Professional Documents

Culture Documents

Carbide End Mill Feeds and Speeds General Purpose TiN

Carbide End Mill Feeds and Speeds General Purpose TiN

Uploaded by

joshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbide End Mill Feeds and Speeds General Purpose TiN

Carbide End Mill Feeds and Speeds General Purpose TiN

Uploaded by

joshCopyright:

Available Formats

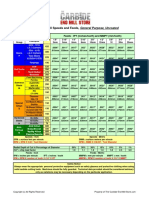

Carbide End Mill Speeds and Feeds, General Purpose, TiN Coated

SMM = SFM X .3048 Speeds Feeds - IPT (inches/tooth) and MMPT (mm/tooth)

Material SFM 1/8" 3/16" 1/4" 5/16" 3/8" 1/2" 5/8" 3/4" 1"

Examples

Group 3mm 5mm 6mm 8mm 10mm 12mm 16 20m 25mm

Mild - 1018

420

(.2-.3 Carbon) .0006" .0011" .0017" .002" .0025" .0028" .0032" .0033" .0041"

Mild - 4140 .016mm .028mm .043mm .051mm .064mm .071mm .081mm .084mm .104mm

300

Steels (.4-.5 Carbon)

P Tool Steels

240

A2/D2/H13/P20 .0004" .0009" .0013" .0016" .0019" .0021" .0026" .0028" .0028"

.010mm .023mm .033mm .041mm .048mm .053mm .066mm .071mm .071mm

Forgings 150

Soft 540

Cast Irons Medium 360 .0006" .0011" .0017" .002" .0025" .0028" .0032" .0033" .0041"

K Hard Chilled 300 .016mm .028mm .043mm .051mm .064mm .071mm .081mm .084mm .104mm

Malleable 270

Free Machining 360 .0006" .0011" .0017" .002" .0025" .0028" .0032" .0033" .0041"

Ferritic 240 .016mm .028mm .043mm .051mm .064mm .071mm .081mm .084mm .104mm

Stainless Austenitic

220

Steels 304/316 .0004" .0009" .0013" .0016" .0019" .0021" .0026" .0028" .0028"

M Martensitic 180 .010mm .023mm .033mm .041mm .048mm .053mm .066mm .071mm .071mm

PH

150

17-4 PH

Titanium .0003" .0005" .0007" .001" .0012" .0014" .0017" .0019" .0025"

210

6AL-V4 .008mm .013mm .018mm .025mm .030mm .036mm .043mm .048mm .063mm

Co-Based Alloys

Special 120

Stellite

Alloys

Ni-Based Alloys .0004" .001" .0012" .0015" .0017" .002" .0025" .003" .003"

S 120

Inconel 625/718 .010mm .025mm .030mm .038mm .043mm .051mm .064mm .076mm .076mm

Fe-Based Alloys

150

Incoloy 800-802

Hardened 35-45Rc 240 .0004" .001" .0012" .0015" .0017" .002" .0025" .003" .003"

Steels 45-55Rc 180 .010mm .025mm .030mm .038mm .043mm .051mm .064mm .076mm .076mm

H 55-65Rc 60

Al/Al Alloys 600

Non-

Brass/Bronze 480 .0011" .0017" .0022" .0027" .0032" .0042" .0065" .0085" .0092"

Ferrous

Mg/Mg Alloys 840 .028mm .043mm .056mm .068mm .081mm .107mm .165mm .216mm .234mm

N

Plastics/Bakelite 960

Speeds - Inch Speeds - Metric

SFM = surface feet per minute SMM = surface meters per minute

RPM = SFM X 3.82 / Tool Diameter RPM = SMM X 318.057 / Tool Diameter

Radial Depth of Cut in Percentage of Diameter 50% 30% 20% 15% 10% 5% 1%

CLF = chip load factor 1.0 1.1 1.2 1.4 1.8 2.3 5.0

Feeds - Inch Feeds - Metric

IPM = inches per minute IPT = inches / tooth MMPM = mm per minute MMPT = mm / tooth

IPM = RPM X number of teeth X CLF X IPT MMPM = RPM X number of teeth X CLF X MMPT

Safety Notice

Always wear the appropriate personal protective equipment such as safety glasses and protective clothing when using

solid carbide cutting tools. Machines should be fully guarded. Technical data provided should be considered advisory

only as variations may be necessary depending on the particular application.

Copyright (c) All Rights Reserved Property of The-Carbide-End-Mill-Store.com

You might also like

- Acnis Brochure-Titanium GradesDocument12 pagesAcnis Brochure-Titanium Gradesanilsamuel0077418No ratings yet

- Carbide End Mill Speeds and Feeds, General Purpose, UncoatedDocument1 pageCarbide End Mill Speeds and Feeds, General Purpose, UncoatedMihir SevakNo ratings yet

- SFM Formulae Chart 2Document2 pagesSFM Formulae Chart 2Carlos Gabriel PensamientoNo ratings yet

- Stainless Steel Molecular Etching PDFDocument6 pagesStainless Steel Molecular Etching PDFp.designNo ratings yet

- Speeds and Feeds 1053 1054Document1 pageSpeeds and Feeds 1053 1054P CHNo ratings yet

- A 400 HB Wear Resistant Steel: StandardDocument4 pagesA 400 HB Wear Resistant Steel: StandardVíctor SandovskyNo ratings yet

- Cutting SpeedDocument5 pagesCutting Speedokooy erusNo ratings yet

- Milling Parameters: N (RPM) (VC (M/min) 1000) / 3.14 Ø d1 (MM) )Document4 pagesMilling Parameters: N (RPM) (VC (M/min) 1000) / 3.14 Ø d1 (MM) )Damir PrstenkovNo ratings yet

- Milling Speeds and FeedsDocument1 pageMilling Speeds and FeedsMahesh Deivasiga Mani DNo ratings yet

- AUT 1076 en US FactSheet Main 01Document2 pagesAUT 1076 en US FactSheet Main 01Victor Solis BrevisNo ratings yet

- Cutting Speed and Feedrate SouthbayDocument5 pagesCutting Speed and Feedrate SouthbayShahed FacebookNo ratings yet

- NPA104 enDocument4 pagesNPA104 enAdelino GasparNo ratings yet

- FR4 4806Document2 pagesFR4 4806Trasma_Yunita_1885No ratings yet

- 05 MachiningDocument12 pages05 MachiningVisvas RajyaguruNo ratings yet

- Precision and Laboratory EquipmentsDocument33 pagesPrecision and Laboratory EquipmentsTone RatanalertNo ratings yet

- NTK General TechnicalDocument32 pagesNTK General TechnicalsathishelakkiyaNo ratings yet

- Mill Details IndiaDocument7 pagesMill Details IndiaYash JainNo ratings yet

- End Mill Speed FeedDocument12 pagesEnd Mill Speed FeedkxeNo ratings yet

- Assignment 4Document2 pagesAssignment 4Lhekha RaviendranNo ratings yet

- Millermatic 350P: The Power of BlueDocument4 pagesMillermatic 350P: The Power of BlueVic HernandezNo ratings yet

- Master Tungsten Carbide Rotary Burrs PDFDocument12 pagesMaster Tungsten Carbide Rotary Burrs PDFFred AksoNo ratings yet

- Specification: EN9 - 070M55: Hollowbar - Co.zaDocument3 pagesSpecification: EN9 - 070M55: Hollowbar - Co.zaAnantha RamanNo ratings yet

- SAF Welding Cutting GuideDocument165 pagesSAF Welding Cutting GuideSelvem0% (1)

- Trimmer PartsDocument29 pagesTrimmer PartsHAVENSALNo ratings yet

- Bi-Metal Tek Screw: Product DatasheetDocument1 pageBi-Metal Tek Screw: Product Datasheetbravo deltafoxNo ratings yet

- Technical Guide For Steel & Stainless Steel Turning - Seco Tools PDFDocument20 pagesTechnical Guide For Steel & Stainless Steel Turning - Seco Tools PDFwilsonNo ratings yet

- 4-1 RN3 - 4 - 6 - Ba - enDocument42 pages4-1 RN3 - 4 - 6 - Ba - enVali BobNo ratings yet

- RFQ of C45 SteelDocument3 pagesRFQ of C45 Steelnhirpara1No ratings yet

- 3835 Series Alumamill End Mill Is Designed For Aggressive Material Removal Rates in Non-Ferrous MaterialsDocument2 pages3835 Series Alumamill End Mill Is Designed For Aggressive Material Removal Rates in Non-Ferrous MaterialsAlex L. CruzNo ratings yet

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- Section 1 Abrasive Produk EbookDocument16 pagesSection 1 Abrasive Produk EbookKurniawanNo ratings yet

- Hot Rolled China SteelDocument43 pagesHot Rolled China Steeledgarc999No ratings yet

- Achteck CatalogueDocument8 pagesAchteck CatalogueManas D SinghNo ratings yet

- 272101GBDocument8 pages272101GBHady AdjahNo ratings yet

- Speeds & Feeds: Drilling & Reaming Surface Feet Per Minute (SFM)Document6 pagesSpeeds & Feeds: Drilling & Reaming Surface Feet Per Minute (SFM)naninoNo ratings yet

- Thyssenkrupp s355jr Product Information Precision Steel en PDFDocument2 pagesThyssenkrupp s355jr Product Information Precision Steel en PDFjackcan501No ratings yet

- EvolutionTekDatasheet PDFDocument1 pageEvolutionTekDatasheet PDFRobNo ratings yet

- Reference Tables: General Guide For Cutting Speeds and Feeds For DrillsDocument1 pageReference Tables: General Guide For Cutting Speeds and Feeds For DrillsleonboneNo ratings yet

- Product Catalogue: Redefining Racing SolutionsDocument22 pagesProduct Catalogue: Redefining Racing SolutionsVaibhav AnandNo ratings yet

- Tooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool CompanyDocument4 pagesTooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool Companyjavier_mor69No ratings yet

- Code Exchanger Axapta MICNDocument428 pagesCode Exchanger Axapta MICNm3123atNo ratings yet

- Speeds and Feeds For Metal CuttingDocument4 pagesSpeeds and Feeds For Metal CuttingAnonymous dh6DITNo ratings yet

- Tgi33 7Document2 pagesTgi33 7infoNo ratings yet

- RS Pro 4 Piece TCT Holesaw Kit, 12mm Cutting Depth: DatasheetDocument2 pagesRS Pro 4 Piece TCT Holesaw Kit, 12mm Cutting Depth: DatasheetoscarNo ratings yet

- RFQ of C45 SteelDocument3 pagesRFQ of C45 Steelnhirpara1No ratings yet

- SS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Document3 pagesSS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Harish AmpoluNo ratings yet

- Standard ThreadmillsDocument1 pageStandard ThreadmillsshawntsungNo ratings yet

- Mitek Cyclone TieDocument7 pagesMitek Cyclone TieTony PedaNo ratings yet

- Machining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthDocument3 pagesMachining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthbasaricaNo ratings yet

- Speeds and Feeds: © 2013 Project Lead The Way, Inc. Computer Integrated ManufacturingDocument28 pagesSpeeds and Feeds: © 2013 Project Lead The Way, Inc. Computer Integrated ManufacturingAbel David Olmos BotelloNo ratings yet

- Fan SpecificationDocument3 pagesFan SpecificationEmrah MertyürekNo ratings yet

- 21 R Wire and Pin Implants PDFDocument8 pages21 R Wire and Pin Implants PDFEduardo BernardinoNo ratings yet

- Data Sheet AluminaDocument10 pagesData Sheet AluminaXin EnNo ratings yet

- OSBORN Crimped Cup BrushDocument2 pagesOSBORN Crimped Cup BrushThái Mai ĐìnhNo ratings yet

- Carbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, IncDocument2 pagesCarbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, Incsemarasik_651536604No ratings yet

- Foot Valve Cataloque IFCDocument2 pagesFoot Valve Cataloque IFCPuntanata SiagianNo ratings yet

- Aristo Feed 3004 U6 With Mig 4002c/6502c Power SupplyDocument3 pagesAristo Feed 3004 U6 With Mig 4002c/6502c Power SupplyChinta IulianNo ratings yet

- PAC - 316L Stainless Steel Tubing DatasheetDocument1 pagePAC - 316L Stainless Steel Tubing DatasheetChan Yong SoonNo ratings yet