Professional Documents

Culture Documents

P21111IA-CC CNEX17ATEX0004X Issue 8 Signed

P21111IA-CC CNEX17ATEX0004X Issue 8 Signed

Uploaded by

abdelrahman MohamedCopyright:

Available Formats

You might also like

- Magnavox Lo3.2U AA For (13MT1431/17, 20MT1331/17)Document44 pagesMagnavox Lo3.2U AA For (13MT1431/17, 20MT1331/17)Jorge G. Manzanero100% (2)

- I.T ReportDocument13 pagesI.T Reportjonathan50% (2)

- P0089 Elec. Pressure Type Tank Level Gauging System Final DRDocument66 pagesP0089 Elec. Pressure Type Tank Level Gauging System Final DRFILIN VLADIMIR100% (3)

- Certificados Dekra 160-800ADocument12 pagesCertificados Dekra 160-800AARGENIS BENITO NAVARRO MAS Y RUBINo ratings yet

- BFR 91 ADocument8 pagesBFR 91 AGunnar Antonio Duran BarronNo ratings yet

- Sira 11atex1006x Iss 16Document27 pagesSira 11atex1006x Iss 16Sankalp AwasthiNo ratings yet

- BFR93Document8 pagesBFR93Andrea GarciaNo ratings yet

- BUL903ED: High Voltage Fast-Switching NPN Power TransistorDocument6 pagesBUL903ED: High Voltage Fast-Switching NPN Power TransistorproctepNo ratings yet

- Datasheet ET1100Document10 pagesDatasheet ET1100Manal FeghaliNo ratings yet

- Iecexptb050023 004 00Document7 pagesIecexptb050023 004 00Rasha MadathilNo ratings yet

- Iecex Kem 10.0002XDocument6 pagesIecex Kem 10.0002XFrancesco_CNo ratings yet

- Cny17 PDFDocument9 pagesCny17 PDFone_blanche6175No ratings yet

- 2N5672Document13 pages2N5672Deepa DevarajNo ratings yet

- Brochure Ex-Pz Pressurized System f830 fs830Document4 pagesBrochure Ex-Pz Pressurized System f830 fs830Ikhtiander IkhtianderNo ratings yet

- 100 EDRS71M4 FG 2GD B KCC TF AL ProductData en DEDocument2 pages100 EDRS71M4 FG 2GD B KCC TF AL ProductData en DEMahesh Daxini ThakkerNo ratings yet

- ET1103Document11 pagesET1103fredy arias duranNo ratings yet

- Datasheet Fotoacoplador EL817Document13 pagesDatasheet Fotoacoplador EL817Manoel Alves Feitosa FilhoNo ratings yet

- IECEx INE 10.0007X 000Document6 pagesIECEx INE 10.0007X 000Marcos SiqueiraNo ratings yet

- B 0553Document6 pagesB 0553Milan BanicNo ratings yet

- 2 N 720Document4 pages2 N 720roozbehxoxNo ratings yet

- Sem210 Series: Programmable In-Head Universal Temperature TransmitterDocument5 pagesSem210 Series: Programmable In-Head Universal Temperature TransmitterjhuskanovicNo ratings yet

- BFR 91Document8 pagesBFR 91hkabagaNo ratings yet

- Surge Voltage ProtectionDocument22 pagesSurge Voltage Protectionrajpre1213No ratings yet

- Dold NetwachterDocument4 pagesDold NetwachternstijntjesNo ratings yet

- CNY17GDocument8 pagesCNY17GBrzata PticaNo ratings yet

- STP9NK65ZFPDocument16 pagesSTP9NK65ZFPJacson FagundesNo ratings yet

- Njl0281D (NPN) Njl0302D (PNP) Complementary Thermaltrakt TransistorsDocument6 pagesNjl0281D (NPN) Njl0302D (PNP) Complementary Thermaltrakt TransistorsDomingo ArroyoNo ratings yet

- Revisions: REV Description Date Issued by - Issue 1Document7 pagesRevisions: REV Description Date Issued by - Issue 1Jose Antonio GBNo ratings yet

- STV9379FADocument5 pagesSTV9379FACintya CardozoNo ratings yet

- Ba 9043Document3 pagesBa 9043Aziz Sultan0% (1)

- STK433 060 eDocument11 pagesSTK433 060 eGustavo EndeNo ratings yet

- IECEx BAS 10.0045X 000Document6 pagesIECEx BAS 10.0045X 000Marcos SiqueiraNo ratings yet

- Certificari Fronius SYMO3-8.2Document2 pagesCertificari Fronius SYMO3-8.2Fair Play SerbanNo ratings yet

- Transistor de Alta TensãoDocument9 pagesTransistor de Alta TensãoitavolpNo ratings yet

- TCLT100. Series: Vishay SemiconductorsDocument6 pagesTCLT100. Series: Vishay Semiconductorsmarcos aragaoNo ratings yet

- 4N33 Opto CouplerDocument6 pages4N33 Opto Couplerthijo19No ratings yet

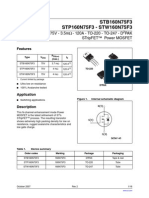

- Stb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetDocument16 pagesStb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetmoabdolyNo ratings yet

- Data Sheet: Low Voltage Mono/stereo Power AmplifierDocument9 pagesData Sheet: Low Voltage Mono/stereo Power AmplifiergusguicorNo ratings yet

- ST2009DHI: High Voltage Fast-Switching NPN Power TransistorDocument7 pagesST2009DHI: High Voltage Fast-Switching NPN Power TransistorMiloud ChouguiNo ratings yet

- Quick Connection Terminal Block QTCDocument4 pagesQuick Connection Terminal Block QTCOualid ZaouichNo ratings yet

- IECEx BAS 13.0142X 003Document5 pagesIECEx BAS 13.0142X 003Marcos SiqueiraNo ratings yet

- IECEx PRE 19.0093U 000Document5 pagesIECEx PRE 19.0093U 000Mangesh MohiteNo ratings yet

- Imkon Gaz/SC20075-1 IMKON GAZ SERVIS/GEO-20364Document25 pagesImkon Gaz/SC20075-1 IMKON GAZ SERVIS/GEO-20364Жасур ТашпулатовNo ratings yet

- Bu 941Document9 pagesBu 941Uriel HernandezNo ratings yet

- IECEx INE 12.0057X 000Document6 pagesIECEx INE 12.0057X 000Marcos SiqueiraNo ratings yet

- pc3sh21 e PDFDocument15 pagespc3sh21 e PDFkyoceramitaNo ratings yet

- PNP General Purpose Amplifier: Absolute Maximum RatingsDocument9 pagesPNP General Purpose Amplifier: Absolute Maximum Ratingscarlos16702014No ratings yet

- TDA2008Document10 pagesTDA2008miusayNo ratings yet

- IECEx BAS 13.0008X 000Document4 pagesIECEx BAS 13.0008X 000Marcos SiqueiraNo ratings yet

- K3020P (G) Series: VishayDocument9 pagesK3020P (G) Series: VishayelecompinnNo ratings yet

- CB Test CertificateDocument3 pagesCB Test Certificatemarino palmaresNo ratings yet

- STV9379F: Vertical Deflection BoosterDocument5 pagesSTV9379F: Vertical Deflection BoosterCarlos RamirezNo ratings yet

- Iecex Certificate of ConformityDocument7 pagesIecex Certificate of ConformityycjpaulNo ratings yet

- U813Bs/U813Bse: 1.1-Ghz Prescaler For Plls in TV, Catv and Sat TV TunersDocument7 pagesU813Bs/U813Bse: 1.1-Ghz Prescaler For Plls in TV, Catv and Sat TV TunersArt EntertainmenNo ratings yet

- CofC ABB ACF5000Document4 pagesCofC ABB ACF5000TAN VU DUYNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Oil Tester - Oil Breakdown Voltage (BDV) Tester - Power ElectronicalDocument2 pagesOil Tester - Oil Breakdown Voltage (BDV) Tester - Power Electronicalmustafa1805100% (1)

- Odi-065r15mjjjj-G DS 200 PDFDocument4 pagesOdi-065r15mjjjj-G DS 200 PDFСергей МирошниченкоNo ratings yet

- Digital Multimeter Basics and PriceDocument5 pagesDigital Multimeter Basics and PriceIshank PuriNo ratings yet

- Oil Centrifuge - ControllerDocument41 pagesOil Centrifuge - Controllerbala manikanta100% (1)

- L1 IntroductDocument29 pagesL1 IntroductRasim UmurNo ratings yet

- Lecture Slides For Learn - Training Document TIA Portal - PDFDocument19 pagesLecture Slides For Learn - Training Document TIA Portal - PDFJemerald MagtanongNo ratings yet

- Phaser 7750 Service ManualDocument505 pagesPhaser 7750 Service ManualFrankTalotta100% (2)

- Jpce Company Profile DecDocument16 pagesJpce Company Profile DecJPCE1288No ratings yet

- Transmission Lines & Termination Techniques: SAED VLSI GroupDocument17 pagesTransmission Lines & Termination Techniques: SAED VLSI GrouplusinNo ratings yet

- AIS Decoder With Ethernet Interface: Bill of MaterialsDocument1 pageAIS Decoder With Ethernet Interface: Bill of MaterialsrizalNo ratings yet

- I4 Industrial UPS Catalogue (Domestic)Document8 pagesI4 Industrial UPS Catalogue (Domestic)p41005679No ratings yet

- Lanco 8.5 Mva GTP Rv.01Document14 pagesLanco 8.5 Mva GTP Rv.01Pankaj TiwariNo ratings yet

- O270404a MilDocument68 pagesO270404a MilAyud EconomicNo ratings yet

- C-Iic EvDocument152 pagesC-Iic EvSohibul HajahNo ratings yet

- Free Space Optical Communication A Bibliography Report By: Arshad AliDocument43 pagesFree Space Optical Communication A Bibliography Report By: Arshad AliArshad AliNo ratings yet

- Manual Mitsubishi - MR-J2-CTDocument212 pagesManual Mitsubishi - MR-J2-CTmiltonrighettoNo ratings yet

- Cat Busbar enDocument22 pagesCat Busbar enmustaphaNo ratings yet

- FM Data For South Zone PDFDocument13 pagesFM Data For South Zone PDFSUDHAKAR BABU MIDUTHURNo ratings yet

- Aoyue: Multi-Function Re-Working SystemDocument10 pagesAoyue: Multi-Function Re-Working Systemmonitors_serviceNo ratings yet

- API Source Inspector Electrical Equipment Exam (SIEE) : Publications Effectivity SheetDocument2 pagesAPI Source Inspector Electrical Equipment Exam (SIEE) : Publications Effectivity SheetJaaffer AliNo ratings yet

- IGBT & Sic MosfetDocument7 pagesIGBT & Sic MosfetNgọc Hưng TạNo ratings yet

- Manual At1500cvDocument8 pagesManual At1500cvHenry MillerNo ratings yet

- Performance Requirements For Protective FootwearDocument2 pagesPerformance Requirements For Protective FootwearDika Safitri0% (1)

- Prueba A Regulador de Alternador Toyota Tacoma 2004Document2 pagesPrueba A Regulador de Alternador Toyota Tacoma 2004Gustavo GamezNo ratings yet

- Charger - Company ProfileDocument18 pagesCharger - Company ProfileUvi BNo ratings yet

- Oda SıcaklığıDocument4 pagesOda SıcaklığıGürkan SaltıkNo ratings yet

- Automatic Light Switch by Light Intensity and Noise: Islamabad-Pakistan Fall 2013Document10 pagesAutomatic Light Switch by Light Intensity and Noise: Islamabad-Pakistan Fall 2013Shykh SheharyarNo ratings yet

- LED Red Beacon Class1 Div2Document2 pagesLED Red Beacon Class1 Div2Fajar Ramdani KusumaNo ratings yet

P21111IA-CC CNEX17ATEX0004X Issue 8 Signed

P21111IA-CC CNEX17ATEX0004X Issue 8 Signed

Uploaded by

abdelrahman MohamedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P21111IA-CC CNEX17ATEX0004X Issue 8 Signed

P21111IA-CC CNEX17ATEX0004X Issue 8 Signed

Uploaded by

abdelrahman MohamedCopyright:

Available Formats

[1] EU-TYPE EXAMINATION CERTIFICATE

[2] Equipment or Protective System intended for use

in Potentially Explosive Atmospheres

Directive 2014/34/EU

[3] EU-Type Examination Certificate Number: CNEX 17 ATEX 0004 X Issue 8

[4] Equipment : Three-phase asynchronous motors series 1MB..53… (see Schedule)

[5] Manufacturer : SIEMENS AG

[6] Address : Vogelweiherstrasse 1-15, 90441 Nürnberg, Germany

[7] This equipment or protective system and any acceptable variation thereto is specified in the schedule to

this certificate and the documents therein referred to.

[8] CNEX-Global B.V., Notified Body number 2614, in accordance with Directive 2014/34/EU of the

European Parliament and of the Council, dated 26 February 2014, certifies that this equipment or

protective system has been found to comply with the Essential Health and Safety Requirements relating

to the design and construction of equipment and protective systems intended for use in potentially

explosive atmospheres given in Annex II to the Directive.

The examination and test results are recorded in confidential Report No. P21111IA-CS

[9] Compliance with the Essential Health and Safety Requirements has been assured by

compliance with:

EN IEC 60079-0:2018 EN 60079-1:2014 EN 60079-7:2015

EN IEC 60079-7:2015/A1:2018 EN 60079-11:2012 EN 60079-31:2014

except in respect of those requirements listed at item 18 of the Schedule.

[10] If the sign "X" is placed after the certificate number, it indicates that the equipment or protective system

is subject to specific conditions for use specified in the schedule to this certificate.

[11] This EU – Type examination certificate relates only to the design of the specified equipment or protective

system. Further requirements of the Directive apply to the manufacture and supply of this equipment or

protective system. These are not covered by this certificate.

[12] The marking of the equipment or protective system shall include the following:

See Schedule.

Certification officer : Hou Yandong Signature:

Date of issue : 2022-09-09

Certification Body: CNEX-Global B.V., Utrechtseweg 310-B42, 6812 AR Arnhem, The Netherlands

This certificate may only be reproduced in its entirety and without any change, including schedule

CNEX-FM-603E Issue 9 Page 1 of 7

[13] SCHEDULE

[14] EU-TYPE EXAMINATION CERTIFICATE No.

CNEX 17 ATEX 0004 X Issue 8

Report: 21111

[15] Description of equipment:

Asynchronous three-phase induction motors model 1MB**53***, with self-ventilated cooling or forced-

air cooled (acc. to CQST/CNEX-Global agreement), squirrel-cage rotor and seated with roller bearings

(antifriction bearings). The cast iron enclosure of the motor is constructed in type of explosion protection

flameproof enclosure ‘db’ for explosive gas atmospheres and in type of explosion protection ‘tb’ for

explosive dust atmospheres. The terminal box can be constructed in type of explosion protection

flameproof enclosure ‘db’ or in type of explosion protection increased safety ‘eb’, for explosive gas

atmospheres and in type of explosion protection ‘tb’ for explosive dust atmospheres. The motors can

be operated direct-on-line or through a frequency converter.

Nomenclature for model 1MB1553-1EA40-2AA4:

1MB - Motor family designation

1 - Motor size: 1 = acc. to IEC up to shaft height 280

5 = acc. to IEC above shaft height 280

5 - Production line: 5 = Global line, 8 = Global Line special insulation system

5 - Protection type: 5 = motor: Ex db

3 - Efficiency: 3 = IE3,

6 = Reduced starting current 600 % with positive tolerance / 50 Hz

only / in combination up to +55 °C / output power might be reduced /

efficiency class might be reduced to IE2

7 = Reduced starting current 700 % with positive tolerance / 50 Hz

only / in combination up to +55 °C / output power might be reduced

1E - Frame size: 0C = 071, 0D = 080, 0E = 090, 1A = 100, 1B = 112, 1C = 132,

1D = 160, 1E = 180, 2A = 200, 2B = 225, 2C = 250, 2D = 280,

3A = 315, 3B = 355

A - Number of poles: A = 2, B = 4, C = 6, D = 8

4 - Core length: 0/1 = Short, 2/3 = Medium, 4/5 = Long, 6/7/8 = “S/M/L” increased output

9 = Special output

0-2 - Voltage, connections and frequency:

0-1 = 50 Hz 230 VY

0-2 = 50 Hz 400 VY

0-4 = 50 Hz 400 VΔ

1-7 = 60 Hz 220 VΔ/380 VY

1-8 = 60 Hz 230 VΔ/400 VY

2-1 = 50 Hz 220 VΔ/380 VY, 60 Hz 440 VY

2-2 = 50 Hz 230 VΔ/400 VY, 60 Hz 460 VY

2-3 = 50 Hz 240 VΔ/415 VY, 60 Hz 480 VY

2-7 = 50 Hz 500 VY

3-0 = 60 Hz 380 VΔ/660 VY

3-1 = 60 Hz 400 VΔ/690 VY

3-3 = 50 Hz 380 VΔ/660 VY, 60 Hz 440 VΔ

This certificate may only be reproduced in its entirety and without any change, including schedule

CNEX-FM-603E Issue 9 Page 2 of 7

[13] SCHEDULE

[14] EU-TYPE EXAMINATION CERTIFICATE No.

CNEX 17 ATEX 0004 X Issue 8

Report: 21111

Nomenclature (continued):

3-4 = 50 Hz 400 VΔ/690 VY, 60 Hz 460 VΔ

3-5 = 50 Hz 415 VΔ, 60 Hz 480 VΔ

4-0 = 50 Hz 500 VΔ

9-0 = Voltage for converter operation or non-standard winding

A - Mounting type:

A = IM B3, T = IM B6, U = IM B7, V = IM B8, D = IM V6, C = IM V5

F = IM B5, G = IM V1, H = IM V3, J = IM B35, W = IM V15, K = IM B14,

L = IM V19, M = V18, N = IM B34, Y = IM V35

A - Winding protection:

A = Without winding protection

B = 3 PTC thermistors for tripping

C = 6 PTC thermistors for alarm and tripping

H = 3 PT100 resistance thermometers

J = 6 PT100 resistance thermometers

K = 1 PT1000 resistance thermometers

L = 2 PT1000 resistance thermometers

Q = 3 PT100 resistance thermometers (3-wire connection)

R = 6 PT100 resistance thermometers (3-wire connection)

4 - Position of terminal box:

4 = On top, 5 = On right hand side, 6 = On left hand side,

7 = Connection box bottom

Ex markings for explosive Gas atmospheres:

II 2 G Ex db IIA/IIB/IIC T4-T6 Gb or Ex db eb IIA/IIB/IIC T4-T6 Gb

Additional Ex markings for explosive Gas atmospheres (only for models FS 315 and FS 355):

II 2 G Ex db ib IIA/IIB/IIC T4 Gb

Ex markings for explosive Dust atmospheres:

II 2 D Ex tb IIIA/IIIB/IIIC Txxx °C Db

Notes: The marking Txxx °C indicates optional values. For T4 the coding will be T130 °C, for T5 the coding will be

T95 °C, for T6 the coding will be T80 °C. Lower temperature codes for Dust can be applied if covered by Test

reports under the terms of the CQST / CNEX-Global agreement with the manufacturer

This certificate may only be reproduced in its entirety and without any change, including schedule

CNEX-FM-603E Issue 9 Page 3 of 7

[13] SCHEDULE

[14] EU-TYPE EXAMINATION CERTIFICATE No.

CNEX 17 ATEX 0004 X Issue 8

Report: 21111

Electrical Data:

Rated power …… : 0.12 kW to 460 kW

The electrical parameters per motor model are detailed in the Test Report Cover Sheet.

(ref. P21111IA-CS).

Mounting Instructions:

See manufacturer’s instructions.

Installation Instructions:

All cable entry devices and blanking elements shall be certified in a suitable type of explosion protection

with respect of the type of explosion protection of the terminal box (e.g. increased safety ‘’eb’’), with an

IP rating minimum equal to the motor IP rating, suitable for the conditions of use and correctly installed.

Unused apertures shall be closed with suitable certified blanking elements.

Optional encoders can be applied on the motor sizes FS100 - FS355, shall be ATEX certified, suitable

for the conditions of use, correctly installed and maintaining the assigned Ingress Protection level.

Optional brake systems can be applied on the motor sizes FS71 - FS200, shall be ATEX certified,

suitable for the conditions of use, correctly installed and maintaining the assigned Ingress Protection

level.

See manufacturer’s instructions.

Routine tests:

Detailed in the Test Report Cover document. (P21111IA-CS).

[16] Descriptive Documents:

Detailed in the Test Report Cover document. (P21111IA-CS).

[17] Specific Conditions for Use:

The ambient temperature range is limited to -40 °C … +60 °C for FS71 to FS355.

For ambient temperatures above +40 °C up to +60 °C, a derating of the power output (between -4%

and -18%) can be applicable to avoid the exceeding of the thermal limiting temperature. The derating

shall ensure that the maximum allowed internal and external temperatures are not exceeded.

For absolute temperatures higher than +70 °C at the entry point or +80 °C at the branching point of the

conductors, the information that heat-resistant cables have to be applied, shall be marked on the motor.

This certificate may only be reproduced in its entirety and without any change, including schedule

CNEX-FM-603E Issue 9 Page 4 of 7

[13] SCHEDULE

[14] EU-TYPE EXAMINATION CERTIFICATE No.

CNEX 17 ATEX 0004 X Issue 8

Report: 21111

[17] Specific Conditions for Use (continued):

The efficiency class IE3 is only guaranteed for motor models 1MB**53*** and 1MB**57*** (with

reduced starting current 700 %). The efficiency class IE3 is not guaranteed in all cases for motor

model 1MB**56*** (with reduced starting current 600 %). The use of the motor model 1MB**56*** is

only allowed when in compliance with local legislation in the country of application.

For repair of the flameproof joints due regard must be given to the structural specifications provided by

the manufacturer. Repair in compliance with the values in Tables 1 and 2 of EN 60079-1 is not allowed.

Motor winding and bearing temperature control with PT100 elements in Ex ib circuits is only allowed

for FS315 and FS355, constructed in Ex db ib IIA/IIB/IIC T4-T6 Gb. These Ex ib circuits shall be

connected in auxiliary terminal boxes (Ex db) to external intrinsic safe (‘ib’) circuits from suitable

certified Ex ib equipment.

The terminal boxes for the motors shall be:

- suitable ATEX certified terminal boxes in type of explosion protection flameproof enclosure ‘db’ or in

type of explosion protection increased safety ‘’eb’’, or

- suitable terminal boxes in type of explosion protection increased safety ‘’eb’’, that are covered by

third-party test reports, with their suitability proven by routine temperature measurements in

combination with the intended motor type, and

- with an IP rating minimum equal to the motor IP rating, suitable for the conditions of use and

correctly installed.

For duty types other than S1, the motor temperature shall be monitored by the resistance thermometers,

or PTC-thermistors, in the stator windings. These devices have to be connected to suitable tripping

units that have been functionally tested for this purpose.

Frequency converter supply of the motor is only allowed by using a voltage-source converter with pulse

width modulation. The frequency converter parameters as listed in the manufacturer’s instructions must

strictly be followed.

Frequency converter supplied motors can apply a thermal utilization F/F for up to 110% of the rated

power at an ambient temperature of maximum +40 °C.

Optional anti-condensation heaters and heating systems can be installed inside the flameproof motor

enclosures, but they shall not be energized when the motor is running.

Alternatively external fan systems can be used for motor sizes FS225 - FS355 instead of the shaft

mounted fan. The suitability of the combination of motor and external fan system must be confirmed by

relevant temperature measurements performed under the control of the certification body.

This certificate may only be reproduced in its entirety and without any change, including schedule

CNEX-FM-603E Issue 9 Page 5 of 7

[13] SCHEDULE

[14] EU-TYPE EXAMINATION CERTIFICATE No.

CNEX 17 ATEX 0004 X Issue 8

Report: 21111

[17] Specific Conditions for Use (continued):

An alternative low noise axial fan, complying with the requirements of the relevant EN standards as

applied for the motor, can optionally be installed on the 2-pole motor sizes FS160 - FS355. The

suitability of the combination of motor and low noise axial fan must be confirmed by relevant

temperature measurements under the control of the certification body.

Alternative, non-standard shaft ends can be added to the motor. The suitability of the combination of

motor and non-standard shaft ends must be confirmed by the certification body.

Use only motor cover bolts with minimum yield stress of 450 N/mm².

All electrical connections shall be tightened with the tightening torques specified in the manufacturer’s

instructions.

[18] Essential Health and Safety Requirements:

The Essential Health and Safety Requirements are covered by the standards listed at item [9].

The manufacturer shall inform the notified body concerning all modifications to the technical

documentation as described in ANNEX III to Directive 2014/34/EU of the European Parliament and the

Council of 26 February 2014.

Additional Information:

The enclosure of the asynchronous three-phase induction motors model 1MB**53***, successfully

passed the tests for the Ingress Protection level IP65 to EN 60529 / EN 60034-5. The IP degree can be

specified from IP55 to IP66, depending on motor variation and client request.

The motors covered by this certificate are manufactured at the following locations:

- Location 1: Siemens, s.r.o. Elektromotory Mohelnice Branch,

Nádražní 395/25, CZ-78985 Mohelnice, Czech Republic

- Location 2: Siemens, s.r.o. Elektromotory Frenstat Branch

Markova 952, CZ-744 01 Frenstat, Czech Republic.

This certificate may only be reproduced in its entirety and without any change, including schedule

CNEX-FM-603E Issue 9 Page 6 of 7

[13] SCHEDULE

[14] EU-TYPE EXAMINATION CERTIFICATE No.

CNEX 17 ATEX 0004 X Issue 8

Report: 21111

Details of changes for issue 2:

Addition of plastic fans acc.to approval drawings of motor assembly.

Addition of motor mounting type IM V35 (all mounting types defined in MLFB at 14th digit).

Addition of special insulation system defined in MLFB at 5th digit by “8”.

Correction of certificate documentation regarding reduced starting current for +55°C ambient

(where needed).

Details of changes for issue 3:

Editorial changes in the text regarding assigned power per motor model.

Details of changes for issue 4:

Update of standards to EN IEC 60079-0:2018 and EN IEC 60079-7:2015/A1:2018.

Change of fan material.

Changes in the type-designation.

Change in manufacturing processes.

Changes in Instructions.

Details of changes for issue 5:

Change of models covered by this certificate.

Details of changes for issue 6:

Change of models covered by this certificate.

Details of changes for issue 7:

Change to include Ex ib circuits for PT-100 sensors in motor models FS315 and FS355.

Addition of models 1MB1553-0EC4, 1MB1553-1AC4 and 1MB1553-1BC2.

Removal of Ex tc.

Details of changes for issue 8:

Minor changes in construction and documentation

Minor manufacturing process changes

Correction of editorial error in certification documentation.

This certificate may only be reproduced in its entirety and without any change, including schedule

CNEX-FM-603E Issue 9 Page 7 of 7

You might also like

- Magnavox Lo3.2U AA For (13MT1431/17, 20MT1331/17)Document44 pagesMagnavox Lo3.2U AA For (13MT1431/17, 20MT1331/17)Jorge G. Manzanero100% (2)

- I.T ReportDocument13 pagesI.T Reportjonathan50% (2)

- P0089 Elec. Pressure Type Tank Level Gauging System Final DRDocument66 pagesP0089 Elec. Pressure Type Tank Level Gauging System Final DRFILIN VLADIMIR100% (3)

- Certificados Dekra 160-800ADocument12 pagesCertificados Dekra 160-800AARGENIS BENITO NAVARRO MAS Y RUBINo ratings yet

- BFR 91 ADocument8 pagesBFR 91 AGunnar Antonio Duran BarronNo ratings yet

- Sira 11atex1006x Iss 16Document27 pagesSira 11atex1006x Iss 16Sankalp AwasthiNo ratings yet

- BFR93Document8 pagesBFR93Andrea GarciaNo ratings yet

- BUL903ED: High Voltage Fast-Switching NPN Power TransistorDocument6 pagesBUL903ED: High Voltage Fast-Switching NPN Power TransistorproctepNo ratings yet

- Datasheet ET1100Document10 pagesDatasheet ET1100Manal FeghaliNo ratings yet

- Iecexptb050023 004 00Document7 pagesIecexptb050023 004 00Rasha MadathilNo ratings yet

- Iecex Kem 10.0002XDocument6 pagesIecex Kem 10.0002XFrancesco_CNo ratings yet

- Cny17 PDFDocument9 pagesCny17 PDFone_blanche6175No ratings yet

- 2N5672Document13 pages2N5672Deepa DevarajNo ratings yet

- Brochure Ex-Pz Pressurized System f830 fs830Document4 pagesBrochure Ex-Pz Pressurized System f830 fs830Ikhtiander IkhtianderNo ratings yet

- 100 EDRS71M4 FG 2GD B KCC TF AL ProductData en DEDocument2 pages100 EDRS71M4 FG 2GD B KCC TF AL ProductData en DEMahesh Daxini ThakkerNo ratings yet

- ET1103Document11 pagesET1103fredy arias duranNo ratings yet

- Datasheet Fotoacoplador EL817Document13 pagesDatasheet Fotoacoplador EL817Manoel Alves Feitosa FilhoNo ratings yet

- IECEx INE 10.0007X 000Document6 pagesIECEx INE 10.0007X 000Marcos SiqueiraNo ratings yet

- B 0553Document6 pagesB 0553Milan BanicNo ratings yet

- 2 N 720Document4 pages2 N 720roozbehxoxNo ratings yet

- Sem210 Series: Programmable In-Head Universal Temperature TransmitterDocument5 pagesSem210 Series: Programmable In-Head Universal Temperature TransmitterjhuskanovicNo ratings yet

- BFR 91Document8 pagesBFR 91hkabagaNo ratings yet

- Surge Voltage ProtectionDocument22 pagesSurge Voltage Protectionrajpre1213No ratings yet

- Dold NetwachterDocument4 pagesDold NetwachternstijntjesNo ratings yet

- CNY17GDocument8 pagesCNY17GBrzata PticaNo ratings yet

- STP9NK65ZFPDocument16 pagesSTP9NK65ZFPJacson FagundesNo ratings yet

- Njl0281D (NPN) Njl0302D (PNP) Complementary Thermaltrakt TransistorsDocument6 pagesNjl0281D (NPN) Njl0302D (PNP) Complementary Thermaltrakt TransistorsDomingo ArroyoNo ratings yet

- Revisions: REV Description Date Issued by - Issue 1Document7 pagesRevisions: REV Description Date Issued by - Issue 1Jose Antonio GBNo ratings yet

- STV9379FADocument5 pagesSTV9379FACintya CardozoNo ratings yet

- Ba 9043Document3 pagesBa 9043Aziz Sultan0% (1)

- STK433 060 eDocument11 pagesSTK433 060 eGustavo EndeNo ratings yet

- IECEx BAS 10.0045X 000Document6 pagesIECEx BAS 10.0045X 000Marcos SiqueiraNo ratings yet

- Certificari Fronius SYMO3-8.2Document2 pagesCertificari Fronius SYMO3-8.2Fair Play SerbanNo ratings yet

- Transistor de Alta TensãoDocument9 pagesTransistor de Alta TensãoitavolpNo ratings yet

- TCLT100. Series: Vishay SemiconductorsDocument6 pagesTCLT100. Series: Vishay Semiconductorsmarcos aragaoNo ratings yet

- 4N33 Opto CouplerDocument6 pages4N33 Opto Couplerthijo19No ratings yet

- Stb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetDocument16 pagesStb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetmoabdolyNo ratings yet

- Data Sheet: Low Voltage Mono/stereo Power AmplifierDocument9 pagesData Sheet: Low Voltage Mono/stereo Power AmplifiergusguicorNo ratings yet

- ST2009DHI: High Voltage Fast-Switching NPN Power TransistorDocument7 pagesST2009DHI: High Voltage Fast-Switching NPN Power TransistorMiloud ChouguiNo ratings yet

- Quick Connection Terminal Block QTCDocument4 pagesQuick Connection Terminal Block QTCOualid ZaouichNo ratings yet

- IECEx BAS 13.0142X 003Document5 pagesIECEx BAS 13.0142X 003Marcos SiqueiraNo ratings yet

- IECEx PRE 19.0093U 000Document5 pagesIECEx PRE 19.0093U 000Mangesh MohiteNo ratings yet

- Imkon Gaz/SC20075-1 IMKON GAZ SERVIS/GEO-20364Document25 pagesImkon Gaz/SC20075-1 IMKON GAZ SERVIS/GEO-20364Жасур ТашпулатовNo ratings yet

- Bu 941Document9 pagesBu 941Uriel HernandezNo ratings yet

- IECEx INE 12.0057X 000Document6 pagesIECEx INE 12.0057X 000Marcos SiqueiraNo ratings yet

- pc3sh21 e PDFDocument15 pagespc3sh21 e PDFkyoceramitaNo ratings yet

- PNP General Purpose Amplifier: Absolute Maximum RatingsDocument9 pagesPNP General Purpose Amplifier: Absolute Maximum Ratingscarlos16702014No ratings yet

- TDA2008Document10 pagesTDA2008miusayNo ratings yet

- IECEx BAS 13.0008X 000Document4 pagesIECEx BAS 13.0008X 000Marcos SiqueiraNo ratings yet

- K3020P (G) Series: VishayDocument9 pagesK3020P (G) Series: VishayelecompinnNo ratings yet

- CB Test CertificateDocument3 pagesCB Test Certificatemarino palmaresNo ratings yet

- STV9379F: Vertical Deflection BoosterDocument5 pagesSTV9379F: Vertical Deflection BoosterCarlos RamirezNo ratings yet

- Iecex Certificate of ConformityDocument7 pagesIecex Certificate of ConformityycjpaulNo ratings yet

- U813Bs/U813Bse: 1.1-Ghz Prescaler For Plls in TV, Catv and Sat TV TunersDocument7 pagesU813Bs/U813Bse: 1.1-Ghz Prescaler For Plls in TV, Catv and Sat TV TunersArt EntertainmenNo ratings yet

- CofC ABB ACF5000Document4 pagesCofC ABB ACF5000TAN VU DUYNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Oil Tester - Oil Breakdown Voltage (BDV) Tester - Power ElectronicalDocument2 pagesOil Tester - Oil Breakdown Voltage (BDV) Tester - Power Electronicalmustafa1805100% (1)

- Odi-065r15mjjjj-G DS 200 PDFDocument4 pagesOdi-065r15mjjjj-G DS 200 PDFСергей МирошниченкоNo ratings yet

- Digital Multimeter Basics and PriceDocument5 pagesDigital Multimeter Basics and PriceIshank PuriNo ratings yet

- Oil Centrifuge - ControllerDocument41 pagesOil Centrifuge - Controllerbala manikanta100% (1)

- L1 IntroductDocument29 pagesL1 IntroductRasim UmurNo ratings yet

- Lecture Slides For Learn - Training Document TIA Portal - PDFDocument19 pagesLecture Slides For Learn - Training Document TIA Portal - PDFJemerald MagtanongNo ratings yet

- Phaser 7750 Service ManualDocument505 pagesPhaser 7750 Service ManualFrankTalotta100% (2)

- Jpce Company Profile DecDocument16 pagesJpce Company Profile DecJPCE1288No ratings yet

- Transmission Lines & Termination Techniques: SAED VLSI GroupDocument17 pagesTransmission Lines & Termination Techniques: SAED VLSI GrouplusinNo ratings yet

- AIS Decoder With Ethernet Interface: Bill of MaterialsDocument1 pageAIS Decoder With Ethernet Interface: Bill of MaterialsrizalNo ratings yet

- I4 Industrial UPS Catalogue (Domestic)Document8 pagesI4 Industrial UPS Catalogue (Domestic)p41005679No ratings yet

- Lanco 8.5 Mva GTP Rv.01Document14 pagesLanco 8.5 Mva GTP Rv.01Pankaj TiwariNo ratings yet

- O270404a MilDocument68 pagesO270404a MilAyud EconomicNo ratings yet

- C-Iic EvDocument152 pagesC-Iic EvSohibul HajahNo ratings yet

- Free Space Optical Communication A Bibliography Report By: Arshad AliDocument43 pagesFree Space Optical Communication A Bibliography Report By: Arshad AliArshad AliNo ratings yet

- Manual Mitsubishi - MR-J2-CTDocument212 pagesManual Mitsubishi - MR-J2-CTmiltonrighettoNo ratings yet

- Cat Busbar enDocument22 pagesCat Busbar enmustaphaNo ratings yet

- FM Data For South Zone PDFDocument13 pagesFM Data For South Zone PDFSUDHAKAR BABU MIDUTHURNo ratings yet

- Aoyue: Multi-Function Re-Working SystemDocument10 pagesAoyue: Multi-Function Re-Working Systemmonitors_serviceNo ratings yet

- API Source Inspector Electrical Equipment Exam (SIEE) : Publications Effectivity SheetDocument2 pagesAPI Source Inspector Electrical Equipment Exam (SIEE) : Publications Effectivity SheetJaaffer AliNo ratings yet

- IGBT & Sic MosfetDocument7 pagesIGBT & Sic MosfetNgọc Hưng TạNo ratings yet

- Manual At1500cvDocument8 pagesManual At1500cvHenry MillerNo ratings yet

- Performance Requirements For Protective FootwearDocument2 pagesPerformance Requirements For Protective FootwearDika Safitri0% (1)

- Prueba A Regulador de Alternador Toyota Tacoma 2004Document2 pagesPrueba A Regulador de Alternador Toyota Tacoma 2004Gustavo GamezNo ratings yet

- Charger - Company ProfileDocument18 pagesCharger - Company ProfileUvi BNo ratings yet

- Oda SıcaklığıDocument4 pagesOda SıcaklığıGürkan SaltıkNo ratings yet

- Automatic Light Switch by Light Intensity and Noise: Islamabad-Pakistan Fall 2013Document10 pagesAutomatic Light Switch by Light Intensity and Noise: Islamabad-Pakistan Fall 2013Shykh SheharyarNo ratings yet

- LED Red Beacon Class1 Div2Document2 pagesLED Red Beacon Class1 Div2Fajar Ramdani KusumaNo ratings yet