfessionalsDocument1 pageSoil Compaction With Plate Compactor JSA HSE ProfessionalsSamadov 13No ratings yet

- 5.19.3 Job Safety Practices Finishing WorksDocument3 pages5.19.3 Job Safety Practices Finishing WorksBarkat UllahNo ratings yet

- Concrete From Batching Plant To Transit Mixer JSADocument1 pageConcrete From Batching Plant To Transit Mixer JSAm.rehanhseNo ratings yet

- 5.19.3 Job Safety Practices Installation of Cable TrayDocument3 pages5.19.3 Job Safety Practices Installation of Cable TrayBarkat UllahNo ratings yet

- Concreting PCC in Plinth JSA HSE ProfessioanlsDocument1 pageConcreting PCC in Plinth JSA HSE ProfessioanlsSamadov 13No ratings yet

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- Expansion Joints in Columns JSA HSE ProfessionalsDocument1 pageExpansion Joints in Columns JSA HSE ProfessionalsSamadov 13No ratings yet

- Temporary Sheds JSA HSE ProfessionalsDocument1 pageTemporary Sheds JSA HSE ProfessionalsAli KaziNo ratings yet

- Rme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20Document1 pageRme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20nanthan06No ratings yet

- Mobile Stone Crushing JSA HSE ProfessionalsDocument1 pageMobile Stone Crushing JSA HSE ProfessionalsLebohang ChakaNo ratings yet

- 20-RAS-Transformer InstallationDocument2 pages20-RAS-Transformer InstallationWalid MarhabaNo ratings yet

- Ewrc SHP Gen Hse Jsa 00040Document12 pagesEwrc SHP Gen Hse Jsa 00040Rickz CabaloNo ratings yet

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- JSA (Job Safety Analysis) Sheet: Activity Name:-Cut Outs in Slab. Location: - DateDocument1 pageJSA (Job Safety Analysis) Sheet: Activity Name:-Cut Outs in Slab. Location: - DateViron BaxhiaNo ratings yet

- Dewatering Works - RADocument4 pagesDewatering Works - RAJames Bonito100% (1)

- Attachment 7505Document11 pagesAttachment 7505Charles DoriaNo ratings yet

- Activity Being Assessed: Risk Assessment For Skate Park ConstructionDocument9 pagesActivity Being Assessed: Risk Assessment For Skate Park ConstructionTerence Tsam0% (1)

- 5.19.3 Job Safety Practices Grouting WorksDocument3 pages5.19.3 Job Safety Practices Grouting WorksBarkat UllahNo ratings yet

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- R.A FOR Condensate PitDocument5 pagesR.A FOR Condensate PitResearcherNo ratings yet

- Grouting of Bolts - Pockets JSA HSE ProfessionalsDocument1 pageGrouting of Bolts - Pockets JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Job Safety Analysis - Cement SiloDocument9 pagesJob Safety Analysis - Cement SiloMohammed Minhaj100% (1)

- JSA - Area Hard BarricationDocument1 pageJSA - Area Hard BarricationNFRN0% (1)

- HIRADC SF MERGE - Water ProofingDocument3 pagesHIRADC SF MERGE - Water ProofingUDAWSA2 WKENo ratings yet

- Task /activity: Installation of Abseil HooksDocument10 pagesTask /activity: Installation of Abseil HooksfrancisbautistaNo ratings yet

- Ladle Cleaning Machine Risk Assessment2Document6 pagesLadle Cleaning Machine Risk Assessment2Edgar PenicelaNo ratings yet

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- Diesel Unloading Dispencing JSA HSE ProfessionalsDocument1 pageDiesel Unloading Dispencing JSA HSE ProfessionalsSamadov 13No ratings yet

- Template JsaDocument1 pageTemplate JsaFadzira Syahira FadzalehNo ratings yet

- Concrete Admixture - S Drum Unloading Dispencing JSA HSE ProfessionalsDocument1 pageConcrete Admixture - S Drum Unloading Dispencing JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Fly Ash Brick Plant Erection and Operation JSA HSE ProfessionalsDocument1 pageFly Ash Brick Plant Erection and Operation JSA HSE ProfessionalsSamadov 13No ratings yet

- Risk Assessment Road Repair PIC R 7514Document5 pagesRisk Assessment Road Repair PIC R 7514Charles DoriaNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Excavation JSADocument9 pagesExcavation JSASuvarnrajNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- Drain Line Work JSADocument2 pagesDrain Line Work JSAm.rehanhseNo ratings yet

- RA - Welding Grinding & Cutting WorksDocument5 pagesRA - Welding Grinding & Cutting WorksResearcherNo ratings yet

- Job Safety Analysis: Rohan Builders (I) PVT LTDDocument3 pagesJob Safety Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- Backfilling ENDocument5 pagesBackfilling ENTilalNo ratings yet

- AR08-16 Laying HDPE Pipes Risk AssessmentDocument5 pagesAR08-16 Laying HDPE Pipes Risk AssessmentAmrou Ben RjebNo ratings yet

- Job Safety Practices Block and Plastering WorksDocument3 pagesJob Safety Practices Block and Plastering WorksBarkat UllahNo ratings yet

- Hazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012Document1 pageHazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012somashekhar. ncclNo ratings yet

- Risk Assessment 2A1Document10 pagesRisk Assessment 2A1Illias ShaikNo ratings yet

- Job Safety Analysis: (Risk Assessment)Document9 pagesJob Safety Analysis: (Risk Assessment)MarhendraNo ratings yet

- Job Safety Practices Backfilling and CompactionDocument3 pagesJob Safety Practices Backfilling and CompactionBarkat UllahNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectiondeepakkumaryadav841441No ratings yet

- Straighten The MS Channels Beam by Manually JSA HSE ProfessionalsDocument1 pageStraighten The MS Channels Beam by Manually JSA HSE ProfessionalsSamadov 13No ratings yet

- RMK Jsa.Document49 pagesRMK Jsa.Vaibhav GaikwadNo ratings yet

- Brick Work JSA HSE ProfessionalsDocument1 pageBrick Work JSA HSE ProfessionalsStansilous Tatenda NyagomoNo ratings yet