Professional Documents

Culture Documents

5.3.6 Minimum Requirements To Concrete Mix: 5.3.6.1 Durability and Structural Design Requirements

5.3.6 Minimum Requirements To Concrete Mix: 5.3.6.1 Durability and Structural Design Requirements

Uploaded by

ahmed alyCopyright:

Available Formats

You might also like

- Al Maths Pure Unit 6 MsDocument8 pagesAl Maths Pure Unit 6 MsHacjer EiNSTi3NNo ratings yet

- CPL Flight Planning ManualDocument94 pagesCPL Flight Planning ManualChina LalaukhadkaNo ratings yet

- Shotcrete RequirementsDocument16 pagesShotcrete Requirementstinz_3100% (2)

- Preceptor Evaluation of Student Jordan ElizabethDocument2 pagesPreceptor Evaluation of Student Jordan Elizabethapi-487459879No ratings yet

- A Rectification Manual - ExampleDocument41 pagesA Rectification Manual - Examplesorobanista100% (1)

- 346 Portland Cement Concrete. (REV 1-8-02) (FA 1-10-02) (7-02)Document72 pages346 Portland Cement Concrete. (REV 1-8-02) (FA 1-10-02) (7-02)Jb SantosNo ratings yet

- Dm-dsi-SPEC09 - Corrosion PR & Odor CNTRLDocument13 pagesDm-dsi-SPEC09 - Corrosion PR & Odor CNTRLhardikNo ratings yet

- Technical Specifications Civil WorksDocument159 pagesTechnical Specifications Civil Worksrcdk2No ratings yet

- Factors in The Choice of Mix DesignDocument31 pagesFactors in The Choice of Mix DesignMudduKrishna shettyNo ratings yet

- Manhole-Bench Mix DesignDocument5 pagesManhole-Bench Mix DesignAhmadNo ratings yet

- Civil Guidelines and SpecificationsDocument65 pagesCivil Guidelines and SpecificationshardikNo ratings yet

- IRS Guidelins HPCDocument12 pagesIRS Guidelins HPCsaritasohamNo ratings yet

- ShotcreteDocument10 pagesShotcreteHemaNo ratings yet

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Concrete Mix Design SpecificationDocument3 pagesConcrete Mix Design SpecificationAnıl ÖzpirinçiNo ratings yet

- 20JE0705 Exp5Document14 pages20JE0705 Exp5Priye RanjanNo ratings yet

- Is Code456-2000Document46 pagesIs Code456-2000mahenderNo ratings yet

- Interlock SpecsDocument4 pagesInterlock SpecsAbdullah AboodiNo ratings yet

- Specification For Permanent Soil Nailed Slope: 1.0 DescriptionDocument12 pagesSpecification For Permanent Soil Nailed Slope: 1.0 DescriptionSiva ViharNo ratings yet

- PE Sleeves 250 Mic. Density 0.915-0.925 GMLDocument1 pagePE Sleeves 250 Mic. Density 0.915-0.925 GMLadnan.yaseenNo ratings yet

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignPratyush Kumar DoraNo ratings yet

- C 928Document4 pagesC 928kanomasiNo ratings yet

- Division 3&4 Concrete&MasonryDocument9 pagesDivision 3&4 Concrete&MasonryAceron Torres MalicdanNo ratings yet

- 3CC System Technical SpecificationDocument3 pages3CC System Technical SpecificationAnonymous qTP5oq7gNo ratings yet

- Concrete GuideDocument38 pagesConcrete GuideAdnan JadoonNo ratings yet

- CsiDocument9 pagesCsiyamanta_rajNo ratings yet

- MortarsDocument20 pagesMortarsmnc19No ratings yet

- APP129Document10 pagesAPP129Gary LoNo ratings yet

- R. Nagendra - Paper On Mix Proportioning As Per Is 10262-2009Document31 pagesR. Nagendra - Paper On Mix Proportioning As Per Is 10262-2009Vinod JogurNo ratings yet

- Dr. S. K. Dubey, Professor (Structures), Deptt. of Civil Engineering., M.A.N.I.T.Document7 pagesDr. S. K. Dubey, Professor (Structures), Deptt. of Civil Engineering., M.A.N.I.T.NeelNo ratings yet

- Concrete Specifications Rev ADocument15 pagesConcrete Specifications Rev ABdteam T2No ratings yet

- Adm Std. Specs-part2-Road StructuresDocument2 pagesAdm Std. Specs-part2-Road StructuresmujeebscribdNo ratings yet

- Marine Concrete Specs-HkDocument5 pagesMarine Concrete Specs-HkMohammed Faisal TNo ratings yet

- KrytonDocument4 pagesKrytonProject Manager IIT Kanpur CPWDNo ratings yet

- Aquafin-2K/M Two-Component Cement-Based Acrylic-Based Waterproofing Guide Aquafin, Inc. SpecificationDocument5 pagesAquafin-2K/M Two-Component Cement-Based Acrylic-Based Waterproofing Guide Aquafin, Inc. SpecificationalpegambarliNo ratings yet

- Cement - Treated Base Course (CTB)Document12 pagesCement - Treated Base Course (CTB)Anduel SelamajNo ratings yet

- IKOTE CM 31 TDS (11-Oct-2023)Document2 pagesIKOTE CM 31 TDS (11-Oct-2023)nguyen hoang AnhNo ratings yet

- Central Business District of The New Adminis Trative CapitalDocument7 pagesCentral Business District of The New Adminis Trative Capitallf chNo ratings yet

- Asphalt Concrete PavingDocument10 pagesAsphalt Concrete Pavingsethu1091No ratings yet

- MORTH 1600 2 Acrylic Elastomeric CoatingDocument4 pagesMORTH 1600 2 Acrylic Elastomeric CoatingRameshNo ratings yet

- Glass Coating Quality Standard: EcofusionDocument3 pagesGlass Coating Quality Standard: EcofusionGilberto BarettaNo ratings yet

- 3CC SpecDocument3 pages3CC SpecKS LeeNo ratings yet

- Hanson Portland Limestone Cement Data SheetDocument2 pagesHanson Portland Limestone Cement Data Sheetyaser666No ratings yet

- Bidding Document-Rio-21-01-008Document58 pagesBidding Document-Rio-21-01-008Sen LinNo ratings yet

- 3 Concrete Mix DesignDocument28 pages3 Concrete Mix DesignPraveen BhandariNo ratings yet

- Adhesive Compounds'2 Component For Sealing Wire and Light in PavementDocument4 pagesAdhesive Compounds'2 Component For Sealing Wire and Light in PavementDevrim GürselNo ratings yet

- QCS 2010 Section 4 Part 2 General Requirements For Concrete PilesDocument6 pagesQCS 2010 Section 4 Part 2 General Requirements For Concrete Pilesbryanpastor106No ratings yet

- Volume-2 SpecificationDocument26 pagesVolume-2 SpecificationRamsha YasirNo ratings yet

- Irc DLCDocument56 pagesIrc DLCAniket Salvi100% (5)

- Design of M100 Grade ACI MethodDocument3 pagesDesign of M100 Grade ACI MethodGaurav PatilNo ratings yet

- Draft - SPECIFICATIONS - CONCRETE SLAB ON GRADE OVER PARTIALLY MILLED ASPHALT PAVEMENTDocument5 pagesDraft - SPECIFICATIONS - CONCRETE SLAB ON GRADE OVER PARTIALLY MILLED ASPHALT PAVEMENTMohammed FasilNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- ISSA Microsurfacing A143-2010Document16 pagesISSA Microsurfacing A143-2010Roger Molero PachecoNo ratings yet

- Copy of MPDocument45 pagesCopy of MPbabubhai23No ratings yet

- Irc SP 105 2015 Explanatory Handbook To Irc 112 2011Document36 pagesIrc SP 105 2015 Explanatory Handbook To Irc 112 2011vivekNo ratings yet

- Technical Info PDFDocument159 pagesTechnical Info PDFEngr RakNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Membrane Processes: Pervaporation, Vapor Permeation and Membrane Distillation for Industrial Scale SeparationsFrom EverandMembrane Processes: Pervaporation, Vapor Permeation and Membrane Distillation for Industrial Scale SeparationsNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Corrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionFrom EverandCorrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionNo ratings yet

- 2410014738242451Document2 pages2410014738242451abdul wahabNo ratings yet

- Rapid Culture of Pratylenchus Zeae On Carrot DiscsDocument2 pagesRapid Culture of Pratylenchus Zeae On Carrot DiscsFrank KagodaNo ratings yet

- I) Height of Retaining Wall H: Preliminary DataDocument10 pagesI) Height of Retaining Wall H: Preliminary DataOmPrakashNo ratings yet

- Nightingale PledgeDocument26 pagesNightingale PledgeIcee SaputilNo ratings yet

- Prevalence and Determinants of Substance Use Among Students at Kampala International University Western Campus, Ishaka Municipality Bushenyi District UgandaDocument18 pagesPrevalence and Determinants of Substance Use Among Students at Kampala International University Western Campus, Ishaka Municipality Bushenyi District UgandaKIU PUBLICATION AND EXTENSIONNo ratings yet

- MANUAL DESENVOLVIMENTO BSSV E24218Document146 pagesMANUAL DESENVOLVIMENTO BSSV E24218valdirsaraujoNo ratings yet

- Astm D3202 - 1 (En)Document3 pagesAstm D3202 - 1 (En)Dinesh SaiNo ratings yet

- Arellano Humss - DDocument5 pagesArellano Humss - Dcarl guillardaNo ratings yet

- Seg-D, Revision 1: Specific ChangesDocument32 pagesSeg-D, Revision 1: Specific ChangesLiavon SokalNo ratings yet

- Condition Assessment of SeawallsDocument7 pagesCondition Assessment of SeawallsJIBEESH01No ratings yet

- NEW Curriculum Vitae Marking Scheme (Jan 2022)Document2 pagesNEW Curriculum Vitae Marking Scheme (Jan 2022)TONo ratings yet

- ProfileDocument21 pagesProfileasersamuel21No ratings yet

- LRS Trading StrategyDocument24 pagesLRS Trading Strategybharatbaba363No ratings yet

- Group 112-111 My Daily RoutineDocument9 pagesGroup 112-111 My Daily Routineapi-306090241No ratings yet

- Writing Analysis OfficialDocument5 pagesWriting Analysis OfficialAva KaiserNo ratings yet

- Tariqah Muammadiyyah As Tariqah Jami ADocument36 pagesTariqah Muammadiyyah As Tariqah Jami AUzairNo ratings yet

- Group Dynamics 7Th Edition Forsyth Test Bank Full Chapter PDFDocument53 pagesGroup Dynamics 7Th Edition Forsyth Test Bank Full Chapter PDFphilippinaspafford100% (13)

- Business ProposalDocument35 pagesBusiness ProposalMJ MacapagalNo ratings yet

- A+ Blog-Class-8-Chemistry-Samagra-Chapter-7-Question Pool (Em)Document9 pagesA+ Blog-Class-8-Chemistry-Samagra-Chapter-7-Question Pool (Em)Riya Maria SijuNo ratings yet

- Tagmemics and Its ImplicationDocument13 pagesTagmemics and Its ImplicationtiqumNo ratings yet

- New Vehicle Data - 25.03 - ENDocument3 pagesNew Vehicle Data - 25.03 - ENcllsjanusNo ratings yet

- Middle Level Reading Part 3 PoemDocument10 pagesMiddle Level Reading Part 3 Poem이세희No ratings yet

- L. N .E.R.-'': and The Silver Jubilee'' TrainDocument3 pagesL. N .E.R.-'': and The Silver Jubilee'' TrainIan FlackNo ratings yet

- Notes For OMDocument77 pagesNotes For OMmukesh jatNo ratings yet

- Aravalli Province: Shashwat Sinha Mtech GLT Iit RoorkeeDocument33 pagesAravalli Province: Shashwat Sinha Mtech GLT Iit RoorkeeGirijesh PandeyNo ratings yet

- CABGDocument3 pagesCABGprofarmahNo ratings yet

5.3.6 Minimum Requirements To Concrete Mix: 5.3.6.1 Durability and Structural Design Requirements

5.3.6 Minimum Requirements To Concrete Mix: 5.3.6.1 Durability and Structural Design Requirements

Uploaded by

ahmed alyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5.3.6 Minimum Requirements To Concrete Mix: 5.3.6.1 Durability and Structural Design Requirements

5.3.6 Minimum Requirements To Concrete Mix: 5.3.6.1 Durability and Structural Design Requirements

Uploaded by

ahmed alyCopyright:

Available Formats

• maintain all plant clean and with suitable reflective surfaces (light colours) and heat

insulation where relevant;

• keep the batching and mixing plant under shade;

• maintain all mixer trucks clean and with a light-coloured reflecting shade covering the drum,

or continuously wet hessian cover on the drum;

• keep waiting trucks under shade

• keep constituent materials fully protected against sun radiation at all times;

• avoid the use of warm cement;

• use cooled or chilled water;

• substitute part of the water with flake-ice or well crushed ice which must be shown to melt

completely during the mixing;

• cool the aggregates;

• mix and deliver at an appropriate time during day or night, considering exposure conditions

during placing as well as the heat development in the young concrete and its coincidence

with ambient temperature variations.

Cooling of materials or mix by use of liquid nitrogen may be considered if suitable equipment is

available and proper procedures with quality control are documented and tested, subject to the

Engineers acceptance.

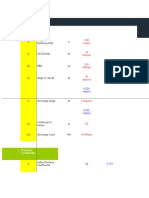

5.3.6 Minimum Requirements to Concrete Mix

5.3.6.1 Durability and Structural Design Requirements

The durability requirements to the mix (mainly the w/c ratio) are expected to give a higher

strength than required from a structural design point of view.

This expected strength shall be used to monitor the contractor's ability to manage and control

his concrete production process. Fluctuations in strength indicate a fluctuation in quality, such

as variations in w/c ratio; therefore, strength fluctuations must be kept within pre-planned limits

in order to have confidence in the production control.

Structural design considerations shall not be used to relax any requirements in this specification.

Strength requirements stated on construction drawings shall always be complied with if they are

higher than the strength requirements to grades in this Specification.

5.3.6.2 Concrete Grades

The following standard range of grades refers to reinforced structures. Exposure Classes are

defined in Chapter 1. Distinction between reinforced and unreinforced structures is made in

terms of cement types and the additional requirements to cement, as explained in Note 1) and

2) below.

• Grade "A"

To be used for all concrete in Exposure Class A.

Minimum characteristic strength =50 MN/m2

Cement ASTM Type I, see Note 1), 2) : 6% < C3A< 9%

Minimum cement content =350kg/m3

Maximum cement content =420 kg/m3

Microsilica content, see Note 2) = 7% of cement weight

Max. free water/cementitious material = 0.40

Admixtures, see Note 3), 4), 5).

Chloride penetrability measured by ASTM C1202 shall be Very Low (100 1,000

coulombs).

Water penetrability measured by BS EN 12390 shall be max 10 mm after 3 days with 5

bars.

11-152120-4800000519-RWF-CIV-SPC-000001 R E V I S I O N CODE : A PAGE 66 OF 171

• Grade "B"

To be used for all concrete in Exposure Class B.

Minimum characteristic strength = 50 MN/m2

Cement ASTM Type I, see Note 1), 2) : 8% < C3A

Minimum cement content =350kg/m3

Maximum cement content =420 kg/m3

Microsilica content, see Note 2) = 7% of cement weight

Max. free water/cementitious material = 0.40

Admixtures, see Note 3), 4), 5).

Chloride penetrability measured by ASTM C1202 shall be Very Low (100 1,000

coulombs).

Water penetrability measured by BS EN 12390 shall be max 10 mm after 3 days with 5

bars.

• Grade "C"

To be used for all concrete in Exposure Class C.

Minimum characteristic strength =45 MN/m2

Cement ASTM Type I, see Note 1), 2) : 5% < C3A

Minimum cement content =350kg/m3

Maximum cement content =390kg/m3

Max. free water/cementitious material = 0.45

Admixtures, see Note 3), 5)

• Grade "D”

To be used only for blinding layers (mud-mats)

Minimum characteristic strength =15 MN/m2

Cement ASTM Type V, see Note 2)

NOTE 1) Cement for reinforced structures shall be ASTM Type I in compliance

with the additional requirements stated in clause 5.2.2.1.1.

NOTE 2) Cement for un-reinforced structures shall be ASTM Type V (or TypeI)

in compliance with the additional requirements stated in section

5.2.2.1.2.

If Type V is used, there shall be no requirement for use of microsilica.

NOTE 3) With the specified limits on the water/cementitious ratio, plasticisers

and/or superplasticisers will generally be needed to produce a workable

mix. Plasticisers providing an entrained air content of about 1% are

generally found to increase the workability as well as reducing the

tendency of segregation. Retarders, e.g. in the form of retarding

superplasticisers may also be needed.

NOTE 4) High-range water-reducing admixtures shall always be used in mixes

containing microsilica.

NOTE 5) Admixtures shall fulfil the requirements specified for constituent

materials; furthermore, the compatibility and the effects of admixtures

shall be documented as part of the pre-testing of the concrete.

11-152120-4800000519-RWF-CIV-SPC-000001 R E V I S I O N CODE : A PAGE 67 OF 171

You might also like

- Al Maths Pure Unit 6 MsDocument8 pagesAl Maths Pure Unit 6 MsHacjer EiNSTi3NNo ratings yet

- CPL Flight Planning ManualDocument94 pagesCPL Flight Planning ManualChina LalaukhadkaNo ratings yet

- Shotcrete RequirementsDocument16 pagesShotcrete Requirementstinz_3100% (2)

- Preceptor Evaluation of Student Jordan ElizabethDocument2 pagesPreceptor Evaluation of Student Jordan Elizabethapi-487459879No ratings yet

- A Rectification Manual - ExampleDocument41 pagesA Rectification Manual - Examplesorobanista100% (1)

- 346 Portland Cement Concrete. (REV 1-8-02) (FA 1-10-02) (7-02)Document72 pages346 Portland Cement Concrete. (REV 1-8-02) (FA 1-10-02) (7-02)Jb SantosNo ratings yet

- Dm-dsi-SPEC09 - Corrosion PR & Odor CNTRLDocument13 pagesDm-dsi-SPEC09 - Corrosion PR & Odor CNTRLhardikNo ratings yet

- Technical Specifications Civil WorksDocument159 pagesTechnical Specifications Civil Worksrcdk2No ratings yet

- Factors in The Choice of Mix DesignDocument31 pagesFactors in The Choice of Mix DesignMudduKrishna shettyNo ratings yet

- Manhole-Bench Mix DesignDocument5 pagesManhole-Bench Mix DesignAhmadNo ratings yet

- Civil Guidelines and SpecificationsDocument65 pagesCivil Guidelines and SpecificationshardikNo ratings yet

- IRS Guidelins HPCDocument12 pagesIRS Guidelins HPCsaritasohamNo ratings yet

- ShotcreteDocument10 pagesShotcreteHemaNo ratings yet

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Concrete Mix Design SpecificationDocument3 pagesConcrete Mix Design SpecificationAnıl ÖzpirinçiNo ratings yet

- 20JE0705 Exp5Document14 pages20JE0705 Exp5Priye RanjanNo ratings yet

- Is Code456-2000Document46 pagesIs Code456-2000mahenderNo ratings yet

- Interlock SpecsDocument4 pagesInterlock SpecsAbdullah AboodiNo ratings yet

- Specification For Permanent Soil Nailed Slope: 1.0 DescriptionDocument12 pagesSpecification For Permanent Soil Nailed Slope: 1.0 DescriptionSiva ViharNo ratings yet

- PE Sleeves 250 Mic. Density 0.915-0.925 GMLDocument1 pagePE Sleeves 250 Mic. Density 0.915-0.925 GMLadnan.yaseenNo ratings yet

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignPratyush Kumar DoraNo ratings yet

- C 928Document4 pagesC 928kanomasiNo ratings yet

- Division 3&4 Concrete&MasonryDocument9 pagesDivision 3&4 Concrete&MasonryAceron Torres MalicdanNo ratings yet

- 3CC System Technical SpecificationDocument3 pages3CC System Technical SpecificationAnonymous qTP5oq7gNo ratings yet

- Concrete GuideDocument38 pagesConcrete GuideAdnan JadoonNo ratings yet

- CsiDocument9 pagesCsiyamanta_rajNo ratings yet

- MortarsDocument20 pagesMortarsmnc19No ratings yet

- APP129Document10 pagesAPP129Gary LoNo ratings yet

- R. Nagendra - Paper On Mix Proportioning As Per Is 10262-2009Document31 pagesR. Nagendra - Paper On Mix Proportioning As Per Is 10262-2009Vinod JogurNo ratings yet

- Dr. S. K. Dubey, Professor (Structures), Deptt. of Civil Engineering., M.A.N.I.T.Document7 pagesDr. S. K. Dubey, Professor (Structures), Deptt. of Civil Engineering., M.A.N.I.T.NeelNo ratings yet

- Concrete Specifications Rev ADocument15 pagesConcrete Specifications Rev ABdteam T2No ratings yet

- Adm Std. Specs-part2-Road StructuresDocument2 pagesAdm Std. Specs-part2-Road StructuresmujeebscribdNo ratings yet

- Marine Concrete Specs-HkDocument5 pagesMarine Concrete Specs-HkMohammed Faisal TNo ratings yet

- KrytonDocument4 pagesKrytonProject Manager IIT Kanpur CPWDNo ratings yet

- Aquafin-2K/M Two-Component Cement-Based Acrylic-Based Waterproofing Guide Aquafin, Inc. SpecificationDocument5 pagesAquafin-2K/M Two-Component Cement-Based Acrylic-Based Waterproofing Guide Aquafin, Inc. SpecificationalpegambarliNo ratings yet

- Cement - Treated Base Course (CTB)Document12 pagesCement - Treated Base Course (CTB)Anduel SelamajNo ratings yet

- IKOTE CM 31 TDS (11-Oct-2023)Document2 pagesIKOTE CM 31 TDS (11-Oct-2023)nguyen hoang AnhNo ratings yet

- Central Business District of The New Adminis Trative CapitalDocument7 pagesCentral Business District of The New Adminis Trative Capitallf chNo ratings yet

- Asphalt Concrete PavingDocument10 pagesAsphalt Concrete Pavingsethu1091No ratings yet

- MORTH 1600 2 Acrylic Elastomeric CoatingDocument4 pagesMORTH 1600 2 Acrylic Elastomeric CoatingRameshNo ratings yet

- Glass Coating Quality Standard: EcofusionDocument3 pagesGlass Coating Quality Standard: EcofusionGilberto BarettaNo ratings yet

- 3CC SpecDocument3 pages3CC SpecKS LeeNo ratings yet

- Hanson Portland Limestone Cement Data SheetDocument2 pagesHanson Portland Limestone Cement Data Sheetyaser666No ratings yet

- Bidding Document-Rio-21-01-008Document58 pagesBidding Document-Rio-21-01-008Sen LinNo ratings yet

- 3 Concrete Mix DesignDocument28 pages3 Concrete Mix DesignPraveen BhandariNo ratings yet

- Adhesive Compounds'2 Component For Sealing Wire and Light in PavementDocument4 pagesAdhesive Compounds'2 Component For Sealing Wire and Light in PavementDevrim GürselNo ratings yet

- QCS 2010 Section 4 Part 2 General Requirements For Concrete PilesDocument6 pagesQCS 2010 Section 4 Part 2 General Requirements For Concrete Pilesbryanpastor106No ratings yet

- Volume-2 SpecificationDocument26 pagesVolume-2 SpecificationRamsha YasirNo ratings yet

- Irc DLCDocument56 pagesIrc DLCAniket Salvi100% (5)

- Design of M100 Grade ACI MethodDocument3 pagesDesign of M100 Grade ACI MethodGaurav PatilNo ratings yet

- Draft - SPECIFICATIONS - CONCRETE SLAB ON GRADE OVER PARTIALLY MILLED ASPHALT PAVEMENTDocument5 pagesDraft - SPECIFICATIONS - CONCRETE SLAB ON GRADE OVER PARTIALLY MILLED ASPHALT PAVEMENTMohammed FasilNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- ISSA Microsurfacing A143-2010Document16 pagesISSA Microsurfacing A143-2010Roger Molero PachecoNo ratings yet

- Copy of MPDocument45 pagesCopy of MPbabubhai23No ratings yet

- Irc SP 105 2015 Explanatory Handbook To Irc 112 2011Document36 pagesIrc SP 105 2015 Explanatory Handbook To Irc 112 2011vivekNo ratings yet

- Technical Info PDFDocument159 pagesTechnical Info PDFEngr RakNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Membrane Processes: Pervaporation, Vapor Permeation and Membrane Distillation for Industrial Scale SeparationsFrom EverandMembrane Processes: Pervaporation, Vapor Permeation and Membrane Distillation for Industrial Scale SeparationsNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Corrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionFrom EverandCorrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionNo ratings yet

- 2410014738242451Document2 pages2410014738242451abdul wahabNo ratings yet

- Rapid Culture of Pratylenchus Zeae On Carrot DiscsDocument2 pagesRapid Culture of Pratylenchus Zeae On Carrot DiscsFrank KagodaNo ratings yet

- I) Height of Retaining Wall H: Preliminary DataDocument10 pagesI) Height of Retaining Wall H: Preliminary DataOmPrakashNo ratings yet

- Nightingale PledgeDocument26 pagesNightingale PledgeIcee SaputilNo ratings yet

- Prevalence and Determinants of Substance Use Among Students at Kampala International University Western Campus, Ishaka Municipality Bushenyi District UgandaDocument18 pagesPrevalence and Determinants of Substance Use Among Students at Kampala International University Western Campus, Ishaka Municipality Bushenyi District UgandaKIU PUBLICATION AND EXTENSIONNo ratings yet

- MANUAL DESENVOLVIMENTO BSSV E24218Document146 pagesMANUAL DESENVOLVIMENTO BSSV E24218valdirsaraujoNo ratings yet

- Astm D3202 - 1 (En)Document3 pagesAstm D3202 - 1 (En)Dinesh SaiNo ratings yet

- Arellano Humss - DDocument5 pagesArellano Humss - Dcarl guillardaNo ratings yet

- Seg-D, Revision 1: Specific ChangesDocument32 pagesSeg-D, Revision 1: Specific ChangesLiavon SokalNo ratings yet

- Condition Assessment of SeawallsDocument7 pagesCondition Assessment of SeawallsJIBEESH01No ratings yet

- NEW Curriculum Vitae Marking Scheme (Jan 2022)Document2 pagesNEW Curriculum Vitae Marking Scheme (Jan 2022)TONo ratings yet

- ProfileDocument21 pagesProfileasersamuel21No ratings yet

- LRS Trading StrategyDocument24 pagesLRS Trading Strategybharatbaba363No ratings yet

- Group 112-111 My Daily RoutineDocument9 pagesGroup 112-111 My Daily Routineapi-306090241No ratings yet

- Writing Analysis OfficialDocument5 pagesWriting Analysis OfficialAva KaiserNo ratings yet

- Tariqah Muammadiyyah As Tariqah Jami ADocument36 pagesTariqah Muammadiyyah As Tariqah Jami AUzairNo ratings yet

- Group Dynamics 7Th Edition Forsyth Test Bank Full Chapter PDFDocument53 pagesGroup Dynamics 7Th Edition Forsyth Test Bank Full Chapter PDFphilippinaspafford100% (13)

- Business ProposalDocument35 pagesBusiness ProposalMJ MacapagalNo ratings yet

- A+ Blog-Class-8-Chemistry-Samagra-Chapter-7-Question Pool (Em)Document9 pagesA+ Blog-Class-8-Chemistry-Samagra-Chapter-7-Question Pool (Em)Riya Maria SijuNo ratings yet

- Tagmemics and Its ImplicationDocument13 pagesTagmemics and Its ImplicationtiqumNo ratings yet

- New Vehicle Data - 25.03 - ENDocument3 pagesNew Vehicle Data - 25.03 - ENcllsjanusNo ratings yet

- Middle Level Reading Part 3 PoemDocument10 pagesMiddle Level Reading Part 3 Poem이세희No ratings yet

- L. N .E.R.-'': and The Silver Jubilee'' TrainDocument3 pagesL. N .E.R.-'': and The Silver Jubilee'' TrainIan FlackNo ratings yet

- Notes For OMDocument77 pagesNotes For OMmukesh jatNo ratings yet

- Aravalli Province: Shashwat Sinha Mtech GLT Iit RoorkeeDocument33 pagesAravalli Province: Shashwat Sinha Mtech GLT Iit RoorkeeGirijesh PandeyNo ratings yet

- CABGDocument3 pagesCABGprofarmahNo ratings yet